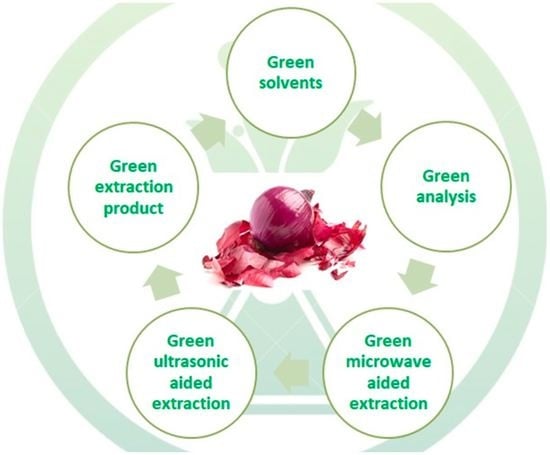

Development of Green and Efficient Extraction Methods of Quercetin from Red Onion Scales Wastes Using Factorial Design for Method Optimization: A Comparative Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Instruments

2.2. Chemicals, Standards and Samples

2.3. Standard and Red Onion Scales Preparation

2.4. HPLC Chromatographic Method

2.5. Different Extraction Protocols

2.5.1. Ultrasound-Assisted Glycerol Extraction (UAGE) Protocol of Quercetin from Onion Scales

2.5.2. Microwave-Assisted Extraction (MAE) Protocol of Quercetin from Onion Scales

2.5.3. The Evaluation of Efficiency of Extraction Protocols of Quercetin from Red Onion Scales

2.5.4. Stability of Quercetin Extracted from Red Onion Scales

2.6. Application of Analytical Eco-Scaling Assessment (ESA) and National Environmental Method Index (NEMI) for Greenness Assessment to Quercetin Methods of Extraction

3. Results

3.1. Optimization and Validation of the Chromatographic Method

3.2. Different Extraction Protocols

3.2.1. Ultrasound-Assisted Glycerol Extraction (UAGE) Protocol of Quercetin from Onion Scales

3.2.2. Microwave-Assisted Extraction of Quercetin from Red Onion Scales

3.2.3. Evaluation of the Efficiency of Extraction Protocols of Quercetin from Red Onion Scales

3.2.4. Stability of Quercetin

3.3. Application of Analytical Eco-Scaling Assessment (ESA) and National Environmental Method Index (NEMI) for Greenness Assessment of Quercetin Methods of Extraction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Medicines Agency. Guideline on Bioanalytical Method Validation. Committee for Medicinal Products for Human Use (EMEA/CHMP/EWP/192217/2009); European Medicines Agency: London, UK, 2011. [Google Scholar]

- Rodrigues, A.S.; Almeida, D.P.; Simal-Gándara, J.; Pérez-Gregorio, J.S.-G.A.M.R.; Pérez-Gregorio, M.R. Onions: A Source of Flavonoids. In Flavonoids—From Biosynthesis to Human Health; Justino, J., Ed.; InTechOpen: London, UK, 2017. [Google Scholar]

- Griffiths, G.; Trueman, L.; Crowther, T.; Thomas, B.; Smith, B. Onions—A global benefit to health. Phytother. Res. 2002, 16, 603–615. [Google Scholar] [CrossRef]

- Al-Suod, H.; Ratiu, A.; Krakowska-Sieprawska, A.; Lahuta, L.; Górecki, R.; Buszewski, B. Subcritical water extraction of flavonol quercetin from onion skin. J. Food Eng. 2011, 102, 327–333. [Google Scholar] [CrossRef]

- Katsampa, P.; Valsamedou, E.; Grigorakis, S.; Makris, D.P. A green ultrasound-assisted extraction process for the recovery of antioxidant polyphenols and pigments from onion solid wastes using Box–Behnken experimental design and kinetics. Ind. Crops Prod. 2015, 77, 535–543. [Google Scholar] [CrossRef]

- Đorđević, B.S.; Todorović, Z.B.; Troter, D.Z.; Stanojević, L.P.; Veljković, V.B. The extraction of quercetin from waste onion (Allium cepa L.): Tunic by the aqueous solutions of different deep eutectic solvents. Adv. Technol. 2018, 7, 5–10. [Google Scholar] [CrossRef]

- Worsfold, P.; Townshend, A.; Poole, C.F.; Miró, M. Encyclopedia of Analytical Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Li, X.; Row, K.H. Preparation of deep eutectic solvent-based hexagonal boron nitride-molecularly imprinted polymer nanoparticles for solid phase extraction of flavonoids. Microchim. Acta 2019, 186, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Abd-ElSalam, H.-A.H.; Al-Ghobashy, M.A.; Zaazaa, H.E.; Ibrahim, M.A. On-column decaffeination and HPLC analysis of epigallocatechin gallate in green tea nutraceuticals. J. Sep. Sci. Technol. 2015, 51, 664–672. [Google Scholar] [CrossRef]

- Kaufmann, B.; Christen, P. Recent extraction techniques for natural products: Microwave-assisted extraction and pressurised solvent extraction. J. Phytochem. Anal. 2002, 13, 105–113. [Google Scholar] [CrossRef]

- Bucar, F.; Wube, A.; Schmid, M. Natural product isolation–how to get from biological material to pure compounds. Nat. Prod. Rep. 2013, 30, 525–545. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Suod, H.; Ratiu, A.; Krakowska-Sieprawska, A.; Lahuta, L.; Górecki, R.; Buszewski, B. Supercritical fluid extraction in isolation of cyclitols and sugars from chamomile flowers. J. Sep. Sci. 2019, 42, 3243–3252. [Google Scholar] [CrossRef]

- Al-Suod, H.; Ratiu, I.; Górecki, R.; Buszewski, B. Pressurized liquid extraction of cyclitols and sugars: Optimization of extraction parameters and selective separation. J. Sep. Sci. 2019, 42, 1265–1272. [Google Scholar] [CrossRef]

- Li, Y.; Fabiano-Tixier, A.-S.; Abert-Vian, M.; Chemat, F. Microwave-assisted extraction of antioxidants and food colors. In Microwave-Assisted Extraction for Bioactive Compounds; Chemat, F., Cravotto, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 103–125. [Google Scholar]

- Routray, W.; Orsat, V. Microwave-assisted extraction of flavonoids: A review. Food Bioprocess. Technol. 2012, 5, 409–424. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, Z. Microwave-assisted extraction of quercetin and acid degradation of its glycosides in Psidium guajava leaves. J. Anal. Sci. 2004, 20, 395–397. [Google Scholar] [CrossRef] [Green Version]

- Huma, Z.-E.-; Vian, M.A.; Fabiano-Tixier, A.-S.; Elmaataoui, M.; Dangles, O.; Chemat, F. A remarkable influence of microwave extraction: Enhancement of antioxidant activity of extracted onion varieties. J. Food Chem. 2011, 127, 1472–1480. [Google Scholar] [CrossRef]

- Kumar, B.; Smita, K.; Kumar, B.; Cumbal, L.; Rosero, G. Microwave-Assisted Extraction and Solid-Phase Separation of Quercetin from Solid Onion (Allium cepa L.). Sep. Sci. Technol. 2014, 49, 2502–2509. [Google Scholar] [CrossRef]

- Das, S.; Mandal, S.C. Effect of process parameters of microwave assisted extraction (MAE) on natural product yield from onion peel. Int. J. Pharm. Sci. Res. 2015, 6, 3260. [Google Scholar] [CrossRef]

- Pal, C.B.T.; Jadeja, G.C. Microwave-assisted deep eutectic solvent extraction of phenolic antioxidants from onion (Allium cepa L.) peel: A Box–Behnken design approach for optimization. J. Food Sci. Technol. 2019, 56, 4211–4223. [Google Scholar] [CrossRef] [PubMed]

- Stefou, I.; Grigorakis, S.; Loupassaki, S.; Makris, D.P. Development of sodium propionate-based deep eutectic solvents for polyphenol extraction from onion solid wastes. Clean Technol. Environ. Policy 2019, 21, 1563–1574. [Google Scholar] [CrossRef]

- Jin, E.Y.; Lim, S.; Kim, S.O.; Park, Y.-S.; Jang, J.K.; Chung, M.-S.; Park, H.; Shim, K.-S.; Choi, Y.J. Optimization of various extraction methods for quercetin from onion skin using response surface methodology. Food Sci. Biotechnol. 2011, 20, 1727–1733. [Google Scholar] [CrossRef]

- Kumar, B.; Smita, K.; Kumar, B. Ultrasound assisted extraction of quercetin from cabbage. Int. J. Pharm. Sci. Res. 2014, 5, 3779. [Google Scholar] [CrossRef]

- Wang, L.; Weller, C.L. Recent advances in extraction of nutraceuticals from plants. Trends Food Sci. Technol. 2006, 17, 300–312. [Google Scholar] [CrossRef]

- Jang, M.; Asnin, L.; Nile, S.H.; Keum, Y.S.; Kim, H.Y.; Park, S.W. Ultrasound-assisted extraction of quercetin from onion solid wastes. Int. J. Food Sci. Technol. 2012, 48, 246–252. [Google Scholar] [CrossRef]

- Philippi, K.; Tsamandouras, N.; Grigorakis, S.; Makris, D.P. Ultrasound-Assisted Green Extraction of Eggplant Peel (Solanum melongena) Polyphenols Using Aqueous Mixtures of Glycerol and Ethanol: Optimisation and Kinetics. Environ. Process. 2016, 3, 369–386. [Google Scholar] [CrossRef]

- Armenta, S.; Garrigues, S.; de la Guardia, M. Green Analytical Chemistry. TrAC Trends Anal. Chem. 2008, 27, 497–511. [Google Scholar] [CrossRef]

- Gałuszka, A.; Migaszewski, Z.; Konieczka, P.; Namiesnik, J. Analytical Eco-Scale for assessing the greenness of analytical procedures. TrAC Trends Anal. Chem. 2012, 37, 61–72. [Google Scholar] [CrossRef]

- Keith, L.H.; Gron, L.U.; Young, J.L. Green Analytical Methodologies. Chem. Rev. 2007, 107, 2695–2708. [Google Scholar] [CrossRef]

- Pal, C.B.T.; Jadeja, G.C. Deep eutectic solvent-based extraction of polyphenolic antioxidants from onion (Allium cepa L.) peel. J. Sci. Food Agric. 2019, 99, 1969–1979. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.A.; Kim, K.-T.; Nah, S.-Y.; Chung, M.-S.; Cho, S.; Paik, H.-D. Antimicrobial and antioxidative effects of onion peel extracted by the subcritical water. Food Sci. Biotechnol. 2011, 20, 543–548. [Google Scholar] [CrossRef]

- Lee, K.A.; Kim, K.-T.; Kim, H.J.; Chung, M.-S.; Chang, P.-S.; Park, H.; Pai, H.-D. Antioxidant activities of onion (Allium cepa L.) peel extracts produced by ethanol, hot water, and subcritical water extraction. Food Sci. Biotechnol. 2014, 23, 615–621. [Google Scholar] [CrossRef]

- Oancea, S.; Radu, M.; Olosutean, H. Development of ultrasonic extracts with strong antioxidant properties from red onion wastes. Rom. Biotechnol. Lett. 2020, 25, 1320–1327. [Google Scholar] [CrossRef]

- Makris, D.P. Kinetics of Ultrasound-Assisted Flavonoid Extraction from Agri-Food Solid Wastes Using Water/Glycerol Mixtures. Resources 2016, 5, 7. [Google Scholar] [CrossRef] [Green Version]

- Gamal, M.; Abd-ElSalam, H.-A.H.; Naguib, I.A.; Al-Ghobashy, M.A.; Zaazaa, H.E.; Abdelkawy, M. Green and cost-effective extraction techniques of quercetin from mixture of nutraceuticals with yield analysis via spectrophotometry and high performance liquid chromatograph methods. J. AOAC Int. 2021. [Google Scholar] [CrossRef]

- Analysis of Flavonoids in Ginkgo Biloba Extract. Application News Schimadzu. High Performance Liquid Chromatography No. L405. Available online: https://www.shimadzu.com/an/sites/shimadzu.com.an/files/pim/pim_document_file/applications/application_note/10781/l405.pdf (accessed on 14 February 2021).

- ICH Harmonized Tripartite Guideline. Validation of Analytical Procedures: Text and Methodology Q2 (R1). 2005, Volume 11. Available online: https://database.ich.org/sites/default/files/Q2%28R1%29%20Guideline.pdf (accessed on 15 July 2021).

- Uzel, R.A. Microwave-assisted green extraction technology for sustainable food processing. In Emerging Microwave Technologies in Industrial, Agricultural, Medical and Food Processing; IntechOpen: London, UK, 2018; p. 159. [Google Scholar]

- Bart, H.J. Extraction of natural products from plants—An Itroduction. In Industrial Scale Natural Products Extraction; Bart, H.J., Pilz, S., Eds.; Wiley: Weinheim, Germany, 2011; pp. 1–25. [Google Scholar]

- Wach, A.; Pyrzyńska, K.; Biesaga, M. Quercetin content in some food and herbal samples. Food Chem. 2007, 100, 699–704. [Google Scholar] [CrossRef]

- Srinivas, K.; King, J.W.; Howard, L.R.; Monrad, J.K. Solubility and solution thermodynamic properties of quercetin and quercetin dihydrate in subcritical water. J. Food Eng. 2010, 100, 208–218. [Google Scholar] [CrossRef]

- Mourtzinos, I.; Anastasopoulou, E.; Petrou, A.; Grigorakis, S.; Makris, D.; Biliaderis, C.G. Optimization of a green extraction method for the recovery of polyphenols from olive leaf using cyclodextrins and glycerin as co-solvents. J. Food Sci. Technol. 2016, 53, 3939–3947. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Summary of Regression Equation Parameters and Method Validation Results | System Suitability Parameters of the HPLC Method | ||||

|---|---|---|---|---|---|

| Parameter | HPLC Method | Parameter 1 | Quercetin in Red Onion Scales | Reference Values 2 | |

| Accuracy (mean ± SD) | 100.11 ± 1.64 | ||||

| Precision | Repeatability * | 100.88 ± 1.95 | Resolution (Rs) | 4.60 | >2.00 |

| Intermediate Precision ** | 100.02 ± 2.83 | ||||

| Range | 1.00–10.00 µg/mL | Peak symmetry (As) | 1.10 | ≤2.00 | |

| Linearity | Regression Equation | ||||

| Correlation Coefficient (r) | 0.999 | Capacity factor (K’) | 1.50 | >2.00 | |

| Standard Deviation of Residuals | 4.70 | Separation factor (α) | 3.00 | >1.00 | |

| Robustness *** | Flow Rate ± 0.10 mL | 2.32% | Number of theoretical plates (N) | 3600 | >2000 |

| Mobile Phase ± 1.00% | 2.05% | ||||

| pH ± 0.10 | 2.86% | ||||

| Wavelength ± 1.00 nm | 2.09% | ||||

| Factor Name | Factor Code | Low Level (−1) | Zero Level | High Level (+1) |

|---|---|---|---|---|

| Ultrasound-Assisted Glycerol Extraction | ||||

| Solid/Liquid Ratio (g/mL) | A | 0.2 5g/25.00 mL | 0.50 g/25.00 mL | 1.00 g/25.00 mL |

| Time of Extraction (h) | B | 1.00 | 3.00 | 4.00 |

| Addition of Ethanol (mL) | C | Not added | 5.00 | 10.00 |

| Addition of concentrated HCl | D | Not added | 1.25 | 2.50 |

| Microwave Aided Extraction | ||||

| Solid/ Liquid Ratio (g/mL) | A | 0.10 g/20.00 mL | 0.20 g/20.00 mL | 0.30 g/20.00 mL |

| Time of Extraction (s) | B | 30.00 | 75.00 | 120.00 |

| Power of Microwave | C | 30% | 50% | 70% |

| Applied Extraction Protocols and Different Methods of Analysis | Eco-Scale Assessment | NEMI Tool | ||

|---|---|---|---|---|

| Parameters | Penalty Points | |||

| 1 | A microwave-assisted extraction (MAE) method was considered for the extraction of total phenolics, total flavonoids and DPPH scavenging activity from onion peels [19]. | Reagents | 35 |  |

| Energy used | 0 | |||

| Waste | 0 | |||

| Occupational hazard | 0 | |||

| Total penalty points | 35 | |||

| Analytical Eco-scale | 65 | |||

| 2 | This study showed the yield targeting total phenolic content and major flavonoids: Quercetin, kaempferol and myricetin [30]. | Reagents | 54 |  |

| Energy used | 2 | |||

| Waste | 3 | |||

| Occupational hazard | 3 | |||

| Total penalty points | 62 | |||

| Analytical Eco-scale | 38 | |||

| 3 | Optimizing microwave-assisted extraction from onion peel wastes [20]. The yield total phenolic content and FRAP were determined only. | Reagents | 54 |  |

| Energy used | 8 | |||

| Waste | 3 | |||

| Occupational hazard | 3 | |||

| Total penalty points | 68 | |||

| Analytical Eco-scale | 32 | |||

| 4 | Conventional solvent extraction, microwave-assisted extraction and ultrasound-assisted extraction were employed [22]. Quercetin concentration was introduced. | Reagents | 20 |  |

| Energy used | 2 | |||

| Waste | 0 | |||

| Occupational hazard | 0 | |||

| Total penalty points | 22 | |||

| Analytical Eco-scale | 78 | |||

| Our work | Microwave aided extraction method. Optimum conditions were discussed in the experimental part. The yield from the first cycle of extraction: Amount of quercetin 27.20 ± 1.55 mg/1g dry weight. | Reagents | 14 |  |

| Energy used | 1 | |||

| Waste | 0 | |||

| Occupational hazard | 0 | |||

| Total penalty points | 15 | |||

| Analytical Eco-scale | 85 | |||

| Our work | Ultrasonic aided glycerol extraction. Optimum conditions were discussed in the experimental part. The yield from the first cycle of extraction: Amount of quercetin 16.55 ± 0.81 mg/1g dry weight. | Reagents | 18 |  |

| Energy used | 1 | |||

| Waste | 3 | |||

| Occupational hazard | 3 | |||

| Total penalty points | 25 | |||

| Analytical Eco-scale | 75 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abd-ElSalam, H.-A.H.; Gamal, M.; Naguib, I.A.; Al-Ghobashy, M.A.; Zaazaa, H.E.; Abdelkawy, M. Development of Green and Efficient Extraction Methods of Quercetin from Red Onion Scales Wastes Using Factorial Design for Method Optimization: A Comparative Study. Separations 2021, 8, 137. https://doi.org/10.3390/separations8090137

Abd-ElSalam H-AH, Gamal M, Naguib IA, Al-Ghobashy MA, Zaazaa HE, Abdelkawy M. Development of Green and Efficient Extraction Methods of Quercetin from Red Onion Scales Wastes Using Factorial Design for Method Optimization: A Comparative Study. Separations. 2021; 8(9):137. https://doi.org/10.3390/separations8090137

Chicago/Turabian StyleAbd-ElSalam, Heba-Alla H., Mohammed Gamal, Ibrahim A. Naguib, Medhat A. Al-Ghobashy, Hala E. Zaazaa, and M. Abdelkawy. 2021. "Development of Green and Efficient Extraction Methods of Quercetin from Red Onion Scales Wastes Using Factorial Design for Method Optimization: A Comparative Study" Separations 8, no. 9: 137. https://doi.org/10.3390/separations8090137