Valuation of Climate Performance of a Low-Tech Greenhouse in Costa Rica

Abstract

:1. Introduction

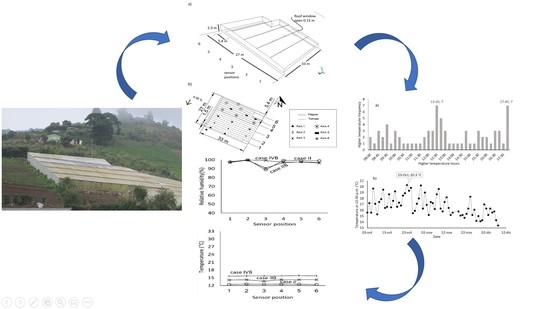

2. Materials and Methods

2.1. Study Area Localization Zone

2.2. Sampling and Data Acquisition

3. Results and Discussion

3.1. Statistical Analysis of Experimental Data

3.2. Temperature and RH Variation between Axes and between Blocks (Day Time)

3.3. Night-Time Period

3.4. Orthogonal Contrasts in the Slope Direction for Temperature and Relative Humidity

3.5. Behavior of Temperature and RH in the Days of Study in Relation to the Needs of the Crop

4. Future Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flores, J. Estudio Del Clima en Los Principales Modelos de Invernaderos en México (Malla Sombra, Multitunel y Baticenital), Mediante la Técnica Del CFD (Computational Fluid Dynamics). Ph.D. Thesis, University of Almería, Almería, Spain, 2010. [Google Scholar]

- McCartney, L.; Orsat, V.; Lefsrud, M.G. An experimental study of the cooling performance and airflow patterns in a model Natural Ventilation Augmented Cooling (NVAC) greenhouse. Biosyst. Eng. 2018, 174, 173–189. [Google Scholar] [CrossRef]

- Akrami, M.; Javadi, A.A.; Hassanein, M.J.; Farmani, R.; Dibaj, M.; Tabor, G.R.; Negm, A. Study of the effects of vent configuration on mono-span greenhouse ventilation using computational fluid dynamics. Sustainability 2020, 12, 986. [Google Scholar] [CrossRef] [Green Version]

- Rico-García, E.; Soto-Zarazua, G.M.; Alatorre-Jacome, O.; De La Torre-Gea, G.A.; Gomez-Melendez, D.G. Aerodynamic study of greenhouses using computational fluid dynamics. Int. J. Phys. Sci. 2011, 6, 6541–6547. [Google Scholar] [CrossRef]

- Leal, P.M.; Costa, E. Apostilla de Ingeniería de Confort en Cultivos Protegidos, 1st ed.; University of Campinas: São Paulo, Brasil, 2011. [Google Scholar]

- Villagran, E.; Leon, R.; Rodriguez, A.; Jaramillo, J. 3D numerical analysis of the natural ventilation behavior in a Colombian greenhouse established in warm climate conditions. Sustainability 2020, 12, 8101. [Google Scholar] [CrossRef]

- Bournet, P.E.; Boulard, T. Effect of ventilator configuration on the distributed climate of greenhouses: A review of experimental and CFD studies. Comput. Electron. Agric. 2010, 74, 195–217. [Google Scholar] [CrossRef]

- Aguilar-Rodríguez, C.E.; Flores-Velázquez, J.; Rojano, F.; Flores-Magdaleno, H.; Panta, E.R. Simulation of Water Vapor and Near Infrared Radiation to Predict Vapor Pressure Deficit in a Greenhouse Using CFD. Processes 2021, 9, 1587. [Google Scholar] [CrossRef]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive Review on Climate Control and Cooling Systems in Greenhouses under Hot and Arid Conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Sedat, B.; Adil, A. Effect of greenhouse cooling methods on the growth and yield of tomato in a Mediterranean climate. Int. J. Hortic. Agric. Food Sci. (IJHAF) 2018, 2, 199–207. [Google Scholar]

- Adams, S.R.; Cockshull, K.E.; Cave, C.R.J. Effects of temperature on the growth and development of tomato fruits. Ann. Bot. 2001, 88, 869–877. [Google Scholar] [CrossRef]

- Morales, D.; Rodriguez, P.; Dell’Amico, J.; Nicolas, J.; Torrecillas, A.; Sanchez-Blanco, M.J. High temperature preconditioning and thermal shock imposition affects water relations, gas exchange and root hydraulic conductivity in Tomato. Biol. Plant. 2003, 47, 6–12. [Google Scholar] [CrossRef]

- Peet, M.; Sato, S.; Clemente, C.; Pressman, E. Heat stress increases sensitivity of pollen, fruit and seed production in tomatoes (Lycopersicon esculentum Mill.) to non-optimal vapor pressure deficits. Acta Hortic. 2003, 618, 209–215. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Li, Y.; Yue, X.; Tian, S.; Li, T. Effect of internal surface structure of the north wall on Chinese solar greenhouse thermal microclimate based on computational fluid dynamics. PLoS ONE 2020, 15, e0231316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bartzanas, T.; Boulard, T.; Kittas, C. Numerical simulation of the airflow and temperature distribution in a tunnel greenhouse equipped with insect-proof screen in the openings. Comput. Electron. Agric. 2002, 34, 207–221. [Google Scholar] [CrossRef]

- Benni, S.; Tassinari, P.; Bonora, F.; Barbaresi, A.; Torreggiani, D. Efficacy of greenhouse natural ventilation: Environmental monitoring and CFD simulations of a study case. Energy Build. 2016, 125, 276–286. [Google Scholar] [CrossRef]

- Reynafarje, X.; Villagrán, E.A.; Bojacá, C.R.; Gil, R.; Schrevens, E. Simulation and validation of the airflow inside a naturally ventilated greenhouse designed for tropical conditions. Acta Hortic. 2020, 1271, 55–62. [Google Scholar] [CrossRef]

- Villagrán, E.A.; Romero, E.J.B.; Bojacá, C.R. Transient CFD analysis of the natural ventilation of three types of greenhouses used for agricultural production in a tropical mountain climate. Biosyst. Eng. 2019, 188, 288–304. [Google Scholar] [CrossRef]

- Molina-Aiz, F.D.; Valera, D.L.; López, A. Airflow at the openings of a naturally ventilated Almería-type greenhouse with insect-proof screens. Acta Hortic. 2011, 893, 545–552. [Google Scholar] [CrossRef]

- Villagrán, E.; Bojacá, C.; Akrami, M. Contribution to the Sustainability of Agricultural Production in Greenhouses Built on Slope Soils: A Numerical Study of the Microclimatic Behavior of a Typical Colombian Structure. Sustainability 2021, 13, 4748. [Google Scholar] [CrossRef]

- Kobayashi, K.; Salam, M.U. Comparing Simulated and Measured Values Using Mean Squared Deviation and its Components. Agron. J. 2000, 92, 345. [Google Scholar] [CrossRef]

- Lopez, A. Validación de un Modelo Matemático Para Predecir Las Condiciones Climáticas Interna en un Invernadero Localizado en la Zona Norte de Cartago, Costa Rica. Bachelor Thesis, Universidad de Costa Rica, San Jose de Costa Rica, Costa Rica, 2012. [Google Scholar]

- Tesi, R. Medios de Protección Para la Horto Florofruticultura y el Viverismo, 3rd ed.; Mundiprensa: Madrid, Spain, 2001. [Google Scholar]

- Subin, M.C.; Lourence, J.S.; Karthikeyan, R.; Periasamy, C. Analysis of materials used for Greenhouse roof covering-structure using CFD. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012068. [Google Scholar] [CrossRef] [Green Version]

- Aguilar-Rodríguez, C.E.; Flores-Velázquez, J.; Rojano, F.; Ojeda-Bustamante, W.; Iñiguez-Covarrubias, M. Tomato (Solanum lycopersicum L.) crop cycle estimation in greenhouse, based on degree day heat (GDC) simulated in CFD. Tecnol. Cienc. Agua 2020, 11, 27–57. [Google Scholar] [CrossRef]

- Mesmoudi, K.; Meguallati, K.; Bournet, P.E. Effect of the greenhouse design on the thermal behavior and microclimate distribution in greenhouses installed under semi-arid climate. Heat Transfer–Asian Res. 2017, 46, 1294–1311. [Google Scholar] [CrossRef]

- Chu, C.R.; Lan, T.W.; Tasi, R.K.; Wu, T.R.; Yang, C.K. Wind-driven natural ventilation of greenhouses with vegetation. Biosyst. Eng. 2017, 164, 221–234. [Google Scholar] [CrossRef]

- Cemek, B.; Atiş, A.; Küçüktopçu, E. Evaluation of temperature distribution in different greenhouse models using computational fluid dynamics (CFD). Anadolu J. Agric. Sci. 2017, 32, 54. [Google Scholar] [CrossRef] [Green Version]

- Taloub, D.; Bouras, A.; Driss, Z. Effect of the Soil Inclination on Natural Convection in Half-Elliptical Greenhouses. J. Eng. Res. Afr. 2020, 50, 70–78. [Google Scholar] [CrossRef]

- Villagran, E.; Bojacá, C. Three-dimensional numerical simulation of the thermal and aerodynamic behavior of a roof structure built on a slope and used for horticultural production. Comun. Sci. 2021, 12, e3593. [Google Scholar]

- Villagran, E.; Bojacá, C. Analysis of the microclimatic behavior of a greenhouse used to produce carnation (Dianthus caryophyllus L.). Ornam. Hortic. 2020, 26, 109–204. [Google Scholar] [CrossRef]

- Ma, D.; Carpenter, N.; Maki, H.; Rehman, T.U.; Tuinstra, M.R.; Jin, J. Greenhouse environment modeling and simulation for microclimate control. Comput. Electron. Agric. 2019, 162, 134–142. [Google Scholar] [CrossRef]

- Saberian, A.; Sajadiye, S.M. The effect of dynamic solar heat load on the greenhouse microclimate using CFD simulation. Renew. Energy 2019, 138, 722–737. [Google Scholar] [CrossRef]

- Villagran, E.; Bojacá, C. Experimental evaluation of the thermal and hygrometric behavior of a Colombian greenhouse used for the production of roses (Rosa spp.). Ornam. Hortic. 2020, 26, 205–219. [Google Scholar] [CrossRef]

- Bojacá, C.R.; Gil, R.; Gómez, S.; Cooman, A.; Schrevens, E. Analysis of greenhouse air temperature distribution using geostatistical methods. Trans. ASABE 2009, 52, 957–968. [Google Scholar] [CrossRef]

- Villagrán, E.A.; Bojacá, C.R. CFD simulation of the increase of the roof ventilation area in a traditional Colombian greenhouse: Effect on air flow patterns and thermal behavior. Int. J. Heat Technol. 2019, 37, 881–892. [Google Scholar]

- Akrami, M.; Mutlum, C.D.; Javadi, A.A.; Salah, A.H.; Fath, H.; Dibaj, M.; Farmani, R.; Mohammed, R.H.; Negm, A. Analysis of inlet configurations on the microclimate conditions of a novel standalone agricultural greenhouse for Egypt using computational fluid dynamics. Sustainability 2021, 13, 1446. [Google Scholar] [CrossRef]

- Kuroyanagi, T. Investigating air leakage and wind pressure coefficients of single-span plastic greenhouses using computational fluid dynamics. Biosyst. Eng. 2017, 163, 15–27. [Google Scholar] [CrossRef]

- Jiao, W.; Liu, Q.; Gao, L.; Liu, K.; Shi, R.; Ta, N. Computational Fluid Dynamics-Based Simulation of Crop Canopy Temperature and Humidity in Double-Film Solar Greenhouse. J. Sens. 2020, 2020, 8874468. [Google Scholar] [CrossRef]

| Sensor | Range of Work | Precision |

|---|---|---|

| Temperature | −40 to 65 °C | ±0.5 °C |

| Relative Humidity | 1 to 100% | ±3% y ±4% over 90% |

| Radiation | 0 to 1800 W m−2 | ±5% |

| Wind velocity | 1 to 80 ms−1 | ±5 ms−1 |

| Wind directions | 16 points of compass | ±5 |

| Case | Date | Time (h) | Temperature (°C) | RH (%) | Wind | |

|---|---|---|---|---|---|---|

| Velocity (m/s) | Predominant Direction | |||||

| I | 23 October | 12:30 | 20.3 | 85 | 2.2 | SW |

| II | 07 November | 04:45 | 12.0 | 97 | 0.4 | SW |

| IIIA | 06 October | 12:30 | 19.7 | 87 | 1.8 | SE |

| IIIB | 06 October | 04:45 | 14.4 | 95 | 0.9 | W |

| IVA | 06 December | 12:30 | 15.8 | 95 | 0.9 | SE |

| IVB | 06 December | 04:45 | 15.2 | 96 | 0.9 | NW |

| Temperature (°C) | RH (%) | ||||||||

| Axis | Average | n | E.E. | Axis | Average | n | E.E. | ||

| 1 | 30.59 | 2 | 1.01 | a | 1 | 50.06 | 1 | 5.74 | a |

| 2 | 30.71 | 3 | 0.82 | a | 2 | 49.55 | 3 | 3.31 | a |

| 3 | 31.53 | 3 | 0.82 | a | 3 | 49.72 | 2 | 4.06 | a |

| 4 | 32.48 | 3 | 0.82 | a | 4 | 42.13 | 2 | 4.06 | a |

| 5 | 32.55 | 3 | 0.82 | a | 5 | 43.53 | 3 | 3.31 | a |

| 6 | 31.8 | 3 | 0.82 | a | 6 | 47.36 | 3 | 3.31 | a |

| Temperature (°C) | RH (%) | ||||||||

| Block | Average | n | E.E. | Block | Average | n | E.E. | ||

| A | 31.69 | 5 | 0.67 | a | A | 44.97 | 4 | 2.89 | a |

| B | 31.68 | 7 | 0.57 | a | B | 47.02 | 6 | 2.36 | a |

| C | 31.64 | 5 | 0.67 | a | C | 48.27 | 4 | 2.89 | a |

| Temperature (°C) | RH (%) | ||||||||

| Axis | Average | n | E.E. | Axis | Average | n | E.E. | ||

| 1 | 22.04 | 2 | 0.55 | a | 1 | 68.56 | 1 | 4.41 | a |

| 2 | 23.11 | 3 | 0.45 | ab | 2 | 66.88 | 3 | 3.6 | a |

| 3 | 23.72 | 3 | 0.45 | ab | 3 | 65.85 | 2 | 4.41 | a |

| 4 | 24.12 | 3 | 0.45 | ab | 4 | 59.74 | 2 | 3.6 | a |

| 5 | 25.18 | 3 | 0.45 | a | 5 | 58.98 | 3 | 3.6 | a |

| 6 | 24.88 | 3 | 0.45 | a | 6 | 60.07 | 3 | 3.6 | a |

| Temperature (°C) | RH (%) | ||||||||

| Block | Average | n | E.E. | Block | Average | n | E.E. | ||

| A | 23.88 | 5 | 0.58 | a | A | 59.35 | 4 | 3.24 | a |

| B | 24.01 | 7 | 0.49 | a | B | 63.37 | 6 | 2.45 | a |

| C | 23.92 | 5 | 0.58 | a | C | 64.97 | 4 | 2.9 | a |

| Axis Grouping Contrast | 1–2–3/4–5–6 (1) | 1–2/5–6 (2) | 1/6 (3) |

|---|---|---|---|

| Case I | 0.0824 | 0.1076 | 0.3704 |

| Case II | 0.7833 | 0.6896 | 0.9441 |

| Case IIIA | 0.0067(p < 0.05) | 0.007 (p < 0.05) | 0.045 (p < 0.05) |

| Case IIIB | 0.2476 | 0.7794 | 0.7708 |

| Case IVA | 0.0007 (p < 0.05) | 0.0003 (p < 0.05) | 0.0021 (p < 0.05) |

| Case IVB | 0.2864 | 0.1777 | 0.3585 |

| Axis Grouping Contrast | 1–2–3/4–5–6 (1) | 1–2/5–6 (2) | 1/6 (3) |

|---|---|---|---|

| Case I | 0.1395 | 0.3141 | 0.694 |

| Case II | 0.2859 | 0.9424 | 0.8291 |

| Case IIIA | 0.1199 | 0.2156 | 0.5903 |

| Case IIIB | 0.0890 | 0.1552 | 0.7830 |

| Case IVA | 0.04 (p < 0.05) | 0.0576 | 0.1672 |

| CasoeIVB | 0.5855 | 0.4823 | 0.6848 |

| Axis | Date | Day Time Period | Night-Time Period | ||

|---|---|---|---|---|---|

| Tmax (°C) | RH (%) | Tmin (°C) | RH (%) | ||

| 6 October | 31.04 | 45.60 | 14.04 | 97.42 | |

| 1 | 23 October | 30.81 | 46.24 | 13.08 | 96.13 |

| 7 November | 31.59 | 44.59 | 11.71 | 97.73 | |

| 6 December | 22.06 | 69.01 | 14.94 | 98.27 | |

| 6 October | 30.63 | 48.40 | 14.16 | 99.87 | |

| 2 | 23 October | 31.22 | 44.68 | 13.65 | 98.25 |

| 7 November | 33.01 | 39.18 | 12.18 | 100.00 | |

| 6 December | 23.11 | 67.46 | 15.04 | 99.28 | |

| 6 October | 30.24 | 48.71 | 14.16 | 98.78 | |

| 3 | 23 October | 31.84 | 40.16 | 13.89 | 96.15 |

| 7 November | 33.89 | 39.44 | 12.23 | 88.75 | |

| 6 December | 23.75 | 66.14 | 15.09 | 90.86 | |

| 6 October | 31.74 | 48.82 | 14.24 | 97.22 | |

| 4 | 23 October | 33.19 | 40.62 | 13.95 | 94.34 |

| 7 November | 35.40 | 31.20 | 12.22 | 99.94 | |

| 6 December | 24.13 | 59.64 | 15.06 | 96.72 | |

| 6 October | 33.26 | 41.92 | 14.23 | 97.49 | |

| 5 | 23 October | 33.39 | 39.71 | 13.87 | 95.10 |

| 7 November | 36.29 | 32.13 | 12.16 | 99.22 | |

| 6 December | 25.17 | 59.37 | 15.10 | 97.64 | |

| 6 October | 33.48 | 43.07 | 14.19 | 96.47 | |

| 23 October | 32.77 | 43.07 | 13.88 | 94.34 | |

| 6 | 7 November | 37.44 | 32.59 | 12.12 | 99.40 |

| 6 December | 24.89 | 60.39 | 15.00 | 96.89 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas-Rishor, A.; Flores-Velazquez, J.; Villagran, E.; Aguilar-Rodríguez, C.E. Valuation of Climate Performance of a Low-Tech Greenhouse in Costa Rica. Processes 2022, 10, 693. https://doi.org/10.3390/pr10040693

Rojas-Rishor A, Flores-Velazquez J, Villagran E, Aguilar-Rodríguez CE. Valuation of Climate Performance of a Low-Tech Greenhouse in Costa Rica. Processes. 2022; 10(4):693. https://doi.org/10.3390/pr10040693

Chicago/Turabian StyleRojas-Rishor, Adriana, Jorge Flores-Velazquez, Edwin Villagran, and Cruz Ernesto Aguilar-Rodríguez. 2022. "Valuation of Climate Performance of a Low-Tech Greenhouse in Costa Rica" Processes 10, no. 4: 693. https://doi.org/10.3390/pr10040693