Traditional cheeses from raw milk harbour specific and unique sensory attributes, which are widely appreciated by consumers. These cheeses result from several technological, biochemical and microbial parameters such as temperature, time of coagulation, syneresis, water activity, pH, salt content, ripening environmental conditions as well as starter and non-starter microorganisms [

8,

9,

30,

31,

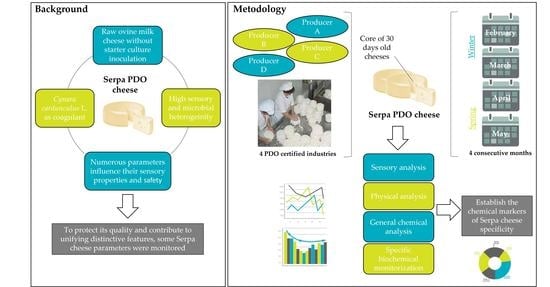

40]. The study of parameters such as FAAs, volatiles, organic acids, physicochemical and rheological is essential to identify chemical markers involved in Serpa cheese uniqueness. Consequently, these related sensory compounds were screened for the first time across different production times and PDO certified producers as well as with distinct sensory classifications.

3.1. Sensory Analysis

All cheeses were submitted to a sensory analysis by a specialised trained panel and

Table 2 summarises the sensory results (as described in

Table 1). During sensory analysis, the maximum total score was 20, with 14 being the minimum value for PDO certification and 4.0 the minimum score out of 6.0 in the taste and smell parameter. Consequently, samples with a total classification lower than 14 or with a score in the taste and smell parameter lower than 4 were classified as “bad”, between 14 and 16 as “good” and with a classification higher than 16 as “excellent”.

Generally, sensory scores of the winter season (February and March) were slightly better than in the spring season (April and May). In the winter, 2 “excellent” cheeses, 3 “good” and 3 “bad” were collected, while in the spring, 3 “excellent” and 5 “bad”. This could be explained by the lower nutritional content of pastures during high temperatures registered in the spring and summer seasons [

41], typically resulting in lower microbiological quality and consequent lower sensory profile [

30]. Most of the cheeses manufactured in dairy A were “excellent”, except in February, which possessed a classification of “bad”, mostly due to a low score (3.6) in taste and aroma, but in general, in both seasons, they had the higher scores in both taste and smell, as in the total score. All samples from producer B were classified as “bad” since this producer had the quality parameters below the minimum demand in both seasons.

Regarding the QDA analysis, which has been applied to assess cheese sensory characteristics and their correlation with the physical–chemical properties [

18], shape, rind and core colour, eyes, odour (ammoniacal), texture (grainy and buttery) and flavour (salty, sour, spicy and bitter) were evaluated. These results are summarised in

Table S1. In the shape parameter, the results suggest significant differences in the “Excellent” cheeses, having this group the highest score. However, in both rind and core colour, no significant differences were revealed. Regarding ammoniacal odour, significant differences between the “Bad” cheeses (5.5) and the other categories of cheese quality were verified. In the grainy texture, the “Excellent” and “Good” groups had the lowest scores (2.31 and 3.0, respectively), with significant differences compared to the “Bad” group, showing the highest score (3.3). In the spicy and salty tastes, there were no significant differences in the three categories, but in the sour taste and bitterness, there were differences: namely, the lowest score was in the “Excellent” and the highest in the “Bad” group.

Figure 1 represents the radar graphic with some of the QDA descriptors: odour (ammoniacal), texture (grainy and buttery) and taste (salty, sour, spicy and bitter), where the three classes of cheese were compared. Above all, these results in QDA taste parameters were in accordance with the scores presented by the panel in taste and aroma.

3.2. Physicochemical Analysis

The main physicochemical and rheological parameters of cheeses from four Serpa cheese producers were also monitored during four consecutive months of production (

Table 3). The cheeses were grouped by the sensory quality, and no significant differences were verified in the physicochemical parameters evaluated except for water activity (a

w). The results show that better quality cheeses are related to lower a

w values (0.90 for excellent quality and 0.92 for good quality). In previous studies, the a

w of Serpa PDO cheeses ranges between 0.96 and 0.98 [

42,

43]. The sodium chloride to moisture ratio is critical in cheese quality, as it has numerous effects, including controlling a

w. This parameter influences cheese microorganism composition and microbial activity, mainly due to the contribution of cheese moisture and salt contents [

44], which vary within traditional small dairies cheesemaking protocols [

43]. These differences are likely to condition the chemical and biochemical reactions upon ripening determined by the microbiota due to selective pressure on microorganisms [

45,

46,

47].

The maturation index, which corresponds to the ratio between soluble nitrogen (WSN) and total nitrogen (TN), established in the Serpa PDO cheese regulation, was set to at least 45% [

6]. However, nowadays, Serpa cheese shows lower values within 30–35% [

36]. The ratio WSN/TN is the only parameter regulated for Serpa PDO cheese, which means the cheese ripening evolution is based on the generic quantification of primary proteolysis. This indicator does not show significant differences concerning the cheese quality, which can be explained by the fact that it is mainly related to primary proteolysis, essentially caused by the coagulating enzymes, native milk proteinases and less related to direct or indirect microbial activity [

48]. The microbial activity generally shows a more significant relationship with the quality of the cheese, mainly aroma and flavour, and can, in a way, be evaluated by indicators such as FAAs and compounds resulting from their catabolism (e.g., organic acids, FFAs and volatile compounds) or also by the ratio NPN/TN [

8,

9,

22,

45,

46,

47,

49,

50,

51]. In our study, we did not find significant differences for this indicator, probably due to the great variability expressed by the high standard deviation for “bad” and “excellent” quality cheeses. However, a highest value is evident for 390 of the “good” cheeses. In a scientific study, the quotient between TN and NPN was 2.3%, TN was 3.5%, and the aminoacidic nitrogen fraction was 3.7% in Serpa cheese [

33]. In PDO specifications, the moisture content on a fat-free basis (MFFB) ranges between 61 and 69% and the fat content on a dry matter (DM) between 45 and 60% [

6], aligning with the results in

Table 3. These values allowed the Serpa cheese classification as soft and full-fat cheese, as set by the Portuguese regulations, which generally follow the Codex Alimentarius general standard for cheese [

52]. In a previous study, the protein content of Serpa was between 36 and 41 g/kg on a DM basis [

7], which is in agreement with our results. Regarding pH and acidity, the previous results reported values between 4.95 and 5.7 [

7,

33,

42,

43] and 7.5 and 9.8 g of lactic acid/kg (equivalent to 8.3–10.9 mL NaOH M/100 g) in Serpa cheese [

7], respectively, being in accordance with the present results.

No significant differences were observed between the cheese groups in the evaluated rheologic parameters. The dynamic rheologic was measured through storage modulus at 1 Hz (G′

1 Hz) and the results are presented in

Table 3. Storage modulus presented values between 7868.08 and 10,589.71 Pa, similar to previous results in Serpa cheese with the same ripening time [

33,

36].

It should be noted that the variability obtained for the physical–chemical parameters was high, which makes statistical analysis and eventual conclusions to be drawn difficult. This fact is a recurring indication concerning traditional cheese production using raw milk, attributed to the variability of manufacturing conditions and the specificities of each cheese factory [

8,

9,

43,

47]. Accordingly, in the following sections, the cheese samples will be analysed by the dairy producer and the month of production.

3.3. Free Amino Acids (FAAs) Profile

Proteolysis has been extensively used to discriminate, for instance, different cheese qualities [

53]. A characteristic FAA pattern is found in each cheese according to the enzymatic and amino acid inter-conversion and degradation systems. The FAAs profile depends on several cheesemaking parameters (e.g., coagulation and ripening conditions) [

54]. Furthermore, the microbiota composition of raw milk and their activity directly impact cheese FAA concentration [

55]. For the first time, the FAAs composition of Serpa cheeses was determined, the results being shown in

Table S2. The results suggested the presence of almost all amino acids in the analysed cheeses and a quantitative variation according to the PDO producer and month of production. The results indicate significant variations according to the dairy producer in all months investigated, which corroborates the higher variability between traditional raw milk cheeses from different PDO producers. The raw milk quality and dairy environment impact the proteolytic activity of bacteria during cheese ripening [

53,

56]. Consequently, these facts affect the levels of FAAs according to producers and months.

Despite the variation registered, glutamic acid (Glu), alanine (Ala), Leu, Val and Phe are the most prevalent FAAs in all samples, with concentrations ranging between 18.76 and 1445.16 mg/100 g. This group of the most incident FAAs through different months in the analysis is present in

Figure 2. Generally, the following most incident FAA was aspartic acid (Asp), with concentrations varying from 42.13 to 428.49 mg/100 g. Val, Leu and Phe are essential flavour precursors [

12,

26]. The results may indicate that this group of FAAs is more prevalent in Serpa cheese with 30 days of ripening and probably may have an essential role in their specificity. Additionally, Serra da Estrela cheese, a traditional Portuguese PDO cheese produced with raw ewe’s milk and coagulated with

C. cardunculus L., showed higher concentrations in some of these FAAs, namely, Leu, Phe, Ala and Val [

26,

57]. Concerning Terrincho cheese, a raw ewe’s milk coagulated with animal rennet, the most incident FAAs identified were Leu, Val, Asp, Glu and Pro [

56]. In another study, Leu, Phe and Val are among the most prevalent FAAs in goat’s, cow’s, and cow’s mixed with goat’s milk cheeses in the final ripening time [

53].

Regarding the total FAAs concentration analysed, the total concentration of FAAs identified was generally higher in the spring than in the winter (

Figure 2). Significant variations in total FAAs were also verified according to the producer and month of production. In the case of producers A and D, the higher concentrations were registered in May, showing values of approximately 3805.04 and 5375.40 mg/100 g, while producers B and C, in April, had values of around 3151.56 and 6116.82 mg/100 g, respectively. Higher concentrations and accumulation of FAAs results from less conversion into volatile compounds [

8].

3.4. Organic Acid Profile

Regarding the SCFAs profile, acetic (C

2), propionic (C

3) and butyric (C

4) were identified and quantified by HPLC for the first time for Serpa cheese, with isobutyric, valeric and isovaleric by SPME-GC/MS. Additionally, lactic acid concentrations in each condition were also investigated by HPLC. Generally, organic acids are the most incident compounds in cheese [

58]. Regarding HPLC analysis, the results suggest quantitative variations according to the month of production (

Table 4). According to the dairy producer, significant differences were also registered. As previously said, this considerable variability may result from the differences in raw milk composition coupled with variations in the cheesemaking and ripening conditions [

59].

Lactic acid was the most abundant acid, with concentrations between 645.03 and 2548.44 mg/100 g. Due to the metabolic processes that occur during cheesemaking and ripening, lactic acid is most abundant in similar cheeses and maturation times. In raw and pasteurised Italian cheeses manufactured with goat, sheep, cow milk or milk mixtures, lactic acid concentrations were between 199 and 3910 mg/100 g [

59]. During the initial ripening phase, the residual lactose is converted into lactic acid, which plays several essential roles in metabolic reactions, such as oxidation, racemisation as well as microbial metabolism [

60]. LAB are the primary lactic acid producers, which may decrease environmental pH and exert an antibacterial effect [

58]. The secondary microflora is generally designated as non-starter LAB (NSLAB) and propionic bacteria, moulds and yeasts are also usually responsible for the complementary action on lactate and other cheese components derived from the primary action of the coagulant and starters (peptides, amino acids, FFAs) [

23]. The antibacterial effect of lowering pH may be crucial for inhibiting foodborne pathogens’ proliferation and the action of NSLAB is important for the sensory cheese properties, mainly odour and flavour, either more directly through its metabolic activity or indirectly through the release of enzymes in the cheese matrix [

61]. Organic acids are important flavour compounds and metabolites of several biochemical processes. They can have different origins, being formed from the catabolism of lactate, amino acids or fatty acids by the action of starters, secondary microflora or propionic bacteria [

21,

62,

63]. The detection and quantification of organic acids can even be used as a classification parameter for different cheeses. The presence of these compounds may reflect the influence of the microbial metabolism [

64,

65].

In Serpa cheese analysed in this study, lactic acid is followed by acetic acid, the concentration ranging between 120.92 and 359.44 mg/100 g (

Table 4). In Torta del Casar cheese, from sheep milk and similar to Serra da Estrela and Serpa cheeses, Ordiales et al. [

45] found that acids were the most abundant volatile compounds, followed by alcohols and carbonyls. Acetic acid, a major odorant of several cheese varieties, was present in all samples analysed and in higher concentrations (15.06–45.89% of volatiles), whose origin is usually linked to residual lactose, lactate and citrate metabolism by LAB [

23,

61]. Garde et al. [

63] found a concentration of 139.3 ± 10.7 mg/100 g in raw milk Manchego cheese, which increased to 186.4 ± 5.8 mg/100 g for the same cheese variety, showing signs of late blowing defect. The Murazzan PDO cheese is manufactured with raw sheep or a mixture of sheep and cow milk, typically within 10 days of ripening. The values of acetic acid in this Italian cheese vary between 3.8 and 124.8 mg/100 g. Concerning Robiola di Roccaverano PDO cheese, an Italian pasteurised ovine cheese inoculated with a starter culture, the acetic acid values ranged between 3.8 and 63.4 mg/100 g. Saras del Fen is also an Italian cheese manufactured with a whey mixture obtained from goat, sheep and cow milk within 20 days of ripening. In this case, the acetic acid varies from 3.3 to 75.9 mg/100 g. Acetic acid typically has higher concentrations in longer ripened cheeses, aligning with the present study results since Serpa PDO cheese possesses at least 30 days of ripening and higher values of acetic acid in the final maturation phase [

59]. Greater concentrations of acetic acid and volatile organic acids such as butanoic, isobutyric and hexanoic acids are related to the sour taste of cheeses [

58], and were found in Azeitão cheese, a Portuguese PDO sheep raw milk cheese made with vegetable rennet (

C. cardunculus L.) [

48].

The presence of C

3 and C

4 is related to the intensity of bacterial fermentation during the maturation period, typically increasing throughout this period [

59]. As previously said, these acids result mainly from lactate catabolism and/or FAAs oxidative deamination in a cheese environment, being involved in aroma properties [

12]. C

2 and C

3 have a typical pungent and vinegar odour, being major odorants of Cheddar, Emmental and Gruyère cheeses; while butyric acid has a rancid cheese-like odour, being important in the flavour of several cheese types, like Camembert, Cheddar, Grana Padano, although large amounts of this acid generally originated from the lactate butyric fermentation are undesirable [

66]. C

4 has been found widely in raw sheep milk PDO cheeses from Spain (Torta del Casar, Roncal, Manchego), Italy (CanestratoPuglise, Fiore Sardo, Pecorino Romano), Portugal (Terrincho) and also Poland (Oscypek) [

48,

67,

68,

69,

70]. The C

3 and C

4 fermentation result from the abundant presence of secondary microorganisms and are likely to have a higher presence in old Port Salut Argentino cheese. Butyric acid concentration can be included in a group of organic acids that can significantly predict the ripening time [

62].

The results suggested that C

3 concentration ranges between 6.69 and 77.01 in the winter season and from 9.80 to 30.86 mg/100 g in the spring season. Regarding C

4, the higher concentration was also verified in winter, with concentrations varying between 3.75 and 41.82 and in spring, between 3.13 and 31.02 mg/100 g. The results are in accordance with the literature data for similar cheeses [

8,

9,

12,

58,

59]. For instance, in a study focused on Serra da Estrela cheese, the concentration of C

4 was 44.26 mg/100 g [

9]. In Torta del Casar cheese, Ordiales et al. [

45] found that C

4 and C

3 represented 3.79–26.61% and 0.00–8.77% of volatiles, respectively, the second and third more important acids in this cheese. In goat cheese from the Muciano–Granadine breed, Buffa et al. [

65] found an average of 6.1 and 8.7 mg/100 g for C

4 and C

3 acids, respectively, in raw milk ripened (60 days) cheese. In comparison, lower levels (2.5 and 6.9 mg/100 g, respectively) were found in pasteurised milk ripened cheese, reflecting the differences in the presence of NSLAB.

3.5. Volatile Profile

Regarding the volatile composition identified for the first time for Serpa cheese, the target cheeses own a significant variability in volatile composition between producers, months and seasons of production. The results suggest the presence of several chemical groups such as volatile acids, aldehydes, aromatic compounds, ketones, alcohols and other compounds (data not shown). Numerous parameters impact volatile composition, such as raw milk quality, microbiota profile and composition (breed, feed, environmental and farming conditions) [

51,

71,

72]. Ripening is a complex biochemical process when numerous volatiles are produced, typically increasing their concentration during this stage [

73]. Vegetable coagulants improve the technological and volatile properties of cheeses. In addition, most vegetable coagulated cheeses are more digestible, resulting in a more intense flavour [

51].

Despite the high variability, in the Serpa cheese samples analysed, volatile acids, esters and ketones are the most representative and typical chemical groups in other cheeses [

12,

58,

71,

73], being the target of the present study. These groups’ high variability and incidence were also found in ewe’s milk cheeses [

73], Serra da Estrela PDO cheese [

12], Castelo Branco PDO cheese [

71] and Azeitão PDO cheese [

51]. Castelo Branco is a PDO cheese, also a raw ewe’s milk cheese produced with a vegetable coagulant [

74]. Native milk and microorganism lipases play important roles in cheese flavour and aroma development. In the case of raw milk, the native lipase was not deactivated by pasteurization [

71]. This fact, coupled with the microbiota profile, may explain the stronger aroma and flavour of raw milk than pasteurised cheeses [

51].

Despite the high variation according to the producer and month of production, the FFAs are the volatiles with higher concentrations in the winter and spring seasons (

Table 5). Generally, the results suggested that the most prevalent volatile acids are iC

5, hexanoic (C

6), octanoic (C

8), decanoic (C

10) and dodecanoic (C

12) acids. These results aligned with other studies focused on raw ewe’s milk cheeses [

12,

51,

71,

72,

73]. SCFAs and medium-chain fatty acids are the main flavour contributors [

71,

73]. Their high content in ewe cheeses contributes to the more savoury and pungent flavour than cow cheeses [

72]. In contrast, long-chain fatty acids (with more than 12 carbon atoms) have a minor impact on cheese flavour, given their relatively high perception thresholds [

72,

73].

C

4 and C

6 are two of the three most represented volatile organic compounds in Azeitão cheese, the third being 2-butanone [

51]. The iC

5 results from Leu catabolism [

9] and their concentration range between 24.60 and 1400.55 mg/100 g. This macromolecule has been associated with the strong cheesy, rancid and piquant odour typically described in ripened cheeses. However, iC

5 in higher concentrations may be unpleasant [

9]. Regarding C

6 produced by LAB through Val catabolism, it is typically correlated with soapy, goaty, waxy and sweaty aromas [

9,

71]. Its concentration varies from 29.69 to 861.46 mg/100 g. High concentrations of this free fatty acid were also found in Azeitão [

51], Castelo Branco [

71] and Serra da Estrela PDO cheese [

8].

Concerning C

10 and C

12, generally, higher concentrations were registered in the winter season. These free fatty acids are associated with soapy flavours and result from bacterial enzyme activity [

72]. iC

4 and C

3 result from starter and non-starter microbial action [

9]. The concentration of iC

4 in the winter and spring seasons ranges between 1.97 and 61.02 as well as 0.21 and 4.76 mg/100 g, respectively. This free fatty acid is derived from Leu catabolism, associated with a cheesy, rancid, sweaty and putrid aroma [

9].

Esters and ketones are important volatile groups in the cheese matrix that were also monitored, present in

Table 6 and

Table 7. The first group can be synthesised, on the one hand, by alcohol and carboxylic acid esterification, or on the other hand, by alcohol and acyl glycerol alcoholysis reaction. Most esters found in cheese have sweet, fruity and floral notes. Some of them have a very low perception threshold, contributing to minimising sharpness and bitterness imparted from fatty acids and amines [

66,

75,

76]. Ethyl isovalerate (0.20–5.33 mg/100 g), ethyl valerate (0.13–1.82 mg/100 g), ethyl heptanoate (0.08–8.62 mg/100 g) and ethyl nonanoate (0.19–9.34 mg/100 g) were detected in almost all cheeses analysed. Ethyl acetate (0.09–0.73 mg/100 g), ethyl butyrate (11.30–40.09 mg/100 g), ethyl hexanoate (16.9223.60 mg/100 g), ethyl octanoate (0.62–39.19 mg/100 g), ethyl decanoate (1.62–59.26 mg/100 g) and ethyl dodecanoate (5.01–12.77 mg/100 g) reached the higher average values for detected esters. Ethyl butanoate has been identified as one of the most potent odorants of Cheddar, Emmental and Pecorino. In contrast, ethyl hexanoate plays an important role in the aroma profiles of aged Cheddar, Grana Padano, Pecorino and Ragusano cheeses [

66]. Ethyl octanoate was noted as significant in the aroma formation of Flor de Guia [

77] and Azeitão cheeses reveal the presence of ethyl butyrate, ethyl hexanoate and ethyl octanoate [

48]

Lipase activity results in ketones and FFAs release as well as flavour substances catabolism [

58]. Ketones are common constituents of most dairy products. Given their typical odours and low perception threshold, they are primarily known for their contribution to the aroma of surface-mould ripened and blue-veined cheeses. In line with the other groups, some significant differences were verified according to the producer, month and season (

Table 7). The ketones identified and quantified were 2-heptanone (0.52–22.91 mg/100 g), 2-octanone (0.04–1.32 mg/100 g), 2-nonanone (0.47–37.46 mg/100 g) and 2-undecanone (0.34–7.09 mg/100 g).

Generally, despite the higher variability, the 2-heptanone and 2-nonanone were the most incident ketones identified, followed by 2-undecanone. The 2-heptanone is related to Blue cheese, Gorgonzola and Emmental cheeses aroma, while 2-nonanone is also a methyl ketone important in Gorgonzola and still in Ragusano cheese, and 2-undecanone seems to be an essential aroma in Camembert cheese. The last two methyl ketones mentioned and 2-octanone and 2-decanone are associated with fruity, floral and musty notes [

66]. Ketones, though, also impact other non-mould ripened cheeses’ aroma: for instance, in Payoya goat cheese, 2-heptanone and 2-nonanone are the most important ketones [

76], but they seem to be much less present in Torta del Casar cheese [

42]. In Azeitão cheese, Cardinali et al. [

51] identified 2-butanone, 2-pentanone and 2-heptanone.

3.6. Results Integration

A PCA analysis included 13 attributes (variables), previously selected as potential biochemical markers, based on the evaluation of successive analyses, trying to reduce the number of variables chosen as markers, while increasing the explained variance. The variables selected were C3, C4, tyrosine (Tyr), tryptophan (Trp), Ile, 2-undecanone, ethyl isovalerate, iC5, C12, MFFB, the nitrogen fractions (WSN/TN%, NPN/TN%) and G’1 Hz. The most important sensory markers, the total score for PDO Serpa cheese certification and 4 flavour attributes (spicy, bitter, ammoniacal and salty) that contribute to the cheese quality definition were used in PCA analysis as supplementary or illustrative variables to test the affinity of the selected markers with the cheese quality. The supplementary variables were projected in the variables map, although they do not influence the analysis.

The projection of the variables in the three planes constituted by the three principal components is shown in

Figure 3. The first three principal components explained 70.6% of the total variance. As can be seen in

Figure 3A1–A3, the first component (PC1) by itself condensed 28.0%, the second component (PC2) explained 23.5% of the total variance and the third component (PC3) explained 19.2% of the total variance. Therefore, the similarity map defined by the first two principal components (PC1 vs PC2) accounted for 51.5% of the total variance, PC1 vs PC3 accounted for 47.2% of the total variance and PC2 vs PC3 took into account 42.7% of the total variance. The PC1 presented negative correlations with C

4—butyric acid (r = −0.66), Tyr (r = −0.63), 2-undecanone (r = −0.62), ethyl isovalerate (r = −0.79), C

12 (r = −0.64) and NPN/TN% (r = −0.78) (

Figure 3A1,A2); the PC2 presented negative correlations with C

3—propionic acid (r = −0.79) and positive correlations with Trp, iC

5 (r = 0.57) and G’

1Hz, (r = 0.66) (

Figure 3A1,A3); and the PC3 presented negative correlations with Ile (r = −0.70), MFFB (r = −0.79) and WSN/TN% (r = −0.92) (

Figure 3A2,A3).

The parameter “total score” was the supplementary sensory variable that guided this study as an indicator for consideration as “Good” cheese, as obtained from the official Serpa cheese sensory panel results. The projection of the variables on the plane (

Figure 3), in particular,

Figure 3A2,A3, presents the sensory attribute “spicy” close to “Total score”, which indicates that such an attribute is associated with high-quality Serpa cheeses. On the other hand, sensory attributes “ammoniacal”, “bitter”, “salty” and “acid” are on the opposite side of the plane, indicating that such features are associated with lower quality cheeses when present intensely. These results are according to the sensory definition of Serpa cheese concerning taste, namely, aroma and flavour definition (

Table 1)—“generally strong and with a predominance of spicy flavour”. Specifically, Serpa cheese must present a slightly spicy taste but not intense ammoniacal, bitter, acid or salty perceptions. On the other hand, the chemical parameters closer to “Total score”, representing cheeses with higher quality, are, in this order, Trp and Tyr. On the opposite side, the biochemical markers associated with poor quality cheeses are high values for WSN/TN, MFFB, Ile, butyric acid and 2-undecanone (

Figure 3A1,A2—PC1 vs. PC3 and PC2 vs. PC3, respectively).

The projection of the samples in the three planes constituted by the three principal components is shown in

Figure 4.

From the results of the PCA analysis, it was possible to aggregate the excellent samples.

Figure 4A2,A3 highlights four (out of five) samples classified as excellent (namely, AEM, AEA, AEMy and CEMy), that were found on the upper side of both planes. The concentration of “excellent” and “good” cheeses in the centre part of

Figure 4A1 reflects the location of the supplementary positive sensory variable “Total score” in the plane defined by PC1 and PC2 (

Figure 3A1), and the low-quality cheeses are spread over the three planes defined by the axes PC1, PC2 and PC3, suggesting the characteristic heterogeneity of the traditional cheese properties [

1,

2,

10,

12]. The excellent cheese samples were characterised, in sensory terms, by a spicy flavour and a low acid, salty, ammoniacal and bitter flavour. Likewise, these samples were characterised by high values of markers, such as Trp and Tyr, and low or intermediate values of WSN/TN, MFFB, Ile, C

4 and 2-undecanone. On the contrary, the plan defined by PC1 and PC2 separates well, and interestingly, the cheeses according to the time of year (

Figure 4B1), and this separation is maintained in

Figure 4B2, not being so evident in

Figure 4B3. Comparing

Figure 4A1–A3 with

Figure 4B1–B3, it can be concluded that even under traditional conditions, it is possible to produce “good” or “excellent” quality cheeses in either of the two periods considered.

With this study, it was possible to confirm the characteristic flavour of Serpa cheese “aroma and flavour—generally strong and with a predominance of spicy flavour”, as established in the legal regulation [

6]. In addition, it was possible to select the biochemical markers that predominate at the end of ripening, resulting from proteolysis, such as the amino acids Trp and Tyr, which have been used as cheese proteolysis based ripening index [

78]. Another relevant marker seems to be WSN/TN (%), which is included in the Serpa cheese certification (minimum of 45%) [

6]. This is probably a regulation value to review as it is a high minimum value. As this study suggests, a more suitable minimum value should fall in the 30 and 35% range, similar to those considered for similar Portuguese cheeses, such as Serra da Estrela and Azeitão PDO cheeses.

On the other hand, PC1 could separate samples by season. From

Figure 4B1,B2, it can be seen that the winter season samples predominate on the left side of the plots, with high values of butyric acid, tyrosine, 2-undecanone, ethyl isovalerate, C

12 and NPN/TN (%) and, simultaneously, samples with low values for these markers were the spring samples, represented on the right side of the plane. This is an old widespread feeling among communities of raw milk cheese producers from different regions. Additionally, the aggregation by dairy (A, B, C and D) is also visible, which is also pointed to as a critical parameter that impacts cheese microbiota and, consequently, the final product properties [

53,

56].