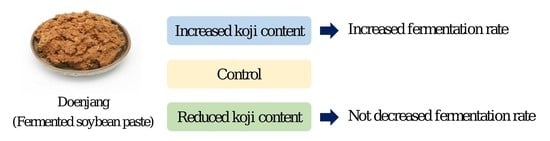

Changes of Physiochemical and Enzymatic Activities of doenjang Prepared with Different Amount of Rice koji during 30 Days of Fermentation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Doenjang Samples Included in This Study

2.2. Physiochemical Analysis of doenjang

2.3. Enzymatic Activity Analysis of doenjang

2.4. Statistical Analysis

3. Results

3.1. Physiochemical Characteristic Analysis

3.2. Enzymatic Analysis Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, H.; Center, L.R.; Lee, M.; Center, L.R.; Lee, S. Physicochemical characteristics of soybean pastes containing sword bean. Food Eng. Prog. 2009, 12, 176–182. [Google Scholar]

- Namgung, H.-J.; Park, H.-J.; Cho, I.H.; Choi, H.-K.; Kwon, D.-Y.; Shim, S.-M.; Kim, Y.-S. Metabolite profiling of doenjang, fermented soybean paste, during fermentation. J. Sci. Food Agric. 2010, 90, 1926–1935. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Kim, J.-Y.; Baek, S.-Y.; Yeo, S.-H.; Koo, B.-S.; Park, H.-Y.; Choi, H.-S. Isolation and Characterization of Oligotrophic Strains with High Enzyme Activity from Buckwheat Sokseongjang. Korean J. Food Sci. Technol. 2011, 43, 735–741. [Google Scholar] [CrossRef]

- Kim, M.K.; Lee, K.G. Correlating consumer perception and consumer acceptability of traditional Doenjang in Korea. J. Food Sci. 2014, 79, S2330–S2336. [Google Scholar] [CrossRef] [PubMed]

- Park, K.Y.; Hwang, K.M.; Jung, K.O.; Lee, K.B. Studies on the standardization of doenjang (Korean soybean paste): 1. Standardization of manufacturing method of doenjang by literatures. J. Korean Soc. Food Sci. Nutr. 2002, 31, 343–350. [Google Scholar]

- Hong, H.H.; Kim, M.K. Physiochemical Quality and Sensory Characteristics of koji Made with Soybean, Rice, and Wheat for Commercial doenjang Production. Foods 2020, 9, 975. [Google Scholar] [CrossRef]

- Kim, M.K.; Chung, H.-J.; Bang, W.-S. Correlating physiochemical quality characteristics to consumer hedonic perception of traditional Doenjang (fermented soybean paste) in Korea. J. Sens. Stud. 2018, 33, e12462. [Google Scholar] [CrossRef]

- So, M.H.; Lee, Y.S. Effects of culture conditions of Rhizopus sp. ZB9 on the production of protease during preparation of rice koji. Korean J. Food Nutr. 2010, 23, 399–404. [Google Scholar]

- Kim, J.-H.; Kwon, Y.-H.; Lee, A.-R.; Kim, H.R.; Ahn, B.H. Manufacture of Koji Using fungi Isolation from Nuruk and Identification of Koji Molds. Korean J. Mycol. 2012, 40, 187–190. [Google Scholar] [CrossRef] [Green Version]

- Onuma, K.; Kanda, Y.; Ikeda, S.S.; Sakaki, R.; Nonomura, T.; Kobayashi, M.; Osaki, M.; Shikanai, M.; Kobayashi, H.; Okada, F. Fermented Brown Rice and Rice Bran with Aspergillus oryzae (FBRA) Prevents Inflammation-Related Carcinogenesis in Mice, through Inhibition of Inflammatory Cell Infiltration. Nutrients 2015, 7, 10237–10250. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shin, H.W.; Jang, E.S.; Moon, B.S.; Lee, J.J.; Lee, D.E.; Lee, C.H.; Shin, C.S. Anti-obesity effects of gochujang products prepared using rice koji and soybean meju in rats. J. Food Sci. Technol. 2016, 53, 1004–1013. [Google Scholar] [CrossRef] [Green Version]

- Yoshizaki, Y.; Kawasaki, C.; Cheng, K.C.; Ushikai, M.; Amitani, H.; Asakawa, A.; Okutsu, K.; Sameshima, Y.; Takamine, K.; Inui, A. Rice koji reduced body weight gain, fat accumulation, and blood glucose level in highfat dietinduced obese mice. PeerJ 2014, 2, e540. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, Y.; Cui, C.; Zhao, H.; Gao, X.; Zhao, M.; Sun, W. Effect of koji fermentation on generation of volatile compounds in soy sauce production. Int. J. Food Sci. Technol. 2013, 48, 609–619. [Google Scholar] [CrossRef]

- Lee, S.-I.; Lee, Y.-K.; Kim, S.-D.; Lee, I.-A.; Choi, J.; Suh, J.-W. Dietary Effects of Fermented Soybean Curd Residue (Biiji) on Body Weight, Serum Lipid Profiles, and Antioxidation-Related Enzymes Activity of Mice Fed a High Fat Diet. J. Korean Soc. Food Sci. Nutr. 2013, 42, 1043–1053. [Google Scholar] [CrossRef]

- Kwon, Y.-H.; Lee, A.-R.; Kim, H.R.; Kim, J.-H.; Ahn, B.H. Quality Properties of Makgeolli Brewed with Various Rice and Kioji. Korean J. Food Sci. Technol. 2013, 45, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.-J.; Choi, Y.-H.; Park, S.-Y.; Choi, H.-S.; Jeong, S.-T.; Kim, E.-M. Quality Characteristics of Kochujang with Different Ratios of Rice-nuruk. Korean J. Community Living Sci. 2012, 23, 339–346. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.S.; Chung, K.S.; Jung, S.W. Effects of preparation methods and aging temperatures on the properties of rice doenjang. Appl. Biol. Chem. 1995, 38, 83–89. [Google Scholar]

- Kim, H.-E.; Han, S.-Y.; Jung, J.-B.; Ko, J.-M.; Kim, Y.-S. Quality Characteristics of Doenjang (Soybean Paste) Prepared with Germinated Regular Soybean and Black Soybean. Korean J. Food Sci. Technol. 2011, 43, 361–368. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-Y.; Kim, I.-S.; Park, S.-L.; Lim, S.-I.; Choi, H.-S.; Choi, S.-Y. Antidiabetic Activity and Enzymatic Activity of Commercial Doenjang Certified for Traditional Foods. KSBB J. 2012, 27, 361–366. [Google Scholar] [CrossRef] [Green Version]

- Bechman, A.; Phillips, R.D.; Chen, J. Changes in selected physical property and enzyme activity of rice and barley koji during fermentation and storage. J. Food Sci. 2012, 77, 318. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Park, N.-Y.; Kim, J.-Y.; Choi, H.-S. Quality Characteristics of Rice-doenjang during Fermentation by Differently Shaped Meju and Adding Starter. Korean J. Food Nutr. 2012, 25, 505–512. [Google Scholar] [CrossRef]

- Lee, J.Y.; Mok, C. Changes in physicochemical properties of low salt soybean paste (Doenjang) during fermentation. Food Eng. Prog. 2010, 14, 153–158. [Google Scholar]

- Jang, S.M.; Lee, J.B.; An, H.; Rhee, C.H.; Park, H.D. Changes of microorganisms, enzyme activity and physiological functionality in the Korean soybean paste with various concentrations of ginseng extract during fermentation. Korean J. Food Preserv. 2000, 7, 313–320. [Google Scholar]

- Mok, C.; Song, K.; Lee, J.; Park, Y.; Lim, S. Changes in microorganisms and enzyme activity of low salt soybean paste (Doenjang) during fermentation. Food Eng. Prog. 2005, 9, 112–117. [Google Scholar]

- Rhee, C.H.; Kim, B.S.; Shin, M.K.; Woo, C.J.; Kim, J.H.; Kwon, K.Y.; Park, H.D. Changes in enzyme activity and physiological functionality of doenjang (soybean paste) prepared with extracts of Phellinus linteus. Korean J. Food Preserv. 2008, 15, 736–742. [Google Scholar]

- Jung, S.W.; Kwon, D.J.; Koo, M.S.; Kim, Y.S. Quality characteristics and acceptance for Doenjang prepared with rice. Appl. Biol. Chem. 1994, 37, 266–271. [Google Scholar]

- Park, W.P.; Kim, N.D.; Lee, S.C.; Kim, S.Y.; Cho, S.H. Effects of powder and concentrates of Prunus mume on the quality of Doenjang during fermentation. Korean J. Food Preserv. 2006, 13, 574–580. [Google Scholar]

- Kim, J.Y.; Lee, S.Y.; Park, N.Y.; Choi, H.S. Quality Characteristics of Black Soybean Paste (Daemaekjang) Prepared with Bacillus subtilis HJ18-4. Korean J. Food Sci. Technol. 2012, 44, 743–749. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Lee, M.; Lee, T. Compositions of sugars and fatty acids in soybean paste (doenjang) prepared with different microbial sources. J. Korean Soc. Food Nutr. 1995, 24, 917–924. [Google Scholar]

- Kim, J.S.; Lee, J.-H.; Chang, Y.-E.; Kim, S.; Kim, K.-M. The Quality Characteristics of Rice Mash by Mixing Ratios of Rice and Rice Koji. J. Korean Soc. Food Sci. Nutr. 2013, 42, 2035–2041. [Google Scholar] [CrossRef]

- Kim, H.; Hong, J.; Song, C.; Shin, H.; Kim, K. Sensory Characteristics and Consumer Acceptability of Fermented Soybean Paste (Doenjang). J. Food Sci. 2010, 75, S375–S383. [Google Scholar] [CrossRef] [PubMed]

| Sample Code | Bean (g) | Salt (g) | Koji (g) | Water (g) |

|---|---|---|---|---|

| K1 | 800 (40%) | 250 (12.5%) | 400 (20%) | 550 (27.5%) |

| K2 | 800 (40%) | 250 (12.5%) | 450 (22.5%) | 500 (25%) |

| K3 | 800 (40%) | 250 (12.5%) | 500 (25%) | 450 (22.5%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, Y.; Bang, W.-s.; Kim, M.K. Changes of Physiochemical and Enzymatic Activities of doenjang Prepared with Different Amount of Rice koji during 30 Days of Fermentation. Foods 2021, 10, 372. https://doi.org/10.3390/foods10020372

Jo Y, Bang W-s, Kim MK. Changes of Physiochemical and Enzymatic Activities of doenjang Prepared with Different Amount of Rice koji during 30 Days of Fermentation. Foods. 2021; 10(2):372. https://doi.org/10.3390/foods10020372

Chicago/Turabian StyleJo, Yongwoo, Woo-suk Bang, and Mina K. Kim. 2021. "Changes of Physiochemical and Enzymatic Activities of doenjang Prepared with Different Amount of Rice koji during 30 Days of Fermentation" Foods 10, no. 2: 372. https://doi.org/10.3390/foods10020372