1. Introduction

Kimchi is a well-known traditional Korean fermented food. In 2001, it was officially recognized as CODEX standard [

1], and kimchi cabbage was listed in CODEX standard as a synonym for Chinese cabbage and napa cabbage in 2012. Moreover, kimjang (making and sharing kimchi) was proudly listed in UNESCO’s list of the intangible cultural heritage of humanity in 2013 [

2]. Kimchi is commonly known to contain abundant nutrients and functional ingredients; and therefore, it exhibits various health benefits, including antioxidant [

3,

4,

5], anti-obesity [

6,

7,

8], anti-diabetic [

9,

10], and anti-cancer effects [

11,

12], among others.

Fermented cabbage inhibits the production of angiotensin-converting enzyme 2 (ACE 2), which is the binding site for coronavirus, aiding in its crossing of the cell membrane and therefore preventing COVID-19 [

13,

14]. Accordingly, interest in its health benefits is increasing worldwide, along with expectations for vegetable fermented food, including kimchi, sauerkraut, and suancai for the prevention of COVID-19. There is ongoing kimchi research focused on its health benefits. Kimchi supplemented with Jeju citrus concentrate shows anti-obesity effects in vitro and in vivo by reducing triglyceride levels and downregulating the expression of obesity-related genes [

7,

8]. In addition, the functionality of lactic acid bacteria (LAB) isolated from kimchi is analyzed extensively [

15,

16,

17].

Lactobacillus fermentum SMFM2017-NK4 isolated from kimchi exhibits an anti-obesity effect in mice by inhibiting fat accumulation [

16]. In addition to the research on the health functionality of kimchi, research on kimchi quality is important. However, there are only a few studies examining the quality of kimchi and comparing the quality of kimchi originating from different countries.

The demand for kimchi is increasing; therefore, it is either manufactured and exported from Korea or manufactured and sold in other countries [

18]. In particular, the production and consumption of kimchi is high in China, Japan, and the United States. In addition, kimchi exports to Hong Kong, Taiwan and Australia are increasing. However, kimchi research is mainly conducted in Korea and has largely focused on an analyses of quality based on fermentation properties [

19,

20,

21]. To date, there has been no report analyzing and comparing the quality characteristics of kimchi produced in different countries. Additionally, the relationship between the origin of kimchi and its quality remains controversial. Interestingly, Lee et al. identified 23 proteins that were differentially expressed between Korean and Chinese kimchi, using proteomic analysis, suggesting a difference in kimchi properties based on geographic origin [

22]. Therefore, a comparison of the quality of kimchi originating from different countries is required.

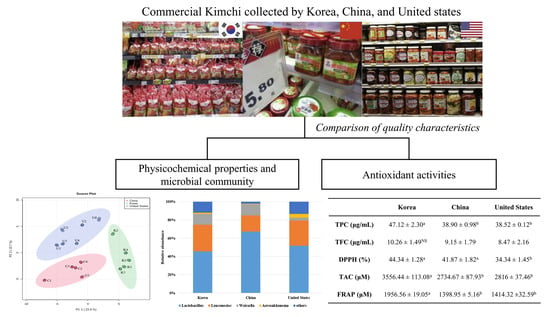

In this study, we compared commercial kimchi manufactured in Korea, China, and the United States for their mineral composition, free sugar, organic acid, free amino acid, and volatile compound contents. We determined their bacterial community composition. In addition, antioxidant activity levels were investigated.

2. Materials and Methods

2.1. Materials

All reagents were obtained from Sigma Aldrich (St. Louis, MO, USA). A total antioxidant capacity (TAC) assay kit was also obtained from Sigma Aldrich (MAK187). Ferric reducing antioxidant power (FRAP) colorimetric detection kit was obtained from Arbor Assays (K043-H1, Ahn Arbor, MI, USA).

2.2. Commercial Kimchi Sample Collection

To compare the quality characteristics, the United States, China, and Japan were initially considered as suitable sources, based on the import and export status of kimchi and the local market. However, Japan was excluded owing to a local situation. Information on commercial kimchi collected from Korea, China, and the United States is presented in

Supplementary Table S1.

In Korea, China, and the United States, 5–6 pieces of each commercial kimchi product were selected based on the volume and location of the producer, because we wanted to ensure the reliability of the sample by choosing producers from various locations rather than focusing on a specific region. There are numerous kimchi producers in Korea, China, and the United States; however, 5–6 companies in each country occupy more than 60% of the kimchi market share. We agree that the number of samples used in study is small; however, producers in various locations with a high market share in each country were selected. We believe that this is sufficiently representative. We selected producers from Oregon, Santa Rosa, LA, and NY in the US; from Beijing, Shanghai, and Qingdao in China’ and from Gangwon-do, Chungcheong-do, and Jeolla-do in Korea. Korean traditional kimchi, which is not sterilized and is naturally fermented, was directly purchased from a local store with a similar manufacturing date and used as an analysis sample. The most common kimchi is fusion-style kimchi that combines locally produced vegetables and red pepper sauce with the traditional Korean kimchi fermentation method. The samples from different countries varied with respect to the packaging type and ingredients. In the United States, most commercial kimchi products are packaged in 300–400 g glass bottles for the local market, whereas 1–1.4 kg plastic containers are used for Korean or large discount stores. Few ingredients in addition to the kimchi cabbage and seasoning are used; and special ingredients, additives, and fish sauce are rarely used. Commercial kimchi in Korea and China shows similar ingredients and packaging characteristics; however, additives (such as potassium sorbate, colorant, sodium l-glutamate (including nucleic acids), alcohol, and sodium dehydroacetate) were more frequently used in China than in Korea. In Korea, kimchi cabbage, seasoning, various fish sauces, and umami ingredients are commonly used, in addition to LAB starters including Leuconostoc mesenteroide and Leuconostoc citreum. Commercial kimchi samples manufactured in Korea, China, and the United States were used in the experiment when pH reached a ripening point of pH 3.8−4.1. Each kimchi sample manufactured in Korea, China, and the United States was homogenated. Data are expressed as mean ± standard deviation (SD) for each country.

2.3. Salinity and Capsaicinoid Contents Analysis

Kimchi juice was prepared by blending all of the kimchi samples. Kimchi juice was diluted with 0.9% saline solution (HAPS DW-9, HUKO FS Co., Ltd., Seoul, Korea) and filtered. Initially, 1 mL of 2% potassium chromate was added and titrated against 0.02 N AgNO3 until reaching a red-brown color. The capsaicinoid content of kimchi was analyzed using high-performance liquid chromatography (HPLC). The sample was diluted, filtered with filter paper, and evaluated using an HPLC analyzer (Agilent Technologies, Santa Clara, CA, USA) coupled with a fluorescence detector (Agilent Technologies). Excitation and emission wavelengths were 208 and 325 nm, respectively. Capsaicinoid contents were calculated from the peak sizes for capsaicin and dihydrocapsaicin chromatograms.

2.4. Mineral Contents Analysis

Mineral contents were examined. Kimchi samples were placed in a furnace at 600 °C for 12 h and subsequently cooled. Samples were reacted with 6 M HCl for 15 h and filtered. Then, 100 μL of the mixture was diluted with 3 mL distilled water and fed into inductively coupled plasma mass-spectrophotometry (ICP-MS, Model # 7500a; Agilent Technology, Palo Alto, CA, USA) to measure the mineral composition.

2.5. Free Sugar Contents Analysis

The free sugar contents of kimchi were measured using HPLC. The sample was diluted, filtered with 0.22 μm filter paper, and evaluated using an HPLC analyzer (Dionex Ultimate3000 attached to Sugar-pak for free sugar; Thermo Dionex, Waltham, MA, USA). To assess free sugars, the mobile phase was eluted with a 100% H2O solution (temperature 70 °C, flow rate 0.5 mL/min, Shodex RI-101 detector, 210 nm, and injection volume 10 μL). Free sugar contents were calculated from the chromatogram.

2.6. Organic Acid Contents Analysis

Organic acid contents in kimchi samples were measured using HPLC. The blended kimchi was diluted, filtered with 0.22 μm filter paper, and evaluated using an HPLC analyzer (Aminex 87H for organic acid; Thermo Dionex, Waltham, MA, USA). The mobile phase was eluted with 0.01 N H2SO4 solution (flow rate 0.5 mL/min, RI detector, 210 nm, and injection volume 10 μL). Organic acid contents were calculated from the chromatogram.

2.7. Free Amino Acid Contents Analysis

Kimchi samples were diluted, homogenized, and refrigerated for 15 h. After filtration with a 0.45 µm membrane filter, the sample solution was analyzed using HPLC (Ultimate 3000; Thermo Dionex) equipped with a VDSpher 100 C18-E column (4.6 × 150 mm, 3.5 µm; VDS optilab, Berlin, Germany) and a Detector (FL Detector 1260 FLD) in an oven at 40 °C. The content of each free amino acid was determined based on the values for the amino acid standards (Agilent Technologies).

2.8. Volatile Compounds Analysis

Volatile compound analysis was performed as described previously [

23]. Volatile compounds were analyzed using gas chromatography–mass spectrometer (GC-MS 7890A; Agilent Technologies) equipped with a DB-WAX column (60 m × 0.25 mm × 0.25 µM) and an autosampler (Multi-Purpose Sample with DHS option, MPS, Gerstel, Germany); the samples were initially extracted using solid-phase microextraction (SPME) fibers (DVB/CAR/PDMS, 50/30 µM, Supelco-57329-U), and absorbed onto polydimethylsiloxane (PDMS) fibers at 100 rpm for 30 min at 50 °C. The SPME fibers (DVB/CAR/PDMS, 50/30 µM, Supelco-57329-U), which extracted the volatile compounds, were automatically injected into a GC-MS injection port, and the volatile compounds were thermally desorbed at 250 °C for 3 min and analyzed using GC-MS with a constant helium flow rate of 1 mL/min. The temperature programs were as follows: 40 °C for 3 min, 2 °C/min up to 150 °C, 150 °C for 10 min, 4 °C/min up to 200 °C, and a final hold at 200 °C for 10 min. Electron impact ionization (70 eV) was performed at a full scan range of 50–550 m/z. Each volatile compound was identified based on a mass spectral library (WILEY 10N). The amounts of the identified volatile compounds were measured from the peak areas of the GC/MS chromatograms for each sample, using the internal standard method and presented as μg/g.

2.9. Microbial Community Analysis

Microbial community analysis was performed according to the method proposed by a previous study [

24]. Extracted total DNA from the kimchi samples was subjected to a PCR cycle using primers specific for the 16S V4 gene. Sequencing was conducted using the Mi-Seq™ platform (Illumina, San Diego, CA, USA) by Macrogen (Macrogen Inc., Seoul, Korea). After eliminating sequencing errors, as well as ambiguous and chimeric sequences, CD-HIT-OTU (operational taxonomic unit) was used to calculate the species-level OTUs using a similarity threshold of 97%. Additionally, representative sequences of each OTU were analyzed using UCLUST (v.1.2.22) in the reference database (SIVA DB) to generate taxonomic assignments based on homology. Microbial communities were analyzed using Ribosomal Database Project (RDP) classifiers in QIIME (v.1.8.0).

2.10. Antioxidant Activity Analysis

To analyze the antioxidant activity of all samples, the total phenol content (TPC), total flavonoid content (TFC), DPPH radical scavenging activity, TAC, and FRAP were measured. TPC was measured using the Folin-Ciocalteu method at 700 nm with a standard curve of gallic acid [

25]. TFC was measured at 415 nm with a standard curve of quercetin as described by Chang et al. [

26] DPPH radical scavenging activity was measured at 515 nm following the method described by Blois [

27]. TAC and FRAP were measured using a commercial kit at 570 nm and 560 nm with a standard curve of Trolox. Fe (II), respectively.

2.11. Statistical Analysis

Data are presented as mean ± SD. Statistical significance was analyzed by one-way analysis of variance followed by Duncan’s multiple range test using GraphPad Prism 7 (GraphPad, Inc., San Diego, CA, USA). p < 0.05 was considered statistically significant.

4. Conclusions

We evaluated commercial kimchi manufactured in Korea, China, and the United States for a comprehensive comparison of quality characteristics. Korean commercial kimchi had a relatively low salinity and capsaicinoid content, high mineral and free sugar contents, a low organic acid content, and an extremely high free amino acid content. In addition, the volatile compounds and microbial community composition of Korean commercial kimchi differed to that of the kimchi from China and the United States. Furthermore, Korean commercial kimchi had the highest levels of antioxidant activity. Consequently, commercial kimchi manufactured in Korea shows high-quality characteristics and antioxidant activity.