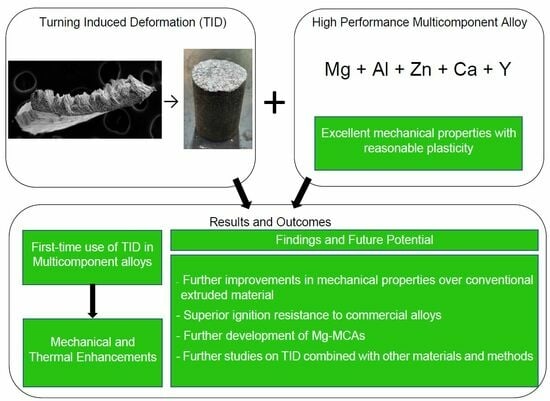

Enhancing Multiple Properties of a Multicomponent Mg-Based Alloy Using a Sinterless Turning-Induced Deformation Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis

2.3. Materials Characterization

2.3.1. Density and Porosity

2.3.2. Damping Analysis

2.3.3. Microstructure Analysis

2.3.4. X-ray Diffraction

2.3.5. Mechanical Properties

2.3.6. Thermal Properties

2.3.7. Corrosion Response

3. Results

3.1. Synthesis

3.2. Density and Porosity

3.3. Damping Analysis

3.4. Microstructure

3.5. X-ray Diffraction

3.6. Mechanical Properties

3.6.1. Hardness

3.6.2. Compressive Properties

3.7. Thermal Properties

3.8. Corrosion Response

4. Discussion

4.1. Synthesis

4.2. Density and Porosity

4.3. Damping Analysis

4.4. Microstructure

4.5. X-ray Diffraction

4.6. Mechanical Properties

4.6.1. Hardness

4.6.2. Compressive Properties

4.7. Thermal Properties

4.8. Corrosion Response

5. Conclusions

- The TID material continued to follow previous trends in morphology, being more porous compared to the DMD counterparts, although the porosity remained at <1%.

- The TID method imparts superior hardness (34% increase in micro-scale and 11% increase in macro-scale) and strength (14% increase in yield strength and nearly 5% increase in ultimate compressive strength) but compromises ductility and energy absorbed until fracture, with the ductility of the TID samples remaining greater than 10%.

- The TID material has, overall, better damping capabilities than the DMD material, with a nearly 20% increase in attenuation coefficient and 24% increase in damping capacity.

- From thermal analyses, the TID method caused the ignition temperature to decrease significantly relative to conventional DMD processing whilst the coefficient of thermal expansion increased slightly. More significantly, the ignition temperature of the TID samples, at over 900 °C, remained significantly higher than the FAA-approved WE43 and E21 alloys.

- The average corrosion rate of the TID material was significantly higher than its DMD counterpart, with nearly double the average corrosion rate.

- An important consideration when performing hot working of this multicomponent alloy as phase transformation was observed from the DSC results when the Mg70Al18Zn6Ca4Y2 multicomponent alloy reached 490 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Viswanadhapalli, B.; Bupesh Raja, V.K. Application of Magnesium Alloys in Automotive Industry—A Review. In Emerging Trends in Computing and Expert Technology; Springer: Cham, Switzerland, 2020; pp. 519–531. [Google Scholar]

- Chirinda, G.; Matope, S. The Lighter the Better: Weight Reduction in the Automotive Industry and its Impact on Fuel Consumption and Climate Change. In Proceedings of the 2nd African International Conference on Industrial Engineering and Operations Management, Harare, Zimbabwe, 20–22 October 2020; pp. 520–533. [Google Scholar]

- Han, Y.; Liu, Z.-H.; Wu, C.-B.; Zhao, Y.; Zu, G.-Q.; Zhu, W.-W.; Ran, X. A short review on the role of alloying elements in duplex stainless steels. Tungsten 2023, 5, 419–439. [Google Scholar] [CrossRef]

- Waizy, H.; Seitz, J.-M.; Reifenrath, J.; Weizbauer, A.; Bach, F.-W.; Meyer-Lindenberg, A.; Denkena, B.; Windhagen, H. Biodegradable magnesium implants for orthopedic applications. J. Mater. Sci. 2013, 48, 39–50. [Google Scholar] [CrossRef]

- Chen, F.-H.; Xie, H.-B.; Huo, M.-S.; Wu, H.; Li, L.-J.; Jiang, Z.-Y. Effects of magnetic field and hydrostatic pressure on the antiferromagnetic–ferromagnetic transition and magneto-functional properties in Hf1−xTaxFe2 alloys. Tungsten 2023, 5, 503–511. [Google Scholar] [CrossRef]

- Ren, K.; Liu, H.; Ma, R.; Chen, S.; Zhang, S.; Wang, R.; Chen, R.; Tang, Y.; Li, S.; Lu, F. Dynamic compression behavior of TiZrNbV refractory high-entropy alloys upon ultrahigh strain rate loading. J. Mater. Sci. Technol. 2023, 161, 201–219. [Google Scholar] [CrossRef]

- Jenczyk, P.; Jarzabek, D.M.; Lu, Z.; Gadalińska, E.; Levintant-Zayonts, N.; Zhang, Y. Unexpected crystallographic structure, phase transformation, and hardening behavior in the AlCoCrFeNiTi0.2 high-entropy alloy after high-dose nitrogen ion implantation. Mater. Des. 2022, 216, 110568. [Google Scholar] [CrossRef]

- Alvi, S.; Milczarek, M.; Jarzabek, D.M.; Hedman, D.; Kohan, M.G.; Levintant-Zayonts, N.; Vomiero, A.; Akhtar, F. Enhanced Mechanical, Thermal and Electrical Properties of High-Entropy HfMoNbTaTiVWZr Thin Film Metallic Glass and its Nitrides. Adv. Eng. Mater. 2022, 24, 2101626. [Google Scholar] [CrossRef]

- Tun, S.; Nahata, A.; Vincent, S.; Gupta, M. Development of a Low Entropy, Lightweight, Multicomponent, High Performance (Hardness + Strength + Ductility) Magnesium-Based Alloy. JOM 2023, 75, 459–469. [Google Scholar] [CrossRef]

- Tun, K.S.; Nahata, A.; Vincent, S.; Gupta, M. Processing, microstructure and mechanical characterization of a new magnesium based multicomponent alloy. Mater. Today Proc. 2020, 28, 1044–1047. [Google Scholar] [CrossRef]

- Johanes, M.; Tekumalla, S.; Gupta, M. Fe3O4 Nanoparticle-Reinforced Magnesium Nanocomposites Processed via Disintegrated Melt Deposition and Turning-Induced Deformation Techniques. Metals 2019, 9, 1225. [Google Scholar] [CrossRef]

- Johanes, M.; Gupta, M. The Promise of Turning Induced Deformation Process for Synthesizing Magnesium Based Materials with Superior Mechanical Response. Technologies 2021, 9, 69. [Google Scholar] [CrossRef]

- Tekumalla, S.; Ajjarapu, M.; Gupta, M. A Novel Turning-Induced-Deformation Based Technique to Process Magnesium Alloys. Metals 2019, 9, 841. [Google Scholar] [CrossRef]

- Tekumalla, S.; Gupta, N.; Gupta, M. Influence of turning speed on the microstructure and properties of magnesium ZK60 alloy pre-processed via turning-induced-deformation. J. Alloys Compd. 2020, 831, 154840. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Yuan, Y.; Ma, A.; Jiang, J.; Lu, F.; Jian, W.; Song, D.; Zhu, Y.T. Optimizing the strength and ductility of AZ91 Mg alloy by ECAP and subsequent aging. Mater. Sci. Eng. A 2013, 588, 329–334. [Google Scholar] [CrossRef]

- Lapovok, R.; Estrin, Y. 4—Superplasticity in magnesium alloys by severe plastic deformation. In Advances in Wrought Magnesium Alloys; Bettles, C., Barnett, M., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 144–185. [Google Scholar]

- Wu, S.; Ji, Z.; Zhang, T. Microstructure and mechanical properties of AZ31B magnesium alloy recycled by solid-state process from different size chips. J. Mater. Process. Technol. 2009, 209, 5319–5324. [Google Scholar] [CrossRef]

- Lapovok, R.Y.; Thomson, P.F. Production of dense rod from magnesium swarf for re-melting. Magnes. Technol. 2004, 1, 149–154. [Google Scholar]

- Singh, I.B.; Singh, M.; Das, S. A comparative corrosion behavior of Mg, AZ31 and AZ91 alloys in 3.5% NaCl solution. J. Magnes. Alloys 2015, 3, 142–148. [Google Scholar] [CrossRef]

- Ravi Kumar, N.V.; Blandin, J.J.; Suéry, M.; Grosjean, E. Effect of alloying elements on the ignition resistance of magnesium alloys. Scr. Mater. 2003, 49, 225–230. [Google Scholar] [CrossRef]

- Tekumalla, S.; Joo Yuan, N.; Haghshenas, M.; Gupta, M. Enhancing Properties of Aerospace Alloy Elektron 21 Using Boron Carbide Nanoparticles as Reinforcement. Appl. Sci. 2019, 9, 5470. [Google Scholar] [CrossRef]

- Parande, G.; Tun, K.S.; Neo, H.J.N.; Gupta, M. An Investigation into the Effect of Length Scale (Nano to Micron) of Cerium Oxide Particles on the Mechanical and Flammability Response of Magnesium. J. Mater. Eng. Perform. 2023, 32, 2710–2722. [Google Scholar] [CrossRef]

- Xie, Z.-K.; Tane, M.; Hyun, S.-K.; Okuda, Y.; Nakajima, H. Vibration–damping capacity of lotus-type porous magnesium. Mater. Sci. Eng. A 2006, 417, 129–133. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, G.; Dong, J.; Hou, J.; He, G. Damping behavior and energy absorption capability of porous magnesium. J. Alloys Compd. 2016, 680, 522–530. [Google Scholar] [CrossRef]

- Colakoglu, M. Factors effecting internal damping in aluminum. J. Theor. Appl. Mech. 2004, 42, 95–105. [Google Scholar]

- Hu, B.-L.; Han, J.-Y.; Ge, S.-W.; Hua, X.-J.; Li, S.-L.; Xing, H.-R.; Wang, K.-S.; Hu, P.; Fu, J.-B.; Zhang, W.; et al. Secondary phases strengthening-toughening effects in the Mo–TiC–La2O3 alloys. Mater. Sci. Eng. A 2022, 831, 142271. [Google Scholar] [CrossRef]

- Mugica, G.W.; Tovio, D.O.; Cuyas, J.C.; González, A.C. Effect of porosity on the tensile properties of low ductility aluminum alloys. Mater. Res. 2004, 7, 221–229. [Google Scholar] [CrossRef]

- Zeleniakienė, D.; Kleveckas, T.; Liukaitis, J.; Marazas, G. The influence of porosity on stress and strain state of porous polymer materials. Mater. Sci. 2003, 9, 358–362. [Google Scholar]

- XingHe, T.; Chee Keat How, W.; Chan Kwok Weng, J.; Kwok Wai Onn, R.; Gupta, M. Development of high-performance quaternary LPSO Mg–Y–Zn–Al alloys by Disintegrated Melt Deposition technique. Mater. Des. 2015, 83, 443–450. [Google Scholar] [CrossRef]

- Stadler, F.; Antrekowitsch, H.; Fragner, W.; Kaufmann, H.; Pinatel, E.R.; Uggowitzer, P.J. The effect of main alloying elements on the physical properties of Al–Si foundry alloys. Mater. Sci. Eng. A 2013, 560, 481–491. [Google Scholar] [CrossRef]

- Arkansas Department of Energy and Environment. Zinc and Lead. Office of the State Geologist. Available online: https://www.geology.arkansas.gov/minerals/metallic/zinc-and-lead.html (accessed on 7 December 2023).

- Aghion, E.; Perez, Y. Effects of porosity on corrosion resistance of Mg alloy foam produced by powder metallurgy technology. Mater. Charact. 2014, 96, 78–83. [Google Scholar] [CrossRef]

| Raw Material | Supplier | Purity |

|---|---|---|

| Magnesium Turnings | Acros Organics, NJ, USA | >99.9% |

| Aluminium Lumps | Phoenix Scientific Industries | >99.9% |

| Zinc Shots | Alfa Aesar | >99.9% |

| Calcium Granules | Alfa Aesar | 99.5% |

| Mg-30Y Master Alloy Ingots | Sunrelier Metal Company, China | 99.9% |

| Material Designation | Processing Method Elaboration |

|---|---|

| Mg70Al18Zn6Ca4Y2-DMD | DMD + Extrusion |

| Mg70Al18Zn6Ca4Y2-TID | TID + Extrusion |

| Processing Method | Element (wt.%) | ||||

|---|---|---|---|---|---|

| Mg | Al | Zn | Ca | Y | |

| DMD | 58 ± 0.4 | 17 ± 0.7 | 15 ± 0.2 | 7 ± 0.5 | 3 ± 0.1 |

| TID | 58 ± 0.4 | 17 ± 0.5 | 14 ± 0.2 | 5 ± 0.8 | 6 ± 0.3 |

| Processing Method | Corrected Theoretical Density (g/cm3) | Experimental Density (g/cm3) | Porosity (%) |

|---|---|---|---|

| DMD | 2.133 ± 0.011 | 2.206 ± 0.018 | 0 * |

| TID | 2.162 ± 0.010 | 2.248 ± 0.011 | 0.87 * |

| Processing Method | Attenuation Coefficient | Regression (R2) | Damping Capacity | Excitation Frequency (Hz) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| DMD | 13.86 | 0.996 | 0.000344 | 13,474.9 | 56.9 |

| TID | 16.57 (↑19.5%) | 0.9952 | 0.000423 (↑23.0%) | 12,929.6 | 54.4 (↓4.4%) |

| Processing Method | Spectrum | Symbol | Detected Element (at.%) | Phase | ||||

|---|---|---|---|---|---|---|---|---|

| Mg | Al | Zn | Ca | Y | ||||

| DMD | 1 | ◯ | 91.81 | 4.56 | 3.26 | 0.36 | - | αMg |

| 2 | ☐ | 2.28 | 62.19 | 3.59 | - | 31.93 | Al2Y | |

| 3 | ☆ | 7.67 | 59.64 | 2.16 | 28.58 | 1.95 | Al2Ca | |

| 4 | △ | 44.04 | 25.49 | 24.80 | 5.67 | - | AlxMgyZnz | |

| TID | 1 | ◯ | 97.09 | - | 2.91 | - | - | αMg |

| 2 | ☐ | 5.45 | 62.68 | 2.81 | - | 29.06 | Al2Y | |

| 3 | ☆ | 8.76 | 58.09 | 2.73 | 30.41 | - | Al2Ca | |

| 4 | △ | 39.06 | 33.81 | 18.07 | 9.06 | - | AlxMgyZnz | |

| Processing Method | Average Size of Secondary Phase (μm) | ||

|---|---|---|---|

| Al2Y | Al2Ca | AlxMgyZnz | |

| DMD | 8.3 ± 2.7 | 6.72 ± 1.4 | 3.4 ± 0.8 |

| TID | 4.5 ± 2.6 (↓45.8%) | 4.96 ± 1.9 (↓26.2%) | 2.6 ± 0.7 (↓23.5%) |

| Processing Method | Area Fraction of Secondary Phase | ||

|---|---|---|---|

| Al2Y | Al2Ca | AlxMgyZnz | |

| DMD | 0.05 ± 0.009 | 0.11 ± 0.038 | 0.20 ± 0.07 |

| TID | 0.08 ± 0.024 (↑60%) | 0.13 ± 0.07 (↑18%) | 0.22 ± 0.06 (↑10%) |

| Processing Method | Average Microhardness (HV) | Average Macrohardness (HRB) |

|---|---|---|

| DMD | 151 ± 8.5 | 71 ± 1.6 |

| TID | 203 ± 8.9 (↑34.4%) | 79 ± 1.6 (↑11.2%) |

| Process | 0.2% Compressive Yield Strength (MPa) | Ultimate Compressive Strength (MPa) | Fracture Strain (%) | Energy Absorbed (MJ/m3) |

|---|---|---|---|---|

| DMD | 485 ± 17 | 653 ± 25 | 15 ± 1.4 | 63 ± 8 |

| TID | 554 ± 17 (↑14.2%) | 684 ± 6 (↑4.8%) | 12 ± 0.2 (↓20%) | 53 ± 2 (↓15.9%) |

| Process | Ignition Temperature (°C) |

|---|---|

| DMD | >1300 |

| TID | 915 |

| WE43 (DMD) [21] | 750 |

| Elektron 21 (E21) (DMD) [22] | 741 |

| Process | Average Coefficient of Thermal Expansion (×10−6/K) |

|---|---|

| DMD | 21 ± 5 |

| TID | 22 ± 3 (↑4.8%) |

| Pure Mg (DMD) [23] | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Johanes, M.; Bin Gombari, A.A.; Gupta, M. Enhancing Multiple Properties of a Multicomponent Mg-Based Alloy Using a Sinterless Turning-Induced Deformation Technique. Technologies 2023, 11, 181. https://doi.org/10.3390/technologies11060181

Johanes M, Bin Gombari AA, Gupta M. Enhancing Multiple Properties of a Multicomponent Mg-Based Alloy Using a Sinterless Turning-Induced Deformation Technique. Technologies. 2023; 11(6):181. https://doi.org/10.3390/technologies11060181

Chicago/Turabian StyleJohanes, Michael, Amirin Adli Bin Gombari, and Manoj Gupta. 2023. "Enhancing Multiple Properties of a Multicomponent Mg-Based Alloy Using a Sinterless Turning-Induced Deformation Technique" Technologies 11, no. 6: 181. https://doi.org/10.3390/technologies11060181