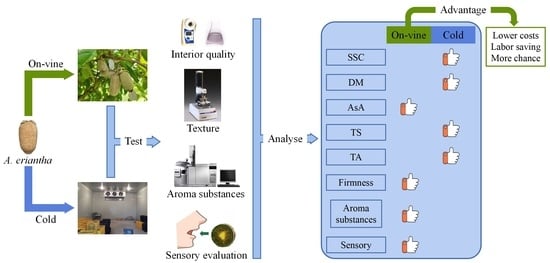

Prolonged On-Vine vs. Cold of Actinidia eriantha: Differences in Fruit Quality and Aroma Substances during Soft Ripening Stage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Fruit Quality

2.3. Sensory Evaluation

2.4. Data Analysis

3. Results

3.1. Differences in Fruit Quality

3.2. Differences of Aroma Components

3.3. The Contents and Variations of Various Aroma Components

3.4. Variations of Main Aroma Components

3.5. Effects of Different Softening Methods on the Sensory Quality of ‘Ganlv-2’

3.6. Modeling Method to Analyze the Index Differences between Two Softening Methods

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Varkonyigasic, E.; Lough, R.H.; Moss, S.M.; Wu, R.; Hellens, R.P. Kiwifruit floral gene APETALA2 is alternatively spliced and accumulates in aberrant indeterminate flowers in the absence of miR172. Plant Mol. Biol. 2012, 78, 417–429. [Google Scholar] [CrossRef] [PubMed]

- Seal, A.G. Plant breeding challenges to making kiwifruit a worldwide mainstream fresh fruit. Acta Hortic. 2003, 610, 75–80. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Yu, Z.; Jian, Z.; Maratab, A.; Liu, G.D.; Zheng, X.L. L-ascorbic acid metabolism in an Ascorbate-rich kiwifruit (Actinidia. Eriantha Benth.) cv. ‘White’ during postharvest. Plant Physiol. Biochem. 2018, 124, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.Q.; Huang, Q.; Jia, D.F.; Zhong, M.; Tao, J.J.; Liao, G.L.; Huang, C.H.; Xu, X.B. Characterization of organic acid metabolism and expression of related genes during fruit development of Actinidia eriantha ‘Ganmi 6′. Plants 2020, 9, 332. [Google Scholar] [CrossRef]

- Liao, G.L.; Jiang, Z.Q.; He, Y.Q.; Zhong, M.; Huang, C.H.; Qu, X.Y.; Xu, X.B. The Comprehensive Evaluation Analysis of the Fruit Quality in Actinidia eriantha Pollinated with Different Pollen Donors Based on the Membership Function Method. Erwerbs-Obstbau 2022, 64, 91–96. [Google Scholar] [CrossRef]

- Qu, J.L. Problems and countermeasures of kiwifruit industry development in China. Sci. Technol. Dev. 2015, 4, 521–529. (In Chinese) [Google Scholar] [CrossRef]

- Byeon, S.E.; Jinwook, L. Fruit maturity differentially affects fruit quality and responses of targeted metabolites in cold-stored gigs (Ficus carica L.). J. Sci. Food Agric. 2021, 101, 673–683. [Google Scholar] [CrossRef]

- Lee, J.; James, P.M.; Rudell, D.R. High storage humidity affects fruit quality attributes and incidence of fruit cracking in cold-stored ‘Royal Gala’ apples. HortScience 2019, 54, 149–154. [Google Scholar] [CrossRef]

- Cano-Salazar, J.; López, M.L.; Crisosto, C.H.; Echeverría, G. Volatile compound emissions and sensory attributes of ‘Big Top’ nctarine and ‘Early Rich’ peach fruit in response to a pre-storage treatment before cold storage and subsequent shelf-life. Postharvest Biol. Technol. 2013, 76, 152–162. [Google Scholar] [CrossRef]

- Khalid, S.; Aman, U.M.; Ahmad, S.K.; Muhammad, S.; Muhammad, S. Tree age, fruit size and storage conditions affect levels of ascorbic acid, total phenolic concentrations and total antioxidant activity of ‘Kinnow’ mandarin juice. J. Sci. Food Agric. 2016, 96, 1319–1325. [Google Scholar] [CrossRef]

- Cruz-Bravo, R.K.; Guzmán-Maldonado, S.H.; Araiza-Herrera, H.A.; Zegbe, J.A. Storage alters physicochemical characteristics, bioactive compounds and antioxidant capacity of cactus pear fruit. Postharvest Biol. Technol. 2019, 150, 105–111. [Google Scholar] [CrossRef]

- Kienzle, S.; Reinhold, C.; Pittaya, S.; Carola, T.; Neidhart, S. Occurrence of Alk(en)ylresorcinols in the Fruits of Two Mango (Mangifera indica L.) Cultivars during On-Tree Maturation and Postharvest Storage. J. Agric. Food Chem. 2014, 62, 28–40. [Google Scholar] [CrossRef] [PubMed]

- Burns, J.K.; Albrigo, L.G. Time of harvest and method of storage affect granulation in grapefruit. HortScience 1998, 33, 728–730. [Google Scholar] [CrossRef]

- Chen, L.; Wang, S.Y.; Zhong, M.; Huang, C.H.; Liao, G.L.; Xu, X.B. Effects of pollens from the 10 selected Actinidia male genotypes on 4 commercial planting kiwifruit female cultivars in southern China. N. Z. J. Crop Hortic. Sci. 2019, 47, 155–169. [Google Scholar] [CrossRef]

- Mittler, R. Oxidative stress, antioxidants and stress tolerance. Trends Plant Sci. 2002, 7, 405–410. [Google Scholar] [CrossRef]

- Wang, S.Y.; Jiao, H.J. Changes in oxygen-scavenging systems and membrane lipid peroxidation during maturation and ripening in blackberry. J. Agric. Food Chem. 2001, 49, 1612–1619. [Google Scholar] [CrossRef]

- Tao, D.; Xia, R.X.; Wang, M.Y.; Xiao, Z.Y.; Liu, P. Changes in dietary fibre, polygalacturonase, cellulase of Navel orange (Citrus sinensis (L.) Osbeck ‘Cara Cara’) fruits under different storage conditions. Sci. Hortic. 2008, 116, 414–420. [Google Scholar] [CrossRef]

- Burdon, J.; Pidakala, P.; Martin, P.; Billing, D. Softening of ‘Hayward’ kiwifruit on the vine and in storage: The effects of temperature. Sci. Hortic. 2017, 220, 176–182. [Google Scholar] [CrossRef]

- Weerawatanakotn, M.; Wu, J.C.; Pan, M.H. Reactivity and stability of selected flavor compounds. J. Food Drug Anal. 2015, 23, 176–190. [Google Scholar] [CrossRef]

- Rouseff, R.; Lruiz, P.C.P.; Jabalpurwala, F. Historical review of citrus flavor research during the past 100 years. J. Agric. Food Chem. 2009, 57, 8115–8124. [Google Scholar] [CrossRef]

- Paterson, V.J.; Macrae, E.A.; Young, H. Relationships between sensory properties and chemical-composition of kiwifruit (Actinidia deliciosa). J. Sci. Food Agric. 1991, 57, 235–251. [Google Scholar] [CrossRef]

- Wan, X.M.; Stevenson, R.J.; Chen, X.D. Application of headspace solid-phase microextraction to volatile flavour profile development during storage and ripening of kiwifruit. Food Res. Int. 1999, 32, 175–183. [Google Scholar] [CrossRef]

- Garcia, C.V.; Quek, S.Y.; Stevenson, R.J. Characterisation of bound volatile compounds of a low flavour kiwifruit species: Actinidia eriantha. Food Chem. 2012, 134, 655–661. [Google Scholar] [CrossRef] [PubMed]

- Da, S.; Édipo, M.; Maraísa, H.T.; Victor, F.D.S.; Rafael, P.; Tales, J.F.; Joel, A.M. Description of blackberry fruit growth by nonlinear regression models. Rev. Bras. Frutic. 2020, 42, 1–11. [Google Scholar] [CrossRef]

- Frédéric, B.; Séverine, P.; Alexandra, J.; Sarah, B.; Isabelle, G.; Pierre, F.; Yann, G.; Mathieu, L.; Éric, L.; Frédéric, N. V-mango: A functional-structural model of mango tree growth, development and fruit production. Ann. Bot. 2020, 126, 745–763. [Google Scholar] [CrossRef]

- Yuan, H.; Martin, P.; Fullerton, C.; Gould, N.; Hall, A.; Burdon, J. Refining the estimation of kiwifruit size from linear fruit dimensions. Sci. Hortic. 2020, 262, 108878. [Google Scholar] [CrossRef]

- Olatunji, J.R.; Love, R.J.; Shim, Y.M.; East, A.R. A shape equation for Hayward kiwifruit. Int. J. Food Prop. 2019, 22, 371–382. [Google Scholar] [CrossRef]

- Hall, A.J.; Minchin, P.E.H.; Michael, J.C.; Génard, M. A biophysical model of kiwifruit (Actinidia deliciosa) berry development. J. Exp. Bot. 2013, 64, 5473–5483. [Google Scholar] [CrossRef]

- Liu, S.Q.; Huang, W.Q.; Lin, L.; Fan, S.X. Effects of orientations and regions on performance of online soluble solids content prediction models based on near-infrared spectroscopy for peaches. Foods 2022, 11, 1502. [Google Scholar] [CrossRef]

- Van Der Sman, R.G.M.; Sanders, M. Prediction of postharvest firmness of apple using biological switch model. J. Theor. Biol. 2012, 310, 239–248. [Google Scholar] [CrossRef]

- Iwasaki, C.; Hiroyoshi, S.; Genichiro, K.; Hitoshi, K. Nonlinear multivariate prediction model of ‘Kyoho’ grape full bloom dates in Japan. Hortic. J. 2022, 91, 195–208. [Google Scholar] [CrossRef]

- Bugaud, C.; Pascaline, A. Volatile and non-volatile compounds as odour and aroma predictors in dessert banana (Musa spp.). Postharvest Biol. Technol. 2016, 112, 14–23. [Google Scholar] [CrossRef]

- Fan, G.J.; Wang, S.Y.; Shi, W.J.; Gong, Z.F.; Gao, M. Simulation parameter calibration and test of typical pear varieties based on discrete element method. Agronomy 2022, 12, 1720. [Google Scholar] [CrossRef]

- Mirás, A.; José, M.; Rosalía, A.; Juan, J.; Alarcón Francisco, P.; Pierre, V.; Françoise, L.; Emilio, N. Combined effects of water stress and fruit thinning on fruit and vegetative growth of a very early-maturing peach cultivar: Assessment by means of a fruit tree model, qualiTree. Irrig. Sci. 2012, 31, 1039–1051. [Google Scholar] [CrossRef]

- Latocha, P.; Paweł, J.; Jadwiga, R. Genotypic difference in postharvest characteristics of hardy kiwifruit (Actinidia arguta and its hybrids), as a New Commercial Crop Part I. Sensory Profiling and Physicochemical differences. Food Res. Int. 2011, 44, 1936–1945. [Google Scholar] [CrossRef]

- Godoy, C.; Gloria, M.; Jorge, T. Analysis of highbush blueberry (Vaccinium corymbosum L.) fruit growth with exponential mixed models. Sci. Hortic. 2008, 115, 368–376. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.Q.; Liao, G.L.; Xu, X.B.; Jia, D.F.; Zhong, M.; Wang, H.L.; Ye, B. Transcriptome and metabolome reveal AsA regulatory network between metabolites and genes after fruit shading by bagging in kiwifruit (Actinidia eriantha). Sci. Hortic. 2022, 302, 111184. [Google Scholar] [CrossRef]

- Lv, Z.X.; He, Y.Q.; Liu, Q.; Huang, C.H.; Jia, D.F.; Xu, X.B. Diversity analysis of kiwifruit germplasm resources and quality resources selection based on fruit characters in the south of Jiangxi Province. Eur. J. Hortic. Sci. 2022, 87. [Google Scholar] [CrossRef]

- Liao, G.L.; Chen, L.; He, Y.Q.; Li, X.S.; Lv, Z.X.; Yi, S.Y.; Zhong, M.; Huang, C.H.; Jia, D.F.; Qu, X.Y.; et al. Three metabolic pathways are responsible for the accumulation and maintenance of high AsA content in kiwifruit (Actinidia eriantha). BMC Genom. 2021, 22, 13. [Google Scholar] [CrossRef]

- Kamal, E.; Afaf, N.G.; Bhawna, S.; Nouf, A.; Sami, G.; Abdul AAli Annica, A.M.A.; Roger, A.; Asha, A.; Fathalla, H. Dietary fiber components, microstructure, and texture of date fruits (Phoenix dactylifera, L.). Sci. Rep. 2020, 10, 21767. [Google Scholar] [CrossRef]

- Liao, G.L.; He, Y.Q.; Li, X.S.; Zhong, M.; Xu, X.B. Effects of bagging on fruit flavor quality and related gene expression of AsA synthesis in Actinidia eriantha. Sci. Hortic. 2019, 256. [Google Scholar] [CrossRef]

- Ma, T.T.; Sun, X.Y.; Zhao, J.M.; You, Y.L.; Lei, Y.S.; Gao, G.T.; Zhan, J.C. Nutrient compositions and antioxidant capacity of kiwifruit (Actinidia) and their relationship with flesh color and commercial value. Food Chem. 2017, 218, 294–304. [Google Scholar] [CrossRef]

- Zhang, B.; Yin, X.R.; Li, X.; Yang, S.L.; Ferguson, I.B.; Chen, K.S. Lipoxygenase gene expression in ripening kiwifruit in relation to ethylene and aroma production. J. Agric. Food Chem. 2009, 57, 2875–2881. [Google Scholar] [CrossRef]

- Kim, M.K.; Hae, W.J.; Kwang-Geun, L. Characterization of key aroma-active compounds isolated from omija fruit treated differently based on odor activity values and descriptive sensory analysis. Foods 2020, 9, 638. [Google Scholar] [CrossRef]

- Einfalt, D.; Klaus, M.; Lena, K.K.I.; Joachim, M. Fruit spirit production from coffee cherries—Process analysis and sensory evaluation. Beverages 2020, 6, 57. [Google Scholar] [CrossRef]

- Gunness, P.; Michael, J.G.; Olena, K.; Bruce, R.D.; Stephen, M.N. Sensory analysis of individual strawberry fruit and comparison with instrumental analysis. Postharvest Biol. Technol. 2009, 52, 164–172. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, K.; Bowen, J.; Allan, A.; Espley, R.; Karunairetnam, S.; Ferguson, I. Differential expression within the LOX gene family in ripening kiwifruit. J. Exp. Bot. 2006, 57, 3825–3836. [Google Scholar] [CrossRef]

- Atkinson, R.G.; Kularajathevan, G.; Wang, M.Y.; Luo, L.; Wang, T.; Norling, C.L.; Johnston, S.L.; Ratnasiri, M.; Roswitha, S.; Schaffer, R.J. Dissecting the role of climacteric ethylene in kiwifruit (Actinidia chinensis) ripening using a 1-aminocyclopropane-1-carboxylic acid oxidase knockdown line. J. Exp. Bot. 2011, 62, 3821–3835. [Google Scholar] [CrossRef]

- Brummell, D.A.; Cin, V.D.; Crisosto, C.H.; Labavitch, J.M. Cell wall metabolism during maturation, ripening and senescence of peach fruit. J. Exp. Bot. 2004, 55, 2029–2039. [Google Scholar] [CrossRef]

- Nardozza, S.; Gamble, J.; Axten, L.G.; Wohlers, M.W.; Clearwater, M.J.; Feng, J.; Harker, F.R. Dry matter content and fruit size affect flavour and texture of Novel Actinidia deliciosa genotypes. J. Sci. Food Agric. 2011, 91, 742–748. [Google Scholar] [CrossRef]

- Karima, Z.A.H.; Nejib, G.; Vandita, S.; Mohanmad, S.R.; Lyutha, A. Instrumental texture profile analysis of date-tamarind fruit leather with different types of hydrocolloids. Food Sci. Technol. Res. 2013, 49, 531–538. [Google Scholar] [CrossRef]

- Huang, X.; Hsieh, F.H. Physical properties, sensory attributes, and consumer preference of pear fruit leather. J. Food Sci. 2005, 70, E177–E186. [Google Scholar] [CrossRef]

- Burdon, J.; Lallu, N. Kiwifruit (Actinidia spp.). In Postharvest Biology and Technology of Tropical and Subtropical Fruit; Yahia, E.M., Ed.; Woodhead Publishing Limited: Sawston, Cambridge, UK, 2011; Volume 3, Cocona to Mango; pp. 326–360. [Google Scholar] [CrossRef]

- Shafiq, M.; Zora, S.; Ahmad, S.K. Delayed harvest and cold storage period influence ethylene production, fruit firmness and quality of ‘Cripps Pink’ apple. Int. J. Food Sci. Technol. 2011, 46, 2520–2529. [Google Scholar] [CrossRef]

- Elena, D.C.; William, V.B.; Mitcham, E.J. Quality of pink lady apples in relation to maturity at harvest, prestorage treatments, and controlled atmosphere during storage. HortScience 2007, 42, 605–610. [Google Scholar] [CrossRef]

- Oh, S.B.; Muneer, S.; Kwack, Y.B.; Shin, M.H.; Kim, J.G. Characteristic of fruit development for optimal harvest date and postharvest storability in ‘Skinny Green’ baby kiwifruit. Sci. Hortic. 2017, 222, 57–61. [Google Scholar] [CrossRef]

- Sandhu, S.S. Effect of pre-harvest sprays of gibberellic acid, vipul, calcium chloride and bavistin on the tree storage of kinnow fruit. Acta Hortic. 1992, 321, 366–371. [Google Scholar] [CrossRef]

- Obenland, D.; Collin, S.; Mackey, B.; Sievert, J.; Arpaia, M.L. Storage temperature and time influences sensory quality of mandarins by altering soluble solids, acidity and aroma volatile composition. Postharvest Biol. Technol. 2011, 59, 187–193. [Google Scholar] [CrossRef]

- Burdon, J.; McLeod, D.; Lallu, N.; Gamble, J.; Petley, M.; Gunson, A. Consumer evaluation of ‘Hayward’ kiwifruit of different at-harvest dry matter contents. Postharvest Biol. Technol. 2004, 34, 245–255. [Google Scholar] [CrossRef]

- Harker, F.R.; Carr, B.T.; Lenjo, M.; MacRae, E.A.; Wismer, W.V.; Marsh, K.B.; Williams, M.; White, A.; Lund, C.M.; Walker, S.B. Consumer liking for kiwifruit flavour: A meta-analysis of five studies on fruit quality. Food Qual. Prefer. 2009, 20, 30–41. [Google Scholar] [CrossRef]

- Mditshwa, A.; Magwaza, L.S.; Tesfay, S.Z.; Opara, U.L. Postharvest factors affecting vitamin C content of citrus fruit: A review. Sci. Hortic. 2017, 218, 95–104. [Google Scholar] [CrossRef]

- Nagy, S. Vitamin C contents of citrus and their products: A review. J. Agric. Food Chem. 1980, 28, 8. [Google Scholar] [CrossRef] [PubMed]

- Ramandeep, K.T.; Geoffrey, P.S. Changes in major antioxidant components of tomatoes during postharvest storage. Food Chem. 2006, 99, 724–727. [Google Scholar] [CrossRef]

- Xu, X.B.; Liao, G.L.; Huang, C.H.; Zhong, M.; Jia, D.F.; Qu, X.Y.; Liu, Q.; He, Y.Q.; Li, Y.Q. Differences of sucrose accumulation concentration and related genes expression between two sucrose accumulation types of Actinidia eriantha. Sci. Rep. 2020, 10, 20474. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Liu, R.L.; Li, B.Q.; Tian, S.P. Characterisation of genes encoding key enzymes involved in sugar metabolism of apple fruit in controlled atmosphere storage. Food Chem. 2013, 141, 3323–3328. [Google Scholar] [CrossRef]

- Li, Y.F.; Jiang, W.J.; Liu, C.H.; Fu, Y.Q.; Wang, Z.Y.; Wang, M.Y.; Chen, C.; Guo, L.; Zhuang, Q.G.; Liu, Z.B. Comparison of fruit morphology and nutrition metabolism in different cultivars of kiwifruit across developmental stages. PeerJ 2021, 9, E11538. [Google Scholar] [CrossRef]

- McMath, K.L.; Paterson, V.J.; Young, H. Factors affecting the sensory perception of sweetness and acidity in kiwifruit. Acta Hortic. 1992, 297, 489–500. [Google Scholar] [CrossRef]

- Young, H.; Paterson, V.J. The Effects of harvest maturity, ripeness and storage on kiwifruit aroma. J. Sci. Food Agric. 1985, 36, 352–358. [Google Scholar] [CrossRef]

- Young, H.; Stec, M.; Paterson, V.J. Volatile compounds affecting kiwifruit flavor. Fruit Flavors 1995, 596, 59–67. [Google Scholar] [CrossRef]

- Li, H.; Tu, Z.S.; Wang, H.; Liu, F.; Li, K.C. Analysis of aroma components of kiwifruit (Actinidia chinensis Planch.) by gas chromatography-mass spectrometry. J. Instrum. Anal. 2002, 2, 58–60. (In Chinese) [Google Scholar] [CrossRef]

- Guo, L.F.; Wang, H.; Ma, S.L. Effect of refrigeration on aroma components of postharvest ‘Jinyan’ kiwifruit. Sci. Technol. Food Ind. 2013, 34, 304–308. (In Chinese) [Google Scholar] [CrossRef]

- Hofmann, T.; Scharbert, S.; Stark, T. Molecular and gustatory characterization of the impact taste compounds in black tea infusions. Dev. Food Sci. 2006, 43, 3–8. [Google Scholar] [CrossRef]

- Fuller, G.H.; Steltenkamp, R.; Tisserand, G.A. The gas chromatograph with human sensor: Perfumer model. Ann. N. Y. Acad. Sci. 2010, 116, 711–724. [Google Scholar] [CrossRef] [PubMed]

- Navarro, R.E.; Hisila, S.; Motomichi, I. complexation of epigallocatechin gallate (a green tea extract, egcg) with mn 2: Nuclear spin relaxation by the paramagnetic ion. J. Inorg. Biochem. 2005, 99, 584–588. [Google Scholar] [CrossRef] [PubMed]

- Meelgaard, M.; Cibille, G.V.; Carr, B.T. Descriptive Analysis Techniques-Sensory Evaluation Tecgniques, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Elortondo, F.; Ojeda, M.; Albisu, M.; Salmeron, J.; Etayo, I.; Molina, M. Food quality certification: An approach for the development of accredited sensory evaluation methods. Food Qual. Prefer. 2007, 18, 425–439. [Google Scholar] [CrossRef]

- Pinto, F.; Fogliatto, F.S.; Qannari, E.M. A method for panelists’ consistency assessment in sensory evaluations based on the Cronbach’s alpha coefficient. Food Qual. Prefer. 2014, 32, 41–47. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, Y.L.; Pan, Q.W.; Zhang, W. Correlation between the sensory evaluation and texture profile analysis of kiwifruit. Sci. Technol. Food Ind. 2018, 39, 243–247+252. (In Chinese) [Google Scholar] [CrossRef]

- Ioannou, I.; Perrot, N.; Hossenlopp, J.; Mauris, G.; Trystram, G. The fuzzy set theory: A helpful tool for the estimation of sensory properties of crusting sausage appearance by a single expert. Food Qual. Prefer. 2002, 13, 589–595. [Google Scholar] [CrossRef]

- Xue, S.; Li, H. Optimization of adding polysaccharides from chicory root based on fuzzy mathematics to improve physicochemical properties of silver carp surimi balls during storage. J. Food Process. Preserv. 2021, 45, e15307. [Google Scholar] [CrossRef]

- Fernandes, G.D.; Ana, C.E.; Adriana, G.; Daniel, B.A. Sensory evaluation of high-quality virgin olive oil: Panel analysis versus consumer perception. Curr. Opin. Food Sci. 2018, 21, 66–71. [Google Scholar] [CrossRef]

- Valli, E.; Bendini, A.; Popp, M.; Bongatz, A. Sensory analysis and consumer acceptance of 140 high-quality extra virgin olive oils. J. Sci. Food Agric. 2014, 94, 2124–2132. [Google Scholar] [CrossRef] [Green Version]

| Organoleptic Properties | Evaluation Criteria and Scores |

|---|---|

| Firmness | Soft ~ Tough (1–10) |

| Flesh color | Pale green ~ Blackish green (1–10) |

| Water content | Few ~ Rich (1–10) |

| Sweetness | Not sweet ~ Very sweet (1–10) |

| Sourness | Special sour ~ Not sour (1–10) |

| Kiwifruit flavor | Light ~ Special thick (1–10) |

| Acetic odor | Light ~ Special thick (1–10) |

| Overripe taste | Special thick ~ Little or none (1–10) |

| Aroma Substance | KICT/KILT | Aroma Description | Qualitative Method |

|---|---|---|---|

| Hexanal | 1015/1040 | Herbaceous flavor | MS/KI/St |

| Octanal | 1243/1255 | Orange flavor | MS/KI/St |

| D-Limonene | 1008/Ne | Sweet fragrance, lemon flavor | MS/St |

| 2-Carene | 1023/Ne | Herbaceous flavor | MS/St |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Z.; Ye, B.; Li, X.; He, Y.; Liu, Q.; Huang, C.; Jia, D.; Xu, X. Prolonged On-Vine vs. Cold of Actinidia eriantha: Differences in Fruit Quality and Aroma Substances during Soft Ripening Stage. Foods 2022, 11, 2860. https://doi.org/10.3390/foods11182860

Lv Z, Ye B, Li X, He Y, Liu Q, Huang C, Jia D, Xu X. Prolonged On-Vine vs. Cold of Actinidia eriantha: Differences in Fruit Quality and Aroma Substances during Soft Ripening Stage. Foods. 2022; 11(18):2860. https://doi.org/10.3390/foods11182860

Chicago/Turabian StyleLv, Zhengxin, Bin Ye, Xishi Li, Yanqun He, Qing Liu, Chunhui Huang, Dongfeng Jia, and Xiaobiao Xu. 2022. "Prolonged On-Vine vs. Cold of Actinidia eriantha: Differences in Fruit Quality and Aroma Substances during Soft Ripening Stage" Foods 11, no. 18: 2860. https://doi.org/10.3390/foods11182860