Grain Quality Characterization of Hybrid Rice Restorer Lines with Resilience to Suboptimal Temperatures during Filling Stage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Materials and Experimental Design

2.2. Determination of Milling Quality

2.3. Chalkiness Degree and Chalky Rice Rate Determination

2.4. Starch Isolation

2.5. Scanning Electron Microscopy (SEM)

2.6. Starch Size Distribution and Chain Length Distribution (CLD) Analysis

2.7. Determination of the Amylose Content (AC), Gel Consistency (GC), and the Alkali Spreading Value (ASV)

2.8. Pasting Property Measurement

2.9. Water Solubility Index and Swelling Power Assay

2.10. Statistical Analysis

3. Results and Discussion

3.1. Milling Quality

3.2. Appearance Quality

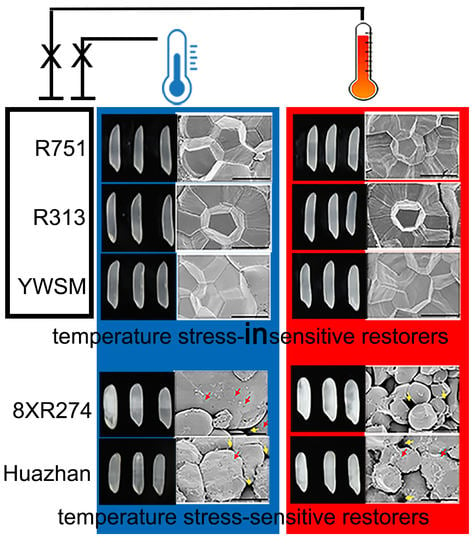

3.3. Starch Granule Morphology and Granule Size Distribution

3.4. Amylose Content

3.5. Alkali Spreading Value and Gel Consistency

3.6. Amylopectin Chain Length Distribution (CLD)

3.7. Starch Pasting Properties as Determined by RVA Analysis

3.8. Water Solubility Index and Swelling Power of Starch Particles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khush, G.S. What it will take to feed 5.0 billion rice consumers in 2030. Plant Mol. Biol. 2005, 59, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Butardo, V.M.; Sreenivasulu, N.; Juliano, B.O. Improving rice grain quality: State-of-the-Art and future prospects. Methods Mol. Biol. 2019, 1892, 19–55. [Google Scholar] [PubMed]

- Mo, Y.-J.; Jeung, J.-U.; Shin, W.-C.; Kim, K.-Y.; Ye, C.R.; Redona, E.D.; Kim, B.-K. Effects of allelic variations in starch synthesis-related genes on grain quality traits of Korean nonglutinous rice varieties under different temperature conditions. Breed. Sci. 2014, 64, 164–175. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, C.; Zhou, L.; Zhu, Z.; Lu, H.; Zhou, X.; Qian, Y.; Li, Q.; Lu, Y.; Gu, M.; Liu, Q. Characterization of grain quality and starch fine structure of two japonica rice (Oryza sativa) cultivars with good sensory properties at different temperatures during the filling stage. J. Agric. Food Chem. 2016, 64, 4048–4057. [Google Scholar] [CrossRef] [PubMed]

- Nakata, M.; Fukamatsu, Y.; Miyashita, T.; Hakata, M.; Kimura, R.; Nakata, Y.; Kuroda, M.; Yamaguchi, T.; Yamakawa, H. High temperature-induced expression of rice alpha-amylases in developing endosperm produces chalky grains. Front. Plant Sci. 2017, 8, 2089. [Google Scholar] [CrossRef] [Green Version]

- Fan, X.; Li, Y.; Zhang, C.; Li, E.; Chen, Z.; Li, Q.; Zhang, Z.; Zhu, Y.; Sun, X.; Liu, Q. Effects of high temperature on the fine structure of starch during the grain-filling stages in rice: Mathematical modeling and integrated enzymatic analysis. J. Sci. Food Agric. 2019, 99, 2865–2873. [Google Scholar] [CrossRef]

- Fan, X.; Li, Y.; Lu, Y.; Zhang, C.; Li, E.; Li, Q.; Tao, K.; Yu, W.; Wang, J.; Chen, Z.; et al. The interaction between amylose and amylopectin synthesis in rice endosperm grown at high temperature. Food Chem. 2019, 301, 125258. [Google Scholar] [CrossRef]

- Hu, Y.; Li, L.; Tian, J.; Zhang, C.; Wang, J.; Yu, E.; Xing, Z.; Guo, B.; Wei, H.; Huo, Z.; et al. Effects of dynamic low temperature during the grain filling stage on starch morphological structure, physicochemical properties, and eating quality of soft japonica rice. Cereal Chem. 2020, 97, 540–550. [Google Scholar] [CrossRef] [Green Version]

- Yao, D.; Wu, J.; Luo, Q.; Li, J.; Zhuang, W.; Xiao, G.; Deng, Q.; Lei, D.Y.; Bai, B. Influence of high natural field temperature during grain filling stage on the morphological structure and physicochemical properties of rice (Oryza sativa L.) starch. Food Chem. 2020, 310, 125817. [Google Scholar] [CrossRef]

- Jackson, N.D.; Konar, M.; Debaere, P.; Sheffield, J. Crop-specific exposure to extreme temperature and moisture for the globe for the last half century. Environ. Res. Lett. 2021, 16, 064006. [Google Scholar] [CrossRef]

- Pörtner, D.C.; Roberts, V.; Masson-Delmotte, P.; Zhai, M.; Tignor, E.; Poloczanska, K.; Mintenbeck, A.; Alegría, M.; Nicolai, A.; Okem, J.; et al. (Eds.) IPCC Special Report on the Ocean and Cryosphere in a Changing Climate; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Fitzgerald, M.A.; Resurreccion, A.P. Maintaining the yield of edible rice in a warming world. Funct. Plant Biol. 2009, 36, 1037–1045. [Google Scholar] [CrossRef] [PubMed]

- Buggenhout, J.; Brijs, K.; Celus, I.; Delcour, J.A. The breakage susceptibility of raw and parboiled rice: A review. J. Food Eng. 2013, 117, 304–315. [Google Scholar] [CrossRef]

- Ball, S.; Guan, H.-P.; James, M.; Myers, A.; Keeling, P.; Mouille, G.; Buleon, A.; Colonna, P.; Preiss, J. From glycogen to amylopectin: A model for the biogenesis of the plant starch granule. Cell 1996, 86, 349–352. [Google Scholar] [CrossRef] [Green Version]

- Li, E.; Wu, A.C.; Li, J.; Liu, Q.; Gilbert, R.G. Improved understanding of rice amylose biosynthesis from advanced starch structural characterization. Rice 2015, 8, 20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Champagne, E.T.; Bett, K.L.; Vinyard, B.T.; McClung, A.M.; Barton, F.E.; Moldenhauer, K.; Linscombe, S.; McKenzie, K. Correlation between cooked rice texture and Rapid Visco Analyser measurements. Cereal Chem. 1999, 76, 764–771. [Google Scholar] [CrossRef]

- Batey, I.L.; Curtin, B.M. Effects on pasting viscosity of starch and flour from different operating conditions for the Rapid Visco Analyser. Cereal Chem. 2000, 77, 754–760. [Google Scholar] [CrossRef]

- Champagne, E.T.; Bett-Garber, K.L.; McClung, A.M.; Bergman, C. Sensory characteristics of diverse rice cultivars as influenced by genetic and environmental factors. Cereal Chem. 2004, 81, 237–243. [Google Scholar] [CrossRef]

- Abe, N.; Asai, H.; Yago, H.; Oitome, N.F.; Itoh, R.; Crofts, N.; Nakamura, Y.; Fujita, N. Relationships between starch synthase I and branching enzyme isozymes determined using double mutant rice lines. BMC Plant Biol. 2014, 14, 80. [Google Scholar] [CrossRef] [Green Version]

- Yamakawa, H.; Hirose, T.; Kuroda, M.; Yamaguchi, T. Comprehensive expression profiling of rice grain filling-related genes under high temperature using DNA microarray. Plant Physiol. 2007, 144, 258–277. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.-J.; Li, C.-Y.; Lin, S.-K.; Yang, F.-H.; Huang, J.-J.; Liu, Y.-H.; Lur, H.-S. Influence of high temperature during grain filling on the accumulation of storage proteins and grain quality in rice (Oryza sativa L.). J. Agric. Food Chem. 2010, 58, 10545–10552. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Hu, M.; Wang, Z.; Hua, H.; Yin, C.; Zeng, H. Different effects of night versus day high temperature on rice quality and accumulation profiling of rice grain proteins during grain filling. Plant Cell Rep. 2011, 30, 1641–1659. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Wu, X.; Ma, J.; Li, T.; Zhou, X.; Guo, T. Effects of high air temperature on rice grain quality and yield under field condition. Agron. J. 2013, 105, 446–454. [Google Scholar] [CrossRef]

- Mitsui, T.; Shiraya, T.; Kaneko, K.; Wada, K. Proteonnics of rice grain under high temperature stress. Front. Plant Sci. 2013, 4, 36. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, Z.-Z.; Pan, G.; Wang, F.-B.; Wei, K.-S.; Li, Z.-W.; Shi, C.-H.; Geng, W.; Cheng, F.-M. Effect of high temperature on the expressions of genes encoding starch synthesis enzymes in developing rice endosperms. J. Integr. Agric. 2015, 14, 642–659. [Google Scholar] [CrossRef]

- Chen, J.; Tang, L.; Shi, P.; Yang, B.; Sun, T.; Cao, W.; Zhu, Y. Effects of short-term high temperature on grain quality and starch granules of rice (Oryza sativa L.) at post-anthesis stage. Protoplasma 2017, 254, 935–943. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, N.; Maekawa, M.; Tetlow, I.J. Effects of low temperature on grain filling, amylose content, and activity of starch biosynthesis enzymes in endosperm of basmati rice. Aust. J. Agric. Res. 2008, 59, 599–604. [Google Scholar] [CrossRef]

- Zhu, D.; Wei, H.; Guo, B.; Dai, Q.; Wei, C.; Gao, H.; Hu, Y.; Cui, P.; Li, M.; Huo, Z.; et al. The effects of chilling stress after anthesis on the physicochemical properties of rice (Oryza sativa L) starch. Food Chem. 2017, 237, 936–941. [Google Scholar] [CrossRef]

- Chen, L.Y.; Lei, D.-Y.; Tang, W.-B.; Xiao, Y.-H. Thoughts and practice on some problems about research and application of two-line hybrid rice. Rice Sci. 2011, 18, 79–85. [Google Scholar] [CrossRef]

- Yuan, L.P. Development of hybrid rice to ensure food security. Rice Sci. 2014, 21, 1–2. [Google Scholar] [CrossRef]

- Man, J.; Cai, J.; Cai, C.; Huai, H.; Wei, C. Physicochemical properties of rhizome starch from a traditional Chinese medicinal plant of Anemone altaica. Carbohydr. Polym. 2012, 89, 571–577. [Google Scholar] [CrossRef]

- Tan, Y.F.; Li, J.X.; Yu, S.B.; Xing, Y.Z.; Xu, C.G.; Zhang, Q. The three important traits for cooking and eating quality of rice grains are controlled by a single locus in an elite rice hybrid, Shanyou 63. Theor. Appl. Genet. 1999, 99, 642–648. [Google Scholar] [CrossRef] [PubMed]

- Mariotti, M.; Fongaro, L.; Catenacci, F. Alkali spreading value and image analysis. J. Cereal Sci. 2010, 52, 227–235. [Google Scholar] [CrossRef]

- Ahmed, N.; Tetlow, I.J.; Nawaz, S.; Iqbal, A.; Mubin, M.; Nawaz ul Rehman, M.S.; Butt, A.; Lightfoot, D.A.; Maekawa, M. Effect of high temperature on grain filling period, yield, amylose content and activity of starch biosynthesis enzymes in endosperm of basmati rice. J. Sci. Food Agric. 2015, 95, 2237–2243. [Google Scholar] [CrossRef] [PubMed]

- Kaneko, K.; Sasaki, M.; Kuribayashi, N.; Suzuki, H.; Sasuga, Y.; Shiraya, T.; Inomata, T.; Itoh, K.; Baslam, M.; Mitsui, T. Proteomic and glycomic characterization of rice chalky grains produced under moderate and high-temperature conditions in field system. Rice 2016, 9, 26. [Google Scholar] [CrossRef] [Green Version]

- Ashida, K.; Iida, S.; Yasui, T. Morphological, physical, and chemical properties of grain and flour from chalky rice mutants. Cereal Chem. 2009, 86, 225–231. [Google Scholar] [CrossRef]

- Kumar, I.; Khush, G.S. Genetics of amylose content in rice (Oryza sativa L). J. Genet. 1986, 65, 1–11. [Google Scholar] [CrossRef]

- Li, H.; Prakash, S.; Nicholson, T.M.; Fitzgerald, M.A.; Gilbert, R.G. The importance of amylose and amylopectin fine structure for textural properties of cooked rice grains. Food Chem. 2016, 196, 702–711. [Google Scholar] [CrossRef] [Green Version]

- Miura, S.; Crofts, N.; Saito, Y.; Hosaka, Y.; Oitome, N.F.; Watanabe, T.; Kumamaru, T.; Fujita, N. Starch synthase IIa-deficient mutant rice line produces endosperm starch with lower gelatinization temperature than japonica rice cultivars. Front. Plant Sci. 2018, 9, 645. [Google Scholar] [CrossRef] [Green Version]

- Suwannaporn, P.; Pitiphunpong, S.; Champangern, S. Classification of rice amylose content by discriminant analysis of physicochemical properties. Starch-Starke 2007, 59, 171–177. [Google Scholar] [CrossRef]

| Varieties | Average Daily Temperature during Grain-Filling (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| LT (Low Temperature) | NT (Normal Temperature) | HT (High Temperature) | |||||||

| Min | Mean | Max | Min | Mean | Max | Min | Mean | Max | |

| R751 | 18.3 | 21.2 | 26.9 | 21.6 | 26.0 | 33.4 | 24.8 | 30.3 | 39.3 |

| R313 | 18.3 | 21.1 | 26.8 | 21.7 | 26.2 | 33.6 | 24.8 | 30.3 | 39.3 |

| YWSM | 18.5 | 21.5 | 27.2 | 22 | 26.6 | 34.1 | 24.8 | 30.4 | 39.4 |

| 8XR274 | 18.5 | 21.5 | 27.2 | 21.9 | 26.4 | 34.0 | 25.2 | 30.3 | 39.1 |

| Huazhan | 18.5 | 21.5 | 27.2 | 21.5 | 25.8 | 33.0 | 24.8 | 30.4 | 39.4 |

| Restorer Varieties | Temperature in the Grouting Period | Proportions of Amylopectin Chains with Various Degree of Polymerization (DP) (%) | |||

|---|---|---|---|---|---|

| 6 ≤ DP ≤ 12 | 13 ≤ DP ≤ 24 | 25 ≤ DP ≤ 36 | DP ≥ 37 | ||

| R751 | LT | 28.44 ± 1.50 a | 48.97 ± 0.12 a | 12.28 ± 0.24 b | 10.31 ± 0.93 c |

| NT | 27.40 ± 1.01 a | 47.91 ± 0.22 b | 13.11 ± 0.12 a | 11.58 ± 0.92 b | |

| HT | 26.91 ± 1.00 a | 47.18 ± 0.12 c | 13.51 ± 0.33 a | 12.40 ± 0.92 a | |

| R313 | LT | 28.06 ± 1.02 a | 48.92 ± 0.10 a | 12.43 ± 0.30 a | 10.59 ± 3.82 b |

| NT | 27.89 ± 1.01 ab | 48.40 ± 0.13 b | 12.75 ± 0.52 a | 10.80 ± 4.41 b | |

| HT | 26.84 ± 0.61 b | 47.04 ± 0.00 c | 13.47 ± 0.54 a | 12.65 ± 4.50 a | |

| YWSM | LT | 29.03 ± 0.20 a | 48.48 ± 0.12 a | 12.17 ± 0.12 b | 10.32 ± 4.52 c |

| NT | 27.89 ± 0.12 b | 47.47 ± 1.44 a | 13.01 ± 0.00 a | 11.62 ± 4.50 a | |

| HT | 28.72 ± 0.00 b | 47.79 ± 1.61 a | 12.82 ± 0.32 a | 10.67 ± 4.54 b | |

| 8XR274 | LT | 30.48 ± 1.43 a | 48.76 ± 0.62 a | 11.75 ± 0.12 b | 9.01 ± 4.30 c |

| NT | 29.01 ± 0.14 ab | 47.38 ± 0.60 a | 12.68 ± 0.30 a | 10.94 ± 4.21 b | |

| HT | 27.98 ± 0.12 b | 47.68 ± 0.00 a | 12.93 ± 0.00 a | 11.40 ± 4.20 a | |

| Huazhan | LT | 23.54 ± 0.10 a | 53.58 ± 0.31 a | 12.12 ± 0.00 c | 10.76 ± 3.71 c |

| NT | 22.78 ± 0.22 ab | 53.54 ± 0.12 a | 12.47 ± 0.12 b | 11.21 ± 3.32 b | |

| HT | 21.63 ± 0.00 b | 53.29 ± 0.14 a | 13.00 ± 0.00 a | 12.07 ± 2.84 a | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Wang, L.; Xiao, Y.; Wang, F.; Zhang, G.; Tang, W.; Deng, H. Grain Quality Characterization of Hybrid Rice Restorer Lines with Resilience to Suboptimal Temperatures during Filling Stage. Foods 2022, 11, 3513. https://doi.org/10.3390/foods11213513

Lu X, Wang L, Xiao Y, Wang F, Zhang G, Tang W, Deng H. Grain Quality Characterization of Hybrid Rice Restorer Lines with Resilience to Suboptimal Temperatures during Filling Stage. Foods. 2022; 11(21):3513. https://doi.org/10.3390/foods11213513

Chicago/Turabian StyleLu, Xuedan, Lu Wang, Yunhua Xiao, Feng Wang, Guilian Zhang, Wenbang Tang, and Huabing Deng. 2022. "Grain Quality Characterization of Hybrid Rice Restorer Lines with Resilience to Suboptimal Temperatures during Filling Stage" Foods 11, no. 21: 3513. https://doi.org/10.3390/foods11213513