Monitoring the Effects of Hemicellulase on the Different Proofing Stages of Wheat Aleurone-Rich Bread Dough and Bread Quality

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bread Baking and Dough Preparation

2.3. Quality Evaluation of the Baking Bread

2.4. Rheological Properties of Dough

2.5. Gluten Quality Measurements

2.6. Quantification of the Free Sulfhydryl and Disulfide Bond in Dough

2.7. Determination of Non-Covalent Bonds in Dough

2.8. Sodium Dodecyl Sulphate-Polyacrylamide Gel Electrophoresis (SDS-PAGE) Analysis

2.9. Determination of Molecular Weight and Distribution of Gliadins

2.10. Determination of the Secondary Structures of Gluten

2.11. Statistical Analysis

3. Results and Discussion

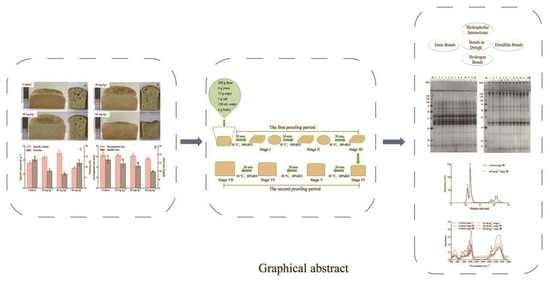

3.1. Effect of Hemicellulase Addition on Bread Quality

3.2. Effect of Hemicellulase Addition on Farinograph Properties of Dough

3.3. Effect of Hemicellulase Addition on Extensograph Properties of Dough

3.4. Effect of Hemicellulase on Content of Wet Gluten and Gluten Index during Dough Proofing

3.5. Effect of Hemicellulase on the Content of Free Sulfhydryl and Disulfide Bond during Dough Proofing

3.6. Effect of Hemicellulase on the Content of Non-Covalent Bonds during Dough Proofing

3.7. SDS-PAGE Profiles of Gluten

3.8. Molecular Weight and Distribution of Gliadins

3.9. Secondary Structure of Gluten

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kissock, K.R.; Neale, E.P.; Beck, E.J. The relevance of whole grain food definitions in estimation of whole grain intake: A secondary analysis of the National Nutrition and Physical Activity Survey 2011–2012. Public Health Nutr. 2020, 23, 1307–1319. [Google Scholar] [CrossRef]

- Seal, C.J.; Courtin, C.M.; Venema, K.; Vries, J.D. Health benefits of whole grain: Effects on dietary carbohydrate quality, the gut microbiome, and consequences of processing. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2742–2768. [Google Scholar] [CrossRef]

- Gómez, M.; Gutkoski, L.C.; Bravo-Núñez, Á. Understanding whole-wheat flour and its effect in breads: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3241–3265. [Google Scholar] [CrossRef]

- Hazard, B.; Trafford, K.; Lovegrove, A.; Griffiths, S.; Shewry, P. Strategies to improve wheat for human health. Nat. Food 2020, 1, 475–480. [Google Scholar] [CrossRef]

- Korczak, R.; Slavin, J.L. Definitions, regulations, and new frontiers for dietary fiber and whole grains. Nutr. Rev. 2020, 78, 6–12. [Google Scholar] [CrossRef] [PubMed]

- Barrett, E.M.; Batterham, M.J.; Ray, S.; Beck, E.J. Whole grain, bran and cereal fibre consumption and CVD: A systematic review. Br. J. Nutr. 2019, 121, 914–937. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.W.; Zha, B.P.; Wang, L.; Wang, R.; Chen, Z.X.; Tian, Y.N. Dissociation of aleurone cell cluster from wheat bran by centrifugal impact milling. Food Res. Int. 2013, 54, 63–71. [Google Scholar] [CrossRef]

- Meziani, S.; Nadaud, I.; Tasleem-Tahir, A.; Nurit, E.; Benguella, R.; Branlard, G. Wheat aleurone layer: A site enriched with nutrients and bioactive molecules with potential nutritional opportunities for breeding. J. Cereal Sci. 2021, 100, 103225. [Google Scholar] [CrossRef]

- Antoine, C.; Peyron, S.; Mabille, F.; Lapierre, C.; Bouchet, B.; Abecassis, J.; Rouau, X. Individual contribution of grain outer layers and their cell wall structure to the mechanical properties of wheat bran. J. Agric. Food Chem. 2003, 51, 2026–2033. [Google Scholar] [CrossRef] [PubMed]

- Moore, K.L.; Zhao, F.J.; Gritsch, C.S.; Tosi, P.; Hawkesford, M.J.; Mcgrath, S.P.; Shewry, P.R.; Grovenor, C.R.M. Localisation of iron in wheat grain using high resolution secondary ion mass spectrometry. J. Cereal Sci. 2012, 55, 183–187. [Google Scholar] [CrossRef]

- Saulnier, L.; Sado, P.E.; Branlard, G.; Charmet, G.; Guillon, F. Wheat arabinoxylans: Exploiting variation in amount and composition to develop enhanced varieties. J. Cereal Sci. 2007, 46, 261–281. [Google Scholar] [CrossRef]

- Chen, Z.W.; Xia, Q.; Zha, B.P.; Sun, J.; Xu, B. Triboelectric separation of wheat bran tissues: Influence of tribo-material, water content, and particle size. J. Food Process Eng. 2020, 43, e13346. [Google Scholar] [CrossRef]

- Atwell, B.; Reding, W.V.; Earling, J.; Kanter, M.; Snow, K. Aleurone: Processing, nutrition, product development, and marketing. In Whole Grains Health; Marquart, L., Jacobs, D.R., Eds.; Blackwell Publishing: Oxford, UK, 2007; Chapter 10; pp. 123–136. [Google Scholar]

- Bucsella, B.; Molnár, D.; Harasztos, A.H.; Tömösközi, S. Comparison of the rheological and end-product properties of an industrial aleurone-rich wheat flour, whole grain wheat and rye flour. J. Cereal Sci. 2016, 69, 40–48. [Google Scholar] [CrossRef]

- Dekker, R.F.; Richards, G.N. Hemicellulases: Their occurrence, purification, properties, and mode of action. Adv. Carbohydr. Chem. Biochem. 1976, 32, 277–352. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, P. Lignocellulosic Biomass in Biotechnology; Susan Dennis: New Delhi, India, 2021; pp. 53–64. [Google Scholar]

- Liu, L.; Sun, Y.; Yue, Y.; Yang, J.; Chen, L.; Ashraf, J.; Wang, L.; Zhou, S.; Tong, L. Composition and foam properties of whole wheat dough liquor as affected by xylanase and glucose oxidase. Food Hydrocoll. 2020, 108, 106050. [Google Scholar] [CrossRef]

- Janssen, F.; Wouters, A.G.B.; Meeus, Y.; Moldenaers, P.; Vermant, J.; Delcour, J.A. The role of non-starch polysaccharides in determining the air-water interfacial properties of wheat, rye, and oat dough liquor constituents. Food Hydrocoll. 2020, 105, 105771. [Google Scholar] [CrossRef]

- Hille, J.D.R.; Schooneveld-Bergmans, M.E.F. Hemicellulases and their synergism in breadmaking. Cereal Foods World 2005, 49, 283–286. [Google Scholar] [CrossRef]

- Altınel, B.; Ünal, S.S. The effects of amyloglucosidase, glucose oxidase and hemicellulase utilization on the rheological behaviour of dough and quality characteristics of bread. Int. J. Food Eng. 2017, 13, 1. [Google Scholar] [CrossRef]

- Matsushita, K.; Tamura, A.; Goshima, D.; Santiago, D.M.; Yamauchi, H. Effect of combining additional bakery enzymes and high pressure treatment on bread making qualities. J. Food Sci. Technol. 2020, 57, 134–142. [Google Scholar] [CrossRef]

- Altınel, B.; Ünal, S.S. The effects of certain enzymes on the rheology of dough and the quality characteristics of bread prepared from wheat meal. J. Food Sci. Technol. 2017, 54, 1628–1637. [Google Scholar] [CrossRef] [Green Version]

- Hemery, Y.; Lullien-Pellerin, V.; Rouau, X.; Abecassis, J.; Samson, M.F.; Åman, P.; Reding, W.V.; Spoerndli, C.; Barron, C. Biochemical markers: Efficient tools for the assessment of wheat grain tissue proportions in milling fractions. J. Cereal Sci. 2009, 49, 55–64. [Google Scholar] [CrossRef]

- T/HBFIA 0011-2020, High Fiber Aleurone Layer Wheat Flour. Available online: http://www.ttbz.org.cn/StandardManage/Detail/42456/ (accessed on 30 June 2021).

- Yegin, S.; Altinel, B.; Tuluk, K. A novel extremophilic xylanase produced on wheat bran from Aureobasidium pullulans NRRL Y-2311-1: Effects on dough rheology and bread quality. Food Hydrocoll. 2018, 81, 389–397. [Google Scholar] [CrossRef]

- GB/T 35869-2018, Bread Baking Test of Wheat Flour-Straight Dough Method. Available online: http://std.samr.gov.cn/gb/search/gbDetailed?id=71F772D82CA5D3A7E05397BE0A0AB82A (accessed on 30 June 2021).

- AACC International Methods Approved Methods of Analysis; Method no. 10-05.01; The American Association of Cereal Chemists International: St. Paul, MN, USA, 2001.

- Park, E.Y.; Fuerst, E.P.; Baik, B. Effect of bran hydration with enzymes on functional properties of flour–bran blends. Cereal Chem. 2019, 96, 273–282. [Google Scholar] [CrossRef]

- AACC International Methods Approved Methods of Analysis; Method no. 54-21.02; The American Association of Cereal Chemists International: St. Paul, MN, USA, 1999.

- AACC International Methods Approved Methods of Analysis; Method no. 54-10.01; The American Association of Cereal Chemists International: St. Paul, MN, USA, 1999.

- AACC International Methods Approved Methods of Analysis; Method no. 38-12A; The American Association of Cereal Chemists International: St. Paul, MN, USA, 2000.

- Chan, K.Y.; Wasserman, B.P. Direct colorimetric assay of free thiol groups and disulfide bonds in suspensions of solubilized and particulate cereal proteins. Cereal Chem. 1993, 70, 22–26. [Google Scholar] [CrossRef]

- Yao, Y.Y.; Jia, Y.Y.; Lu, X.R.; Li, H.J. Release and conformational changes in allergenic proteins from wheat gluten induced by high hydrostatic pressure. Food Chem. 2021, 368, 130805. [Google Scholar] [CrossRef]

- Wang, K.Q.; Luo, S.Z.; Zhong, X.Y.; Jing, C.; Zheng, Z. Changes in chemical interactions and protein conformation during heat-induced wheat gluten gel formation. Food Chem. 2017, 214, 393–399. [Google Scholar] [CrossRef]

- Wang, P.; Chen, H.; Mohanad, B.; Xu, L.; Ning, Y.; Xu, J.; Wu, F.; Yang, N.; Jin, Z.; Xu, X. Effect of frozen storage on physico-chemistry of wheat gluten proteins: Studies on gluten-, glutenin- and gliadin-rich fractions. Food Hydrocoll. 2014, 39, 187–194. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Zhao, J.; Mu, M.; Wang, J. Aggregative and structural properties of wheat gluten induced by pectin. J. Cereal Sci. 2021, 100, 103247. [Google Scholar] [CrossRef]

- Oliveira, D.S.; Telis-Romero, J.; Da-Silva, R.; Franco, C.M. Effect of a Thermoascus aurantiacus thermostable enzyme cocktail on wheat bread quality. Food Chem. 2014, 143, 139–146. [Google Scholar] [CrossRef]

- Ghoshal, G.; Shivhare, U.S.; Banerjee, U.C. Effect of xylanase on quality attributes of whole-wheat bread. J. Food Qual. 2013, 36, 172–180. [Google Scholar] [CrossRef]

- Fanari, F.; Carboni, G.; Grosso, M.; Desogus, F. Thermal Properties of Semolina Doughs with Different Relative Amount of Ingredients. Sustainability 2020, 12, 2235. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, Z.; Butt, M.S.; Ahmed, A.; Khalid, N. Xylanolytic modification in wheat flour and its effect on dough rheological characteristics and bread quality attributes. J. Korean Soc. Appl. Biol. Chem. 2013, 56, 723–729. [Google Scholar] [CrossRef]

- Hardt, N.A.; Boom, R.M.; Van der Goot, A.J. Wheat dough rheology at low water contents and the influence of xylanases. Food Res. Int. 2014, 66, 478–484. [Google Scholar] [CrossRef]

- Nishitsuji, Y.; Whitney, K.; Nakamura, K.; Hayakawa, K.; Simsek, S. Changes in structure and solubility of wheat arabinoxylan during the breadmaking process. Food Hydrocoll. 2020, 109, 106129. [Google Scholar] [CrossRef]

- Khalid, K.H.; Ohm, J.B.; Simsek, S. Whole wheat bread: Effect of bran fractions on dough and end-product quality. J. Cereal Sci. 2017, 78, 48–56. [Google Scholar] [CrossRef]

- Ma, F.M.; Dang, Y.L.; Xu, S.Y. Interaction between gluten proteins and their mixtures with water-extractable arabinoxylan of wheat by rheological, molecular anisotropy and CP/MAS13C NMR measurements. Eur. Food Res. Technol. 2016, 242, 1177–1185. [Google Scholar] [CrossRef]

- Jiang, Z.J.; Liu, L.Y.; Yang, W.; Ding, L.; Awais, M.; Wang, L.; Zhou, S.M. Improving the physicochemical properties of whole wheat model dough by modifying the water-unextractable solids. Food Chem. 2018, 259, 18–24. [Google Scholar] [CrossRef]

- Tatsuya, N.; Kazumasa, T.; Hiroaki, Y.; Koki, M.; Dennis Marvin, S.; Sakura, K. The bread making qualities of bread dough supplemented with whole wheat flour and treated with enzymes. Food Sci. Technol. Res. 2017, 23, 403–410. [Google Scholar] [CrossRef] [Green Version]

- Nawrocka, A.; Szymańska-Chargot, M.; Miś, A.; Wilczewska, A.Z.; Markiewicz, K.H. Dietary fiber-induced changes in the structure and thermal properties of gluten proteins studied by fourier transform-raman spectroscopy and thermogravimetry. J. Agric. Food Chem. 2016, 64, 2094–2104. [Google Scholar] [CrossRef]

- Liu, L.Y.; Yang, W.; Cui, S.W.; Jiang, Z.J.; Chen, Q.; Qian, H.F.; Wang, L.; Zhou, S.M. Effects of pentosanase and glucose oxidase on the composition, rheology, and microstructure of whole wheat dough. Food Hydrocoll. 2018, 8, 545–551. [Google Scholar] [CrossRef]

- Alpers, T.; Tauscher, V.; Steglich, T.; Becker, T.; Jekle, M. The self-enforcing starch-gluten system-strain-dependent effects of yeast metabolites on the polymeric matrix. Polymers 2020, 13, 30. [Google Scholar] [CrossRef] [PubMed]

- Kotsiou, K.; Sacharidis, D.; Matsakidou, A.; Biliaderis, C.G.; Lazaridou, A. Impact of Roasted Yellow Split Pea Flour on Dough Rheology and Quality of Fortified Wheat Breads. Foods 2021, 10, 1832. [Google Scholar] [CrossRef] [PubMed]

| Dosage of Enzyme Added (mg kg−1) | Farinograph Parameters | |||

|---|---|---|---|---|

| WA (%) | DDT (min) | ST (min) | DS (UF) | |

| Control | 67.47 ± 0.25 a | 6.26 ± 0.35 b | 12.70 ± 0.8 c | 35.33 ± 2.08 a |

| 20 mg kg−1 | 67.73 ± 0.21 a | 6.17 ± 0.11 b | 11.76 ± 0.79 bc | 37.00 ± 2.65 ab |

| 40 mg kg−1 | 67.57 ± 0.15 a | 6.15 ± 0.24 b | 11.23 ± 0.53 ab | 40.00 ± 1.73 b |

| 60 mg kg−1 | 67.27 ± 0.32 a | 5.58 ± 0.13 a | 9.88 ± 0.07 a | 45.00 ± 2.65 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, B.; Zhou, C.; Li, D.; Pei, J.; Guo, A.; Liu, S.; Li, H. Monitoring the Effects of Hemicellulase on the Different Proofing Stages of Wheat Aleurone-Rich Bread Dough and Bread Quality. Foods 2021, 10, 2427. https://doi.org/10.3390/foods10102427

Tian B, Zhou C, Li D, Pei J, Guo A, Liu S, Li H. Monitoring the Effects of Hemicellulase on the Different Proofing Stages of Wheat Aleurone-Rich Bread Dough and Bread Quality. Foods. 2021; 10(10):2427. https://doi.org/10.3390/foods10102427

Chicago/Turabian StyleTian, Boyu, Chenxia Zhou, Dongxiao Li, Jiawei Pei, Ailiang Guo, Shuang Liu, and Huijing Li. 2021. "Monitoring the Effects of Hemicellulase on the Different Proofing Stages of Wheat Aleurone-Rich Bread Dough and Bread Quality" Foods 10, no. 10: 2427. https://doi.org/10.3390/foods10102427