Effect of Supercritical Fluid Extraction Process on Chemical Composition of Polianthes tuberosa Flower Extracts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tuberose Cultivation

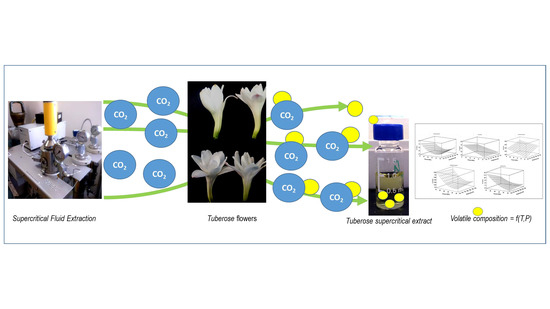

2.2. Supercritical Fluid Extraction

2.3. Gas Chromatography–Mass Spectrometry Analysis

3. Results and Discussion

3.1. Supercritical Fluid Extraction

3.2. Chemical Composition in Tuberose Flowers

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Solano, C.E. Sistemática del Genero Polianthes L. (Agavaceae). Ph.D. Thesis, Facultad de Ciencias, Universidad Nacional Autonoma, Mexico City, Mexico, June 2000. [Google Scholar]

- Rakthaworn, P.; Dilokkunanant, U.; Sukkatta, U.; Vajrodaya, S.; Haruethaitanasan, V.; Pitpiangchan, P.; Punjee, P. Extraction methods for tuberose oil and their chemical components. Kasetsart J. (Nat. Sci.) 2009, 43, 204–211. [Google Scholar]

- Rawani, A.; Banerjee, A.; Chandra, G. Mosquito larvicidal and biting deterrency activity of bud of Polianthes tuberosa plants extract against Anopheles stephensi and Culex quinquefasciatus. Asian Pac. J. Trop. Dis. 2009, 44, 79–89. [Google Scholar] [CrossRef]

- Gosh, P.K.; Bhattacharjee, P.; Stadal, D. Antimicrobial activity of supercritical carbon dioxide extracts of tuberose (Polianthes tuberosa Linn.) flowers against common pathogens. Int. J. Pharm. Sci. Res. 2014, 5, 1279–1289. [Google Scholar] [CrossRef]

- Moates, G.K.; Reynolds, J. Comparison of Rose Extracts Produced by Different Extraction Techniques. JEOR 1991, 3, 289–294. [Google Scholar] [CrossRef]

- Ahmadian, M.; Ahmadi, N.; Babaei, A.; Naghavi, M.R.; Ayyari, M. Comparison of volatile compounds at various developmental stages of tuberose (Polianthes tuberosa L. cv. Mahallati) flower with different extraction methods. JEOR 2018, 30, 197–206. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, J.; Zhang, H.; Dzah, C.S.; Zandile, M.; Duan, Y.; Ma, H.; Luo, X. Advances in ultrasound assisted extraction of bioactive compounds from cash crops—A review. Ultrason. Sonochem. 2018, 48, 538–549. [Google Scholar] [CrossRef] [PubMed]

- Ameer, K.; Muhammad, S.H.; Ho Kwon, J. Green extraction methods for polyphenols from plant matrices and their byproducts: A review. Comp. Rev. Food Saf. 2017, 16, 295–315. [Google Scholar] [CrossRef]

- Couto, R.M.; Fernandes, J.; Da Silva, M.D.R.G.; Simões, P.C. Supercritical fluid extraction of lipids from spent coffee grounds. J. Supercrit. Fluids. 2009, 51, 159–166. [Google Scholar] [CrossRef]

- Garlapati, C.; Madras, G. Solubilities of palmitic and stearic fatty acids in supercritical carbon dioxide. J. Chem. Thermodyn. 2010, 42, 193–197. [Google Scholar] [CrossRef]

- Sahena, F.; Zaidul, I.S.M.; Jinap, S.; Karim, A.A.; Abbas, K.A.; Norulaini, N.A.N.; Omar, A.K.M. Application of supercritical CO2 in lipid extraction—A review. J. Food Eng. 2009, 95, 240–253. [Google Scholar] [CrossRef]

- Ghosh, P.K.; Bhattacharjee, P. Mathematical modeling of supercritical carbon dioxide extraction of methyl eugenol from tuberose flowers. Korean J. Chem. Eng. 2015, 32, 1–11. [Google Scholar] [CrossRef]

- Reverchon, E. Supercritical fluid extraction, and fractionation of essential oils and related products. J. Supercrit. Fluids. 1997, 10, 1–37. [Google Scholar] [CrossRef]

- Zhou, B.; Ren, H.T.; Zhang, J.S.; Xia, K.G.; Qin, T.F. The Analysis of the Chemical Constituents of Absolute Oil of Tuberose by GC-MS. Mod. Food Sci. Technol. 2012, 28, 1215–1218. [Google Scholar]

- Maiti, S.; Moon, U.R.; Bera, P.; Samanta, T.; Mitra, A. The in vitro antioxidant capacities of Polianthes tuberosa L. flower extracts. Acta Physiol. Plant. 2014, 36, 2597–2605. [Google Scholar] [CrossRef]

- Nidiry, E.S.J.; Babu, C.S.B. Antifungal activity of tuberose absolute and some of its constituents. Phytother. Res. 2005, 19, 447–449. [Google Scholar] [CrossRef] [PubMed]

- De Melo, M.M.R.; Silvestre, A.J.D.; Silva, C.M. Supercritical fluid extraction of vegetable matrices: Applications, trends and future perspectives of a convincing green technology. J. Supercrit. Fluids 2014, 92, 115–176. [Google Scholar] [CrossRef]

- Gomes, P.B.; Mata, V.G.; Rodrigues, A.E. Production of rose geranium oil using supercritical fluid extraction. J. Supercrit. Fluids 2007, 41, 50–60. [Google Scholar] [CrossRef]

- Sánchez-Camargo, A.P.; Mendiola, J.A.; Ibáñez, E.; Herrero, M. Supercritical Fluid Extraction. In Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Madrid, Spain, 2014; Volume 1, pp. 1–17. ISBN 978-0-12-409547-2. [Google Scholar]

- Reverchon, E.; Porta, G.D. Tuberose concrete fractionation by supercritical carbon dioxide. J. Agric. Food Chem. 1997, 1356–1360. [Google Scholar] [CrossRef]

- Linstrom, P.J.; Mallard, W.G. NIST Chemistry Webbook; NIST Standard Reference Database No. 69. Available online: https://webbook.nist.gov (accessed on 15 October 2016).

- Da Silva, R.P.F.F.; Rocha-Santos, T.A.P.; Duarte, A.C. Supercritical fluid extraction of bioactive compounds. TrAC 2016, 76, 40–51. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Fu, Y.J.; Zu, Y.G.; Tong, M.H.; Wu, N.; Liu, X.L.; Zhang, S. Supercritical carbon dioxide extraction of seed oil from Opuntia dillenii Haw and its antioxidant activity. Food Chem. 2009, 114, 334–339. [Google Scholar] [CrossRef]

- Yu, J.; Dandekar, D.V.; Toledo, R.T.; Singh, R.K.; Patil, B.S. Supercritical fluid extraction of limonoids and naringin from grapefruit (Citrus paradisi Macf.) seeds. Food Chem. 2007, 105, 1026–1031. [Google Scholar] [CrossRef]

- Aladić, K.; Jarni, K.; Barbir, T.; Vidović, S.; Vladić, J.; Bilić, M.; Jokić, S. Supercritical CO2 extraction of hemp (Cannabis sativa L.) seed oil. Ind. Crop. Prod. 2015, 76, 472–478. [Google Scholar] [CrossRef]

- Sheela, V.L. Flowers for Trade. In Horticultural Science Series Vol. 10; New India Publishing Agency: New Delhi, India, 2008; pp. 267–276. [Google Scholar]

- Anu Kiruthika, K.; Amutha Jaisheeba, A.; Sornaraj, R. Evaluation of antibacterial activity of some selected Angiosperm flower extract. Int. J. Chem. Tech. Res. 2011, 3, 1945–1951. [Google Scholar]

- Lapczynski, A.; Bhatia, S.P.; Letizia, C.S.; Api, A.M. Fragrance material review on dl-citronellol. Food Chem. Toxicol. 2008, 46, 103–109. [Google Scholar] [CrossRef] [PubMed]

| Experiment | Pressure (MPa) | Temperature (K) | Extract Yield (%) |

|---|---|---|---|

| 1 | 18 | 333.15 | 0.73 |

| 2 | 28 | 323.15 | 2.43 |

| 3 | 18 | 313.15 | 1.11 |

| 4 | 28 | 323.15 | 2.28 |

| 5 | 38 | 313.15 | 1.49 |

| 6 | 38 | 333.15 | 1.75 |

| 7 | 18 | 333.15 | 1.11 |

| 8 | 28 | 323.15 | 2.52 |

| 9 | 18 | 313.15 | 1.06 |

| 10 | 28 | 323.15 | 2.54 |

| 11 | 38 | 313.15 | 2.42 |

| 12 | 38 | 333.15 | 2 |

| Process Conditions | 38 MPa/333.15 K | 38 MPa/313.15 K | 28 MPa/323.15 K | 28 MPa/323.15 K | 18 MPa/333.15 K | 18 MPa/313.15 K | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Experiment a | 6 | 12 | 5 | 11 | 2 | 8 | 4 | 10 | 1 | 7 | 3 | 9 | |||

| Compound | KIR g | R.T. (min) b | % AREA | ID | |||||||||||

| Geraniol | 1781 | 28.7 | 0.08 | 0.07 | 0.07 | 0.09 | 0.07 | 0.05 | 0.04 | 0.04 | 0.06 | 0.07 | 0.07 | 0.07 | MS, STD, KI |

| Benzyl alcohol | 1889 | 29.6 | 0.11 | 0.12 | 0.09 | 0.09 | 0.11 | 0.09 | 0.10 | 0.09 | 0.14 | 0.17 | 0.13 | 0.12 | MS, STD, KI |

| Methyl eugenol c,d | 2028 | 32.3 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 | MS, STD, KI |

| Caprylic acid | 2039 | 33.1 | - | - | 0.07 | 0.07 | 0.07 | 0.05 | 0.05 | 0.05 | 0.06 | 0.08 | 0.07 | 0.06 | MS, STD, KI |

| Heneicosane | 2100 | 33.7 | 0.09 | 0.10 | 0.05 | 0.07 | 0.08 | 0.08 | 0.08 | 0.07 | 0.09 | 0.08 | 0.09 | 0.09 | MS, STD, KI |

| Methyl isoeugenol d,f | 2185 | 35.6 | 0.36 | 0.39 | 0.36 | 0.33 | 0.47 | 0.35 | 0.35 | 0.31 | 0.48 | 0.54 | 0.52 | 0.54 | MS, STD, KI |

| Methyl palmitate | 2218 | 36.1 | 0.22 | 0.24 | 0.18 | 0.20 | 0.22 | 0.18 | 0.18 | 0.15 | 0.23 | 0.23 | 0.23 | 0.19 | MS, STD, KI |

| δ-Decalactone f | 2193 | 36.2 | 0.26 | 0.22 | 0.32 | 0.30 | 0.34 | 0.26 | 0.26 | 0.23 | 0.36 | 0.40 | 0.36 | 0.37 | MS, KI |

| Ethyl palmitate | 2250 | 36.7 | 2.56 | 2.70 | 2.98 | 3.54 | 2.66 | 2.74 | 2.15 | 1.96 | 2.21 | 2.37 | 4.10 | 4.06 | MS, STD, KI |

| Methyl anthranilate d,f | 2232 | 36.9 | 0.49 | 0.53 | 0.33 | 0.31 | 0.57 | 0.49 | 0.42 | 0.41 | 0.56 | 0.62 | 0.52 | 0.45 | MS, KI |

| Tricosane | 2300 | 37.4 | 1.56 | 1.14 | 2.32 | 2.21 | 2.20 | 2.04 | 1.78 | 1.66 | 2.40 | 2.73 | 2.15 | 1.65 | MS, KI |

| Farnesol d,f | 2356 | 38.5 | 0.90 | 0.94 | 1.11 | 1.09 | 1.05 | 0.86 | 0.79 | 0.71 | 1.04 | 1.21 | 1.12 | 0.88 | MS, STD, KI |

| Isoeugenol d,f | 2352 | 38.7 | 0.06 | 0.06 | 0.06 | 0.05 | 0.09 | 0.07 | 0.07 | 0.07 | 0.08 | 0.09 | 0.07 | 0.07 | MS, STD, KI |

| Tetracosane | 2400 | 39.0 | 0.41 | 0.38 | 0.37 | 0.34 | 0.34 | 0.37 | 0.38 | 0.34 | 0.42 | 0.34 | 0.40 | 0.38 | MS, STD, KI |

| Methyl stereate | 2422 | 39.8 | 0.06 | 0.06 | - | - | - | - | - | - | 0.06 | 0.06 | 0.07 | 0.05 | MS, STD, KI |

| Ethyl stereate | 2464 | 40.4 | 0.16 | 0.17 | 0.23 | 0.21 | 0.19 | 0.21 | 0.09 | 0.09 | 0.11 | 0.11 | 0.25 | 0.22 | MS, STD, KI |

| Benzoic acid c,e | 2448 | 40.4 | 0.36 | 0.36 | 0.40 | 0.37 | 0.40 | 0.35 | 0.33 | 0.32 | 0.38 | 0.33 | 0.27 | 0.28 | MS, KI |

| Ethyl oleate | 2493 | 40.9 | 0.13 | 0.14 | 0.16 | 0.15 | 0.15 | 0.16 | 0.11 | 0.11 | 0.14 | 0.15 | 0.19 | 0.18 | MS, STD, KI |

| Pentacosane c,d | 2500 | 41.2 | 6.54 | 7.19 | 6.52 | 6.15 | 7.05 | 7.63 | 7.76 | 6.97 | 9.93 | 7.52 | 10.97 | 11.06 | MS, STD, KI |

| Methyl linoleate f | 2509 | 41.4 | 0.13 | 0.14 | 0.13 | 0.13 | 0.12 | 0.12 | 0.04 | 0.04 | 0.32 | 0.27 | 0.06 | 0.06 | MS, STD, KI |

| Ethyl linoleate | 2536 | 42.0 | 0.26 | 0.24 | 0.38 | 0.36 | 0.31 | 0.35 | 0.32 | 0.28 | 0.36 | 0.35 | 0.48 | 0.44 | MS, STD, KI |

| Methyl linolenate | 2583 | 42.8 | 0.21 | 0.21 | 0.21 | 0.19 | 0.18 | 0.20 | 0.19 | 0.19 | 0.25 | 0.23 | 0.28 | 0.28 | MS, STD, KI |

| Hexacosane | 2600 | 43.4 | 0.62 | 0.57 | 0.41 | 0.47 | 0.49 | 0.55 | 0.60 | 0.55 | 0.63 | 0.50 | 0.72 | 0.78 | MS, STD, KI |

| Ethyl linolenate | 2613 | 43.6 | 0.53 | 0.52 | 0.77 | 0.75 | 0.58 | 0.65 | 0.66 | 0.59 | 0.80 | 0.78 | 1.06 | 1.03 | MS, STD, KI |

| Benzyl benzoate c,d,e,f | 2655 | 45.1 | 6.19 | 6.71 | 5.53 | 5.41 | 6.33 | 5.40 | 5.17 | 4.76 | 6.67 | 7.39 | 7.17 | 7.89 | MS, STD, KI |

| Heptacosene | 2688 | 46.1 | 5.09 | 5.44 | 5.47 | 5.03 | 5.87 | 6.58 | 6.52 | 5.85 | 7.68 | 6.01 | 8.29 | 7.26 | MS, STD, KI |

| Heptacosane | 2700 | 46.9 | 0.15 | 0.11 | - | - | 0.11 | 0.11 | 0.14 | 0.13 | 0.14 | 0.13 | 0.16 | 0.14 | MS, STD, KI |

| Octacosene | 2794 | 47.6 | 0.36 | 0.27 | 0.34 | 0.31 | 0.27 | 0.28 | 0.27 | 0.27 | 0.33 | 0.28 | 0.36 | 0.39 | MS, STD, KI |

| Octacosane | 2800 | 49.2 | 0.29 | 0.24 | 0.25 | 0.23 | 0.25 | 0.28 | 0.31 | 0.45 | 0.38 | 0.31 | 0.38 | 0.41 | MS, STD, KI |

| Benzyl salicylate f | 2810 | 50.2 | 1.14 | 1.24 | 1.12 | 1.03 | 1.09 | 0.97 | 0.95 | 0.90 | 1.21 | 1.33 | 1.34 | 1.44 | MS, STD, KI |

| Nonacosane | 2900 | 53.5 | 1.76 | 1.83 | 0.42 | 0.69 | 2.02 | 2.22 | 2.51 | 2.19 | 2.52 | 1.99 | 2.69 | 2.64 | MS, STD, KI |

| Palmitic acid | 2930 | 53.9 | 12.85 | 13.44 | 16.10 | 14.87 | 12.38 | 13.83 | 12.94 | 12.67 | 13.24 | 11.91 | 12.79 | 13.93 | MS, STD, KI |

| Stearic acid | 3090 | 66.6 | 4.08 | 4.29 | 4.91 | 4.62 | 3.59 | 4.12 | 4.67 | 4.60 | 4.79 | 3.57 | 3.82 | 4.00 | MS, STD, KI |

| Oleic acid | 3157 | 69.0 | 2.00 | 2.13 | 2.46 | 2.25 | 1.90 | 2.15 | 2.48 | 2.38 | 2.56 | 1.99 | 2.19 | 2.34 | MS, STD, KI |

| Linoleic acid e | 3168 | 73.9 | 8.82 | 9.34 | 11.90 | 11.05 | 8.46 | 9.21 | 11.42 | 11.37 | 10.40 | 10.40 | 10.37 | 10.08 | MS, STD, KI |

| 9,12,15-Octadecatrienonic acid | 3554 | 80.5 | 33.93 | 31.25 | 28.97 | 30.76 | 33.97 | 31.18 | 28.32 | 31.98 | 22.48 | 29.71 | 17.73 | 17.39 | MS, KI |

| n-Hexatriacontano | 3600 | 99.1 | 4.65 | 4.58 | 2.28 | 3.56 | 3.11 | 2.99 | 5.32 | 5.21 | 3.56 | 3.37 | 5.11 | 5.60 | MS, STD, KI |

| Number of Identified Compounds | 36 | 36 | 35 | 35 | 36 | 36 | 36 | 36 | 37 | 37 | 37 | 37 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fragoso-Jiménez, J.C.; Tapia-Campos, E.; Estarron-Espinosa, M.; Barba-Gonzalez, R.; Castañeda-Saucedo, M.C.; Castillo-Herrera, G.A. Effect of Supercritical Fluid Extraction Process on Chemical Composition of Polianthes tuberosa Flower Extracts. Processes 2019, 7, 60. https://doi.org/10.3390/pr7020060

Fragoso-Jiménez JC, Tapia-Campos E, Estarron-Espinosa M, Barba-Gonzalez R, Castañeda-Saucedo MC, Castillo-Herrera GA. Effect of Supercritical Fluid Extraction Process on Chemical Composition of Polianthes tuberosa Flower Extracts. Processes. 2019; 7(2):60. https://doi.org/10.3390/pr7020060

Chicago/Turabian StyleFragoso-Jiménez, Javier C., Ernesto Tapia-Campos, Mirna Estarron-Espinosa, Rodrigo Barba-Gonzalez, Ma. Claudia Castañeda-Saucedo, and Gustavo A. Castillo-Herrera. 2019. "Effect of Supercritical Fluid Extraction Process on Chemical Composition of Polianthes tuberosa Flower Extracts" Processes 7, no. 2: 60. https://doi.org/10.3390/pr7020060