Numerical Study on Separation Performance of Cyclone Flue Used in Grate Waste Incinerator

Abstract

:1. Introduction

2. Model Description

2.1. Adiabatic Cyclone Flue Model

2.2. Governing Equation

2.3. Boundary Conditions and Numerical Schemes

2.4. Grid Independence Study

2.5. Model Validation

3. Results and Discussion

3.1. Characteristics of Flow Field

3.2. Particle Separation Efficiency and Pressure Drop

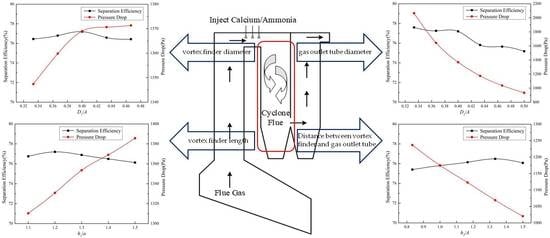

3.2.1. The Influence of the Vortex Finder Length

3.2.2. The Influence of the Vortex Finder Diameter

3.2.3. The Influence of the Gas Outlet Tube Diameter

3.2.4. The Influence of the Distance between Vortex Finder and Gas Outlet Tube

3.3. Comprehensive Performance Evaluation

- (1)

- Establish the initial decision matrix X = {xij}. Two evaluation indexes of separation efficiency and pressure drop of cyclone flue were considered, and xij is the j-th evaluation index of the i-th evaluation object.

- (2)

- Assimilation of indicator attributes. The inverse method was used to convert low-quality indicators into high-quality indicators, that is, the higher the value is, the better the performance will be. The pressure drop was a low-quality indicator, which needed to be converted into a high-quality indicator to obtain a new matrix X’.

- (3)

- Calculating the standard decision matrix Z. The dimensionless processing of each indicator can eliminate the effects of dimension and magnitude between different attribute indicators. The equation was as follows:

- (4)

- Calculate the set of positive ideal (S+) and negative ideal (S−) solutions of the decision matrix. S+ is the set of maximum values of each index, that is, when the separation efficiency of the cyclone flue is the highest, the pressure drop will be the smallest. S− is the set of minimum values of each index, that is, when the efficiency is lowest, the pressure drop will be largest.

- (5)

- Calculating the Euclidean distances of each evaluation scheme to the S+ and S−. The equations are as follows:

- (6)

- Calculating the relative proximity (Ci) of each evaluation scheme to the S+. The equation is as follows:

- (7)

- Ranking according to the value of Ci. the larger the value of Ci is, the closer the scheme to S+ and the farther away from S−, the better the scheme is.

4. Conclusions

- (1)

- The inlet of the gas outlet tube of the cyclone flue was a high-speed and low-pressure zone, where the velocity was the largest and the pressure was the smallest. The internal pressure was symmetrically distributed along the central axis, which is consistent with the conventional cyclone. In addition, there was a local vortex at the corner in the flue.

- (2)

- The particle separation efficiency increased at first and then decreased with the increase of the vortex finder length, the vortex finder diameter, and the distance between the vortex finder and the gas outlet tube, while it decreased with the increase of the gas outlet tube diameter. Above all, the gas outlet tube diameter had the most important influence on the separation efficiency.

- (3)

- The pressure drop increased with the increase of the vortex finder length, and the vortex finder diameter, while it decreased with the increase of the distance between vortex finder and gas outlet tube, and the gas outlet tube diameter. In addition, the gas outlet tube diameter had the greatest influence on the pressure drop.

- (4)

- The comprehensive performance of the cyclone flue was negatively correlated with the vortex finder diameter and the vortex finder length, while it was positively correlated with the distance between the vortex finder and the gas outlet tube, and the gas outlet tube diameter.

- (5)

- In the scope of this study, when h1/a = 1.1, D1/A = 0.33, h2/A = 1.5, D2/A = 0.50, the comprehensive performance of the cyclone flue was better, and the separation efficiency reached to 75%, which can remove the fly ash in the flue gas effectively, alleviate erosion wear and ash corrosion of the tail heating surface, and reduce the burden of the bag filter.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Nomenclature | |

| A | body edge length (m) |

| a | inlet height (m) |

| b | inlet width (m) |

| l | inlet length (m) |

| h1 | vortex finder length (m) |

| D1 | vortex finder diameter (m) |

| h2 | distance between vortex finder and gas outlet tube (m) |

| D2 | gas outlet tube diameter (m) |

| H | cyclone flue height (m) |

| u | velocity (m/s) |

| P | pressure (Pa) |

| ρ | density (kg/m3) |

| ν | kinematic viscosity (m2/s) |

| μ | dynamic viscosity (Pa·s) |

| k | turbulent kinetic energy (m2/s2) |

| ε | turbulent dissipation rate (m2/s3) |

| σ | turbulent Prandtl number |

| Rep | relative Reynold’s number |

| gx | gravitational acceleration (m/s2) |

| I | turbulence intensity (%) |

| Ci | relative proximity coefficient |

References

- Li, M.; Xiang, J.; Hu, S.; Sun, L.S.; Su, S.; Li, P.S.; Sun, X.X. Characterization of solid residues from municipal solid waste incinerator. Fuel 2004, 83, 1397–1405. [Google Scholar] [CrossRef]

- He, J.; Lin, B. Assessment of waste incineration power with considerations of subsidies and emissions in China. Energy Policy 2019, 126, 190–199. [Google Scholar] [CrossRef]

- Niu, J.; Liland, S.E.; Yang, J.; Rout, K.R.; Ran, J.; Chen, D. Effect of oxide additives on the hydrotalcite derived Ni catalysts for CO2 reforming of methane. Chem. Eng. J. 2019, 377, 119763. [Google Scholar] [CrossRef]

- Makarichi, L.; Jutidamrongphan, W.; Techato, K.A. The evolution of waste-to-energy incineration: A review. Renew. Sustain. Energy Rev. 2018, 91, 812–821. [Google Scholar] [CrossRef]

- Wang, P.; Hu, Y.; Cheng, H. Municipal solid waste (MSW) incineration fly ash as an important source of heavy metal pollution in China. Environ. Pollut. 2019, 252, 461–475. [Google Scholar] [CrossRef] [PubMed]

- Valente, T. Fireside corrosion of superheater materials in chlorine containing flue gas. J. Mater. Eng. Perform. 2001, 10, 608–613. [Google Scholar] [CrossRef]

- Stieglitz, L.; Bautz, H.; Roth, W.; Zwick, G. Investigation of precursor reactions in the de-novo synthesis of PCDD/PCDF on fly ash. Chemosphere 1997, 34, 1083–1090. [Google Scholar] [CrossRef]

- Gullett, B.K.; Bruce, K.R.; Beach, L.O.; Drago, A.M. Mechanistic steps in the production of PCDD and PCDF during waste combustion. Chemosphere 1992, 25, 1387–1392. [Google Scholar] [CrossRef]

- Zhang, Z.E.; Yan, Y.F.; Zhang, L.; Ju, S.X. Hollow fiber membrane contactor absorption of CO2 from the flue gas: Review and perspecrive. Glob. Nest J. 2014, 16, 354–373. [Google Scholar]

- Niu, J.; Du, X.; Ran, J.; Wang, R. Dry (CO2) reforming of methane over Pt catalysts studied by DFT and kinetic modeling. Appl. Surf. Sci. 2016, 376, 79–90. [Google Scholar] [CrossRef]

- Wissing, F.; Wirtz, S.; Scherer, V. Scherer. Simulating municipal solid waste incineration with a DEM/CFD method-Influences of waste properties, grate and furnace design. Fuel 2017, 206, 638–656. [Google Scholar] [CrossRef]

- Zhang, N.; Pan, Z.; Zhang, Z.; Zhang, W.; Zhang, L.; Baena-Moreno, F.M.; Lichtfouse, E. CO2 capture from coalbed methane using membranes: A review. Environ. Chem. Lett. 2019, 8, 1–18. [Google Scholar] [CrossRef]

- Xiang, R.B.; Lee, K.W. Numerical study of flow field in cyclones of different height. Chem. Eng. Process. 2005, 44, 877–883. [Google Scholar] [CrossRef]

- Raoufi, A.; Shams, M.; Farzaneh, M.; Ebrahimi, R. Numerical simulation and optimization of fluid flow in cyclone vortex finder. Chem. Eng. Process. Process. Intensif. 2008, 47, 128–137. [Google Scholar] [CrossRef]

- Safikhani, H.; Zamani, J.; Musa, M. Numerical study of flow field in new design cyclone separators with one, two and three tangential inlets. Adv. Powder Technol. 2018, 29, 611–622. [Google Scholar] [CrossRef]

- Bogodage, S.G.; Leung, A.Y. CFD simulation of cyclone separators to reduce air pollution. Powder Technol. 2015, 286, 488–506. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, G.; Yan, X. Evaluation and improvement of particle collection efficiency and pressure drop of cyclones by redistribution of dustbins. Chem. Eng. Res. Des. 2018, 139, 52–61. [Google Scholar] [CrossRef]

- Parvaz, F.; Hosseini, S.H.; Elsayed, K.; Ahmadi, G. Numerical investigation of effects of inner cone on flow field, performance and erosion rate of cyclone separators. Sep. Purif. Technol. 2018, 201, 223–237. [Google Scholar] [CrossRef]

- Safikhani, H.; Shams, M.; Dashti, S. Numerical simulation of square cyclones in small sizes. Adv. Powder Technol. 2011, 22, 359–365. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, A.; Zhao, B. Numerical simulation of effect of inlet configuration on square cyclone separator performance. Powder Technol. 2011, 210, 293–303. [Google Scholar] [CrossRef]

- Raoufi, A.; Shams, M.; Kanani, H. CFD analysis of flow field in square cyclones. Powder Technol. 2009, 191, 349–357. [Google Scholar] [CrossRef]

- Oh, J.; Choi, S.; Kim, J. Numerical simulation of an internal flow field in a uniflow cyclone separator. Powder Technol. 2015, 274, 135–145. [Google Scholar] [CrossRef]

- Fatahian, H.; Fatahian, E.; Nimvari, M.E. Improving efficiency of conventional and square cyclones using different configurations of the laminarizer. Powder Technol. 2018, 339, 232–243. [Google Scholar] [CrossRef]

- Fatahian, H.; Fatahian, E.; Nimvari, M.E. Numerical investigation of the effect of the cylindrical height on separation performances of uniflow hydrocyclone. Chem. Eng. Sci. 2015, 122, 500–513. [Google Scholar]

- Cen, K.F. Theoretical Design and Operation of CFB Boiler; China Electric Power Press: Beijing, China, 1998. (In Chinese) [Google Scholar]

- Su, Y.; Mao, Y. Experimental study on the gas-solid suspension flow in a square cyclone separator. Chem. Eng. J. 2006, 121, 51–58. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, Z.; Zhang, Q.; Wang, Q.; Lv, X. Numerical study on gas-solid flow characteristics of ultra-light particles in a cyclone separator. Powder Technol. 2019, 344, 784–796. [Google Scholar] [CrossRef]

- Vavva, C.; Voutsas, E.; Magoulas, K. Process development for chemical stabilization of fly ash from municipal solid waste incineration. Chem. Eng. Res. Des. 2017, 125, 57–71. [Google Scholar] [CrossRef]

- Bayuseno, A.P.; Schmahl, W.W. Characterization of MSWI fly ash through mineralogy and water extraction. Resour. Conserv. Recycl. 2011, 55, 524–534. [Google Scholar] [CrossRef]

- Loginova, E.; Proskurnin, M.; Brouwers, H.J.H. Municipal solid waste incineration (MSWI) fly ash composition analysis: A case study of combined chelatant-based washing treatment efficiency. J. Environ. Manag. 2019, 235, 480–488. [Google Scholar] [CrossRef]

- Triesch, O.; Bohnet, M. Measurement and CFD prediction of velocity and concentration profiles in a decelerated gas-solid flow. Powder Technol. 2001, 155, 101–113. [Google Scholar] [CrossRef]

- Gauthier, T.A.; Briens, C.L.; Bergougnou, M.A.; Galtier, P. Uniflow cyclone efficiency study. Powder Technol. 1990, 62, 217–225. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications a State-of-the-Art Survey; Springer: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Wang, C.N.; Tsai, T.T.; Huang, Y.F. A Model for Optimizing Location Selection for Biomass Energy Power Plants. Processes 2019, 7, 353. [Google Scholar] [CrossRef]

- Wang, C.N.; Huang, Y.F.; Cheng, I.; Nguyen, V. A Multi-Criteria Decision-Making (MCDM) Approach Using Hybrid SCOR Metrics, AHP, and TOPSIS for Supplier Evaluation and Selection in the Gas and Oil Industry. Processes 2018, 6, 252. [Google Scholar] [CrossRef] [Green Version]

- Jin, L.; Zhang, C.; Fei, X. Realizing Energy Savings in Integrated Process Planning and Scheduling. Processes 2019, 7, 120. [Google Scholar] [CrossRef] [Green Version]

| Dimension | Selection Principle [25] | Length (m) | Dimension Ration (Dimension/A) |

|---|---|---|---|

| Body edge length, A | Consistent with depth of grate furnace (Usually for 3–4 m) | 3.0 | 1 |

| Inlet height, a | a = 2.2–2.5b | 2.0 | 2.5b |

| Inlet width, b | b = (A − D1)/3 − (A − D1)/2 | 0.8 | 0.27 |

| Inlet length, l | l = 0.75 A | 2.25 | 0.75 |

| Vortex finder length, h1 | h1 = 1–1.5a | 2.2 | 1.1a |

| 2.4 | 1.2a | ||

| 2.6 | 1.3a | ||

| 2.8 | 1.4a | ||

| 3.0 | 1.5a | ||

| Vortex finder diameter, D1 | D1 = 0–0.5A | 1.0 | 0.33 |

| 1.1 | 0.37 | ||

| 1.2 | 0.40 | ||

| 1.3 | 0.43 | ||

| 1.4 | 0.47 | ||

| Distance between vortex finder and gas outlet tube, h2 | Ensure that the gas flow section is larger than the gas outlet tube section | 2.5 | 0.83 |

| 3.0 | 1.00 | ||

| 3.5 | 1.17 | ||

| 4.0 | 1.33 | ||

| 4.5 | 1.50 | ||

| Gas outlet tube diameter, D2 | D2 = 0.3–0.5A | 1.0 | 0.33 |

| 1.1 | 0.37 | ||

| 1.2 | 0.40 | ||

| 1.3 | 0.43 | ||

| 1.4 | 0.47 | ||

| 1.5 | 0.50 | ||

| Cyclone flue height, H | --- | 10.0 | 3.33 |

| Name | Boundary Condition Type | Discrete Phase Model (DPM) Boundary Condition Type |

|---|---|---|

| Gas–solid inlet | velocity-inlet | wall-jet |

| gas outlet | outflow | escape |

| particle outlet | wall | trap |

| wall | wall | reflect |

| Variable 1 | Variable 2 | Variable 3 | Variable 4 | ||||

|---|---|---|---|---|---|---|---|

| h1/a | Ci | D1/A | Ci | h2/A | Ci | D2/A | Ci |

| 1.1 | 0.91 | 0.33 | 0.65 | 0.83 | 0 | 0.33 | 0.04 |

| 1.2 | 0.73 | 0.37 | 0.48 | 1.00 | 0.25 | 0.37 | 0.21 |

| 1.3 | 0.43 | 0.40 | 0.39 | 1.17 | 0.48 | 0.40 | 0.42 |

| 1.4 | 0.22 | 0.43 | 0.11 | 1.33 | 0.74 | 0.43 | 0.63 |

| 1.5 | 0 | 0.47 | 0.01 | 1.5 | 0.97 | 0.47 | 0.82 |

| / | / | / | / | / | / | 0.50 | 0.96 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.-m.; Ran, J.-y.; Niu, J.-t.; Yang, Z.-q.; Pu, G.; Yang, L. Numerical Study on Separation Performance of Cyclone Flue Used in Grate Waste Incinerator. Processes 2019, 7, 866. https://doi.org/10.3390/pr7120866

Chen D-m, Ran J-y, Niu J-t, Yang Z-q, Pu G, Yang L. Numerical Study on Separation Performance of Cyclone Flue Used in Grate Waste Incinerator. Processes. 2019; 7(12):866. https://doi.org/10.3390/pr7120866

Chicago/Turabian StyleChen, Dong-mei, Jing-yu Ran, Jun-tian Niu, Zhong-qing Yang, Ge Pu, and Lin Yang. 2019. "Numerical Study on Separation Performance of Cyclone Flue Used in Grate Waste Incinerator" Processes 7, no. 12: 866. https://doi.org/10.3390/pr7120866