Design of Saline Gel Coil for Inner Heating of Electrolyte Solution and Liquid Foods under Induced Electric Field

Abstract

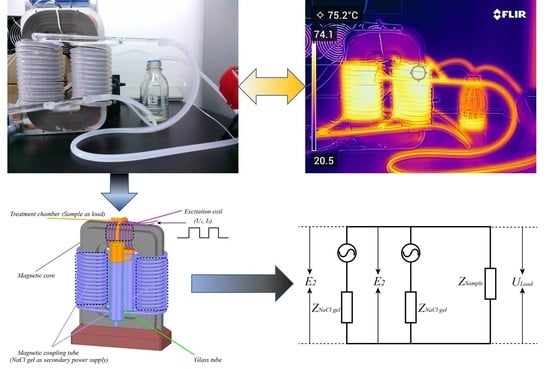

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Principle

2.3. Experiments

2.4. Temperature Rise and Conductivity

2.5. Statistical Analysis

3. Results and Discussion

3.1. Influence of Saline Gel Coil

3.2. Influence of Physicochemical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fryer, P.J.; Robbins, P.T. Heat transfer in food processing: Ensuring product quality and safety. Appl. Therm. Eng. 2005, 25, 2499–2510. [Google Scholar] [CrossRef]

- Jaeger, H.; Roth, A.; Toepfl, S.; Holzhauser, T.; Engel, K.-H.; Knorr, D.; Vogel, R.F.; Bandick, N.; Kulling, S.; Heinz, V.; et al. Opinion on the use of ohmic heating for the treatment of foods. Trends Food Sci. Technol. 2016, 55, 84–97. [Google Scholar] [CrossRef]

- He, J.; Yang, Y.; Zhu, H.; Li, K.; Yao, W.; Huang, K. Microwave heating based on two rotary waveguides to improve efficiency and uniformity by gradient descent method. Appl. Therm. Eng. 2020, 178, 115594. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.; Li, X.; Gao, X. Process intensification for improving the uniformity and efficiency of microwave heating reactor by bubbles-enhanced flow method. Appl. Therm. Eng. 2021, 197, 117346. [Google Scholar] [CrossRef]

- Marra, F.; Zhang, L.; Lyng, J.G. Radio frequency treatment of foods: Review of recent advances. J. Food Eng. 2009, 91, 497–508. [Google Scholar] [CrossRef]

- Hao, Y.; Mao, Y.; Hou, L.; Wang, S. Developing a rotation device in radio frequency systems for improving the heating uniformity in granular foods. Innov. Food Sci. Emerg. Technol. 2021, 72, 102751. [Google Scholar] [CrossRef]

- Knirsch, M.C.; Alves dos Santos, C.; Martins de Oliveira Soares Vicente, A.A.; Vessoni Penna, T.C. Ohmic heating—A review. Trends Food Sci. Technol. 2010, 21, 436–441. [Google Scholar] [CrossRef]

- Makroo, H.A.; Rastogi, N.K.; Srivastava, B. Ohmic heating assisted inactivation of enzymes and microorganisms in foods: A review. Trends Food Sci. Technol. 2020, 97, 451–465. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H.; Yan, B.; Zhu, H.; Gao, W.; Zhao, J.; Zhang, H.; Chen, W.; Fan, D. Continuous flow microwave system with helical tubes for liquid food heating. J. Food Eng. 2021, 294, 110409. [Google Scholar] [CrossRef]

- Jeong, S.G.; Kang, D.H. Influence of moisture content on inactivation of Escherichia coli O157: H7 and Salmonella enterica serovar Typhimurium in powdered red and black pepper spices by radio-frequency heating. Int. J. Food Microbiol. 2014, 176, 15–22. [Google Scholar] [CrossRef]

- Moirangthem, T.T.; Macana, R.; Baik, O.-D. Characterization of 50-ohm radio frequency heating of bulk canola seeds (Brassica napus L.) in a tubular applicator with parallel electrodes and post-treatment quality. Innov. Food Sci. Emerg. Technol. 2020, 64, 102409. [Google Scholar] [CrossRef]

- Lan, W.; Wang, H.; Liu, Q.; Zhang, X.; Chen, J.; Li, Z.; Feng, K.; Chen, S. Investigation on the microwave heating technology for coalbed methane recovery. Energy 2021, 237, 121450. [Google Scholar] [CrossRef]

- Bedane, T.F.; Erdogdu, F.; Lyng, J.G.; Marra, F. Effects of geometry and orientation of food products on heating uniformity during radio frequency heating. Food Bioprod. Process. 2021, 125, 149–160. [Google Scholar] [CrossRef]

- Müller, W.A.; Ferreira Marczak, L.D.; Sarkis, J.R. Microbial inactivation by ohmic heating: Literature review and influence of different process variables. Trends Food Sci. Technol. 2020, 99, 650–659. [Google Scholar] [CrossRef]

- Samaranayake, C.P.; Sastry, S.K. Electrode and pH effects on electrochemical reactions during ohmic heating. J. Electroanal. Chem. 2005, 577, 125–135. [Google Scholar] [CrossRef]

- Cappato, L.P.; Ferreira, M.V.S.; Guimaraes, J.T.; Portela, J.B.; Costa, A.L.R.; Freitas, M.Q.; Cunha, R.L.; Oliveira, C.A.F.; Mercali, G.D.; Marzack, L.D.F.; et al. Ohmic heating in dairy processing: Relevant aspects for safety and quality. Trends Food Sci. Technol. 2017, 62, 104–112. [Google Scholar] [CrossRef]

- Huang, M.-S.; Liao, C.-C.; Li, Z.-F.; Shih, Z.-R.; Hsueh, H.-W. Quantitative Design and Implementation of an Induction Cooker for a Copper Pan. IEEE Access 2021, 9, 5105–5118. [Google Scholar] [CrossRef]

- Lucía, Ó.; Domínguez, A.; Sarnago, H.; Burdío, J.M. Chapter 21—Induction Heating. In Control of Power Electronic Converters and Systems; Blaabjerg, F., Ed.; Academic Press: Randers, Denmark, 2018; pp. 265–287. [Google Scholar]

- Grewal, R.; Kumar, M. A comprehensive review on stepped solar still and induction heating applications. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Sanz-Serrano, F.; Sagues, C.; Llorente, S. Inverse modeling of pan heating in domestic cookers. Appl. Therm. Eng. 2016, 92, 137–148. [Google Scholar] [CrossRef] [Green Version]

- Jin, Y.; Yang, N.; Xu, X. Innovative induction heating technology based on transformer theory: Inner heating of electrolyte solution via alternating magnetic field. Appl. Therm. Eng. 2020, 179, 115732. [Google Scholar] [CrossRef]

- Wu, S.; Yang, N.; Jin, Y.; Li, D.; Xu, Y.; Xu, X.; Jin, Z. Development of an innovative induction heating technique for the treatment of liquid food: Principle, experimental validation and application. J. Food Eng. 2020, 271, 109780. [Google Scholar] [CrossRef]

- González-Monroy, A.D.; Rodríguez-Hernández, G.; Ozuna, C.; Sosa-Morales, M.E. Microwave-assisted pasteurization of beverages (tamarind and green) and their quality during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2018, 49, 51–57. [Google Scholar] [CrossRef]

- He, X.; Zhang, B.-X.; Wang, S.-L.; Wang, Y.-F.; Yang, Y.-R.; Wang, X.-D.; Lee, D.-J. Electrocoalescence of two charged nanodroplets under different types of external electric fields. J. Mol. Liq. 2021, 341, 117417. [Google Scholar] [CrossRef]

- Żywica, R.; Banach, J.K.; Kiełczewska, K. An attempt of applying the electrical properties for the evaluation of milk fat content of raw milk. J. Food Eng. 2012, 111, 420–424. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Ryu, S.; Kang, D.-H. Effect of frequency and waveform on inactivation of Escherichia coli O157:H7 and Salmonella enterica Serovar Typhimurium in salsa by ohmic heating. Appl. Environ. Microbiol. 2013, 79, 10–17. [Google Scholar] [CrossRef] [Green Version]

| Liquid Sample | Conductivity (ms/cm) | Initial Temperature (°C) | Excitation Coil Turns | Magnetic Coupling Tube Turns | Frequency (kHz) | Duty Cycle | Flow Rate (mL/min) |

|---|---|---|---|---|---|---|---|

| Commercial mineral water | 0.473 | 25 | 1 | 30 | 60 | 40% | 120 |

| NaCl solution (0.2%) | 4.333 | 25 | 1 | 30 | 60 | 40% | 120 |

| NaCl solution (0.4%) | 7.837 | 25 | 1 | 30 | 60 | 40% | 120 |

| NaCl solution (0.6%) | 11.24 | 25 | 1 | 30 | 60 | 40% | 120 |

| White vinegar | 2.98 | 25 | 1 | 20 | 40, 60, 80 | 20%, 40%, 60% | 10 |

| Black vinegar | 30.00 | 25 | 1 | 20 | 40, 60, 80 | 20%, 40%, 60% | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Liu, F.; Wang, T.; Wu, S.; Jin, Y.; Yang, N.; Xu, X. Design of Saline Gel Coil for Inner Heating of Electrolyte Solution and Liquid Foods under Induced Electric Field. Foods 2022, 11, 213. https://doi.org/10.3390/foods11020213

Zhang L, Liu F, Wang T, Wu S, Jin Y, Yang N, Xu X. Design of Saline Gel Coil for Inner Heating of Electrolyte Solution and Liquid Foods under Induced Electric Field. Foods. 2022; 11(2):213. https://doi.org/10.3390/foods11020213

Chicago/Turabian StyleZhang, Lingtao, Fan Liu, Ting Wang, Shilin Wu, Yamei Jin, Na Yang, and Xueming Xu. 2022. "Design of Saline Gel Coil for Inner Heating of Electrolyte Solution and Liquid Foods under Induced Electric Field" Foods 11, no. 2: 213. https://doi.org/10.3390/foods11020213