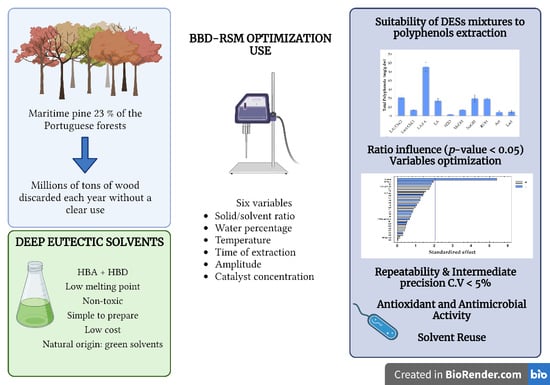

Ultrasound-Assisted Extraction of Polyphenols from Maritime Pine Residues with Deep Eutectic Solvents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Samples

2.3. Polyphenols Extraction

2.3.1. Ultrasound-Assisted Extraction System

2.3.2. Box–Behnken Design of Experiments

2.3.3. Total Polyphenols Content

2.4. Antioxidant Activity

2.5. Antimicrobial Activity

2.6. Solvent Reuse

2.7. Data Analysis

3. Results and Discussion

3.1. Suitability of DESs Solvents

3.2. BBD-RSM Optimization

Two-Factorial Design

3.3. Repeatability and Intermediate Precision

3.4. Bioactive Properties of the Extracts

3.5. Solvent Recyclability and Reuse

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alegria, C.; Roque, N.; Albuquerque, T.; Fernandez, P.; Ribeiro, M.M. Modelling Maritime Pine (Pinus pinaster Aiton) Spatial Distribution and Productivity in Portugal: Tools for Forest Management. Forests 2021, 12, 368. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Arroja, L.; Dias, A.C. Environmental Comparison of Forest Biomass Residues Application in Portugal: Electricity, Heat and Biofuel. Renew. Sustain. Energy Rev. 2020, 134, 110302. [Google Scholar] [CrossRef]

- Santos, J.; Pereira, J.; Ferreira, N.; Paiva, N.; Ferra, J.; Magalhães, F.D.; Martins, J.M.; Dulyanska, Y.; Carvalho, L.H. Valorisation of Non-Timber by-Products from Maritime Pine (Pinus pinaster, Ait) for Particleboard Production. Ind. Crops Prod. 2021, 168, 113581. [Google Scholar] [CrossRef]

- Alonso-Esteban, J.I.; Carocho, M.; Barros, D.; Velho, M.; Heleno, S.; Barros, B. Chemical Composition and Industrial Applications of Maritime Pine (Pinus pinaster Ait.) Bark and Other Non-Wood Parts. Rev. Environ. Sci. Biotechnol. 2022, 21, 583–633. [Google Scholar] [CrossRef]

- Ramos, P.A.B.; Pereira, C.; Gomes, A.P.; Neto, R.T.; Almeida, A.; Santos, S.A.O.; Silva, A.M.S.; Silvestre, A.J.D. Chemical Characterisation, Antioxidant and Antibacterial Activities of Pinus pinaster Ait. and Pinus pinea L. Bark Polar Extracts: Prospecting Forestry By-Products as Renewable Sources of Bioactive Compounds. Appl. Sci. 2022, 12, 784. [Google Scholar] [CrossRef]

- Pagano, I.; Campone, L.; Celano, R.; Piccinelli, A.L.; Rastrelli, L. Green Non-Conventional Techniques for the Extraction of Polyphenols from Agricultural Food by-Products: A Review. J. Chromatogr. A 2021, 1651, 462295. [Google Scholar] [CrossRef]

- Chupin, L.; Maunu, S.L.; Reynaud, S.; Pizzi, A.; Charrier, B.; Charrier-EL Bouhtoury, F. Microwave Assisted Extraction of Maritime Pine (Pinus pinaster) Bark: Impact of Particle Size and Characterization. Ind. Crops Prod. 2015, 65, 142–149. [Google Scholar] [CrossRef]

- Meullemiestre, A.; Petitcolas, E.; Maache-Rezzoug, Z.; Chemat, F.; Rezzoug, S.A. Impact of Ultrasound on Solid–Liquid Extraction of Phenolic Compounds from Maritime Pine Sawdust Waste. Kinetics, Optimization and Large Scale Experiments. Ultrason. Sonochem. 2016, 28, 230–239. [Google Scholar] [CrossRef]

- de Hoyos-Martínez, P.L.; Merle, J.; Labidi, J.; Charrier-El Bouhtoury, F. Tannins Extraction: A Key Point for Their Valorization and Cleaner Production. J. Clean. Prod. 2019, 206, 1138–1155. [Google Scholar] [CrossRef] [Green Version]

- Rente, D.; Paiva, A.; Duarte, A.R. The Role of Hydrogen Bond Donor on the Extraction of Phenolic Compounds from Natural Matrices Using Deep Eutectic Systems. Molecules 2021, 26, 2336. [Google Scholar] [CrossRef]

- Naqvi, S.A.R.; Akbar, N.; Shah, S.M.A.; Ali, S.; Abbas, A. Chapter 14—Green Approaches for the Extraction of Bioactive from Natural Sources for Pharmaceutical Applications. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Boddula, R., Ahamed, M.I., Asiri, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 269–291. ISBN 978-0-12-821885-3. [Google Scholar]

- Mansinhos, I.; Gonçalves, S.; Rodríguez-Solana, R.; Ordóñez-Díaz, J.L.; Moreno-Rojas, J.M.; Romano, A. Ultrasonic-Assisted Extraction and Natural Deep Eutectic Solvents Combination: A Green Strategy to Improve the Recovery of Phenolic Compounds from Lavandula pedunculata Subsp. lusitanica (Chaytor) Franco. Antioxidants 2021, 10, 582. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; van Spronsen, J.; Witkamp, G.-J.; Verpoorte, R.; Choi, Y.H. Natural Deep Eutectic Solvents as New Potential Media for Green Technology. Anal. Chim. Acta 2013, 766, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Mansinhos, I.; Gonçalves, S.; Rodríguez-Solana, R.; Duarte, H.; Ordóñez-Díaz, J.L.; Moreno-Rojas, J.M.; Romano, A. Response of Thymus lotocephalus In Vitro Cultures to Drought Stress and Role of Green Extracts in Cosmetics. Antioxidants 2022, 11, 1475. [Google Scholar] [CrossRef]

- Abbott, A.P.; Boothby, D.; Capper, G.; Davies, D.L.; Rasheed, R.K. Deep Eutectic Solvents Formed between Choline Chloride and Carboxylic Acids: Versatile Alternatives to Ionic Liquids. J. Am. Chem. Soc. 2004, 126, 9142–9147. [Google Scholar] [CrossRef] [PubMed]

- Satlewal, A.; Agrawal, R.; Bhagia, S.; Sangoro, J.; Ragauskas, A.J. Natural Deep Eutectic Solvents for Lignocellulosic Biomass Pretreatment: Recent Developments, Challenges and Novel Opportunities. Biotechnol. Adv. 2018, 36, 2032–2050. [Google Scholar] [CrossRef]

- Fernandes, C.; Melro, E.; Magalhães, S.; Alves, L.; Craveiro, R.; Filipe, A.; Valente, A.J.M.; Martins, G.; Antunes, F.E.; Romano, A.; et al. New Deep Eutectic Solvent Assisted Extraction of Highly Pure Lignin from Maritime Pine Sawdust (Pinus pinaster Ait.). Int. J. Biol. Macromol. 2021, 177, 294–305. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Yu, J.; Lu, Y.; Jiang, B.; Fan, Y.; Wang, Z. High-Purity Lignin Isolated from Poplar Wood Meal through Dissolving Treatment with Deep Eutectic Solvents. R. Soc. Open Sci. 2019, 6, 181757. [Google Scholar] [CrossRef] [Green Version]

- Hammond, O.S.; Bowron, D.T.; Edler, K.J. The Effect of Water upon Deep Eutectic Solvent Nanostructure: An Unusual Transition from Ionic Mixture to Aqueous Solution. Angew. Chem. Int. Ed. 2017, 56, 9782–9785. [Google Scholar] [CrossRef] [Green Version]

- Yang, M. Efficient Extraction of Bioactive Flavonoids from Ginkgo Biloba Leaves Using Deep Eutectic Solvent/Water Mixture as Green Media. Chem. Biochem. Eng. Q. 2018, 32, 315–324. [Google Scholar] [CrossRef]

- Dai, Y.; Witkamp, G.-J.; Verpoorte, R.; Choi, Y.H. Tailoring Properties of Natural Deep Eutectic Solvents with Water to Facilitate Their Applications. Food Chem. 2015, 187, 14–19. [Google Scholar] [CrossRef]

- Jablonský, M.; Škulcová, A.; Malvis, A.; Šima, J. Extraction of Value-Added Components from Food Industry Based and Agro-Forest Biowastes by Deep Eutectic Solvents. J. Biotechnol. 2018, 282, 46–66. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, B.; Parkinson, C.; Gonzalez-Miquel, M. Extraction of Polyphenolic Antioxidants from Orange Peel Waste Using Deep Eutectic Solvents. Sep. Purif. Technol. 2018, 206, 1–13. [Google Scholar] [CrossRef]

- Moreira, M.M.; Barroso, M.F.; Boeykens, A.; Withouck, H.; Morais, S.; Delerue-Matos, C. Valorization of Apple Tree Wood Residues by Polyphenols Extraction: Comparison between Conventional and Microwave-Assisted Extraction. Ind. Crops Prod. 2017, 104, 210–220. [Google Scholar] [CrossRef] [Green Version]

- Chanioti, S.; Tzia, C. Extraction of Phenolic Compounds from Olive Pomace by Using Natural Deep Eutectic Solvents and Innovative Extraction Techniques. Innov. Food Sci. Emerg. Technol. 2018, 48, 228–239. [Google Scholar] [CrossRef]

- Alam, M.A.; Muhammad, G.; Khan, M.N.; Mofijur, M.; Lv, Y.; Xiong, W.; Xu, J. Choline Chloride-Based Deep Eutectic Solvents as Green Extractants for the Isolation of Phenolic Compounds from Biomass. J. Clean. Prod. 2021, 309, 127445. [Google Scholar] [CrossRef]

- Magalhães, S.; Filipe, A.; Melro, E.; Fernandes, C.; Vitorino, C.; Alves, L.; Romano, A.; Rasteiro, M.G.; Medronho, B. Lignin Extraction from Waste Pine Sawdust Using a Biomass Derived Binary Solvent System. Polymers 2021, 13, 1090. [Google Scholar] [CrossRef]

- Dejaegher, B.; Heyden, Y.V. Experimental Designs and Their Recent Advances in Set-up, Data Interpretation, and Analytical Applications. J. Pharm. Biomed. Anal. 2011, 56, 141–158. [Google Scholar] [CrossRef]

- Ayyubi, S.N.; Purbasari, A.; Kusmiyati. The Effect of Composition on Mechanical Properties of Biodegradable Plastic Based on Chitosan/Cassava Starch/PVA/Crude Glycerol: Optimization of the Composition Using Box Behnken Design. Mater. Today 2022, 63, S78–S83. [Google Scholar] [CrossRef]

- Ferreira, S.L.C.; Bruns, R.E.; Ferreira, H.S.; Matos, G.D.; David, J.M.; Brandão, G.C.; da Silva, E.G.P.; Portugal, L.A.; dos Reis, P.S.; Souza, A.S.; et al. Box-Behnken Design: An Alternative for the Optimization of Analytical Methods. Anal. Chim. Acta 2007, 597, 179–186. [Google Scholar] [CrossRef]

- Khatib, I.; Chow, M.Y.T.; Ruan, J.; Cipolla, D.; Chan, H.-K. Modeling of a Spray Drying Method to Produce Ciprofloxacin Nanocrystals inside the Liposomes Utilizing a Response Surface Methodology: Box-Behnken Experimental Design. Int. J. Pharm. 2021, 597, 120277. [Google Scholar] [CrossRef]

- Magalhães, S.; Moreira, A.; Almeida, R.; Cruz, P.F.; Alves, L.; Costa, C.; Mendes, C.; Medronho, B.; Romano, A.; Carvalho, M. da G.; et al. Acacia Wood Fractionation Using Deep Eutectic Solvents: Extraction, Recovery, and Characterization of the Different Fractions. ACS Omega 2022, 7, 26005–26014. [Google Scholar] [CrossRef] [PubMed]

- Medronho, B.; Duarte, H.; Magalhães, S.; Alves, L.; Valente, A.J.M.; Romano, A. From a New Cellulose Solvent to the Cyclodextrin Induced Formation of Hydrogels. Colloids Surf. A Physicochem. Eng. Asp. 2017, 532, 548–555. [Google Scholar] [CrossRef]

- Diaconeasa, Z. Time-Dependent Degradation of Polyphenols from Thermally-Processed Berries and Their In Vitro Antiproliferative Effects against Melanoma. Molecules 2018, 23, 2534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaeswurm, J.A.H.; Scharinger, A.; Teipel, J.; Buchweitz, M. Absorption Coefficients of Phenolic Structures in Different Solvents Routinely Used for Experiments. Molecules 2021, 26, 4656. [Google Scholar] [CrossRef]

- Miliauskas, G.; Venskutonis, P.R.; van Beek, T.A. Screening of Radical Scavenging Activity of Some Medicinal and Aromatic Plant Extracts. Food Chem. 2004, 85, 231–237. [Google Scholar] [CrossRef]

- Voß, D.; Kahl, M.; Albert, J. Continuous Production of Formic Acid from Biomass in a Three-Phase Liquid–Liquid–Gas Reaction Process. ACS Sustain. Chem. Eng. 2020, 8, 10444–10453. [Google Scholar] [CrossRef]

- Xue, H.; Li, J.; Wang, G.; Zuo, W.; Zeng, Y.; Liu, L. Ultrasound-Assisted Extraction of Flavonoids from Potentilla fruticosa L. Using Natural Deep Eutectic Solvents. Molecules 2022, 27, 5794. [Google Scholar] [CrossRef]

- Zhen, S.; Chen, S.; Geng, S.; Zhang, H.; Chen, Y.; Liu, B. Ultrasound-Assisted Natural Deep Eutectic Solvent Extraction and Bioactivities of Flavonoids in Ampelopsis Grossedentata Leaves. Foods 2022, 11, 668. [Google Scholar] [CrossRef]

- Braham, F.; Amaral, L.M.P.F.; Biernacki, K.; Carvalho, D.O.; Guido, L.F.; Magalhães, J.M.C.S.; Zaidi, F.; Souza, H.K.S.; Gonçalves, M.P. Phenolic Extraction of Moringa Oleifera Leaves in DES: Characterization of the Extracts and Their Application in Methylcellulose Films for Food Packaging. Foods 2022, 11, 2641. [Google Scholar] [CrossRef]

- Aspé, E.; Fernández, K. The Effect of Different Extraction Techniques on Extraction Yield, Total Phenolic, and Anti-Radical Capacity of Extracts from Pinus radiata Bark. Ind. Crops Prod. 2011, 34, 838–844. [Google Scholar] [CrossRef]

- Nisca, A.; Ștefănescu, R.; Stegăruș, D.I.; Mare, A.D.; Farczadi, L.; Tanase, C. Comparative Study Regarding the Chemical Composition and Biological Activity of Pine (Pinus nigra and P. sylvestris) Bark Extracts. Antioxidants 2021, 10, 327. [Google Scholar] [CrossRef] [PubMed]

- Kotani, A.; Watanabe, R.; Hayashi, Y.; Hakamata, H. Chemometric Evaluations of Repeatability and Detection Limit in High-Performance Liquid Chromatography with Electrochemical Detection. J. Chromatogr. A 2022, 1673, 463075. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Zhao, L.; Li, H.; Wang, K.; Li, X.; Guo, C.; Yang, H. Effects of Electrolysed Water and Levulinic Acid Combination on Microbial Safety and Polysaccharide Nanostructure of Organic Strawberry. Food Chem. 2022, 394, 133533. [Google Scholar] [CrossRef]

| Experiment | Solid-to-Solvent Ratio (g/10 mL Solvent) | Water (%) | Temperature (°C) | Time (h) | Amplitude (%) | Catalyst (M) | Total Polyphenols Observed (mg/g dw) | Total Polyphenols Adjusted (mg/g dw) | Error (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2.5 | 30 | 45 | 30.0 | 80 | 1 | 58.77 | 60.33 | 2.66 |

| 2 | 1.5 | 60 | 45 | 17.5 | 80 | 0 | 31.05 | 30.09 | 3.08 |

| 3 | 2.5 | 30 | 45 | 30.0 | 20 | 1 | 20.72 | 18.45 | 10.97 |

| 4 | 1.5 | 30 | 45 | 17.5 | 50 | 1 | 80.31 | 81.08 | 0.95 |

| 5 | 0.5 | 30 | 60 | 17.5 | 50 | 0 | 81.39 | 82.49 | 1.35 |

| 6 | 2.5 | 30 | 30 | 17.5 | 50 | 0 | 32.14 | 32.21 | 0.23 |

| 7 | 1.5 | 0 | 45 | 17.5 | 20 | 0 | 28.37 | 30.51 | 7.55 |

| 8 | 1.5 | 0 | 45 | 17.5 | 80 | 0 | 91.24 | 93.06 | 1.99 |

| 9 | 1.5 | 30 | 30 | 5.0 | 50 | 0 | 81.18 | 81.58 | 0.50 |

| 10 | 1.5 | 0 | 60 | 17.5 | 20 | 1 | 39.91 | 38.02 | 4.73 |

| 11 | 0.5 | 30 | 45 | 5.0 | 80 | 1 | 103.62 | 121.54 | 17.29 |

| 12 | 1.5 | 30 | 30 | 30.0 | 50 | 0 | 82.21 | 83.98 | 2.15 |

| 13 | 1.5 | 30 | 45 | 17.5 | 50 | 1 | 77.90 | 81.08 | 4.08 |

| 14 | 1.5 | 30 | 60 | 5.0 | 50 | 0 | 48.57 | 47.12 | 2.98 |

| 15 | 1.5 | 0 | 60 | 17.5 | 80 | 1 | 137.89 | 112.67 | 18.29 |

| 16 | 0.5 | 30 | 45 | 5.0 | 20 | 1 | 114.86 | 98.94 | 13.86 |

| 17 | 1.5 | 30 | 45 | 17.5 | 50 | 1 | 82.88 | 81.08 | 2.18 |

| 18 | 1.5 | 0 | 30 | 17.5 | 20 | 1 | 118.36 | 101.59 | 14.17 |

| 19 | 0.5 | 30 | 45 | 30.0 | 20 | 1 | 102.27 | 107.00 | 4.63 |

| 20 | 1.5 | 60 | 60 | 17.5 | 80 | 1 | 84.73 | 87.57 | 3.36 |

| 21 | 1.5 | 30 | 45 | 17.5 | 50 | 1 | 78.48 | 81.08 | 3.31 |

| 22 | 2.5 | 60 | 45 | 5.0 | 50 | 1 | 52.29 | 48.16 | 7.91 |

| 23 | 0.5 | 0 | 45 | 30.0 | 50 | 1 | 205.00 | 204.78 | 0.11 |

| 24 | 1.5 | 30 | 45 | 17.5 | 50 | 1 | 89.24 | 81.08 | 9.15 |

| 25 | 1.5 | 30 | 30 | 30.0 | 50 | 2 | 87.33 | 86.91 | 0.48 |

| 26 | 0.5 | 30 | 60 | 17.5 | 50 | 2 | 121.38 | 119.44 | 1.60 |

| 27 | 2.5 | 30 | 30 | 17.5 | 50 | 2 | 49.45 | 49.01 | 0.89 |

| 28 | 2.5 | 30 | 45 | 5.0 | 20 | 1 | 74.31 | 70.56 | 5.05 |

| 29 | 0.5 | 30 | 30 | 17.5 | 50 | 0 | 189.79 | 155.78 | 17.92 |

| 30 | 1.5 | 60 | 45 | 17.5 | 20 | 2 | 34.47 | 28.73 | 16.64 |

| 31 | 1.5 | 60 | 45 | 17.5 | 80 | 2 | 28.89 | 30.67 | 6.16 |

| 32 | 2.5 | 30 | 60 | 17.5 | 50 | 0 | 65.28 | 64.64 | 0.99 |

| 33 | 0.5 | 30 | 30 | 17.5 | 50 | 2 | 162.77 | 175.28 | 7.68 |

| 34 | 0.5 | 0 | 45 | 5.0 | 50 | 1 | 166.03 | 150.24 | 9.51 |

| 35 | 1.5 | 30 | 60 | 5.0 | 50 | 2 | 49.04 | 49.14 | 0.19 |

| 36 | 1.5 | 30 | 60 | 30.0 | 50 | 0 | 83.67 | 77.57 | 7.29 |

| 37 | 2.5 | 0 | 45 | 5.0 | 50 | 1 | 53.86 | 54.31 | 0.83 |

| 38 | 1.5 | 30 | 60 | 30.0 | 50 | 2 | 86.50 | 97.96 | 13.25 |

| 39 | 2.5 | 0 | 45 | 30.0 | 50 | 1 | 42.64 | 48.68 | 14.16 |

| 40 | 1.5 | 60 | 60 | 17.5 | 20 | 1 | 26.76 | 26.34 | 1.57 |

| 41 | 1.5 | 60 | 30 | 17.5 | 20 | 1 | 58.43 | 57.58 | 1.46 |

| 42 | 0.5 | 60 | 45 | 5.0 | 50 | 1 | 86.66 | 84.98 | 1.94 |

| 43 | 1.5 | 60 | 30 | 17.5 | 80 | 1 | 49.45 | 47.42 | 4.11 |

| 44 | 2.5 | 30 | 60 | 17.5 | 50 | 2 | 47.93 | 50.08 | 4.49 |

| 45 | 1.5 | 60 | 45 | 17.5 | 20 | 0 | 35.10 | 35.01 | 0.26 |

| 46 | 2.5 | 60 | 45 | 30.0 | 50 | 1 | 44.69 | 44.83 | 0.32 |

| 47 | 1.5 | 30 | 45 | 17.5 | 50 | 1 | 77.64 | 81.08 | 4.42 |

| 48 | 1.5 | 0 | 45 | 17.5 | 80 | 2 | 50.13 | 50.22 | 0.19 |

| 49 | 1.5 | 30 | 30 | 5.0 | 50 | 2 | 71.91 | 66.14 | 8.02 |

| 50 | 2.5 | 30 | 45 | 5.0 | 80 | 1 | 17.55 | 17.17 | 2.15 |

| 51 | 0.5 | 60 | 45 | 30.0 | 50 | 1 | 146.63 | 141.83 | 3.28 |

| 52 | 1.5 | 0 | 30 | 17.5 | 80 | 1 | 107.50 | 104.84 | 2.47 |

| 53 | 1.5 | 0 | 45 | 17.5 | 20 | 2 | 34.78 | 34.88 | 0.28 |

| 54 | 0.5 | 30 | 45 | 30.0 | 80 | 1 | 226.76 | 224.87 | 0.83 |

| Variable | Sum of Squares | F-Value | p-Value |

|---|---|---|---|

| A: Solid-to-solvent ratio | 55,828.20 | 29.21 | 0.0000 |

| B: Water % | 7163.94 | 3.75 | 0.0638 |

| C: Temperature | 822.16 | 0.43 | 0.5177 |

| D: Time | 3934.98 | 2.06 | 0.1632 |

| E: Amplitude | 6236.83 | 3.26 | 0.0824 |

| F: Catalyst | 36.70 | 0.02 | 0.8908 |

| AA | 3008.53 | 1.57 | 0.2208 |

| AB | 1747.00 | 0.91 | 0.3478 |

| AC | 5586.77 | 2.92 | 0.0992 |

| AD | 3620.43 | 1.89 | 0.1804 |

| AE | 2886.48 | 1.51 | 0.2301 |

| AF | 1326.38 | 0.69 | 0.4124 |

| BB | 481.22 | 0.25 | 0.6200 |

| BC | 522.78 | 0.27 | 0.6054 |

| BD | 2.67 | 0.00 | 0.9705 |

| BE | 179.76 | 0.09 | 0.7615 |

| BF | 942.21 | 0.49 | 0.4888 |

| CC | 1475.29 | 0.77 | 0.3877 |

| CD | 393.54 | 0.21 | 0.6537 |

| CE | 2548.62 | 1.33 | 0.2587 |

| CF | 304.50 | 0.16 | 0.6930 |

| DD | 356.53 | 0.19 | 0.6694 |

| DE | 4538.19 | 2.37 | 0.1354 |

| DF | 168.82 | 0.09 | 0.7687 |

| EE | 2076.20 | 1.09 | 0.3069 |

| EF | 1113.92 | 0.58 | 0.4521 |

| FF | 6499.48 | 3.40 | 0.0766 |

| Total Error | 49,689.10 |

| Experiment | Solid-to-Solvent Ratio (g/10 mL Solvent) | Time (min) | Total Polyphenols Observed (mg/g dw) | Total Polyphenols Adjusted (mg/g dw) | Error (%) |

|---|---|---|---|---|---|

| 1 | 0.50 | 5.00 | 87.76 | 91.40 | 4.14 |

| 2 | 0.50 | 32.50 | 126.71 | 126.11 | 0.47 |

| 3 | 0.30 | 60.00 | 151.78 | 145.60 | 4.07 |

| 4 | 0.30 | 32.50 | 138.01 | 163.72 | 18.63 |

| 5 | 0.50 | 60.00 | 104.55 | 101.51 | 2.91 |

| 6 | 0.10 | 32.50 | 280.01 | 254.90 | 8.97 |

| 7 | 0.10 | 60.00 | 234.03 | 243.25 | 3.94 |

| 8 | 0.10 | 5.00 | 191.33 | 207.22 | 8.31 |

| 9 | 0.30 | 5.00 | 142.06 | 122.53 | 13.75 |

| Average (mg/g dw) | Standard Deviation | CV (%) | ||

|---|---|---|---|---|

| Pine Needle | Repeatability | 266.87 | 4.41 | 1.65 |

| Intermediate precision | 274.38 | 10.75 | 3.92 | |

| Pine Bark | Repeatability | 315.50 | 5.18 | 1.64 |

| Intermediate precision | 314.62 | 10.57 | 3.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duarte, H.; Gomes, V.; Aliaño-González, M.J.; Faleiro, L.; Romano, A.; Medronho, B. Ultrasound-Assisted Extraction of Polyphenols from Maritime Pine Residues with Deep Eutectic Solvents. Foods 2022, 11, 3754. https://doi.org/10.3390/foods11233754

Duarte H, Gomes V, Aliaño-González MJ, Faleiro L, Romano A, Medronho B. Ultrasound-Assisted Extraction of Polyphenols from Maritime Pine Residues with Deep Eutectic Solvents. Foods. 2022; 11(23):3754. https://doi.org/10.3390/foods11233754

Chicago/Turabian StyleDuarte, Hugo, Valentim Gomes, María José Aliaño-González, Leonor Faleiro, Anabela Romano, and Bruno Medronho. 2022. "Ultrasound-Assisted Extraction of Polyphenols from Maritime Pine Residues with Deep Eutectic Solvents" Foods 11, no. 23: 3754. https://doi.org/10.3390/foods11233754