Effects of Compostable Packaging and Perforation Rates on Cucumber Quality during Extended Shelf Life and Simulated Farm-to-Fork Supply-Chain Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Packaging Treatments

2.3. Storage Conditions

2.4. Quality Evaluations

2.5. Statistical Analysis

3. Results

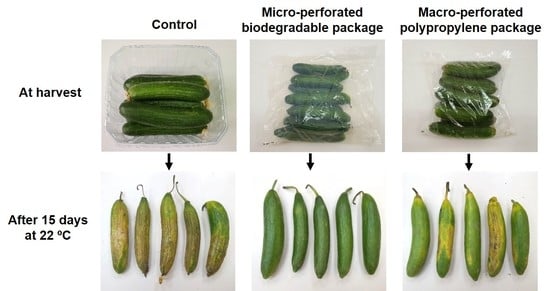

3.1. Visual Appearance

3.2. Atmosphere Compositions

3.3. Water Loss and Condensation

3.4. Peel Blemishes

3.5. Peel Color

3.6. Decay Development

3.7. Fruit Flavor

3.8. Visual-Acceptance Score

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kader, A.A. Postharvest biology and technology: An overview. In Postharvest Technology of Horticultural Crops; Kader, A.A., Ed.; Regents of the University of California, Division of Agricultural and Natural Resources: Oakland, CA, USA, 2002; pp. 39–47. [Google Scholar]

- FAO (Food and Agriculture Organization of the United Nations). Global Food Losses and Food Waste: Extent, Causes and Prevention; Study Conducted for the International Congress SAVE FOOD! At Interpack, Düsseldorf, Germany; FAO: Rome, Italy, 2011; Available online: http://www.fao.org/docrep/014/mb060e/mb060e00.Pdf (accessed on 1 February 2021).

- Lipinski, B.; Hanson, C.; Lomax, J.; Kitinoja, L.; Waite, R.; Searchinger, T. Reducing food loss and waste. In Working Paper, In-stallment 2 of Creating a Sustainable Food Future; World Resources Institute: Washington, DC, USA, 2013; Available online: https://pdf.wri.org/reducing_food_loss_and_waste.pdf (accessed on 1 February 2021).

- NRDC. Wasted: How America is Losing Up to 40 Percent of Its Food from Farm to Fork to Landfill. NRDC Issue PAPER, R: 17-05-A (2nd edition of NRDC’s original paper from 2012). 2017. Available online: https://www.nrdc.org/sites/default/files/wasted-2017-report.pdf (accessed on 1 February 2021).

- Buzby, J.C.; Wells, H.F.; Hyman, J. The Estimated Amount, Value, and Calories of Postharvest Food Losses at the Retail and Consumer Levels in the United States, EIB-121, U.S. Department of Agriculture, Economic Research Service. 2014. Available online: https://www.ers.usda.gov/webdocs/publications/43833/43680_eib121.pdf (accessed on 1 February 2021).

- Opara, U.L. A review on the role of packaging in securing food system: Adding value to food products and reducing losses and waste. Afric. J. Agric. Res. 2013, 8, 2621–2630. [Google Scholar]

- Verghese, K.; Lewis, H.; Lockrey, S.; Williams, H. Packaging’s Role in Minimizing Food Loss and Waste Across the Supply Chain. Packag. Technol. Sci. 2015, 28, 603–620. [Google Scholar] [CrossRef]

- Wikström, F.; Verghese, K.; Auras, R.; Olsson, A.; Williams, H.; Wever, R.; Grönman, K.; Pettersen, M.K.; Møller, H.; Soukka, R. Packaging Strategies That Save Food: A Research Agenda for 2030. J. Ind. Ecol. 2018, 23, 532–540. [Google Scholar] [CrossRef]

- AMERIPEN. Quantifying the Value of Packaging as a Strategy to Prevent Food Waste in America. 2018. Available online: https://www.ameripen.org/page/foodwastereport (accessed on 1 February 2021).

- Kader, A.A.; Zagory, D.; Kerbel, E.L.; Wang, C.Y. Modified atmosphere packaging of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 1989, 28, 1–30. [Google Scholar] [CrossRef]

- Rai, D.R.; Oberoi, H.S.; Baboo, B. Modified atmosphere packaging and its effect on quality and shelf life of fruits and vegeta-bles: An overview. J. Food Sci. Tech. 2002, 39, 199–207. [Google Scholar]

- Kader, A.A. Modified atmosphere during transport and storage. In Postharvest Technology of Horticultural Crops; Kader, A.A., Ed.; Regents of the University of California, Division of Agricultural and Natural Resources: Oakland, CA, USA, 2002; pp. 135–144. [Google Scholar]

- Saltveit, M. A summary of CA requirements and recommendations for vegetables. Acta Hortic. 2003, 600, 723–727. [Google Scholar] [CrossRef]

- Xanthos, D.; Walker, T.R. International policies to reduce plastic marine pollution from single-use plastics (plastic bags and microbeads): A review. Mar. Pollut. Bull. 2017, 118, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Ellen MacArthur Foundation & UNEP. The New Plastics Economy Global Commitment Progress Report. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/Global-Commitment-2019-Progress-Report.pdf (accessed on 1 February 2021).

- Khalil, H.P.S.A.; Banerjee, A.; Saurabh, C.K.; Tye, Y.Y.; Suriani, A.B.; Mohamed, A.; Karim, A.A.; Rizal, S.; Paridah, M.T. Biodegradable Films for Fruits and Vegetables Packaging Application: Preparation and Properties. Food Eng. Rev. 2018, 10, 139–153. [Google Scholar] [CrossRef]

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Borowski, G.; Szczypiński, M.; Klepka, T.; Thakur, V.K. Recent progress in biode-gradable polymers and nanocomposite-based packaging materials for sustainable environment. Inter. J. Poly. Anal. Char. 2018, 23, 383–395. [Google Scholar] [CrossRef]

- Jamróz, E.; Kopel, P.; Tkaczewska, J.; Dordevic, D.; Jancikova, S.; Kulawik, P.; Milosavljevic, V.; Dolezelikova, K.; Smerkova, K.; Svec, P.; et al. Nanocomposite Furcellaran Films—the Influence of Nanofillers on Functional Properties of Furcellaran Films and Effect on Linseed Oil Preservation. Polymers 2019, 11, 2046. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suslow, T.V.; Cantwell, M. Cucumbers: Recommendations for Maintaining Postharvest Quality. 2002. Available online: http://ucanr.edu/sites/Postharvest_Technology_Center_/Commodity_Resources/Fact_Sheets/Datastores/Vegetables_English/?uid=19&ds=799 (accessed on 1 February 2021).

- Kahramanoğlu, I.; Usanmaz, S. Improving Postharvest Storage Quality of Cucumber Fruit by Modified Atmosphere Packaging and Biomaterials. HortScience 2019, 54, 2005–2014. [Google Scholar] [CrossRef] [Green Version]

- Manjunatha, M.; Anurag, R.K. Effect of modified atmosphere packaging and storage conditions on quality characteristics of cucumber. J. Food Sci. Technol. 2012, 51, 3470–3475. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Watkins, B.C. Responses of horticultural commodities to high carbon dioxide as related to modified atmosphere packaging. HortTechnology 2000, 10, 501–506. [Google Scholar] [CrossRef]

- Mir, N.; Beaudry, R. Modified atmosphere packaging. In The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks. Agriculture Handbook 66; Gross, K.C., Wang, C.Y., Saltveit, M., Eds.; USDA, Agricultural Research Service: Washington, DC, USA, 2016; pp. 42–53. [Google Scholar]

- Saltveit, M.E. Biological basis for CA and MA. In Controlled and Modified Atmospheres for Fresh and Fresh-Cut Produce; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 3–22. [Google Scholar]

- Fonseca, S.C.; Oliveira, F.A.; Brecht, J.K. Modelling respiration rate of fresh fruits and vegetables for modified atmosphere packages: A review. J. Food Eng. 2002, 52, 99–119. [Google Scholar] [CrossRef]

- Flodberg, G.; Helland, I.; Thomsson, L.; Fredriksen, S.B. Barrier properties of polypropylene carbonate and poly(lactic acid) cast films. Eur. Polym. J. 2015, 63, 217–226. [Google Scholar] [CrossRef]

- Wang, J.; Gardner, D.J.; Stark, N.M.; Bousfield, D.W.; Tajvidi, M.; Cai, Z. Moisture and Oxygen Barrier Properties of Cellulose Nanomaterial-Based Films. ACS Sustain. Chem. Eng. 2018, 6, 49–70. [Google Scholar] [CrossRef]

- González, J.; Ferrer, A.; Oria, R.; Salvador, M.L. Determination of O2 and CO2 transmission rates through microperforated films for modified atmosphere packaging of fresh fruits and vegetables. J. Food Eng. 2008, 86, 194–201. [Google Scholar] [CrossRef]

- Rodov, V.; Aharoni, N.; Cohen, S.; Ben-Yehoshua, S. Modified Humidity Packaging of Fresh Produce. Hortic. Rev. 2010, 37, 281–329. [Google Scholar] [CrossRef]

- Aharoni, N.; Rodov, V.; Fallik, E.; Afek, U.; Chalupowicz, D.; Aharon, Z.; Maurer, D.; Orenstein, J. Modified Atmosphere Packaging for Vegetable Crops Using High-Water-Vapor-Permeable Films; CRC Press: Boca Raton, FL, USA, 2007; pp. 73–112. [Google Scholar]

- Hong, S.-I.; Krochta, J.M. Oxygen barrier performance of whey-protein-coated plastic films as affected by temperature, relative humidity, base film and protein type. J. Food Eng. 2006, 77, 739–745. [Google Scholar] [CrossRef]

- Das, A.; Uchimiya, H. Oxygen stress and adaptation of a semi-aquatic plant: Rice (Oryza sativa). J. Plant Res. 2002, 115, 315–320. [Google Scholar] [CrossRef]

- Bovi, G.G.; Caleb, O.J.; Rauh, C.; Mahajan, P.V. Condensation regulation of packaged strawberries under fluctuating storage temperature. Packag. Technol. Sci. 2019, 32, 545–554. [Google Scholar] [CrossRef]

- Bovi, G.G.; Caleb, O.J.; Klaus, E.; Tintchev, F.; Rauh, C.; Mahajan, P.V. Moisture absorption kinetics of FruitPad for packag-ing of fresh strawberry. J. Food Engin. 2018, 223, 248–254. [Google Scholar] [CrossRef] [Green Version]

- Briassoulis, D.; Giannoulis, A. Evaluation of the functionality of bio-based food packaging films. Polym. Test. 2018, 69, 39–51. [Google Scholar] [CrossRef]

- Przybytek, A.; Sienkiewicz, M.; Kucińska-Lipka, J.; Janik, H. Preparation and characterization of biodegradable and com-postable PLA/TPS/ESO compositions. Indus. Crops Prod. 2018, 122, 375–383. [Google Scholar] [CrossRef]

- Dhall, R.K.; Sharma, S.R.; Mahajan, B.V.C. Effect of shrink wrap packaging for maintaining quality of cucumber during storage. J. Food Sci. Technol. 2011, 49, 495–499. [Google Scholar] [CrossRef] [Green Version]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Owoyemi, A.; Porat, R.; Rodov, V. Effects of Compostable Packaging and Perforation Rates on Cucumber Quality during Extended Shelf Life and Simulated Farm-to-Fork Supply-Chain Conditions. Foods 2021, 10, 471. https://doi.org/10.3390/foods10020471

Owoyemi A, Porat R, Rodov V. Effects of Compostable Packaging and Perforation Rates on Cucumber Quality during Extended Shelf Life and Simulated Farm-to-Fork Supply-Chain Conditions. Foods. 2021; 10(2):471. https://doi.org/10.3390/foods10020471

Chicago/Turabian StyleOwoyemi, Abiola, Ron Porat, and Victor Rodov. 2021. "Effects of Compostable Packaging and Perforation Rates on Cucumber Quality during Extended Shelf Life and Simulated Farm-to-Fork Supply-Chain Conditions" Foods 10, no. 2: 471. https://doi.org/10.3390/foods10020471