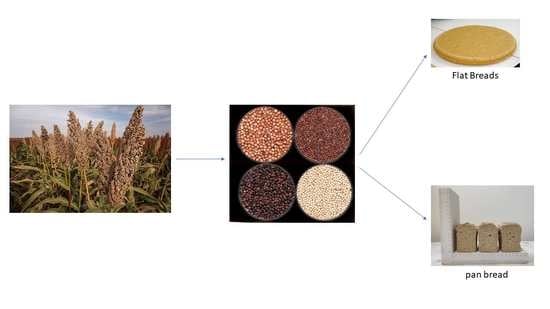

Sorghum Flour Application in Bread: Technological Challenges and Opportunities

Abstract

:1. Introduction

2. Methodology

3. Flat Breads

3.1. Roti

3.2. Tortillas

3.3. Injera

| Research Results | Reference |

|---|---|

| Substantial variations in injera texture, mouth feel, suppleness, and overall rate among the cereal flour blends (teff, barley, sorghum, and corn) were observed. No variations in injera in color, flavor, or the appearance of injera surface gas holes were observed. | [81] |

| Tannin levels were strongly associated with color and negatively associated with taste, whereas high starch content was associated with softness and rollability. | [84] |

| Eleven new sorghum varieties and eight promising experimental hybrids were compared for kisra-making quality with popular local varieties | [87] |

| Tannin had a negative effect on the protein quality and physical properties of kisra with tannin sorghums. White tan and non-tannin sorghum cultiivars were found more suitable for kisra production. | [88] |

| Tannins, phytic acid, and trypsin inhibitory activity in kisra bread were significantly decreased by traditional Sudanese kisra processing. | [89] |

| Kisra bread was improved with legume protein isolates in order to increase the protein content of Kisra and the amino acid profile, especially lysine. | [90] |

| A blend of teff (0.55%), sorghum (0.37%), and maize (0.07%) was found desirable and healthful, especially for people who lead sedentary lives and do not require much energy. | [91] |

| The addition of wheat bran to sorghum flour lowers sugar, in vitro protein, and starch digestibilities but increased crude fiber and the starch content of kisra. | [92] |

| By replacing 20% wheat and 10% pigeon pea with sorghum, changes in antinutrients and in vitro protein digestibility might well be obtained. | [93] |

| Brown bread for newborns (different types of kisra, some fortified with chickpeas or peanuts) should not include more than 10% wheat or sorghum bran, as this reduces digestion. | [94] |

| Waxy sorghum was recommended for making high-functional-quality gluten-free injera. | [95] |

| The addition of Monechma ciliatum seed flour to sorghum kisra significantly improved its nutritional value. | [96] |

| The overall acceptability of injera produced using disc mill flour was greater than that of hammer mill and blade mill flours. The injera produced using blade mill flour had the lowest level of rapidly available glucose and fast digested starch. | [97] |

| During kisra fermentation, the tannin level of the protein fractions was reduced, particularly in the albumin and glutelin fractions. | [98] |

| Fermentation increased the protein solubility, oil-binding capacity, emulsifying capacity, and emulsifying stability, while it decreased the water-binding capacity. | [99] |

| The addition of Saccharomyces cerevisiae to the prior starter (Lactobacillus fermentum, Lactobacillus brevis, and Lactobacillus amylovorus) reduced the sorghum fermentation time down to 4 h. | [100] |

| The microflora of Sudanese sorghum flour, a spontaneously fermented sourdough, and a long-term sourdough produced in a Sudanese household by consecutive reinoculations, was produced. | [101] |

| Traditional fermentation decreased soluble sugar content while increasing major by-products such as lactic acid, acetic acid, and ethanol. | [102] |

| Sorghum flour fermentation increased lysine and phenylalanine content while decreasing isoleucine, leucine, tryptophan, valine, methionine, and tyrosine levels. Baking reduced cystine and phenylalanine levels while increasing valine, isoleucine, and leucine content. | [103] |

| Fermented baobab fruit pulp flour as a starter decreased the antinutritional components of the fermented sorghum dough. | [104] |

| Kisra fermentation increased protein digestibility while having no effect on sample sensory quality. Sorghum can be supplemented with whey protein to increase its nutritional content and acceptability, even after baking. | [105] |

| Kisra fermentation resulted in a moderate improvement in protein, tyrosine, and methionine content, as well as a significant decrease in starch, total, and non-reducing sugars. | [106] |

| A nutritionally balanced Injera can be produced by fermenting 55% teff, 30% sorghum, and 15 % faba bean for 72 h. | [107] |

| Fermentation and heating increased the antioxidant potential of Tabat and Wad Ahmed sorghum grains. | [108] |

| During the fermentation of the Sudanese kisra dough, although many bacteria and molds grow, the bacteria with the highest population was P. pentosaceus. | [109] |

| The addition of 30% edible groundnut flour improved protein content and kisra quality significantly. | [110] |

| The main bacteria in fermented sorghum kisra and hulumur doughs were firmicutes and proteobacteria phyla. | [111] |

3.4. Kisra

4. Pan Breads

4.1. Gluten-Free Pan Bread

4.2. Sorghum–Wheat Composite Pan Breads

5. Future Perspectives

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rashwan, A.K.; Yones, H.A.; Karim, N.; Taha, E.M.; Chen, W. Potential processing technologies for developing sorghum-based food products: An update and comprehensive review. Trends Food Sci. Technol. 2021, 110, 168–182. [Google Scholar] [CrossRef]

- Assefa, Y.; Roozeboom, K.; Thompson, C.; Schlegel, A.; Stone, L.; Lingenfelser, J. Corn and Grain Sorghum Comparison: All Things Considered; Academic Press: Amsterdam, NY, USA, 2014; pp. 1–116. [Google Scholar]

- Halford, N.G.; Curtis, T.Y.; Chen, Z.; Huang, J. Effects of abiotic stress and crop management on cereal grain composition: Implications for food quality and safety. J. Exp. Bot. 2014, 66, 1145–1156. [Google Scholar] [CrossRef] [PubMed]

- Lobell, D.B.; Hammer, G.; Chenu, K.; Zheng, B.; McLean, G.; Chapman, S. The shifting influence of drought and heat stress for crops in northeast Australia. Glob. Chang. Biol. 2015, 21, 4115–4127. [Google Scholar] [CrossRef] [PubMed]

- Chadalavada, K.; Kumari, B.D.R.; Kumar, T.S. Sorghum mitigates climate variability and change on crop yield and quality. Planta 2021, 253, 113. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Nedumaran, S.; Traore, P.C.S.; Boote, K.J.; Rattunde, H.F.W.; Prasad, P.V.V.; Singh, N.P.; Srinivas, K.; Bantilan, M.C.S. Quantifying potential benefits of drought and heat tolerance in rainy season sorghum for adapting to climate change. Agric. For. Meteorol. 2014, 185, 37–48. [Google Scholar] [CrossRef]

- Singh, V.; Nguyen, C.T.; McLean, G.; Chapman, S.C.; Zheng, B.; van Oosterom, E.J.; Hammer, G.L. Quantifying high temperature risks and their potential effects on sorghum production in Australia. Field Crop. Res. 2017, 211, 77–88. [Google Scholar] [CrossRef]

- Chen, J.; Chopra, R.; Hayes, C.; Morris, G.; Marla, S.; Burke, J.; Xin, Z.; Burow, G. Genome-Wide Association Study of Developing Leaves’ Heat Tolerance during Vegetative Growth Stages in a Sorghum Association Panel. Plant Genome 2017, 10, 1–15. [Google Scholar] [CrossRef]

- Hacisalihoglu, G.; Armstrong, P.R. Flax and Sorghum: Multi-Element Contents and Nutritional Values within 210 Varieties and Potential Selection for Future Climates to Sustain Food Security. Plants 2022, 11, 451. [Google Scholar] [CrossRef]

- Belton, P.S.; Taylor, J.R.N. Sorghum and millets: Protein sources for Africa. Trends Food Sci. Technol. 2004, 15, 94–98. [Google Scholar] [CrossRef]

- Hadebe, S.T.; Modi, A.T.; Mabhaudhi, T. Drought Tolerance and Water Use of Cereal Crops: A Focus on Sorghum as a Food Security Crop in Sub-Saharan Africa. J. Agron. Crop Sci. 2017, 203, 177–191. [Google Scholar] [CrossRef]

- Kimber, C.T.; Dahlberg, J.A.; Kresovich, S. The gene pool of Sorghum bicolor and its improvement. In Genomics of the Saccharinae; Paterson, A.H., Ed.; Plant Genetics and Genomics: Crops and Models; Springer: New York, NY, USA, 2013; pp. 23–41. [Google Scholar] [CrossRef]

- Kulamarva, A.G.; Sosle, V.R.; Raghavan, G.S.V. Nutritional and Rheological Properties of Sorghum. Int. J. Food Prop. 2009, 12, 55–69. [Google Scholar] [CrossRef]

- Bean, S.; Wilson, J.; Moreau, R.; Galant, A.; Awika, J.; Kaufman, R.C.; Adrianos, S.; Ioerger, B. Structure and composition of the grain. In Sorghum: State of the Art and Future Perspectives; Ciampitti, I., Prasad, V., Eds.; ASA and CSSA: Madison, WI, USA, 2016. [Google Scholar] [CrossRef]

- Bean, S.R.; Zhu, L.; Smith, B.M.; Wilson, J.D.; Ioerger, B.P.; Tilley, M. Starch and protein chemistry and functional properties. In Sorghum and Millets: Chemistry, Technology, and Nutritional Attributes, 2nd ed.; Taylor, J.R.N., Duodu, K.G., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 131–170. [Google Scholar] [CrossRef]

- Serna-Saldivar, S.O.; Espinosa-Ramírez, J. Grain Structure and Grain Chemical Composition. In Sorghum and Millets: Chemistry, Technology, and Nutritional Attributes, 2nd ed.; Taylor, J.R.N., Duodu, K.G., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 85–129. [Google Scholar] [CrossRef]

- Taylor, J.R.N.; Schober, T.J.; Bean, S.R. Novel food and non-food uses for sorghum and millets. J. Cereal Sci. 2006, 44, 252–271. [Google Scholar] [CrossRef]

- Duodu, K.G.; Awika, J.M. Phytochemical-Related Health-Promoting Attributes of Sorghum and Millets. In Sorghum and Millets: Chemistry, Technology, and Nutritional Attributes, 2nd ed.; Taylor, J.R.N., Duodu, K.G., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 225–258. [Google Scholar] [CrossRef]

- Anglani, C. Sorghum for human food—A review. Plant Foods Hum. Nutr. 1998, 52, 85–95. [Google Scholar] [CrossRef]

- Delcour, J.A.; Hoseney, R.C. Principles of Cereal Science and Technology; AACC International, Inc.: Saint Paul, MN, USA, 2010; pp. 177–206. [Google Scholar]

- Cauvain, S. Technology of Breadmaking; Springer: Cham, Switzerland, 2015; pp. 21–51. [Google Scholar]

- Rooney, L.W.; Murty, D.S. Evaluation of Sorghum Food Quality. In Sorghum in the Eighties, Proceedings of the International Symposium on Sorghum, Patancheru, India, 2–7 November 1981; House, L.R., Mughogho, L.K., Peacock, J.M., Eds.; ICRISAT: Andhra Pradesh, India, 1982. [Google Scholar]

- Subramanian, V.; Jambunathan, R.; Ramaiah, C.D. Physical and Chemical Characteristics of Pearl Millet Grains and Their Relationship to Roti Quality. J. Food Sci. 1986, 51, 1005–1008. [Google Scholar] [CrossRef]

- Chavan, U.D.; Lande, S.B.; Kotecha, P.M. Evaluation of initial advance hybrid sorghum genotypes for roti and nutritional quality. Int. J. Chem. Stud. 2019, 7, 19–23. [Google Scholar]

- Unhale, D.S.; Sakhale, B.K.; Ranveer, R.C.; Pawar, V.D. Studies on shelf life extension of sorghum roti. Int. Food. Res. J. 2012, 19, 733–736. [Google Scholar]

- Nirmal, U.C.S.; Pawar, M.S.G.; Dalvi, S.G.U. Nutritional Quality of Hybrid Sorghum Genotypes. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 586–592. [Google Scholar] [CrossRef]

- Chavan, U.; Kajjdoni, S.; Shinde, M.; Dalvi, U.; Nirmal, S.; Patil, V.; Awari, V.; Pawar, G.; Jadhav, A. Regional Effect on Nutritional Quality of Sorghum Hybrid Genotypes. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 75–85. [Google Scholar] [CrossRef]

- Syed, I.; Kulkarni, P.J.; Borikar, S.T. Variability in nutritional composition and Roti-making quality traits in sorghum. Int. Sorghum Millets Newsl. 2000, 41, 56–58. [Google Scholar]

- Chavan, U.D.; Patil, J.V.; Shinde, M.S. Nutritional quality of high yielding rabi sorghum genotypes. J. Agric. Res. Technol. 2012, 37, 46–50. [Google Scholar]

- Radhakrishnan, M.R.; Sivaprasad, J. Tannin content of sorghum varieties and their role in iron bioavailability. J. Agric. Food Chem. 1980, 28, 55–57. [Google Scholar] [CrossRef] [PubMed]

- Nandini, C.D.; Salimath, P.V. Carbohydrate composition of wheat, wheat bran, sorghum and bajra with good chapati/roti (Indian flat bread) making quality. Food Chem. 2001, 73, 197–203. [Google Scholar] [CrossRef]

- Chavan, U.; Patil, J.; Shinde, M. Nutritional and roti quality of sorghum genotypes. Indones. J. Agric. Sci. 2009, 10, 80–87. [Google Scholar] [CrossRef]

- Nandini, C.D.; Salimath, P.V. Structural features of arabinoxylans from sorghum having good roti-making quality. Food Chem. 2001, 74, 417–422. [Google Scholar] [CrossRef]

- Desai, G.; Deshmukh, N.; Kshirsagar, R. Effect of malting and roasting of grains on nutritional and sensory quality of sorghum based multigrain roti. Trends Biosci. 2017, 10, 2235–2240. [Google Scholar]

- Murty, D.S.; Subramanian, V. Sorghum roti: I. Traditional methods of consumption and standard procedures for evaluation. In Proceedings of the International Symposium on Sorghum Grain Quality, Patancheru, India, 28–31 October 1982; Rooney, L.W., Murty, D.S., Mertin, J.V., Eds.; 1982; pp. 73–78. [Google Scholar]

- Gajmal, D.B.; Pawar, V.S.; Shinde, E.M.; Shingote, A.B. The effect of flour particle size distribution on sorghum gluten-free flat bread quality (Roti). J. Curr. Res. Food Sci. 2021, 2, 1–4. Available online: https://www.foodresearchjournal.com/article/36/2-1-17-133.pdf (accessed on 17 June 2022).

- Subramanian, V.; Jambunathan, R.; Rao, N.S. Textural Properties of Sorghum Dough. J. Food Sci. 1983, 48, 1650–1653. [Google Scholar] [CrossRef]

- Murty, D.S.; Patil, H.D.; House, L.R. Sorghum Roti: II. Genotypic and Environmental Variation for Roti Quality Parameters. In Proceedings of the International Symposium on Sorghum Grain Quality, Patancheru, India, 28–31 October 1982; Rooney, L.W., Murty, D.S., Mertin, J.V., Eds.; 1981; pp. 79–91. [Google Scholar]

- Subramanian, V.; Jambunathan, R. Properties of Sorghum Grain and their Relationship to Roti Quality. In Proceedings of the International Symposium on Sorghum Grain Quality, Patancheru, India, 28–31 October 1982; Rooney, L.W., Murty, D.S., Mertin, J.V., Eds.; 1982; pp. 280–288. [Google Scholar]

- Subramanian, V.; Jambunathan, R.; Rao, K.P. Dry milling characteristics of sorghum grains and their relationship to product quality. In Proceedings of the National Seminar on Technology and Application for Alternative Uses of Sorghum, Parbhani, India, 2–3 February 1987; pp. 45–54. [Google Scholar]

- Gajmal, D.B.; Pawar, V.S.; Shinde, E.M.; Shingote, A.B. Effect of particle size based sorghum flour of physicochemical properties on sensory characteristics of roti prepared from Parbhani Moti and Parbhani Super Moti. Pharma Innov. 2021, 10, 315–318. [Google Scholar]

- Rao, B.D.; Kalpana, K.; Srinivas, K.; Patil, J. Development and Standardization of Sorghum-Rich Multigrain Flour and Assessment of Its Storage Stability with Addition of TBHQ. J. Food Process. Preserv. 2015, 39, 451–457. [Google Scholar] [CrossRef]

- Prasad, M.P.R.; Rao, B.D.; Kalpana, K.; Rao, M.V.; Patil, J.V. Glycaemic index and glycaemic load of sorghum products. J. Sci. Food Agric. 2015, 95, 1626–1630. [Google Scholar] [CrossRef]

- Chandrashekar, A.; Desikachar, H. Quality of sorghum for use in Indian foods. In Proceedings of the International Symposium on Sorghum Grain Quality, Patancheru, India, 28–31 October 1981; Rooney, L.W., Murty, D.S., Mertin, J.V., Eds.; 1981; pp. 262–268. [Google Scholar]

- Aboubacar, A.; Hamaker, B.R. Physicochemical Properties of Flours that Relate to Sorghum Couscous Quality. Cereal Chem. 1999, 76, 308–313. [Google Scholar] [CrossRef]

- Dhingra, M.; Srivastava, S.; Chauhan, G.S. Nutrient composition and relationship between physico-chemical and sensory qualities of sorghum genotypes. J. Food Sci. Technol. 1992, 29, 97–100. [Google Scholar]

- Ioerger, B.; Bean, S.R.; Tuinstra, M.R.; Pedersen, J.F.; Erpelding, J.; Lee, K.M.; Herrman, T.J. Characterization of Polymeric Proteins from Vitreous and Floury Sorghum Endosperm. J. Agric. Food Chem. 2007, 55, 10232–10239. [Google Scholar] [CrossRef] [PubMed]

- Chandrashekar, A.; Desikachar, H.S.R. Sorghum quality studies. I. Rolling quality of sorghum dough in relation to some physico-chemical properties. J. Food Sci. Technol. 1983, 20, 281–284. [Google Scholar]

- Taylor, J.R.N.; Emmambux, M.N. Review: Developments in Our Understanding of Sorghum Polysaccharides and Their Health Benefits. Cereal Chem. 2010, 87, 263–271. [Google Scholar] [CrossRef]

- Nambiar, V.S.; Patwardhan, T. Assessment of glycemic index (GI) and glycemic load (GL) for selected traditional millet-based Indian recipes. Int. J. Diabetes Dev. Ctries. 2015, 35, 157–162. [Google Scholar] [CrossRef]

- Rizley, N.F.; Suter, D.A. Sorghum tortillas: Process and product attributes. J. Food Sci. 1977, 42, 1435–1438. [Google Scholar] [CrossRef]

- Gómez, M.H.; McDonough, C.M.; Rooney, L.W.; Waniska, R.D. Changes in Corn and Sorghum during Nixtamalization and Tortilla Baking. J. Food Sci. 1989, 54, 330–336. [Google Scholar] [CrossRef]

- Iruegas, A.; Cejudo, H.; Guiragossian, V. Screening and evaluation of tortilla from sorghum and sorghum-maize mixtures. In Proceedings of the International Symposium on Sorghum Grain Quality, Patancheru, India, 28–31 October 1981; Rooney, L.W., Murty, D.S., Mertin, J.V., Eds.; 1981; pp. 92–99. [Google Scholar]

- Serna-Saldivar, S.O.; Gómez, M.H.; Gómez, F.; Meckenstock, D.; Cossette, C.; Rooney, L.W. The tortilla making properties of two improved maicillo cultivars from Honduras. Arch. Latinoam. Nutr. 1993, 43, 299–303. [Google Scholar]

- Quintero-Fuentes, X. Characterization of Corn and Sorghum Tortillas during Storage. Ph.D. Dissertation, Texas A&M University, College Station, TX, USA, 1999. [Google Scholar]

- Khan, M.N.; Rooney, L.W.; Rosenow, D.T.; Miller, F.R. Sorghums with improved tortilla making characteristics. J. Food Sci. 1980, 45, 720–722. [Google Scholar] [CrossRef]

- Winger, M.; Khouryieh, H.; Aramouni, F.; Herald, T. Sorghum Flour Characterization and Evaluation in Gluten-Free Flour Tortilla. J. Food Qual. 2014, 37, 95–106. [Google Scholar] [CrossRef]

- Vivas, N.E.; Waniska, R.D.; Rooney, L.W. Effect of tortilla production on proteins in sorghum and maize. Cereal Chem. 1987, 64, 384–389. [Google Scholar]

- Buitimea-Cantúa, N.E.; Serna-Saldívar, S.O. Effect of processing on the hydroxycinnamic acids, flavones, and cellular antioxidant activity of tortillas supplemented with sorghum bran. Cereal Chem. 2020, 97, 382–393. [Google Scholar] [CrossRef]

- Buitimea-Cantúa, N.E.; De La Rosa-Millán, J. Physicochemical, textural, and in vitro starch digestion properties of nixtamalized maize flour and tortillas enriched with sorghum (Sorghum bicolor (L.) Moench) bran. Cereal Chem. 2018, 95, 829–837. [Google Scholar] [CrossRef]

- Buitimea-Cantúa, N.E.; Torres-Chávez, P.I.; Ramírez-Wong, B.; Serna-Saldívar, S.O.; Rouzaud-Sández, O.; Rosas-Burgos, E.; Platt-Lucero, L.C.; Salazar-García, M.G. Phenolic Compounds and Antioxidant Activity of Extruded Nixtamalized Corn Flour and Tortillas Enriched with Sorghum Bran. Cereal Chem. 2017, 94, 277–283. [Google Scholar] [CrossRef]

- Bedolla, S. Development and Characterization of an Instant Tortilla Flour from Sorghum and Maize by Infrared Cooking (Micronizing) and Extrusion Cooking. Ph.D. Dissertation, Texas A&M University, College Station, TX, USA, 1983. [Google Scholar]

- Martínez, F.; Ciacco, C.F. Chemical changes in sorghum during the extrusion and tortilla preparation process. Arch. Latinoam. Nutr. 1992, 42, 52–58. [Google Scholar]

- Johnson, B.A.; Rooney, L.W.; Khan, M.N. Tortilla-making characteristics of micronized sorghum and corn flours. J. Food Sci. 1980, 45, 671–674. [Google Scholar] [CrossRef]

- Choto, C.E.; Morad, M.M.; Rooney, L.W. The quality of tortillas containing whole sorghum and pearled sorghum alone and blended with yellow maize. Cereal Chem. 1995, 62, 51–55. [Google Scholar]

- Torres, P.I.; Ramirez-Wong, B.; Serna-Saldivar, S.O.; Rooney, L.W. Effect of decorticated sorghum addition on the rheological properties of wheat tortilla dough. Cereal Chem. 1994, 71, 509–512. [Google Scholar]

- Serna-Saldivar, S.; Knabe, D.; Rooney, L.; Tanksley, T.; Sproule, A. Nutritional value of sorghum and maize tortillas. J. Cereal Sci. 1988, 7, 83–94. [Google Scholar] [CrossRef]

- Rooney, L.W.; Serna-Saldivar, S.O. Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Luzardo-Ocampo, I.; Ramírez-Jiménez, A.; Cabrera-Ramírez, A.H.; Rodríguez-Castillo, N.; Campos-Vega, R.; Loarca-Piña, G.; Gaytán-Martínez, M. Impact of cooking and nixtamalization on the bioaccessibility and antioxidant capacity of phenolic compounds from two sorghum varieties. Food Chem. 2020, 309, 125684. [Google Scholar] [CrossRef] [PubMed]

- Gaytán-Martínez, M.; Cabrera-Ramírez, H.; Morales-Sánchez, E.; Ramírez-Jiménez, A.K.; Cruz-Ramírez, J.; Campos-Vega, R.; Velazquez, G.; Loarca-Piña, G.; Mendoza, S. Effect of nixtamalization process on the content and composition of phenolic compounds and antioxidant activity of two sorghums varieties. J. Cereal Sci. 2017, 77, 1–8. [Google Scholar] [CrossRef]

- Cabrera-Ramírez, A.; Luzardo-Ocampo, I.; Ramírez-Jiménez, A.; Morales-Sánchez, E.; Campos-Vega, R.; Gaytán-Martínez, M. Effect of the nixtamalization process on the protein bioaccessibility of white and red sorghum flours during in vitro gastrointestinal digestion. Food Res. Int. 2020, 134, 109234. [Google Scholar] [CrossRef]

- Ali, N.; Eltinay, A.; ElKhalifa, A.; Salih, O.; Yousif, N. Effect of alkaline pretreatment and cooking on protein fractions of a high-tannin sorghum cultivar. Food Chem. 2009, 114, 646–648. [Google Scholar] [CrossRef]

- Buitimea-Cantúa, N.E.; Torres-Chávez, P.I.; Ramírez-Wong, B.; Ledesma-Osuna, A.I.; Gutiérrez-Uribe, J.A.; Serna-Guerrero, D.A.; Serna-Saldívar, S.O. Ferulic, p-coumaric, diferulic and triferulic acids contents of corn tortillas prepared with extruded corn flour and enriched with sorghum (Sorghum bicolor (L.) Moench) bran. J. Food Meas. Charact. 2018, 12, 1633–1640. [Google Scholar] [CrossRef]

- da Silva, L.S.; Taylor, J.R.N. Sorghum Bran as a Potential Source of Kafirin. Cereal Chem. 2004, 81, 322–327. [Google Scholar] [CrossRef]

- Bedolla, S.; de Palacios, M.G.; Rooney, L.W. Cooking characteristics of sorghum and corn for tortilla preparation by several cooking methods. Cereal Chem. 1983, 60, 263–268. [Google Scholar]

- Ghebrehiwot, H.M.; Shimelis, H.A.; Kirkman, K.P.; Laing, M.D.; Mabhaudhi, T. Nutritional and Sensory Evaluation of Injera Prepared from tef and Eragrostis curvula (Schrad.) Nees. Flours with Sorghum Blends. Front. Plant Sci. 2016, 7, 1059. [Google Scholar] [CrossRef]

- Neela, S.; Fanta, S.W. Injera (An Ethnic, Traditional Staple Food of Ethiopia): A review on Traditional Practice to Scientific Developments. J. Ethn. Foods 2020, 7, 32. [Google Scholar] [CrossRef]

- Yetneberk, S.; de Kock, H.L.; Rooney, L.W.; Taylor, J.R.N. Effects of Sorghum Cultivar on Injera Quality. Cereal Chem. 2004, 81, 314–321. [Google Scholar] [CrossRef]

- Gebrekidan, B.; GebreHiwot, B. Sorghum injera preparations and quality parameters. In Proceedings of the International Symposium on Sorghum Grain Quality, Patancheru, India, 28–31 October 1981; Rooney, L.W., Murty, D.S., Mertin, J.V., Eds.; 1982; pp. 55–65. [Google Scholar]

- Yetneberk, S.; Rooney, L.W.; Taylor, J.R. Improving the quality of sorghum injera by decortication and compositing with tef. J. Sci. Food Agric. 2005, 85, 1252–1258. [Google Scholar] [CrossRef]

- Abraha, A.; Abay, F. Effect of different cereal blends on the quality of Injera a staple food in the highlands of Ethiopia. Momona Ethiop. J. Sci. 2017, 9, 232. [Google Scholar] [CrossRef]

- Yetneberk, S.; Haile, T. Studies on methods to improve injera making qualities of two brown sorghum cultivars. In Proceedings of the 8th EARSAM Regional Workshop on Sorghum and Millet, Wad Medani, Sudan, 30 October–5 November 1992; Mukuru, S.Z., King, S.B., Eds.; ICRISAT: Patancheru, India, 1992; pp. 177–183. [Google Scholar]

- Zegeye, A. Acceptability of injera with stewed chicken. Food Qual. Prefer. 1997, 8, 293–295. [Google Scholar] [CrossRef]

- Fox, G.; Nugusu, Y.; Nida, H.; Tedessa, T.; McLean, G.; Jordan, D. Evaluation of variation in Ethiopian sorghum injera quality with new imaging techniques. Cereal Chem. 2020, 97, 362–372. [Google Scholar] [CrossRef]

- Alfeo, V.; Bravi, E.; Ceccaroni, D.; Perretti, G.; Marconi, O.; Sileoni, V. Effect of Baking Time and Temperature on Nutrients and Phenolic Compounds Content of Fresh Sprouts Breadlike Product. Foods 2020, 9, 1447. [Google Scholar] [CrossRef]

- Mohammed, N.A.; Ahmed, I.A.M.; Babiker, E.E. Nutritional evaluation of sorghum flour (Sorghum bicolor L. Moench) during processing of injera. Int. J. Food Nutr. Food Eng. 2011, 51, 99–103. [Google Scholar] [CrossRef]

- Ejeta, G. Kisra quality: Testing new sorghum varieties and hybrids. In Proceedings of the International Symposium on Sorghum Grain Quality, Patancheru, India, 28–31 October 1982; Rooney, L.W., Murty, D.S., Mertin, J.V., Eds.; 1982; pp. 67–72. [Google Scholar]

- Awad Elkareem, A.M.; Taylor, J.R.N. Protein Quality and Physical Characteristics of Kisra (Fermented Sorghum Pancake-like Flatbread) Made from Tannin and Non-Tannin Sorghum Cultivars. Cereal Chem. 2011, 88, 344–348. [Google Scholar] [CrossRef]

- Rahman, I.E.A.; Osman, M.A.W. Effect of sorghum type (Sorghum bicolor) and traditional fermentation on tannins and phytic contents and trypsin inhibitor activity. J. Food Agric. Env. 2011, 9, 163–166. [Google Scholar]

- El Tinaysp, A.H.; El Mahdi, Z.M.; El Soubki, A. Supplementation of fermented sorghum Kisra bread with legume protein isolates. Int. J. Food Sci. Technol. 1985, 20, 679–687. [Google Scholar] [CrossRef]

- Awulachew, M.T. Evaluation of Proximate Composition and Sensory Quality Acceptability of Ethiopian Flat Bread (Injera) Prepared from Composite Flour, Blend of Maize, Teff and Sorghum. Int. J. Food Eng. Technol. 2020, 4, 18. [Google Scholar] [CrossRef]

- Mallasy, L.O.H. Biochemical and Sensory Evaluation of Wheat Bran Supplemented Sorghum Kisra Bread. Sudan 1998. Available online: https://www.osti.gov/etdeweb/biblio/696155 (accessed on 17 June 2022).

- Abdallah, E.A.; Babiker, E.E. Content of anti-nutrients and in vitro protein digestibility of sorghum-based kisra bread: Effect of fortification with wheat and pigeon pea seed flour. Life Sci. Int. J. 2010, 4, 1356–1360. Available online: http://khartoumspace.uofk.edu/items/03919acf-c588-48e0-8b6b-dbc40f0e9cde/full (accessed on 17 June 2022).

- Badi, S.; Pedersen, B.; Monowar, L.; Eggum, B.O. The nutritive value of new and traditional sorghum and millet foods from Sudan. Plant Food Hum. Nutr. 1990, 40, 5–19. [Google Scholar] [CrossRef] [PubMed]

- Mezgebe, A.G.; Taylor, J.R.N.; De Kock, H.L. Influence of Waxy (High Amylopectin) and High Protein Digestibility Traits in Sorghum on Injera Sourdough-Type Flatbread Sensory Characteristics. Foods 2020, 9, 1749. [Google Scholar] [CrossRef] [PubMed]

- Mariod, A.A.; Abdalrahman, E.M.; Shakak, M. Impact of incorporation of Monechma ciliatum seed flour on the chemical composition, nutritional value and sensory evaluation of sorghum Kisra. Egypt. J. Food Sci. 2021, 49, 97–106. [Google Scholar] [CrossRef]

- Assefa, Y.; Emire, S.; Villanueva, M.; Abebe, W.; Ronda, F. Influence of milling type on teff injera quality. Food Chem. 2018, 266, 155–160. [Google Scholar] [CrossRef] [PubMed]

- El Khalifa, A.O.; El Tinay, A.H. Effect of fermentation on protein fractions and tannin content of low- and high-tannin cultivars of sorghum. Food Chem. 1994, 49, 265–269. [Google Scholar] [CrossRef]

- Elkhalifa, A.E.O.; Schiffler, B.; Bernhardt, R. Effect of fermentation on the functional properties of sorghum flour. Food Chem. 2005, 92, 1–5. [Google Scholar] [CrossRef]

- Ali, A.A.; Mustafa, M.M. Use of Starter Cultures of Lactic Acid Bacteria and Yeasts in the Preparation of Kisra, a Sudanese Fermented Food. Pak. J. Nutr. 2009, 8, 1349–1353. [Google Scholar] [CrossRef]

- Hamad, S.; Dieng, M.; Ehrmann, M.; Vogel, R. Characterization of the bacterial flora of Sudanese sorghum flour and sorghum sourdough. J. Appl. Microbiol. 1997, 83, 764–770. [Google Scholar] [CrossRef]

- Osman, M.A.; AbdelRahman, I.E.; Hamad, S.H.; Dirar, H.A. Biochemical changes occurring during traditional Sudanese processing of Kisra bread. J. Food Agric. Environ. 2010, 8, 102–106. [Google Scholar]

- Ahmed, A.H.R.; Ramanatham, G. Essential amino acid composition and in vitro digestibility of protein of sorghum bread “Kisra” enriched with edible defatted groundnut flour. Nutr. Rep. Int. 1987, 35, 487–495. [Google Scholar]

- Makawi, A.B.; Mustafa, A.I.; Adiamo, O.Q.; Ahmed, I.A.M. Quality attributes of Kisra prepared from sorghum flour fermented with baobab fruit pulp flour as starter. J. Food Sci. Technol. 2019, 56, 3754–3763. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, F.; Babiker, E.; Yousif, N.; Eltinay, A. Effect of fermentation on biochemical and sensory characteristics of sorghum flour supplemented with whey protein. Food Chem. 2005, 92, 285–292. [Google Scholar] [CrossRef]

- El Tinay, A.H.; Gadir, A.M.A.; El Hidai, M. Sorghum fermented kisra bread. I—Nutritive value of kisra. J. Sci. Food Agric. 1979, 30, 859–863. [Google Scholar] [CrossRef]

- Mihrete, Y.; Bultosa, G. The Effect of Blending Ratio of Tef [Eragrostis tef (Zucc) Trotter], Sorghum (Sorghum bicolor (L.) Moench) and Faba Bean (Vicia faba) and Fermentation Time on Chemical Composition of Injera. J. Nutr. Food Sci. 2017, 7, 1–7. [Google Scholar] [CrossRef]

- Zaroug, M.; Orhan, I.E.; Senol, F.S.; Yagi, S. Comparative antioxidant activity appraisal of traditional Sudanese kisra prepared from two sorghum cultivars. Food Chem. 2014, 156, 110–116. [Google Scholar] [CrossRef]

- Mohammed, S.I. Isolation and Characterization of Microorganisms Associated with the Traditional Sorghum Fermentation and Development of Starter Culture for Production of Sudanese kisra. Ph.D. Dissertation, Purdue University, West Lafayette, IN, USA, 1991. [Google Scholar]

- Ahmed, A.R.; Chandrasekhara, H.N.; Ramanatham, G. The protein quality of sorghum bread ‘Kisra’ enriched with edible defatted groundnut flour. Nutr. Rep. Int. 1987, 35, 205–210. [Google Scholar]

- Eltayeb, M.M.; Eltigani, S.A.; Taniguchi, T. Pyrosequencing scrutiny of bacterial and fungal communities in two Sudanese sorghum-based fermented foods. Ann. Microbiol. 2020, 70, 1–10. [Google Scholar] [CrossRef]

- Taylor, J.R.; Duodu, K.G. Traditional Sorghum and Millet Food and Beverage Products and Their Technologies. In Sorghum and Millets: Chemistry, Technology, and Nutritional Attributes, 2nd ed.; Taylor, J.R.N., Duodu, K.G., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 259–292. [Google Scholar] [CrossRef]

- Demirkesen, I.; Ozkaya, B. Recent strategies for tackling the problems in gluten-free diet and products. Crit. Rev. Food Sci. Nutr. 2022, 62, 571–597. [Google Scholar] [CrossRef]

- Culetu, A.; Susman, I.; Duta, D.; Belc, N. Nutritional and Functional Properties of Gluten-Free Flours. Appl. Sci. 2021, 11, 6283. [Google Scholar] [CrossRef]

- Rumler, R.; Schönlechner, R. Effect of Sorghum on Rheology and Final Quality of Western Style Breads: A Literature Review. Foods 2021, 10, 1392. [Google Scholar] [CrossRef] [PubMed]

- Afify, A.E.-M.M.R.; El-Beltagi, H.S.; El-Salam, S.M.A.; Omran, A.A. Bioavailability of Iron, Zinc, Phytate and Phytase Activity during Soaking and Germination of White Sorghum Varieties. PLoS ONE 2011, 6, e25512. [Google Scholar] [CrossRef] [PubMed]

- Afify, A.E.-M.M.R.; El-Beltagi, H.S.; El-Salam, S.M.A.; Omran, A.A. Protein Solubility, Digestibility and Fractionation after Germination of Sorghum Varieties. PLoS ONE 2012, 7, e31154. [Google Scholar] [CrossRef] [PubMed]

- Afify, A.E.-M.M.R.; El-Beltagi, H.S.; El-Salam, S.M.A.; Omran, A.A. Effect of soaking, cooking, germination and fermentation processing on proximate analysis and mineral content of three white sorghum varieties (Sorghum bicolor L. Moench). Not. Bot. Horti Agrobot. Cluj-Napoca 2012, 40, 92–98. [Google Scholar] [CrossRef]

- Elkhalifa, A.E.O.; Bernhardt, R. Influence of grain germination on functional properties of sorghum flour. Food Chem. 2010, 121, 387–392. [Google Scholar] [CrossRef]

- Ocheme, O.B.; Adedeji, O.E.; Lawal, G.; Zakari, U.M. Effect of Germination on Functional Properties and Degree of Starch Gelatinization of Sorghum Flour. J. Food Res. 2014, 4, 159. [Google Scholar] [CrossRef]

- Phattanakulkaewmorie, N.; Paseephol, T.; Moongngarm, A. Chemical compositions and physico-chemical properties of malted sorghum flour and characteristics of gluten free bread. Eng. Technol. 2011, 5, 532–538. [Google Scholar]

- Wolter, A.; Hager, A.-S.; Zannini, E.; Arendt, E.K. In vitro starch digestibility and predicted glycaemic indexes of buckwheat, oat, quinoa, sorghum, teff and commercial gluten-free bread. J. Cereal Sci. 2013, 58, 431–436. [Google Scholar] [CrossRef]

- Akin, P.A.; Miller, R.; Jaffe, T.; Koppel, K.; Ehmke, L. Sensory profile and quality of chemically leavened gluten-free sorghum bread containing different starches and hydrocolloids. J. Sci. Food Agric. 2019, 99, 4391–4396. [Google Scholar] [CrossRef]

- Schober, T.J.; Messerschmidt, M.; Bean, S.R.; Park, S.-H.; Arendt, E.K. Gluten-Free Bread from Sorghum: Quality Differences Among Hybrids. Cereal Chem. 2005, 82, 394–404. [Google Scholar] [CrossRef]

- Trappey, E.F.; Khouryieh, H.; Aramouni, F.; Herald, T. Effect of sorghum flour composition and particle size on quality properties of gluten-free bread. Food Sci. Technol. Int. 2015, 21, 188–202. [Google Scholar] [CrossRef] [PubMed]

- Hart, M.R.; Graham, R.P.; Gee, M.; Morgan, A.I. Bread from sorghum and barley flours. J. Food Sci. 1970, 35, 661–665. [Google Scholar] [CrossRef]

- Olatunji, O.; Koleoso, O.A.; Oniwinde, A.B. Recent experience on the milling of sorghum, millet, and maize for making nonwheat bread, cake, and sausage in Nigeria. In Utilization of Sorghum and Millets; Gomez, M.I., House, L.R., Rooney, L.W., Dendy, D.A.V., Eds.; International Crops Research Institute for the Semi-Arid Tropics: Patancheru, India, 1992; pp. 83–88. [Google Scholar]

- Hugo, L.F.; Waniska, R.D.; Rooney, L.W. Production of bread from composite flours. In Harnessing Cereal Science and Technology for Sustainable Development; CSIR ICC-SA: Pretoria, South Africa, 1997; pp. 100–114. [Google Scholar]

- Schober, T.J.; Bean, A.S.R.; Boyle, D.L. Gluten-Free Sorghum Bread Improved by Sourdough Fermentation: Biochemical, Rheological, and Microstructural Background. J. Agric. Food Chem. 2007, 55, 5137–5146. [Google Scholar] [CrossRef] [PubMed]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT Food Sci. Technol. 2011, 44, 681–686. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Batter rheology and bread texture of sorghum-based gluten-free formulations modified with native or pregelatinised cassava starch and α-amylase. Int. J. Food Sci. Technol. 2010, 45, 1228–1235. [Google Scholar] [CrossRef]

- Monthe, O.C.; Grosmaire, L.; Nguimbou, R.M.; Dahdouh, L.; Ricci, J.; Tran, T.; Ndjouenkeu, R. Rheological and textural properties of gluten-free doughs and breads based on fermented cassava, sweet potato and sorghum mixed flours. LWT 2019, 101, 575–582. [Google Scholar] [CrossRef]

- Drub, T.F.; dos Santos, F.G.; Centeno, A.C.L.S.; Capriles, V.D. Sorghum, millet and pseudocereals as ingredients for gluten-free whole-grain yeast rolls. Int. J. Gastron. Food Sci. 2021, 23, 100293. [Google Scholar] [CrossRef]

- Mert, I.D.; Sumnu, G.; Sahin, S. Microstructure of gluten-free baked products. In Imaging Technologies and Data Processing for Food Engineers; Sozer, N., Ed.; Springer: Cham, Switzerland, 2016; pp. 197–242. [Google Scholar] [CrossRef]

- Mir, S.A.; Shah, M.A.; Naik, H.R.; Zargar, I.A. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Technol. 2016, 51, 49–57. [Google Scholar] [CrossRef]

- Salehi, F. Improvement of gluten-free bread and cake properties using natural hydrocolloids: A review. Food Sci. Nutr. 2019, 7, 3391–3402. [Google Scholar] [CrossRef]

- Zoghi, A.; Mirmahdi, R.S.; Mohammadi, M. The role of hydrocolloids in the development of gluten-free cereal-based products for coeliac patients: A review. Int. J. Food Sci. Technol. 2020, 56, 3138–3147. [Google Scholar] [CrossRef]

- Culetu, A.; Duta, D.E.; Papageorgiou, M.; Varzakas, T. The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index. Foods 2021, 10, 3121. [Google Scholar] [CrossRef] [PubMed]

- Onyango, C.; Unbehend, G.; Lindhauer, M.G. Effect of cellulose-derivatives and emulsifiers on creep-recovery and crumb properties of gluten-free bread prepared from sorghum and gelatinised cassava starch. Food Res. Int. 2009, 42, 949–955. [Google Scholar] [CrossRef]

- Velázquez, N.; Sánchez, H.; Osella, C.; Santiago, L.G. Using white sorghum flour for gluten-free breadmaking. Int. J. Food Sci. Nutr. 2012, 63, 491–497. [Google Scholar] [CrossRef]

- Akin, P.A.; Miller, R.A. Starch–Hydrocolloid Interaction in Chemically Leavened Gluten-Free Sorghum Bread. Cereal Chem. 2017, 94, 897–902. [Google Scholar] [CrossRef]

- Oliveira, L.D.L.D.; de Oliveira, G.T.; de Alencar, E.R.; Queiroz, V.A.V.; Figueiredo, L.F.D.A. Physical, chemical, and antioxidant analysis of sorghum grain and flour from five hybrids to determine the drivers of liking of gluten-free sorghum breads. LWT Food Sci. Technol. 2022, 153, 112407. [Google Scholar] [CrossRef]

- Gallo, L.R.D.R.; Reis, C.E.G.; Mendonça, M.A.; da Silva, V.S.N.; Pacheco, M.T.B.; Botelho, R.B.A. Impact of Gluten-Free Sorghum Bread Genotypes on Glycemic and Antioxidant Responses in Healthy Adults. Foods 2021, 10, 2256. [Google Scholar] [CrossRef]

- Adiamo, O.Q.; Fawale, O.S.; Olawoye, B. Recent Trends in the Formulation of Gluten-Free Sorghum Products. J. Culin. Sci. Technol. 2018, 16, 311–325. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced properties of gluten-free cookies, cakes, and crackers: A review. Trends Food Sci. Technol. 2020, 103, 200–213. [Google Scholar] [CrossRef]

- Demirkesen, I.; Sumnu, G.; Sahin, S. Quality of Gluten-Free Bread Formulations Baked in Different Ovens. Food Bioprocess Technol. 2014, 7, 619–626. [Google Scholar] [CrossRef]

- Demirkesen, I.; Kelkar, S.; Campanella, O.H.; Sumnu, G.; Sahin, S.; Okos, M. Characterization of structure of gluten-free breads by using X-ray microtomography: Relationship between microstructure and quality characteristics. Food Hydrocoll. 2014, 36, 37–44. [Google Scholar] [CrossRef]

- Demirkesen, I.; Campanella, O.H.; Sumnu, G.; Sahin, S.; Hamaker, B.R. A Study on Staling Characteristics of Gluten-Free Breads Prepared with Chestnut and Rice Flours. Food Bioprocess Technol. 2014, 7, 806–820. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B.; Sumnu, G.; Sahin, S. Rheological properties of gluten-free bread formulations. J. Food Eng. 2010, 96, 295–303. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B.; Sumnu, G.; Sahin, S. Utilization of chestnut flour in gluten-free bread formulations. J. Food Eng. 2010, 101, 329–336. [Google Scholar] [CrossRef]

- Demirkesen, I.; Sumnu, G.; Sahin, S. Image Analysis of Gluten-free Breads Prepared with Chestnut and Rice Flour and Baked in Different Ovens. Food Bioprocess Technol. 2013, 6, 1749–1758. [Google Scholar] [CrossRef]

- Demirkesen, I.; Sumnu, G.; Sahin, S.; Uysal, N. Optimisation of formulations and infrared-microwave combination baking conditions of chestnut-rice breads. Int. J. Food Sci. Technol. 2011, 46, 1809–1815. [Google Scholar] [CrossRef]

- Bize, M.; Smith, B.M.; Aramouni, F.M.; Bean, S. The Effects of Egg and Diacetyl Tartaric Acid Esters of Monoglycerides Addition on Storage Stability, Texture, and Sensory Properties of Gluten-Free Sorghum Bread. J. Food Sci. 2017, 82, 194–201. [Google Scholar] [CrossRef]

- Ngemakwe, P.N.; Le Roes-Hill, M.; Jideani, V. Advances in gluten-free bread technology. Food Sci. Technol. Int. 2015, 21, 256–276. [Google Scholar] [CrossRef]

- Padalino, L.; Conte, A.; Del Nobile, M.A. Overview on the General Approaches to Improve Gluten-Free Pasta and Bread. Foods 2016, 5, 87. [Google Scholar] [CrossRef]

- Bender, D.; Schönlechner, R. Innovative approaches towards improved gluten-free bread properties. J. Cereal Sci. 2020, 91, 102904. [Google Scholar] [CrossRef]

- Rosell, C.M. Enzymatic Manipulation of Gluten-Free Breads. In Gluten-Free Food Science and Technology; Gallagher, E., Ed.; Wiley-Blackwell: Oxford, UK, 2009; pp. 83–98. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Rheological and baking characteristics of batter and bread prepared from pregelatinised cassava starch and sorghum and modified using microbial transglutaminase. J. Food Eng. 2010, 97, 465–470. [Google Scholar] [CrossRef]

- Renzetti, S.; Arendt, E.K. Effects of oxidase and protease treatments on the breadmaking functionality of a range of gluten-free flours. Eur. Food Res. Technol. 2009, 229, 307–317. [Google Scholar] [CrossRef]

- Bárcenas, M.E.; Altamirano-Fortoul, R.; Rosell, C.M. Effect of high hydrostatic pressure treatment on bread dough. LWT Food Sci. Technol. 2010, 43, 12–19. [Google Scholar] [CrossRef]

- Vallons, K.J.R.; Ryan, L.A.M.; Koehler, P.; Arendt, E.K. High pressure–treated sorghum flour as a functional ingredient in the production of sorghum bread. Eur. Food Res. Technol. 2010, 231, 711–717. [Google Scholar] [CrossRef]

- Onyango, C.; Mewa, E.A.; Mutahi, A.W.; Okoth, M.W. Effect of heat-moisture-treated cassava starch and amaranth malt on the quality of sorghum-cassava-amaranth bread. Afr. J. Food Sci. 2013, 7, 80–86. [Google Scholar] [CrossRef]

- Sun, Q.; Han, Z.; Wang, L.; Xiong, L. Physicochemical differences between sorghum starch and sorghum flour modified by heat-moisture treatment. Food Chem. 2014, 145, 756–764. [Google Scholar] [CrossRef] [PubMed]

- Marston, K.; Khouryieh, H.; Aramouni, F. Effect of heat treatment of sorghum flour on the functional properties of gluten-free bread and cake. LWT Food Sci. Technol. 2016, 65, 637–644. [Google Scholar] [CrossRef]

- Knorr, D.; Heinz, V.; Buckow, R. High pressure application for food biopolymers. Biochim. Biophys. Acta Proteins Proteom. 2006, 1764, 619–631. [Google Scholar] [CrossRef]

- Nionelli, L.; Rizzello, C.G. Sourdough-Based Biotechnologies for the Production of Gluten-Free Foods. Foods 2016, 5, 65. [Google Scholar] [CrossRef]

- Schwab, C.; Mastrangelo, M.; Corsetti, A.; Gänzle, M. Formation of Oligosaccharides and Polysaccharides by Lactobacillus reuteri LTH5448 and Weissella cibaria 10M in Sorghum Sourdoughs. Cereal Chem. 2008, 85, 679–684. [Google Scholar] [CrossRef]

- Olojede, A.; Sanni, A.; Banwo, K. Effect of legume addition on the physiochemical and sensorial attributes of sorghum-based sourdough bread. LWT 2020, 118, 108769. [Google Scholar] [CrossRef]

- Olojede, A.; Sanni, A.; Banwo, K. Rheological, textural and nutritional properties of gluten-free sourdough made with functionally important lactic acid bacteria and yeast from Nigerian sorghum. LWT 2020, 120, 108875. [Google Scholar] [CrossRef]

- Olojede, A.; Sanni, A.; Banwo, K.; Adesulu-Dahunsi, A. Sensory and antioxidant properties and in-vitro digestibility of gluten-free sourdough made with selected starter cultures. LWT 2020, 129, 109576. [Google Scholar] [CrossRef]

- Ogunsakin, O.A.; Banwo, K.; Ogunremi, O.R.; Sanni, A.I. Microbiological and physicochemical properties of sourdough bread from sorghum flour. Int. Food Res. J. 2015, 22, 2610–2618. Available online: http://www.ifrj.upm.edu.my/22%20(06)%202015/(48).pdf (accessed on 17 June 2022).

- Galle, S.; Schwab, C.; Bello, F.D.; Coffey, A.; Gänzle, M.G.; Arendt, E.K. Influence of in-situ synthesized exopolysaccharides on the quality of gluten-free sorghum sourdough bread. Int. J. Food Microbiol. 2012, 155, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Akin, P.A.; Bean, S.R.; Smith, B.M.; Tilley, M. Factors Influencing Zein-Whole Sorghum Flour Dough Formation and Bread Quality. J. Food Sci. 2019, 84, 3522–3534. [Google Scholar] [CrossRef]

- Marston, K.; Khouryieh, H.; Aramouni, F. Evaluation of sorghum flour functionality and quality characteristics of gluten-free bread and cake as influenced by ozone treatment. Food Sci. Technol. Int. 2015, 21, 631–640. [Google Scholar] [CrossRef]

- Carson, L.C.; Sun, X.S. Breads from white grain sorghum: Rheological properties and baking volume with exogenous gluten protein. Appl. Eng. Agric. 2000, 16, 423–429. [Google Scholar] [CrossRef]

- Taylor, J.R.N.; Hugo, L.; Yetnerberk, S. Developments in sorghum bread making. In Using Cereal Science and Technology for the Benefit of Consumers, Proceedings of the 12th International ICC Cereal and Bread Congress, Harrogate, UK, 23–26 May 2004; Cauvain, S.P., Salmon, S.S., Young, L.S., Eds.; Woodhead Publishing: Harrogate, UK, 2005; pp. 51–56. [Google Scholar] [CrossRef]

- Sibanda, T.; Ncube, T.; Ngoromani, N. Rheological properties and bread making quality of white grain sorghum-wheat flour composites. Int. J. Food Sci. Nutr. Eng. 2015, 5, 176–182. [Google Scholar] [CrossRef]

- Dube, N.M.; Xu, F.; Zhao, R.; Chen, J. Effect of using Zimbabwean Marcia sorghum and high-gluten flour on composite bread specific volume. J. Food Process. Preserv. 2021, 45, e15367. [Google Scholar] [CrossRef]

- Keregero, M.M.; Mtebe, K. Acceptability of wheat-sorghum composite flour products: An assessment. Plant Food Hum. Nutr. 1994, 46, 305–312. [Google Scholar] [CrossRef]

- Ognean, C.F. Technological and sensorial effects of sorghum addition at wheat bread. Agric. Food 2015, 3, 209–217. Available online: https://www.scientific-publications.net/get/1000010/1432395419468613.pdf (accessed on 17 June 2022).

- Elkhalifa, A.E.O.; El-Tinay, A.H. Effect of cysteine on bakery products from wheat–sorghum blends. Food Chem. 2002, 77, 133–137. [Google Scholar] [CrossRef]

- Hamaker, B.R.; Bugusu, B.A. Overview: Sorghum proteins and food quality. In Workshop on the Proteins of Sorghum and Millets: Enhancing Nutritional and Functional Properties for Africa; Belton, P.S., Taylor, J.R.N., Eds.; AFIPRO: Pretoria, South Africa, 2002; p. 8. Available online: http://www.afripro.org.uk/PAPERS/PAPER08HAMAKER.PDF (accessed on 17 June 2022).

- Goodall, M.A.; Campanella, O.H.; Ejeta, G.; Hamaker, B.R. Grain of high digestible, high lysine (HDHL) sorghum contains kafirins which enhance the protein network of composite dough and bread. J. Cereal Sci. 2012, 56, 352–357. [Google Scholar] [CrossRef]

- Bugusu, B.A.; Campanella, O.; Hamaker, B.R. Improvement of Sorghum-Wheat Composite Dough Rheological Properties and Breadmaking Quality through Zein Addition. Cereal Chem. 2001, 78, 31–35. [Google Scholar] [CrossRef]

- Carson, L.C.; Sun, X.S. Breads from white grain sorghum: Effects of SSL, DATEM, and xanthan gum on sorghum bread volume. Appl. Eng. Agric. 2000, 16, 431–436. [Google Scholar] [CrossRef]

- Jafari, M.; Koocheki, A.; Milani, E. Physicochemical and sensory properties of extruded sorghum–wheat composite bread. J. Food Meas. Charact. 2018, 12, 370–377. [Google Scholar] [CrossRef]

- Jafari, M.; Koocheki, A.; Milani, E. Functional effects of xanthan gum on quality attributes and microstructure of extruded sorghum-wheat composite dough and bread. LWT 2018, 89, 551–558. [Google Scholar] [CrossRef]

- Hugo, L.F.; Rooney, L.W.; Taylor, J. Malted Sorghum as a Functional Ingredient in Composite Bread. Cereal Chem. 2000, 77, 428–432. [Google Scholar] [CrossRef]

- Karrar, E.; Musa, A.; Sheth, S.; Huang, W.; Sarpong, F.; Wang, X. Effect of sorghum sourdough and nabag (Zizyphus spina-christi) pulp powder on dough fermentation and quality characteristics of bread. J. Food Meas. Charact. 2020, 14, 455–464. [Google Scholar] [CrossRef]

- Angioloni, A.; Collar, C. Effects of pressure treatment of hydrated oat, finger millet and sorghum flours on the quality and nutritional properties of composite wheat breads. J. Cereal Sci. 2012, 56, 713–719. [Google Scholar] [CrossRef]

- Hussein, M.A.; Abd-Alla, F.H. The baking quality of some wheat flour mixtures. Period. Polytech. Chem. Eng. 1976, 20, 145–152. [Google Scholar]

- de Aguiar, L.A.; Rodrigues, D.B.; Queiroz, V.A.V.; Melo, L.; Pineli, L.D.L.D.O. Comparison of two rapid descriptive sensory techniques for profiling and screening of drivers of liking of sorghum breads. Food Res. Int. 2020, 131, 108999. [Google Scholar] [CrossRef] [PubMed]

- Carson, L.; Setser, C.; Sun, X.S. Sensory characteristics of sorghum composite bread. Int. J. Food Sci. Technol. 2000, 35, 465–471. [Google Scholar] [CrossRef]

| Research Results | Ingredients | Reference |

|---|---|---|

| Sorghum roti could be kept at room temperature for 6 days in polyethylene bags with either 0.5 g of potassium sorbate or 100 ppm of ascorbic acid in the roti formulation. | Sorghum flour, potassium sorbate, and ascorbic acid | [25] |

| Certain sorghum genotypes (CSH 16, SHD 36, CSH 15 and SHD 6, SPH 1864, and SPH 1867) developed through a systematic breeding program were reported to be promising for flour, dough, roti, and nutritional quality. | Sorghum flour | [26,27] |

| Significant differences in the overall proximate composition of nine improved sorghum types were found and one sorghum line (PVK 801) was identified as producing high-quality roti in terms of color, appearance, storage stability, aroma, and acceptability. | Teff, sorghum, and/or maize flour | [28] |

| In terms of nutritional quality and organoleptic parameters (color, appearance, flavor, texture, and overall acceptability), for roti quality, certain local land races and genotypes (SPV 1546, RSV 423) were found to be promising for protein, sugar, water absorption, and soluble protein content. | Sorghum flour | [29] |

| The tannin level in sorghum was found to have a modest influence on iron bioavailability. | Sorghum flour | [30] |

| The effect of these components on the quality of the chapati/roti was not reported. The hemicellulose B included similar levels of arabinose and xylose, while the hemicellulose A had more arabinose than xylose among the pentosans in the barium hydroxide extract of sorghum. | Sorghum flour | [31] |

| The high content of crude protein, total soluble sugars, soluble proteins, and soluble amylose was mostly responsible for the roti’s high quality. | Sorghum flour | [32] |

| Arabinoxylans were shown to be significant in roti quality because they were responsible for gas entrapment in the dough, resulting in a softer final product. | Sorghum flour | [33] |

| Germination and roasting of sorghum were found to impact the nutritional quality of the final roti. | Sorghum flour, millet flour, and/or amaranth flour, soybean flour | [34] |

| The traditional methods of milling, dough, and roti preparation were described in detail. No conclusion related to the evaluation of milling, dough, and roti preparation. | Sorghum flour | [35] |

| Sorghum flour with a specific particle size was required for desirable roti attributes such as extensibility and color. | Sorghum flour | [36] |

| To make good roti, the dough must be sufficiently cohesive and elastic. | Sorghum flour | [37] |

| Hard rotis with poor holding quality with grains containing 100% corneous endosperm were obtained. A weak dough, and rotis with poor flavor and preservation quality with floury grain varieties were obtained. | Sorghum flour | [38] |

| A strong positive correlation between the texture of rotis and protein/total amylose of sorghum flour was observed. A negative correlation between soluble sugars of sorghum flour and the texture of roti was found. | Sorghum flour | [39] |

| Higher levels of starch damage in sorghum flour resulted in a firmer roti texture and less acceptable among panelists in sensory evaluation. | Sorghum flour | [40] |

| The color, appearance, flavor, texture, taste, and overall acceptability were substantially altered as the proportion of sorghum flour replaced was increased. | Sorghum flour | [41] |

| Roti bread with sorghum-rich multigrain was negatively affected as the amount of sorghum flour increased. | Sorghum flour, wheat flour, ragi, black gram dhal, and fenugreek | [42] |

| All sorghum-based products tested, with the exception of sorghum roti, had a lower glycemic index than their respective wheat/rice-based foods. | Sorghum flour | [43] |

| Research Results | Ingredients | Reference |

|---|---|---|

| The alkali weakened the cell walls and led to the swelling and partial loss of starch granules, altering the physical appearance of the protein structures. | Sorghum flour, calcium hydroxide | [52] |

| Two sorghum lines were identified that produced tortillas with similar quality as maize tortillas (both in terms of color and sensory properties). | Sorghum flour, calcium oxide solution | [53] |

| Tortillas made from the improved sorghum hybrids compared favorably to the positive control in the study. | [54] | |

| Grain from sorghum cultivars with a tan plant, white pericarp without subcoat, intermediate endosperm texture, and low levels of color precursors gave tortillas with acceptable color and texture. The modification of cooking parameters, pearling levels, and corn-to-sorghum levels can result in more effective sorghum use, either alone or in combination with corn, for tortillas. | Sorghum flour, lime | [55] |

| Kernel size, texture, and structure all influenced sorghum cooking time and grinding characteristics. A good correlation was found between the alkali test and tortilla color. | Sorghum flour, calcium hydroxide | [56] |

| Sorghum hybrids’ kernel and flour properties differ, making it possible to assess the quality of sorghum flour for gluten-free food. | Sorghum flour, salt, xanthan gum, shortening, baking powder, citric acid, granulated sugar, monoglycerides, glycerin | [57] |

| Protein solubility and structure were found to be considerably altered when sorghum and maize were processed into tortillas. | Sorghum flour, calcium oxide | [58] |

| Sorghum bran supplementation increased bound and free hydroxycinnamic acids, flavones, total anthocyanins, and cellular antioxidant activity in corn tortillas. | Corn flour, sorghum bran, calcium oxide | [59] |

| Sorghum bran can be an effective option for increasing total dietary fiber content, lowering the predicted glycemic index, and improving the overall texture of maize tortillas. | Corn flour, sorghum bran, calcium oxide | [60] |

| Combining sorghum bran with extruded nixtamalized corn flour was critical for retaining antioxidants in tortillas and was sufficient for the production of novel functional cereal-based snacks with acceptable textural characteristics and color. | Nixtamalized corn flours, extruded nixtamalized corn, flours, sorghum bran | [61] |

| Extruded tortillas were less palatable than micronized or nixtamalized tortillas due to their brownish color and absence of an alkaline aroma. | micronized and extruded sorghum flour, calcium oxide | [62] |

| Thiamine, calcium, and amino acids (histidine, arginine, and leucine) were found to be the most influenced throughout the extrusion process. | [63] | |

| Micronized sorghum absorbed more water, and the dough’s pliability improved. Tortillas with up to 20% micronized sorghum had acceptable color, taste, and texture. | Micronized pearled sorghum flour, alkali solution | [64] |

| As the amount of pearled sorghum in the blend increased, so did the cooking and steeping durations. | Pearled and whole sorghum flours, maize flour, calcium oxide | [65] |

| Sorghum flour (15 or 30%) in the wheat tortillas resulted in increased dough viscosity and increased stress in uniaxial tests. | Decorticated sorghum flour with different particle size, wheat flour, salt, citric acid, shortening, baking powder, potassium sorbate | [66] |

| The nutritional value of tortillas should not be affected by substituting sorghum for all or part of the maize. | Cooked or nixtamalized maize, whole sorghum, pearled sorghum | [67] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ari Akin, P.; Demirkesen, I.; Bean, S.R.; Aramouni, F.; Boyaci, I.H. Sorghum Flour Application in Bread: Technological Challenges and Opportunities. Foods 2022, 11, 2466. https://doi.org/10.3390/foods11162466

Ari Akin P, Demirkesen I, Bean SR, Aramouni F, Boyaci IH. Sorghum Flour Application in Bread: Technological Challenges and Opportunities. Foods. 2022; 11(16):2466. https://doi.org/10.3390/foods11162466

Chicago/Turabian StyleAri Akin, Pervin, Ilkem Demirkesen, Scott R. Bean, Fadi Aramouni, and Ismail Hakkı Boyaci. 2022. "Sorghum Flour Application in Bread: Technological Challenges and Opportunities" Foods 11, no. 16: 2466. https://doi.org/10.3390/foods11162466