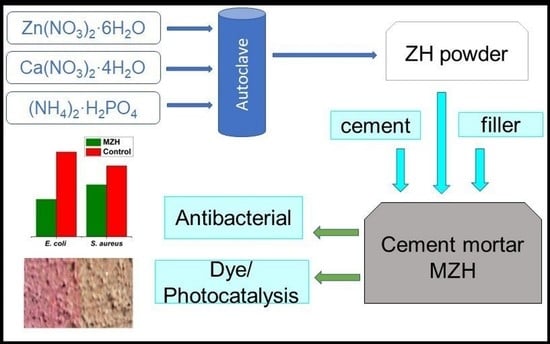

Self-Cleaning and Antibacterial Properties of the Cement Mortar with ZnO/Hydroxyapatite Powders

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Zinc Oxide/Hydroxyapatite Powder (ZH)

3.1.1. X-ray Diffraction (XRD) of ZH Powder

3.1.2. Scanning Electron Microscopy (SEM) of ZH Powder

3.1.3. Adsorption–Desorption Isotherms of ZH Particles

3.2. Cement Mortar Acquisition and Characterization

3.2.1. Self-Cleaning Properties

3.2.2. Antibacterial Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Geng, Z.; Xin, M.; Zhu, X.; Xu, H.; Cheng, X.; Wang, D. A review: A new method for preparing photocatalytic cement-based materials and the investigation on properties and mechanism. J. Build. Eng. 2021, 35, 102080. [Google Scholar] [CrossRef]

- Guo, M.Z.; Maury-Ramirez, A.; Chi, S.P. Photocatalytic activities of titanium dioxide incorporated architectural mortars: Effects of weathering and activation light. Build Environ. 2015, 94, 395–402. [Google Scholar] [CrossRef]

- Goffredo, G.B.; Accoroni, S.; Totti, C. Titanium dioxide-based nano-treatments to inhibit microalgal fouling on building stone surfaces. Build Environ. 2017, 112, 209–222. [Google Scholar] [CrossRef]

- Folli, A.; Pade, C.; Hansen, T.B. TiO2 photocatalysis in cementitious systems: Insights into self-cleaning and depollution chemistry. Cem. Concr. Res. 2012, 42, 539–548. [Google Scholar] [CrossRef]

- Mejía-de Gutiérrez, R.; Villaquirán-Caicedo, M.; Ramírez-Benavides, S.; Astudillo, M.; Mejía, D. Evaluation of the antibacterial activity of a geopolymer mortar based on metakaolin supplemented with TiO2 and CuO particles using glass waste as fine aggregate. Coatings 2020, 10, 157. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Review. Geopolymer, green alkali activated cementitious material: Synthesis, applications and challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- Mondragón-Figueroa, M.; Guzmán-Carrillo, H.; Rico, M.A.; Reyez-Araiza, J.L.; Pineda-Piñón, J.; López-Naranjo, E.J.; Columba-Palomares, M.C.; López-Romero, J.M.; Gasca-Tirado, J.R.; Manzano-Ramírez, A. Development of a construction material for indoor and outdoor, metakaolinite-based geopolymer, with environmental properties. J. Mater. Sci. Eng. A 2019, 9, 131–142. [Google Scholar] [CrossRef] [Green Version]

- Oltulu, M.; Şahin, R. Effect of nano-SiO2, nano-Al2O3 and nano-Fe2O3 powders on compressive strengths and capillary water absorption of cement mortar containing fly ash: A comparative study. Energ. Build. 2013, 58, 292–301. [Google Scholar] [CrossRef]

- Kumar, M.; Bansal, M.; Garg, R. An overview of beneficiary aspects of zinc oxide nanoparticles on performance of cement composites. Mater. Today Proc. 2021, 43, 892–898. [Google Scholar] [CrossRef]

- Voicu, G.; Tiuca, G.A.; Badanoiu, A.I.; Holban, A.M. Nano and mesoscopic SiO2 and ZnO powders to modulate hydration, hardening and antibacterial properties of Portland cements. J. Build. Eng. 2022, 57, 104862. [Google Scholar] [CrossRef]

- Jo, B.W.; Kim, C.H.; Tae, C.; Park, J.B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Sikora, P.; Augustyniak, A.; Cendrowski, K.; Nawrotek, P.; Mijowska, E. Antimicrobial activity of Al2O3, CuO, Fe3O4, and ZnO nanoparticles in scope of their further application in cement-based building materials. Nanomaterials 2018, 8, 212. [Google Scholar] [CrossRef] [Green Version]

- Klapiszewska, I.; Parus, A.; Ławniczak, Ł.; Jesionowski, T.; Klapiszewski, Ł.; Ślosarczyk, A. Production of antibacterial cement composites containing ZnO/lignin and ZnO–SiO2/lignin hybrid ad mixtures. Cem. Concr. Compos. 2021, 124, 104250. [Google Scholar] [CrossRef]

- Cai, Y.; Hou, P.; Cheng, X.; Du, P.; Ye, Z. The effects of nano-SiO2 on the properties of fresh and hardened cement-based materials through its dispersion with silica fume. Constr. Build. Mater. 2017, 148, 770–780. [Google Scholar] [CrossRef]

- Kontoleontos, F.; Tsakiridis, P.E.; Marinos, A.; Kaloidas, V.; Katsioti, M. Influence of colloidal nanosilica on ultrafine cement hydration: Physicochemical and microstructural characterization. Constr. Build. Mater. 2012, 35, 347–360. [Google Scholar] [CrossRef]

- Nath, D.; Jangid, K.; Susaniya, A.; Kumar, R.; Vaish, R. Eggshell derived CaO-Portland cement antibacterial composites. Compos. C 2021, 5, 100123. [Google Scholar] [CrossRef]

- Adnan, M.A.M.; Julkapli, N.M.; Amir, M.N.I.; Maamor, A. Effect on different TiO2 photocatalyst supports on photo-decolorization of synthetic dyes: A review. Int. J. Environ. Sci. Tehnol. 2019, 16, 547–566. [Google Scholar] [CrossRef]

- Dehkordi, B.A.; Nilforoushan, M.R.; Talebian, N.; Tayebi, M. A comparative study on the self-cleaning behavior and antibacterial activity of Portland cement by addition of TiO2 and ZnO nanoparticles. Mater. Res. Express 2021, 8, 035403. [Google Scholar] [CrossRef]

- Esmaili, M.; Nilforoushana, M.R.; Tayebi, M.; Aghaie, E. Effect of micro/nano TiO2 addition on the densification behavior and mechanical properties of multifunctional resistant porcelains. Ceram. Int. 2021, 47, 17435–17444. [Google Scholar] [CrossRef]

- Mohammadi, H.; Nilforoushan, M.R.; Tayebi, M. Effect of nanosilica addition on bioactivity and in vivo properties of calcium aluminate cement. Ceram. Int. 2020, 46, 4335–4343. [Google Scholar] [CrossRef]

- Rossi, M.; Ghiara, M.R.; Chita, G.; Capitelli, F. Crystal-chemical and structural characterization of fluorapatites in ejecta from Somma-Vesuvius volcanic complex. Am. Mineral. 2011, 96, 1828–1837. [Google Scholar] [CrossRef]

- Baldassarre, F.; Altomare, A.; Corriero, N.; Mesto, E.; Lacalamita, M.; Bruno, G.; Sacchetti, A.; Dida, B.; Karaj, D.; Ventura, G.D.; et al. Crystal Chemistry and Luminescence Properties of Eu-Doped Polycrystalline Hydroxyapatite Synthesized by Chemical Precipitation at Room Temperature. Crystals 2020, 10, 250. [Google Scholar] [CrossRef] [Green Version]

- Stern, Y.; Barulli, D. Cognitive reserve. Handb. Clin. Neurol. 2019, 167, 181–190. [Google Scholar] [CrossRef] [PubMed]

- Muşat, V.; Anghel, E.M.; Zaharia, A.; Atkinson, I.; Mocioiu, O.C.; Buşilă, M.; Alexandru, P. A Chitosan–Agarose Polysaccharide-Based Hydrogel for Biomimetic Remineralization of Dental Enamel. Biomolecules 2021, 11, 1137. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Functionalized calcium orthophosphates (CaPO4) and their biomedical applications. J. Mater. Chem. B 2019, 7, 7471. [Google Scholar] [CrossRef]

- SR EN 998-1:2016; Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar. European Standard (EN) translated in Romanian (SR) by Romanian Standards Association (ASRO): Bucuresti, Romania, 2016.

- SR EN 1015-11:2020; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Standard (EN) translated in Romanian (SR) by Romanian Standards Association (ASRO): Bucuresti, Romania, 2020.

| Point 1 | Point 2 | ||||||

|---|---|---|---|---|---|---|---|

| Element | Weight % | Atomic % | Error % | Element | Weight % | Atomic % | Error % |

| O | 18.94 | 48.39 | 9.44 | O | 38.13 | 59.76 | 11.53 |

| Ca | 2.38 | 2.42 | 19.37 | P | 16.72 | 13.54 | 4.63 |

| Zn | 78.68 | 49.19 | 6.81 | Ca | 38.76 | 24.25 | 3.54 |

| Zn | 6.39 | 2.45 | 34.03 | ||||

| Batch Name | CIE DL* | CIE Da* | CIE Db* | CIE DC* | CIE DH* | CIE DE* |

|---|---|---|---|---|---|---|

| Standard | −0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| Bright area 1 | −6.58 | 8.47 | −2.15 | 3.28 | −8.10 | 10.94 |

| Bright area 2 | −3.90 | 8.90 | −1.28 | 4.06 | −8.02 | 9.80 |

| Bright area 3 | −3.98 | 8.89 | −1.04 | 4.18 | −7.92 | 9.80 |

| Dark area 1 | −10.36 | 18.97 | −8.72 | 12.85 | −16.45 | 23.31 |

| Dark area 2 | −13.24 | 17.74 | −8.84 | 11.65 | −16.04 | 23.84 |

| Dark area 3 | −12.78 | 17.02 | −7.45 | 10.80 | −15.11 | 22.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mocioiu, A.-M.; Mohanu, I.; Piticescu, R.M.; Tudor, I.A.; Petre, I.; Ghiță, M.; Ghiță, A.N.; Ioța, M.A.; Vitan, N.; Enache, M.; et al. Self-Cleaning and Antibacterial Properties of the Cement Mortar with ZnO/Hydroxyapatite Powders. Inorganics 2022, 10, 241. https://doi.org/10.3390/inorganics10120241

Mocioiu A-M, Mohanu I, Piticescu RM, Tudor IA, Petre I, Ghiță M, Ghiță AN, Ioța MA, Vitan N, Enache M, et al. Self-Cleaning and Antibacterial Properties of the Cement Mortar with ZnO/Hydroxyapatite Powders. Inorganics. 2022; 10(12):241. https://doi.org/10.3390/inorganics10120241

Chicago/Turabian StyleMocioiu, Ana-Maria, Ileana Mohanu, Roxana Mioara Piticescu, Ioan Albert Tudor, Ionela Petre, Mihai Ghiță, Andreea Nicoleta Ghiță, Miruna Adriana Ioța, Nicoleta Vitan, Mădălin Enache, and et al. 2022. "Self-Cleaning and Antibacterial Properties of the Cement Mortar with ZnO/Hydroxyapatite Powders" Inorganics 10, no. 12: 241. https://doi.org/10.3390/inorganics10120241