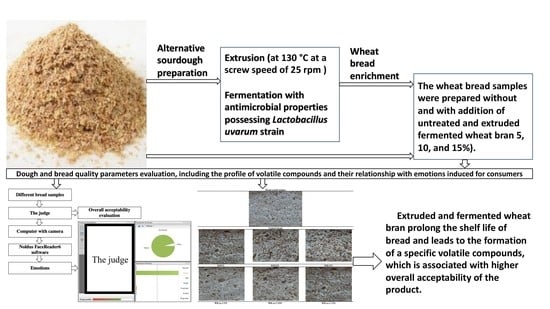

The Contribution of Extruded and Fermented Wheat Bran to the Quality Parameters of Wheat Bread, Including the Profile of Volatile Compounds and Their Relationship with Emotions Induced for Consumers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used for Bread Preparation

2.2. Bread Preparation

2.3. Evaluation of Bread Quality Parameters

2.4. Statistical Analysis

3. Results and Discussion

3.1. Influence of Non-Pre-Treated and Extruded/Fermented Wheat Bran on Dough Color Characteristics and Hardness

3.2. Influence of Non-Pre-Treated and Extruded/Fermented Wheat Bran on Bread Quality Parameters and Changes in Bread Firmness during Storage

3.3. Overall Acceptability and Emotions Induced for Consumers of Bread Prepared with Different Quantities of Untreated and Extruded/Fermented Wheat Bran

3.4. Volatile Compound Profile of Bread Prepared with Different Quantities of Untreated and Extruded/Fermented Wheat Bran

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bartkiene, E.; Juodeikiene, G.; Basinskiene, L.; Liukkonen, K.-H.; Adlercreutz, H.; Kluge, H. Enterolignans Enterolactone and Enterodiol Formation from Their Precursors by the Action of Intestinal Microflora and Their Relationship with Non-Starch Polysaccharides in Various Berries and Vegetables. LWT Food Sci. Technol. 2011, 44, 48–53. [Google Scholar] [CrossRef]

- Hemdane, S.; Jacobs, P.J.; Dornez, E.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Wheat (Triticum Aestivum L.) Bran in Bread Making: A Critical Review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 28–42. [Google Scholar] [CrossRef] [Green Version]

- Spaggiari, M.; Ricci, A.; Calani, L.; Bresciani, L.; Neviani, E.; Dall’Asta, C.; Lazzi, C.; Galaverna, G. Solid State Lactic Acid Fermentation: A Strategy to Improve Wheat Bran Functionality. LWT 2020, 118, 108668. [Google Scholar] [CrossRef]

- Verni, M.; Rizzello, C.G.; Coda, R. Fermentation Biotechnology Applied to Cereal Industry By-Products: Nutritional and Functional Insights. Front. Nutr. 2019, 6, 42. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roye, C.; Henrion, M.; Chanvrier, H.; De Roeck, K.; De Bondt, Y.; Liberloo, I.; King, R.; Courtin, C.M. Extrusion-Cooking Modifies Physicochemical and Nutrition-Related Properties of Wheat Bran. Foods 2020, 9, 738. [Google Scholar] [CrossRef]

- Bartkiene, E.; Zokaityte, E.; Lele, V.; Starkute, V.; Zavistanaviciute, P.; Klupsaite, D.; Cernauskas, D.; Ruzauskas, M.; Bartkevics, V.; Pugajeva, I.; et al. Combination of Extrusion and Fermentation with Lactobacillus Plantarum and L. Uvarum Strains for Improving the Safety Characteristics of Wheat Bran. Toxins 2021, 13, 163. [Google Scholar] [CrossRef] [PubMed]

- Zokaityte, E.; Lele, V.; Starkute, V.; Zavistanaviciute, P.; Klupsaite, D.; Bartkevics, V.; Pugajeva, I.; Bērziņa, Z.; Gruzauskas, R.; Sidlauskiene, S.; et al. The Influence of Combined Extrusion and Fermentation Processes on the Chemical and Biosafety Parameters of Wheat Bran. LWT 2021, 146, 111498. [Google Scholar] [CrossRef]

- Wang, W.-M.; Klopfenstein, C.; Ponte, J.G. Effects of Twin-Screw Extrusion on the Physical Properties of Dietary Fiber and Other Components of Whole Wheat and Wheat Bran and on the Baking Quality of the Wheat Bran. Cereal Chem. 1993, 70, 707–711. [Google Scholar]

- Gómez, M.; Jiménez, S.; Ruiz, E.; Oliete, B. Effect of Extruded Wheat Bran on Dough Rheology and Bread Quality. LWT Food Sci. Technol. 2011, 44, 2231–2237. [Google Scholar] [CrossRef]

- AACC Approved Methods of Analysis, 11th Edition—AACC Method 10-05.01. Guidelines for Measurement of Volume by Rapeseed Displacement. Available online: http://methods.aaccnet.org/summaries/10-05-01.aspx (accessed on 3 September 2021).

- Lithuanian Standard Board (LST). Bread and Bread Products. Porosity (LST 1442:(1996)); LST: Vilnius, Lithuania, 1996. [Google Scholar]

- Bartkiene, E.; Mockus, E.; Mozuriene, E.; Klementaviciute, J.; Monstaviciute, E.; Starkute, V.; Zavistanaviciute, P.; Zokaityte, E.; Cernauskas, D.; Klupsaite, D. The Evaluation of Dark Chocolate-Elicited Emotions and Their Relation with Physico Chemical Attributes of Chocolate. Foods 2021, 10, 642. [Google Scholar] [CrossRef]

- Ugarčić-Hardi, Ž.; Komlenić, D.; Jukić, M.; Kuleš, A.; Jurkin, I. Quality Properties of White Bread with Native and Extruded Wheat Bran Supplements. Czech J. Food Sci. 2009, 27, S285–S289. [Google Scholar]

- Ralet, M.-C.; Thibault, J.-F.; Della Valle, G. Influence of Extrusion-Cooking on the Physico-Chemical Properties of Wheat Bran. J. Cereal Sci. 1990, 11, 249–259. [Google Scholar] [CrossRef]

- Zhang, D.; Moore, W.R. Effect of Wheat Bran Particle Size on Dough Rheological Properties. J. Sci. Food Agric. 1997, 74, 490–496. [Google Scholar] [CrossRef]

- Sanz Penella, J.M.; Collar, C.; Haros, M. Effect of Wheat Bran and Enzyme Addition on Dough Functional Performance and Phytic Acid Levels in Bread. J. Cereal Sci. 2008, 48, 715–721. [Google Scholar] [CrossRef]

- Katina, K.; Juvonen, R.; Laitila, A.; Flander, L.; Nordlund, E.; Kariluoto, S.; Piironen, V.; Poutanen, K. Fermented Wheat Bran as a Functional Ingredient in Baking. Cereal Chem. 2012, 89, 126–134. [Google Scholar] [CrossRef]

- Coda, R.; Kärki, I.; Nordlund, E.; Heiniö, R.-L.; Poutanen, K.; Katina, K. Influence of Particle Size on Bioprocess Induced Changes on Technological Functionality of Wheat Bran. Food Microbiol. 2014, 37, 69–77. [Google Scholar] [CrossRef]

- Gobbetti, M.; Corsetti, A.; Rossi, J. Interaction between Lactic Acid Bacteria and Yeasts in Sour-Dough Using a Rheofermentometer. World J. Microbiol. Biotechnol. 1995, 11, 625–630. [Google Scholar] [CrossRef] [PubMed]

- Gan, Z.; Galliard, T.; Ellis, P.R.; Angold, R.E.; Vaughan, J.G. Effect of the Outer Bran Layers on the Loaf Volume of Wheat Bread. J. Cereal Sci. 1992, 15, 151–163. [Google Scholar] [CrossRef]

- Katina, K.; Laitila, A.; Juvonen, R.; Liukkonen, K.-H.; Kariluoto, S.; Piironen, V.; Landberg, R.; Åman, P.; Poutanen, K. Bran Fermentation as a Means to Enhance Technological Properties and Bioactivity of Rye. Food Microbiol. 2007, 24, 175–186. [Google Scholar] [CrossRef]

- Katina, K.; Salmenkallio-Marttila, M.; Partanen, R.; Forssell, P.; Autio, K. Effects of Sourdough and Enzymes on Staling of High-Fibre Wheat Bread. LWT Food Sci. Technol. 2006, 39, 479–491. [Google Scholar] [CrossRef]

- Danner, L.; Sidorkina, L.; Joechl, M.; Duerrschmid, K. Make a Face! Implicit and Explicit Measurement of Facial Expressions Elicited by Orange Juices Using Face Reading Technology. Food Qual. Prefer. 2014, 32, 167–172. [Google Scholar] [CrossRef]

- Hemdane, S.; Jacobs, P.J.; Bosmans, G.M.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Study on the Effects of Wheat Bran Incorporation on Water Mobility and Biopolymer Behavior during Bread Making and Storage Using Time-Domain 1H NMR Relaxometry. Food Chem. 2017, 236, 76–86. [Google Scholar] [CrossRef]

- Köster, E.P. Diversity in the Determinants of Food Choice: A Psychological Perspective. Food Qual. Prefer. 2009, 20, 70–82. [Google Scholar] [CrossRef]

| Bread Samples | Color Characteristics | Dough Hardness, mJ | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| Control | 95.1 ± 0.97 e | −1.31 ± 0.05 a | 21.49 ± 0.31 b | 0.2 a |

| Dough with untreated wheat bran | ||||

| WB5% | 88.3 ± 0.13 c | 1.14 ± 0.20 d | 20.81 ± 0.43 a | 0.2 a |

| WB10% | 84.3 ± 1.28 a | 2.55 ± 0.05 f | 20.20 ± 0.41 a | 0.3 b |

| WB15% | 79.1 ± 0.87 b | 3.63 ± 0.36 g | 20.80 ± 0.38 a | 0.4 c |

| Dough with extruded fermented wheat bran | ||||

| WB ex-f-5% | 91.5 ± 0.60 d | −0.06 ± 0.02 b | 21.90 ± 0.29 b | 0.2 a |

| WB ex-f-10% | 87.9 ± 1.97 c | 0.79 ± 0.12 c | 22.30 ± 0.42 b | 0.2 a |

| WB ex-f-15% | 82.9 ± 1.70 a | 1.88 ± 0.06 e | 22.75 ± 0.23 b,c | 0.2 a |

| Bread Samples | Specific Volume, cm3 g−1 | Porosity, % | Shape Coefficient | Mass Loss after Baking, % | ||

|---|---|---|---|---|---|---|

| Control | 2.72 ± 0.04 d | 68.3 ± 0.98 e | 2.48 ± 0.14 b | 8.83 ± 2.3 a | ||

| Wheat bread with untreated wheat bran | ||||||

| WB5% | 2.66 ± 0.02 c | 61.5 ± 1.2 c | 2.67 ± 0.15 c | 12.08 ± 1.28 b | ||

| WB10% | 2.39 ± 0.07 b | 56.5 ± 2.5 b | 2.40 ± 0.18 b | 11.75 ± 0.90 b | ||

| WB15% | 2.09 ± 0.03 a | 46.4 ± 1.1 a | 1.97 ± 0.07 a | 10.33 ± 0.52 b | ||

| Wheat bread with extruded fermented wheat bran | ||||||

| WB ex-f-5% | 2.78 ± 0.03 d | 68.5 ± 0.9 e | 2.48 ± 0.12 b | 15.00 ± 4.82 c | ||

| WB ex-f-10% | 2.80 ± 0.04 d | 69.3 ± 0.6 e | 2.48 ± 0.17 b | 16.33 ± 1.15 c,d | ||

| WB ex-f-15% | 2.76 ± 0.02 d | 65.6 ± 1.6 d | 2.43 ± 0.19 b | 14.75 ± 1.32 c | ||

| Bread samples | Color characteristics | |||||

| Crust | Crumb | |||||

| L* | a* | b* | L* | a* | b* | |

| Control | 53.14 ± 1.55 d | 12.97 ± 1.03 e | 26.44 ± 0.87 c | 80.14 ± 0.23 d | −1.14 ± 0.09 a | 24.13 ± 0.21 e |

| Wheat bread with untreated wheat bran | ||||||

| WB5% | 48.84 ± 2.90 b | 11.57 ± 0.21 d | 22.55 ± 2.27 a,b | 71.14 ± 0.02 c | 2.21 ± 0.07 d | 22.18 ± 0.21 c |

| WB10% | 43.33 ± 1.03 a | 11.73 ± 0.85 d | 20.33 ± 1.90 a | 67.96 ± 0.84 b | 3.39 ± 0.24 e | 20.69 ± 0.11 a |

| WB15% | 45.90 ± 2.99 a,b | 10.58 ± 0.24 c | 21.62 ± 2.36 a | 62.07 ± 1.24 a | 4.95 ± 0.37 f | 20.93 ± 0.30 a |

| Wheat bread with extruded fermented wheat bran | ||||||

| WB ex-f-5% | 50.08 ± 3.95 b,c | 9.33 ± 0.49 b | 22.55 ± 1.36 a,b | 70.86 ± 0.92 c | 0.64 ± 0.13 b | 22.81 ± 0.12 d |

| WB ex-f-10% | 52.75 ± 1.52 d | 8.72 ± 0.40 a | 23.29 ± 1.00 b | 66.24 ± 1.51 b | 1.69 ± 0.04 c | 22.23 ± 0.09 c |

| WB ex-f-15% | 48.25 ± 2.50 b | 8.25 ± 1.35 a | 19.85 ± 0.94 a | 62.84 ± 1.20 a | 2.34 ± 0.09 d | 21.40 ± 0.32 b |

| Bread crumb images | ||||||

| ||||||

| Control bread | ||||||

|  |  | ||||

| WB5% | WB10% | WB15% | ||||

|  |  | ||||

| WB ex-f-5% | WB ex-f-10% | WB ex-f-15% | ||||

| Bread Samples | Overall Acceptability | Emotions Induced by the Bread (From 0 to 1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Neutral | Happy | Sad | Angry | Surprised | Scared | Disgusted | Contempt | Valence | ||

| Control | 88.2 ± 10.1 a | 0.8431 ± 0.0045 d | 0.0248 ± 0.0019 a | 0.0056 ± 0.0004 b | 0.0117 ± 0.0011 b | 0.0005 ± 0.0002 a | 0.0002 ± 0.0001 a | 0.0004 ± 0.0001 a | 0.0032 ± 0.0003 b | 0.0576 ± 0.0042 f |

| WB5% | 105.3 ± 12.4 a | 0.8916 ± 0.0031 f | 0.0390 ± 0.0016 c | 0.0241 ± 0.0021 c | 0.0129 ± 0.0014 b | 0.0102 ± 0.0009 c | 0.0002 ± 0.0001 a | 0.0012 ± 0.0001 c | 0.0003 ± 0.0001 a | 0.0006 ± 0.0001 a |

| WB10% | 99.4 ± 8.6 a | 0.6980 ± 0.0063 a | 0.0270 ± 0.0019 b | 0.0203 ± 0.0014 c | 0.0730 ± 0.0023 d | 0.0020 ± 0.0001 b | 0.0002 ± 0.0001 a | 0.0008 ± 0.0001 b | 0.0050 ± 0.0004 c | 0.0430 ± 0.0036 e |

| WB15% | 95.2 ± 9.7 a | 0.8270 ± 0.0059 c | 0.0360 ± 0.0032 c | 0.0209 ± 0.0017 c | 0.0150 ± 0.0012 c | 0.0024 ± 0.0002 b | 0.0001 ± 0.0001 a | 0.0012 ± 0.0001 c | 0.0068 ± 0.0005 d | 0.0500 ± 0.0049 f |

| WB ex-f-5% | 131.6 ± 8.4 a | 0.9200 ± 0.0103 g | 0.0470 ± 0.0038 d | 0.0040 ± 0.0002 b | 0.0006 ± 0.0001 a | 0.0009 ± 0.0002 a | 0.0007 ± 0.0002 b | 0.0011 ± 0.0002 c | 0.0004 ± 0.0001 a | 0.0040 ± 0.0003 c |

| WB ex-f-10% | 130.4 ± 9.4 a | 0.8610 ± 0.0114 e | 0.0451 ± 0.0034 d | 0.0030 ± 0.0004 a | 0.0013 ± 0.0002 a | 0.0022 ± 0.0001 b | 0.0001 ± 0.0001 a | 0.0008 ± 0.0001 b | 0.0003 ± 0.0001 a | 0.0030 ± 0.0002 b |

| WB ex-f-15% | 132.9 ± 6.9 a | 0.7525 ± 0.0127 b | 0.0472 ± 0.0039 d | 0.0031 ± 0.0001 a | 0.0008 ± 0.0001 a | 0.0014 ± 0.0003 a | 0.0028 ± 0.0003 c | 0.0004 ± 0.0001 a | 0.0004 ± 0.0001 a | 0.0137 ± 0.0021 d |

| RT, min | Volatile Compounds | Bread Samples | r | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Control | WB5% | WB10% | WB15% | WB ex-f-5% | WB ex-f-10% | WB ex-f-15% | OA/VC | ‘H’/VC | ||

| 4.066 | Ethanol | 9.91 ± 0.32 a | 20.2 ± 1.3 e | 16.3 ± 0.4 d | 15.0 ± 0.5 c | 13.1 ± 0.9 b | 15.9 ± 0.3 d | 12.9 ± 1.1 b | 0.0402 | 0.1578 |

| 10.336 | 1-Butanol, 3-methyl- | 8.63 ± 0.41 a | 14.0 ± 0.2 e | 15.4 ± 0.5 f | 12.3 ± 0.1 c | 12.4 ± 0.2 c | 13.3 ± 0.4 d | 11.8 ± 0.2 b | 0.2410 | 0.1523 |

| 12.011 | Pyrazine, methyl- | 3.72 ± 0.21 c | 3.21 ± 0.17 b | 2.48 ± 0.19 a | 3.74 ± 0.23 c | 4.04 ± 0.12 d | 4.29 ± 0.17 d | 4.20 ± 0.15 d | 0.4876 | 0.6595 |

| 13.546 | Pyrazine, 2,6-dimethyl- | 1.72 ± 0.09 b | 1.02 ± 0.21 a | 1.35 ± 0.18 a | 1.51 ± 0.14 a,b | 2.03 ± 0.32 b,c | 1.56 ± 0.11 a,b | 1.84 ± 0.13 b | 0.3971 | 0.3338 |

| 13.88 | Pyrazine, 2-ethyl- | 3.63 ± 0.25 c,d | 2.49 ± 0.19 a | 2.77 ± 0.23 a,b | 3.51 ± 0.14 c | 4.08 ± 0.28 d | 3.39 ± 0.17 c | 3.43 ± 0.16 c | 0.2507 | 0.2877 |

| 14.004 | 1-Hexanol | 12.4 ± 0.1 e | 11.8 ± 0.2 d | 11.6 ± 0.3 d | 10.8 ± 0.10 c | 9.00 ± 0.11 b | 8.91 ± 0.07 b | 8.71 ± 0.05 a | −0.8314 | −0.8516 |

| 14.884 | Pyrazine, 2-ethyl-6-methyl- | 0.78 ± 0.05 a | 0.87 ± 0.04 a | 1.03 ± 0.05 b | 1.13 ± 0.08 b | 1.66 ± 0.18 d | 1.39 ± 0.11 c | 1.65 ± 0.21 d | 0.8159 | 0.8071 |

| 15.062 | Nonanal | 3.74 ± 0.08 d | 3.55 ± 0.09 c | 6.03 ± 0.25 e | 2.40 ± 0.13 b | 2.07 ± 0.09 a | 2.47 ± 0.18 b | 2.44 ± 0.15 b | −0.4331 | −0.7344 |

| 15.39 | Pyrazine, 2-ethyl-3-methyl- | 1.70 ± 0.08 b | 1.46 0.05 a | 1.60 ± 0.04 b | 1.79 ± 0.12 b,c | 2.46 ± 0.23 d | 1.82 ± 0.05 c | 2.07 ± 0.11 c,d | 0.6028 | 0.6020 |

| 16.54 | Formic acid, heptyl ester | 1.07 ± 0.04 f | 0.86 ± 0.04 d | 0.96 ± 0.02 e | 0.70 ± 0.05 c | 0.29 ± 0.03 a | 0.49 ± 0.05 b | 0.69 ± 0.03 c | −0.7211 | −0.8340 |

| 16.894 | Furfural | 7.87 ± 0.12 a | 8.39 ± 0.23 b | 10.1 ± 1.4 b | 13.3 ± 0.9 c | 16.0 ± 0.7 e | 14.8 ± 0.3 d | 14.7 ± 0.4 d | 0.7379 | 0.7770 |

| 17.116 | 2-Propanol, 1-(2-methoxy-1-methylethoxy)- | 1.65 ± 0.18 d | 1.07 ± 0.04 c | 1.12 ± 0.03 c | 0.97 ± 0.03 b | 0.91 ± 0.02 b | 1.15 ± 0.04 c | 0.78 ± 0.09 a | −0.6016 | −0.7147 |

| 17.836 | Ethanone, 1-(2-furanyl)- | 1.42 ± 0.04 a | 1.47 ± 0.08 a | 1.97 ± 0.07 b | 2.07 ± 0.10 b,c | 2.54 ± 0.11 d | 2.52 ± 0.14 d | 2.56 ± 0.12 d | 0.7890 | 0.7375 |

| 18.043 | 2-Propanol, 1-(2-methoxypropoxy)- | 2.29 ± 0.14 e | 1.48 ± 0.06 b | 1.74 ± 0.10 c | 1.73 ± 0.09 c | 1.51 ± 0.07 b | 1.96 ± 0.08 d | 1.15 ± 0.09 a | −0.4480 | −0.5199 |

| 18.31 | Benzaldehyde | 1.57 ± 0.11 a | 1.71 ± 0.04 a,b | 1.49 ± 0.09 a | 1.42 ± 0.07 a | 1.97 ± 0.02 c | 1.88 ± 0.06 b | 2.59 ± 0.14 d | 0.7087 | 0.6976 |

| 18.411 | 2-Nonenal, (E)- | 3.41 ± 0.21 e | 1.82 ± 0.03 c | 1.79 ± 0.04 b,c | 1.69 ± 0.03 b | 1.75 ± 0.06 b | 1.56 ± 0.02 a | 2.38 ± 0.11 d | −0.3672 | −0.4587 |

| 18.736 | 1-Octanol | 0.750.06 e | 0.57 ± 0.03 c,d | 0.59 ± 0.02 d | 0.49 ± 0.03 c | 0.24 ± 0.02 a | 0.34 ± 0.03 b | 0.42 ± 0.02 c | −0.8204 | −0.8799 |

| 19.387 | 2-Furancarboxaldehyde, 5-methyl- | 1.50 ± 0.04 a | 1.56 ± 0.03 a | 2.26 ± 0.12 b | 3.09 ± 0.15 c | 4.38 ± 0.10 e | 4.08 ± 0.11 d | 4.99 ± 0.17 f | 0.7952 | 0.7942 |

| 19.515 | Hexadecane | 0.74 ± 0.06 c | 0.58 ± 0.04 b | 0.37 ± 0.02 a | 0.43 a,b | 0.39 ± 0.03 a | 0.55 ± 0.04 b | 0.39 ± 0.02 a | −0.4945 | −0.4305 |

| 20.35 | Butanoic acid | 0.29 | nd | nd | nd | nd | nd | nd | −0.5373 | −0.6070 |

| 21.04 | 3-Furanmethanol | 8.78 ± 0.15 c,d | 8.64 ± 0.12 c | 8.04 ± 0.10 a | 8.35 ± 0.09 b | 11.42 ± 0.32 f | 8.89 ± 0.10 d | 9.53 ± 0.18 e | 0.5850 | 0.6154 |

| 21.438 | 3-Nonen-1-ol, (Z)- | 0.58 ± 0.02 c | 0.57± 0.04 c | 0.63 ± 0.03 d | 0.60 ± 0.04 d | 0.25 ± 0.03 a | 0.27 ± 0.04 a | 0.37 ± 0.03 b | −0.8235 | −0.8100 |

| 22.706 | D-Carvone | nd | 0.28 0.01 a | nd | 0.34 ± 0.03 b | nd | nd | nd | −0.4434 | −0.0528 |

| 23.554 | 3-Hydroxypyridine monoacetate | nd | nd | nd | nd | nd | nd | 0.85 ± 0.09 | 0.4405 | 0.4231 |

| 23.725 | Dec-(4Z)-en-1-ol | 0.35 ± 0.03 b | 0.28 ± 0.02 a | 0.80 ± 0.07 e | 0.45 ± 0.04c | nd | nd | 0.55 ± 0.03 d | −0.3827 | −0.5316 |

| 24.175 | 2,4-Decadienal, (E,E)- | 0.66 ± 0.03d | 0.36 ± 0.02 a | 0.93 ± 0.07 e | 0.54 ± 0.04 c | 0.43 ± 0.02 b | 0.44 0.03 b | 0.82 ± 0.06 e | −0.1232 | −0.4300 |

| 24.48 | 1H-Pyrrole, 1-(2-furanylmethyl)- | nd | nd | nd | 0.23 ± 0.03a | 0.33b | nd | 0.33± 0.05b | 0.4272 | 0.5704 |

| 24.64 | Hexanoic acid | 1.24 ± 0.11 b | 1.50 ± 0.14 c | 1.34 ± 0.18 b,c | 2.94 ± 0.23 e | 1.02 ± 0.14 a | 1.57 ± 0.11 c | 1.97 ± 0.15 d | −0.2091 | 0.0734 |

| 24.871 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 1.27 ± 0.02 b | nd | nd | 0.22 ± 0.01 a | 0.18 ± 0.03 a | 0.24 ± 0.02 a | nd | −0.5021 | −0.5366 |

| 25.101 | Propanoic acid, 2-methyl-, 3-hydroxy-2,4,4-trimethylpentyl ester | 1.95 ± 0.14 d | 1.43 ± 0.17 c | 0.90 ± 0.07 b | 1.01 ± 0.08 b | 0.50 ± 0.04 a | 0.97 ± 0.07 b | 0.52± 0.03 a | −0.7329 | −0.6900 |

| 25.54 | Propanoic acid, 2-methyl-, 2,2-dimethyl-1-(2-hydroxy-1-methylethyl)propyl ester | 1.72 ± 0.19 e | 1.44 ± 0.21 d | 0.97 ± 0.18 b,c | 0.99 ± 0.14 b,c | 0.47 ± 0.03 a | 0.78 ± 0.05 b | 0.53 ± 0.04 a | −0.7835 | −0.7364 |

| 26.051 | Phenethyl alcohol | 5.95 ± 0.41 e | 4.82 ± 0.34 d | 3.16 ± 0.11 c | 2.43 ± 0.19 a | 2.69 ± 0.18 b | 2.58 ± 0.21 a,b | 2.53 ± 0.14 a | −0.5360 | −0.4593 |

| 27.134 | Maltol | nd | nd | nd | 1.54 ± 0.13 a | 1.88 ± 0.9 b | 1.82 ± 0.07 b | 1.96 ± 0.11 b,c | 0.6769 | 0.7943 |

| 28.279 | 2(3H)-Furanone, dihydro-5-pentyl- | 0.56 ± 0.02 b | 0.85 ± 0.04 c | 1.13 0.05 d | 1.27 ± 0.09 d,e | nd | nd | 0.34 ± 0.03 a | −0.6956 | −0.6229 |

| 29.072 | p-Cresol | 3.30 ± 0.22 b | 0.65 ± 0.05 a | nd | nd | nd | nd | nd | −0.5728 | −0.6052 |

| 31.07 | Guaiacol, 4-vinyl- | nd | nd | 0.27 ± 0.03 a | 0.42 ± 0.05 b | nd | nd | nd | −0.4453 | −0.3814 |

| 34.912 | Indole | 3.11 ± 0.23 d | 1.18 ± 0.14 c | 0.86 ± 0.05 b | 0.60 ± 0.04 a | nd | nd | nd | −0.7501 | −0.7868 |

| 35.511 | 1H-Indole, 3-methyl- | 1.76 ± 0.28 | nd | nd | nd | nd | nd | nd | −0.5316 | −0.6052 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartkiene, E.; Jomantaite, I.; Mockus, E.; Ruibys, R.; Baltusnikiene, A.; Santini, A.; Zokaityte, E. The Contribution of Extruded and Fermented Wheat Bran to the Quality Parameters of Wheat Bread, Including the Profile of Volatile Compounds and Their Relationship with Emotions Induced for Consumers. Foods 2021, 10, 2501. https://doi.org/10.3390/foods10102501

Bartkiene E, Jomantaite I, Mockus E, Ruibys R, Baltusnikiene A, Santini A, Zokaityte E. The Contribution of Extruded and Fermented Wheat Bran to the Quality Parameters of Wheat Bread, Including the Profile of Volatile Compounds and Their Relationship with Emotions Induced for Consumers. Foods. 2021; 10(10):2501. https://doi.org/10.3390/foods10102501

Chicago/Turabian StyleBartkiene, Elena, Ieva Jomantaite, Ernestas Mockus, Romas Ruibys, Aldona Baltusnikiene, Antonello Santini, and Egle Zokaityte. 2021. "The Contribution of Extruded and Fermented Wheat Bran to the Quality Parameters of Wheat Bread, Including the Profile of Volatile Compounds and Their Relationship with Emotions Induced for Consumers" Foods 10, no. 10: 2501. https://doi.org/10.3390/foods10102501