Lignocellulosic Biomasses from Agricultural Wastes Improved the Quality and Physicochemical Properties of Frying Oils

Abstract

:1. Introduction

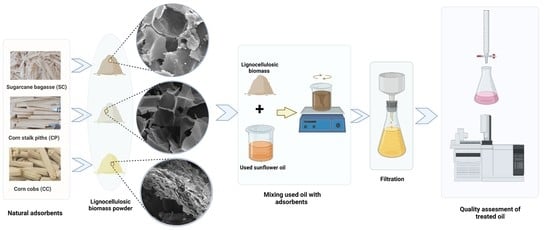

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Adsorbents Preparation

2.2.2. Scanning Electron Microscope (SEM)

2.2.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.2.4. X-ray Diffraction (XRD)

2.2.5. Frying Process

2.2.6. Filtration

2.2.7. Acid Value (AV)

2.2.8. Peroxide Value (PV)

2.2.9. p-AV and the Total Oxidation Value (TOTOX)

2.2.10. Fatty Acids Analysis

2.2.11. Color

2.2.12. Statistical Analysis

3. Results and Discussion

3.1. Characterizations of Adsorbents

3.1.1. FTIR Analysis

3.1.2. Crystallinity Analysis

3.1.3. Microstructure of Adsorbents

3.2. Acid and Peroxide Values

3.3. p-AV and TOTOX

3.4. Fatty Acid Composition

3.5. Color Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ogata, F.; Kawasaki, N. Regeneration of Waste Edible Oil by the Use of Virgin and Calcined Magnesium Hydroxide as Adsorbents. J. Oleo Sci. 2016, 65, 941–948. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aşkın, B.; Kaya, Y. Effect of Deep Frying Process on the Quality of the Refined Oleic/Linoleic Sunflower Seed Oil and Olive Oil. J. Food Sci. Technol. 2020, 57, 4716–4725. [Google Scholar] [CrossRef]

- Mohammadalinejhad, S.; Dehghannya, J. Effects of Ultrasound Frequency and Application Time Prior to Deep-Fat Frying on Quality Aspects of Fried Potato Strips. Innov. Food Sci. Emerg. Technol. 2018, 47, 493–503. [Google Scholar] [CrossRef]

- Asokapandian, S.; Swamy, G.J.; Hajjul, H. Deep Fat Frying of Foods: A Critical Review on Process and Product Parameters. Crit. Rev. Food Sci. Nutr. 2020, 60, 3400–3413. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zhang, M.; Wang, H.; Devahastin, S. Effects of Carbon Dots in Combination with Rosemary-Inspired Carnosic Acid on Oxidative Stability of Deep Frying Oils. Food Control 2021, 125, 107968. [Google Scholar] [CrossRef]

- Yuan, Y.; Cui, C.; Liu, H.; Li, X.; Cao, Y.; Zhang, Y.; Yan, H. Effects of Oxidation and Hydrolysis of Frying Oil on MCPD Esters Formation in Chinese Fried Dough Sticks. LWT 2022, 154, 112576. [Google Scholar] [CrossRef]

- Hwang, H.S.; Ball, J.C.; Doll, K.M.; Anderson, J.E.; Vermillion, K. Investigation of Polymers and Alcohols Produced in Oxidized Soybean Oil at Frying Temperatures. Food Chem. 2020, 317, 126379. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Yang, X.; Lee, W.J.; Huang, F.; Wang, Y.; Li, Y. Comparison between Synthetic and Rosemary-Based Antioxidants for the Deep Frying of French Fries in Refined Soybean Oils Evaluated by Chemical and Non-Destructive Rapid Methods. Food Chem. 2021, 335, 127638. [Google Scholar] [CrossRef]

- Udomkun, P.; Innawong, B.; Jumrusjumroendee, N. Cellulose Acetate and Adsorbents Supported on Cellulose Fiber Extracted from Waxy Corn Husks for Improving Shelf Life of Frying Oil. LWT 2018, 97, 45–52. [Google Scholar] [CrossRef]

- Ganesan, K.; Sukalingam, K.; Xu, B. Impact of Consumption and Cooking Manners of Vegetable Oils on Cardiovascular Diseases- A Critical Review. Trends Food Sci. Technol. 2018, 71, 132–154. [Google Scholar] [CrossRef]

- Ganesan, K.; Sukalingam, K.; Xu, B. Impact of Consumption of Repeatedly Heated Cooking Oils on the Incidence of Various Cancers- A Critical Review. Crit. Rev. Food Sci. Nutr. 2019, 59, 488–505. [Google Scholar] [CrossRef]

- Perumalla Venkata, R.; Subramanyam, R. Evaluation of the Deleterious Health Effects of Consumption of Repeatedly Heated Vegetable Oil. Toxicol. Rep. 2016, 3, 636–643. [Google Scholar] [CrossRef] [Green Version]

- Ahmad Nazri, K.A.; Fauzi, N.M.; Buang, F.; Mohd Saad, Q.H.; Husain, K.; Jantan, I.; Jubri, Z. Gynura Procumbens Standardised Extract Reduces Cholesterol Levels and Modulates Oxidative Status in Postmenopausal Rats Fed with Cholesterol Diet Enriched with Repeatedly Heated Palm Oil. Evid. Based Complement. Altern. Med. 2019, 2019, 7246756. [Google Scholar] [CrossRef] [Green Version]

- Kummerow, F.A. Interaction between Sphingomyelin and Oxysterols Contributes to Atherosclerosis and Sudden Death. Am. J. Cardiovasc. Dis. 2013, 3, 17. [Google Scholar] [PubMed]

- Cárdenas, J.; Orjuela, A.; Sánchez, D.L.; Narváez, P.C.; Katryniok, B.; Clark, J. Pre-Treatment of Used Cooking Oils for the Production of Green Chemicals: A Review. J. Clean. Prod. 2021, 289, 125129. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Nizami, A.S.; Kalogirou, S.A.; Gupta, V.K.; Park, Y.K.; Fallahi, A.; Sulaiman, A.; Ranjbari, M.; Rahnama, H.; Aghbashlo, M.; et al. Environmental Life Cycle Assessment of Biodiesel Production from Waste Cooking Oil: A Systematic Review. Renew. Sustain. Energy Rev. 2022, 161, 112411. [Google Scholar] [CrossRef]

- Bhattacharya, A.B.; Sajilata, M.G.; Tiwari, S.R.; Singhal, R.S. Regeneration of Thermally Polymerized Frying Oils with Adsorbents. Food Chem. 2008, 110, 562–570. [Google Scholar] [CrossRef]

- Subramanian, R.; Nandini, K.E.; Sheila, P.M.; Gopalakrishna, A.G.; Raghavarao, K.S.M.S.; Nakajima, M.; Kimura, T.; Maekawa, T. Membrane Processing of Used Frying Oils. J. Am. Oil Chem. Soc. 2000, 77, 323. [Google Scholar] [CrossRef]

- Yılmaz, E.; Güner, M. Regeneration of Used Frying Oils by Selected Metal–Organic Frameworks as Adsorbents. J. Am. Oil Chem. Soc. 2018, 95, 1497–1508. [Google Scholar] [CrossRef]

- Somnuk, C.; Innawong, B.; Tirawattanawanich, C. Cytotoxicity of Used Frying Oil Recovered by Different Adsorbents. Kasetsart J. Natural Sci. 2013, 47, 874–884. [Google Scholar]

- Adejumo, A.L.; Azeez, L.; Oyedeji, A.O.; Adetoro, R.O.; Aderibigbe, F.A. Nanostructured and Surface Functionalized Corncob as Unique Adsorbents for Anionic Dye Remediation. SN Appl. Sci. 2020, 2, 301. [Google Scholar] [CrossRef]

- Herrera-Barros, A.; Tejada-Tovar, C.; Villabona-Ortiz, A.D.; Gonzalez-Delgado, A.D.; Alvarez-Calderon, J. Adsorption of Nickel and Cadmium by Corn Cob Biomass Chemically Modified with Alumina Nanoparticles. Indian J. Sci. Technol. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Patel, S. Potential of Fruit and Vegetable Wastes as Novel Biosorbents: Summarizing the Recent Studies. Rev. Environ. Sci. Biotechnol. 2012, 11, 365–380. [Google Scholar] [CrossRef]

- Bavaresco, A.; Fonseca, J.M.; Scheufele, F.B.; da Silva, C.; Teleken, J.G. Use of Carbonized Corn Cob Biomass to Reduce Acidity of Residual Frying Oil. Acta Sci. Technol. 2021, 43, e51303. [Google Scholar] [CrossRef]

- Torre, P.; Aliakbarian, B.; Rivas, B.; Domínguez, J.M.; Converti, A. Release of Ferulic Acid from Corn Cobs by Alkaline Hydrolysis. Biochem. Eng. J. 2008, 40, 500–506. [Google Scholar] [CrossRef]

- Singh, H.K.; Patil, T.; Vineeth, S.K.; Das, S.; Pramanik, A.; Mhaske, S.T. Isolation of Microcrystalline Cellulose from Corn Stover with Emphasis on Its Constituents: Corn Cover and Corn Cob. Mater. Today Proc. 2020, 27, 589–594. [Google Scholar] [CrossRef]

- Alves, C.C.O.; Franca, A.S.; Oliveira, L.S. Evaluation of an Adsorbent Based on Agricultural Waste (Corn Cobs) for Removal of Tyrosine and Phenylalanine from Aqueous Solutions. BioMed Res. Int. 2013, 2013, 978256. [Google Scholar] [CrossRef] [Green Version]

- Han, Q.; Gao, X.; Zhang, H.; Chen, K.; Peng, L.; Jia, Q. Preparation and Comparative Assessment of Regenerated Cellulose Films from Corn (Zea Mays) Stalk Pulp Fines in DMAc/LiCl Solution. Carbohydr. Polym. 2019, 218, 315–323. [Google Scholar] [CrossRef]

- Peng, D.; Li, W.; Zheng, L. Laccase-Modified Cornstalk Pith for Cleanup of Spilled Diesel Oil. Cellulose 2021, 28, 7123–7142. [Google Scholar] [CrossRef]

- Fan, T.; Cheng, S.; Peng, D.; Kong, S. A Comparative Study on Sorption Characteristics by Corn Stalk Pith Using Green Modification with Different Polycarboxylic Acids. Fibers Polym. 2021, 22, 862–876. [Google Scholar] [CrossRef]

- Peng, D.; Cheng, S.; Li, H.; Guo, X. Effective Multi-Functional Biosorbent Derived from Corn Stalk Pith for Dyes and Oils Removal. Chemosphere 2021, 272, 129963. [Google Scholar] [CrossRef] [PubMed]

- Karnitz, O.; Gurgel, L.V.A.; de Melo, J.C.P.; Botaro, V.R.; Melo, T.M.S.; de Freitas Gil, R.P.; Gil, L.F. Adsorption of Heavy Metal Ion from Aqueous Single Metal Solution by Chemically Modified Sugarcane Bagasse. Bioresour. Technol. 2007, 98, 1291–1297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Loh, Y.R.; Sujan, D.; Rahman, M.E.; Das, C.A. Sugarcane Bagasse—The Future Composite Material: A Literature Review. Resour. Conserv. Recycl. 2013, 75, 14–22. [Google Scholar] [CrossRef]

- Wannahari, R.; Firdhaus, M.; Nordin, M. Under a Creative Commons Attribution (CC-BY) 3.0 License The Recovery of Used Palm Cooking Oil Using Bagasse as Adsorbent. Am. J. Eng. Appl. Sci. 2012, 5, 59–62. [Google Scholar]

- Schneider, L.T.; Bonassa, G.; Alves, H.J.; Meier, T.R.W.; Frigo, E.P.; Teleken, J.G. Use of Rice Husk in Waste Cooking Oil Pretreatment. Environ. Technol. 2019, 40, 594–604. [Google Scholar] [CrossRef]

- Ali, R.F.M.; el Anany, A.M. Recovery of Used Frying Sunflower Oil with Sugar Cane Industry Waste and Hot Water. J. Food Sci. Technol. 2014, 51, 3002–3013. [Google Scholar] [CrossRef] [Green Version]

- Gunstone, F.D. Vegetable Oils in Food Technology: Composition, Properties and Uses, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2011; ISBN 9781444332681. [Google Scholar]

- Ponnusamy, V.K.; Nguyen, D.D.; Dharmaraja, J.; Shobana, S.; Banu, J.R.; Saratale, R.G.; Chang, S.W.; Kumar, G. A Review on Lignin Structure, Pretreatments, Fermentation Reactions and Biorefinery Potential. Bioresour. Technol. 2019, 271, 462–472. [Google Scholar] [CrossRef]

- Rodrigues, R.C.L.B.; Green Rodrigues, B.; Vieira Canettieri, E.; Acosta Martinez, E.; Palladino, F.; Wisniewski, A.; Rodrigues, D. Comprehensive Approach of Methods for Microstructural Analysis and Analytical Tools in Lignocellulosic Biomass Assessment—A Review. Bioresour. Technol. 2022, 348, 126627. [Google Scholar] [CrossRef]

- Xu, Q.; Chen, Z.; Wu, Z.; Xu, F.; Yang, D.; He, Q.; Li, G.; Chen, Y. Novel Lanthanum Doped Biochars Derived from Lignocellulosic Wastes for Efficient Phosphate Removal and Regeneration. Bioresour. Technol. 2019, 289, 121600. [Google Scholar] [CrossRef]

- Galal, A.M.F.; DiaaAtta; Abouelsayed, A.; Ibrahim, M.A.; Hanna, A.G. Configuration and Molecular Structure of 5-Chloro-N-(4-Sulfamoylbenzyl) Salicylamide Derivatives. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 214, 476–486. [Google Scholar] [CrossRef]

- Karthika, K.; Arun, A.B.; Rekha, P.D. Enzymatic Hydrolysis and Characterization of Lignocellulosic Biomass Exposed to Electron Beam Irradiation. Carbohydr. Polym. 2012, 90, 1038–1045. [Google Scholar] [CrossRef]

- Hrebień-Filisińska, A. Application of Natural Antioxidants in the Oxidative Stabilization of Fish Oils: A Mini-Review. J. Food Process. Preserv. 2021, 45, e15342. [Google Scholar] [CrossRef]

- Udomkun, P.; Innawong, B.; Siasakul, C.; Okafor, C. Utilization of Mixed Adsorbents to Extend Frying Oil Life Cycle in Poultry Processing. Food Chem. 2018, 248, 225–229. [Google Scholar] [CrossRef]

- AOCS. Official Methods and Recommended Practices of the American Oil Chemists’ Society, 4th ed.; AOCS Press: Champaign, IL, USA, 2004. [Google Scholar]

- Nuru, Z.; Getachew, P. Improving the Quality of Used Frying Niger Seed Oil with Adsorbent Treatment. Heliyon 2021, 7, e06748. [Google Scholar] [CrossRef] [PubMed]

- IUPAC, C. Method Number 2.504. Determination of the P-Anisidine Value (P-AV). Stand. Methods Anal. Oils Fats Deriv. 1987, 51, 2–207. [Google Scholar]

- Sun-Waterhouse, D.; Zhou, J.; Miskelly, G.M.; Wibisono, R.; Wadhwa, S.S. Stability of Encapsulated Olive Oil in the Presence of Caffeic Acid. Food Chem. 2011, 126, 1049–1056. [Google Scholar] [CrossRef]

- Yang, Y.; Ferro, M.D.; Cavaco, I.; Liang, Y. Detection and Identification of Extra Virgin Olive Oil Adulteration by GC-MS Combined with Chemometrics. J. Agric. Food Chem. 2013, 61, 3693–3702. [Google Scholar] [CrossRef]

- Su, C. Pamela White Frying Stability of High-Oleate and Regular Soybean Oil Blends. AOCS 2004, 81, 783–788. [Google Scholar]

- Boukir, A.; Fellak, S.; Doumenq, P. Structural Characterization of Argania Spinosa Moroccan Wooden Artifacts during Natural Degradation Progress Using Infrared Spectroscopy (ATR-FTIR) and X-ray Diffraction (XRD). Heliyon 2019, 5, e02477. [Google Scholar] [CrossRef] [Green Version]

- Asemani, M.; Rabbani, A.R. Detailed FTIR Spectroscopy Characterization of Crude Oil Extracted Asphaltenes: Curve Resolve of Overlapping Bands. J. Pet. Sci. Eng. 2020, 185, 106618. [Google Scholar] [CrossRef]

- Moura, H.O.M.A.; Campos, L.M.A.; da Silva, V.L.; de Andrade, J.C.F.; de Assumpção, S.M.N.; Pontes, L.A.M.; de Carvalho, L.S. Investigating Acid/Peroxide-Alkali Pretreatment of Sugarcane Bagasse to Isolate High Accessibility Cellulose Applied in Acetylation Reactions. Cellulose 2018, 25, 5669–5685. [Google Scholar] [CrossRef]

- Shao, X.; Wang, J.; Liu, Z.; Hu, N.; Liu, M.; Xu, Y. Preparation and Characterization of Porous Microcrystalline Cellulose from Corncob. Ind. Crops Prod. 2020, 151, 112457. [Google Scholar] [CrossRef]

- Pereira, S.C.; Maehara, L.; Machado, C.M.M.; Farinas, C.S. Physical–Chemical–Morphological Characterization of the Whole Sugarcane Lignocellulosic Biomass Used for 2G Ethanol Production by Spectroscopy and Microscopy Techniques. Renew. Energy 2016, 87, 607–617. [Google Scholar] [CrossRef]

- Ninomiya, K.; Soda, H.; Ogino, C.; Takahashi, K.; Shimizu, N. Effect of Ionic Liquid Weight Ratio on Pretreatment of Bamboo Powder Prior to Enzymatic Saccharification. Bioresour. Technol. 2013, 128, 188–192. [Google Scholar] [CrossRef]

- Mou, H.; Wu, S. Comparison of Hydrothermal, Hydrotropic and Organosolv Pretreatment for Improving the Enzymatic Digestibility of Bamboo. Cellulose 2017, 24, 85–94. [Google Scholar] [CrossRef]

- Yao, W.; Weng, Y.; Catchmark, J.M. Improved Cellulose X-Ray Diffraction Analysis Using Fourier Series Modeling. Cellulose 2020, 27, 5563–5579. [Google Scholar] [CrossRef]

- Zou, Y.; Fu, J.; Chen, Z.; Ren, L. The Effect of Microstructure on Mechanical Properties of Corn Cob. Micron 2021, 146, 103070. [Google Scholar] [CrossRef]

- Nayak, P.K.; Dash, U.; Rayaguru, K.; Krishnan, K.R. Physio-Chemical Changes during Repeated Frying of Cooked Oil: A Review. J. Food Biochem. 2016, 40, 371–390. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.; Fan, D. Effect of Ultrasonic on Deterioration of Oil in Microwave Vacuum Frying and Prediction of Frying Oil Quality Based on Low Field Nuclear Magnetic Resonance (LF-NMR). Ultrason. Sonochem. 2019, 51, 77–89. [Google Scholar] [CrossRef]

- Farag, R.S.; El-Anany, A.M. Improving the Quality of Fried Oils by Using Different Filter Aids. J. Sci. Food Agric. 2006, 86, 2228–2240. [Google Scholar] [CrossRef]

- Nwadiogbu, J.O.; Ajiwe, V.I.E.; Okoye, P.A.C. Removal of Crude Oil from Aqueous Medium by Sorption on Hydrophobic Corncobs: Equilibrium and Kinetic Studies. J. Taibah Univ. Sci. 2016, 10, 56–63. [Google Scholar] [CrossRef] [Green Version]

- Shahidi, F. Bailey’s Industrial Oil and Fat Products, Industrial and Nonedible Products from Oils and Fats, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Choe, E.; Min, D.B. Chemistry of Deep-Fat Frying Oils. J. Food Sci. 2007, 72, R77–R86. [Google Scholar] [CrossRef]

- Ismail, S.A.E.A.; El-Anany, A.M.; Ali, R.F.M. Regeneration of Used Frying Palm Oil with Coffee Silverskin (CS), CS Ash (CSA) and Nanoparticles of CS (NCS). J. Oleo Sci. 2017, 66, 897–905. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koohikamali, S.; Alam, M.S. Improvement in Nutritional Quality and Thermal Stability of Palm Olein Blended with Macadamia Oil for Deep-Fat Frying Application. J. Food Sci. Technol. 2019, 56, 5063–5073. [Google Scholar] [CrossRef]

- Solati, Z.; Baharin, B.S. Antioxidant Effect of Supercritical CO2 Extracted Nigella sativa L. Seed Extract on Deep Fried Oil Quality Parameters. J. Food Sci. Technol. 2015, 52, 3475–3484. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aydinkaptan, E.; Mazi, B.G.; Barutçu Mazi, I. Microwave Heating of Sunflower Oil at Frying Temperatures: Effect of Power Levels on Physicochemical Properties. J. Food Process. Eng. 2017, 40, e12402. [Google Scholar] [CrossRef]

- Sharoba, A.M.; Ramadan, M.F. Impact of Frying on Fatty Acid Profile and Rheological Behaviour of Some Vegetable Oils. J. Food Process. Technol. 2017, 3, 7. [Google Scholar] [CrossRef]

- Udomkun, P.; Niruntasuk, P.; Innawong, B. Impact of Novel Far-Infrared Frying Technique on Quality Aspects of Chicken Nuggets and Frying Medium. J. Food Process. Preserv. 2019, 43, e13931. [Google Scholar] [CrossRef]

| Samples | TCI (A1372/A2900) | CrI (%) |

|---|---|---|

| CC | 0.53 ± 0.08 a | 53.32 ± 1.13 a |

| CP | 0.40 ± 0.05 c | 48.53 ± 0.92 b |

| SC | 0.45 ± 0.06 b | 49.24 ± 0.24 a,b |

| Samples | Carbon | Oxygen | Calcium | Potassium | Cobalt |

|---|---|---|---|---|---|

| CC | 69.52 ± 3.35 a | 27.87 ± 0.75 b | - | 2.23 ± 0.95 a | 0.59 ± 0.02 |

| CP | 57.53 ± 2.63 a,b | 35.25 ± 0.92 a,b | 4.14 ± 0.13 | 3.26 ± 0.23 a | - |

| SC | 53.30 ± 1.84 b | 39.34 ± 1.22 a | 5.67 ± 0.17 | 1.88 ± 0.27 a | - |

| 0 h | 4 h | 8 h | 12 h | 16 h | 20 h | |

|---|---|---|---|---|---|---|

| Fresh oil | 0.11 ± 0.00 | - | - | - | - | - |

| Used oil | - | 0.32 ± 0.01 a | 0.39 ± 0.05 a | 0.44 ± 0.02 a | 0.59 ± 0.03 a | 0.63 ± 0.02 a |

| CC-treated oil | - | 0.22 ± 0.01 b | 0.27 ± 0.00 b | 0.37 ± 0.05 b | 0.50 ± 0.08 a,b | 0.58 ± 0.03 a,b |

| CP-treated oil | - | 0.17 ± 0.01 c | 0.28 ± 0.02 b | 0.35 ± 0.01 b | 0.49 ± 0.04 a,b | 0.54 ± 0.00 b,c |

| SC-treated oil | - | 0.14 ± 0.03 c | 0.23 ± 0.03 b | 0.34 ± 0.02 b | 0.41 ± 0.09 b | 0.51 ± 0.02 c |

| 0 h | 4 h | 8 h | 12 h | 16 h | 20 h | |

|---|---|---|---|---|---|---|

| Fresh oil | 4.63 ± 1.03 | - | - | - | - | - |

| Used oil | - | 9.11 ± 0.13 a | 8.72 ± 2.84 a | 11.10 ± 0.89 a | 10.96 ± 1.39 a | 9.45 ± 0.56 a |

| CC-treated oil | - | 3.43 ± 0.29 c | 5.22 ± 0.77 b | 9.37 ± 1.45 a | 6.21 ± 0.96 b | 8.23 ± 1.76 a |

| CP-treated oil | - | 5.26 ± 1.30 b | 6.40 ± 0.76 a,b | 9.02 ± 0.80 a | 4.99 ± 0.93 b | 8.96 ± 0.61 a |

| SC-treated oil | - | 2.55 ± 0.41 c | 5.19 ± 0.44 b | 5.97 ± 1.03 b | 5.01 ± 0.92 b | 6.91 ± 0.12 b |

| 0 h | 4 h | 8 h | 12 h | 16 h | 20 h | |

|---|---|---|---|---|---|---|

| Fresh oil | 16.40 ± 1.32 | - | - | - | - | - |

| Used oil | - | 43.23 ± 2.30 a | 53.81 ± 5.43 a | 69.32 ± 4.75 a | 73.89 ± 3.68 a | 98.45 ± 6.31 a |

| CC-treated oil | - | 36.91 ± 1.42 b | 49.71 ± 3.65 b | 61.71 ± 6.15 c | 71.35 ± 2.43 a,b | 88.84 ± 5.74 b |

| CP-treated oil | - | 31.86 ± 1.97 c | 51.79 ± 4.59 a,b | 66.39 ± 3.35 b | 70.59 ± 2.67 a,b | 83.56 ± 4.53 c |

| SC-treated oil | - | 32.17 ± 2.23 c | 48.99 ± 2.36 b | 60.10 ± 2.84 c | 69.63 ± 4.21 b | 77.92 ± 3.65 d |

| 0 h | 4 h | 8 h | 12 h | 16 h | 20 h | |

|---|---|---|---|---|---|---|

| Fresh oil | 25.66 ± 2.32 | - | - | - | - | - |

| Used oil | - | 61.45 ± 5.31 a | 71.25 ± 6.25 a | 91.52 ± 4.32 a | 95.81 ± 3.81 a | 117.35 ± 9.15 a |

| CC-treated oil | - | 43.77 ± 3.84 b | 60.15 ± 3.34 d | 80.45 ± 5.26 b | 83.77 ± 4.43 b | 105.3 ± 5.32 b |

| CP-treated oil | - | 42.38 ± 4.19 b | 64.59 ± 4.65 b | 84.43 ± 3.79 b | 80.57 ± 3.32 b | 101.5 ± 6.62 b |

| SC-treated oil | - | 38.27 ± 2.27 c | 59.37 ± 3.43 c | 72.04 ± 4.54 c | 79.65 ± 2.73 b | 91.74 ± 4.76 c |

| Fatty Acids (%) | 0 h | 12 h | 20 h | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Fresh Oil | Used | CC-Treated Oil | CP-Treated Oil | SC-Treated Oil | Used | CC-Treated Oil | CP-Treated Oil | SC-Treated Oil | |

| C16:0 | 6.84 ± 0.14 b | 7.92 ± 0.22 b | 13.92 ± 0.36 a | 9.83 ± 0.69 b | 9.45 ± 0.84 b | 8.78 ± 0.54 b | 7.98 ± 1.59 b | 8.04 ± 0.54 b | 8.32 ± 0.73 b |

| C18:0 | 3.41 ± 0.11 a | 3.75 ± 0.19 a | 4.30 ± 0.66 a | 4.28 ± 0.43 a | 4.49 ± 0.18 a | 4.27 ± 0.62 a | 3.52 ± 0.97 a | 3.58 ± 0.61 a | 3.45 ± 0.84 a |

| C18:1 | 21.64 ± 0.90 a | 23.63 ± 0.37 a | 22.93 ± 0.72 a | 25.81 ± 1.21 a | 24.44 ± 0.95 a | 24.72 ± 0.85 a | 22.99 ± 1.10 a | 22.7 ± 0.92 a | 23.43 ± 1.18 a |

| C18:2 | 65.30 ± 1.12 a | 62.39 ± 1.13 a,b | 52.89 ± 2.31 b | 56.68 ± 1.23 a,b | 57.27 ± 1.52 a,b | 58.84 ± 1.18 a,b | 61.39 ± 1.14 a,b | 61.99 ± 2.25 a,b | 61.05 ± 1.93 a,b |

| SFA (%) ** | 12.31 ± 0.63 b | 13.78 ± 0.82 b | 23.07 ± 2.17 a | 17.51 ± 0.65 a,b | 17.46 ± 0.74 a,b | 15.98 ± 0.59 b | 15.39 ± 0.89 b | 15.31 ± 0.64 b | 15.14 ± 0.54 b |

| USFA (%) *** | 87.69 ± 1.89 a | 86.22 ± 1.21 a | 76.93 ± 2.46 a | 82.49 ± 1.13 a | 82.53 ± 1.78 a | 84.02 ± 2.15 a | 84.61 ± 1.76 a | 84.69 ± 2.32 a | 84.86 ± 1.86 a |

| Frying Time (h) | Samples | L* | a* | b* |

|---|---|---|---|---|

| 0 | Fresh oil | 40.91 ± 0.32 a | −1.69 ± 0.03 c | 7.38 ± 1.21 d |

| 4 | Used oil | 38.79 ± 0.41 a | −1.74 ± 0.04 c | 13.27 ± 2.34 c |

| CC-treated oil | 39.47 ± 0.65 a | −1.70 ± 0.02 c | 13.32 ± 2.12 c | |

| CP-treated oil | 39.29 ± 0.43 a | −1.98 ± 0.02 c | 14.57 ± 1.84 b,c | |

| SC-treated oil | 40.30 ± 1.23 a | −1.96 ± 0.03 c | 14.37 ± 2.47 c | |

| 12 | Used oil | 36.82 ± 0.95 a | 0.49 ± 0.06 a,b,c | 17.65 ± 1.59 a,b |

| CC-treated oil | 36.94 ± 0.56 a | 0.78 ± 0.05 a,b,c | 19.23 ± 0.12 a | |

| CP-treated oil | 36.68 ± 0.77 a | 0.56 ± 0.06 a,b,c | 17.68 ± 0.36 a,b | |

| SC-treated oil | 36.62 ± 0.84 a | 0.25 ± 0.02 b,c | 17.90 ± 0.83 a,b | |

| 20 | Used oil | 35.96 ± 0.92 a | 1.78 ± 0.08 a,b | 18.60 ± 0.32 a |

| CC-treated oil | 35.29 ± 0.75 a | 3.31 ± 0.21 a,b | 17.76 ± 0.89 a,b | |

| CP-treated oil | 35.55 ± 0.54 a | 3.71 ± 0.33 a | 18.52 ± 1.10 a | |

| SC-treated oil | 38.51 ± 0.42 a | 2.38 ± 0.16 a,b | 20.84 ± 0.97 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, E.; Zeitoun, A.; Hamad, G.; Zeitoun, M.A.M.; Taha, A.; Korma, S.A.; Esatbeyoglu, T. Lignocellulosic Biomasses from Agricultural Wastes Improved the Quality and Physicochemical Properties of Frying Oils. Foods 2022, 11, 3149. https://doi.org/10.3390/foods11193149

Ahmed E, Zeitoun A, Hamad G, Zeitoun MAM, Taha A, Korma SA, Esatbeyoglu T. Lignocellulosic Biomasses from Agricultural Wastes Improved the Quality and Physicochemical Properties of Frying Oils. Foods. 2022; 11(19):3149. https://doi.org/10.3390/foods11193149

Chicago/Turabian StyleAhmed, Eman, Ashraf Zeitoun, Gamal Hamad, Mohamed A. M. Zeitoun, Ahmed Taha, Sameh A. Korma, and Tuba Esatbeyoglu. 2022. "Lignocellulosic Biomasses from Agricultural Wastes Improved the Quality and Physicochemical Properties of Frying Oils" Foods 11, no. 19: 3149. https://doi.org/10.3390/foods11193149