Bond between Fibre-Reinforced Polymer Tubes and Sea Water Sea Sand Concrete: Mechanisms and Effective Parameters: Critical Overview and Discussion

Abstract

:1. Introduction

2. Significance of FRP and SWSSC and Their Bond Strength in Construction

2.1. Fibre-Reinforced Polymers

2.2. Seawater and Sea sand Concrete

2.3. Bond Strength in Composite Materials

2.4. Cyclic Behaviour and Bond Strength

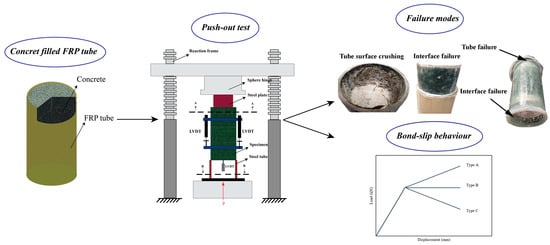

3. Overview of Recent Bond-Slip Studies under Pushout Loads

3.1. Materials and Samples

3.2. Type of Test

3.3. Parameters

3.4. Test Set-Up

4. Discussion on Findings from Previous Pushout Test Results

4.1. Bond Mechanisms

4.2. Failure Modes

4.3. Bond Strength Test Results

4.4. Load–Displacement Curves

5. Effect of Varying Parameters on Bond Strength

5.1. Effect of Fibre Type

5.2. Effect of Tube Dimensions

5.3. Effect of Fibre Orientation

5.4. Tube Surface Roughness

5.5. Concrete Type and Age

6. Recommendations for Future Studies

7. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oskouei, A.V.; Bazli, M.; Ashrafi, H.; Imani, M. Flexural and web crippling properties of GFRP pultruded profiles subjected to wetting and drying cycles in different sea water conditions. Polym. Test. 2018, 69, 417–430. [Google Scholar] [CrossRef]

- Li, Y.; Teng, J.; Zhao, X.; Raman, R.S. Theoretical model for seawater and sea sand concrete-filled circular FRP tubular stub columns under axial compression. Eng. Struct. 2018, 160, 71–84. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Akin, E. Behavior of FRP-Confined Normal- and High-Strength Concrete under Cyclic Axial Compression. J. Compos. Constr. 2012, 16, 451–463. [Google Scholar] [CrossRef] [Green Version]

- Najafabadi, E.P.; Bazli, M.; Ashrafi, H.; Oskouei, A.V. Effect of applied stress and bar characteristics on the short-term creep behavior of FRP bars. Constr. Build. Mater. 2018, 171, 960–968. [Google Scholar] [CrossRef]

- Bazli, M.; Bazli, L.; Rahmani, R.; Mansoor, S.; Ahmadi, M.; Pouriamanesh, R. Concrete filled FRP–PVC tubular columns used in the construction sector: A review. J. Compos. Compd. 2019, 2, 155–162. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Jafari, A.; Ozbakkaloglu, T. Tensile properties of GFRP laminates after exposure to elevated temperatures: Effect of fiber configuration, sample thickness, and time of exposure. Compos. Struct. 2020, 238, 111971. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Jafari, A.; Ashrafi, H.; Raman, R.S.; Bai, Y.; Khezrzadeh, H. Durability of glass-fibre-reinforced polymer composites under seawater and sea-sand concrete coupled with harsh outdoor environments. Adv. Struct. Eng. 2020, 24, 1090–1109. [Google Scholar] [CrossRef]

- Bazli, M.; Li, Y.-L.; Zhao, X.-L.; Raman, R.S.; Bai, Y.; Al-Saadi, S.; Haque, A. Durability of seawater and sea sand concrete filled filament wound FRP tubes under seawater environments. Compos. Part B Eng. 2020, 202, 108409. [Google Scholar] [CrossRef]

- Jafari, A.; Ashrafi, H.; Bazli, M.; Ozbakkaloglu, T. Effect of thermal cycles on mechanical response of pultruded glass fiber reinforced polymer profiles of different geometries. Compos. Struct. 2019, 223, 110959. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Jafari, A.; Ashrafi, H.; Bai, Y.; Raman, R.S.; Khezrzadeh, H. Mechanical properties of pultruded GFRP profiles under seawater sea sand concrete environment coupled with UV radiation and moisture. Constr. Build. Mater. 2020, 258, 120369. [Google Scholar] [CrossRef]

- Jafari, A.; Oskouei, A.V.; Bazli, M.; Ghahri, R. Effect of the FRP sheet’s arrays and NSM FRP bars on in-plane behavior of URM walls. J. Build. Eng. 2018, 20, 679–695. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Bai, Y.; Raman, R.S.; Al-Saadi, S. Bond-slip behaviour between FRP tubes and seawater sea sand concrete. Eng. Struct. 2019, 197, 109421. [Google Scholar] [CrossRef]

- Chen, J.; Chouw, N. Effect of the interface condition on the bond between flax FRP tube and coconut fibre reinforced concrete composites. Constr. Build. Mater. 2018, 167, 597–604. [Google Scholar] [CrossRef]

- Ferdous, W.; Almutairi, A.D.; Huang, Y.; Bai, Y. Short-term flexural behaviour of concrete filled pultruded GFRP cellular and tubular sections with pin-eye connections for modular retaining wall construction. Compos. Struct. 2018, 206, 1–10. [Google Scholar] [CrossRef]

- Oskouei, A.V.; Kivi, M.P.; Araghi, H.; Bazli, M. Experimental study of the punching behavior of GFRP reinforced lightweight concrete footing. Mater. Struct. 2017, 50, 256. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Oskouei, A.V. Enhancement of bond characteristics of ribbed-surface GFRP bars with concrete by using carbon fiber mat anchorage. Constr. Build. Mater. 2017, 134, 507–519. [Google Scholar] [CrossRef]

- Ali, A.M.; Dieng, L.; Masmoudi, R. Experimental, analytical and numerical assessment of the bond-slip behaviour in concrete-filled-FRP tubes. Eng. Struct. 2020, 225, 111254. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X.; Singh, R.R.; Al-Saadi, S. Tests on seawater and sea sand concrete-filled CFRP, BFRP and stainless steel tubular stub columns. Thin-Walled Struct. 2016, 108, 163–184. [Google Scholar] [CrossRef]

- Li, G.; Torres, S.; Alaywan, W.; Abadie, C. Experimental Study of FRP Tube-encased Concrete Columns. J. Compos. Mater. 2005, 39, 1131–1145. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X.; Singh, R.R.; Al-Saadi, S. Experimental study on seawater and sea sand concrete filled GFRP and stainless steel tubular stub columns. Thin-Walled Struct. 2016, 106, 390–406. [Google Scholar] [CrossRef]

- Teng, J.; Yu, T.; Dai, J.; Chen, G. FRP composites in new construction: Current status and opportunities. In Proceedings of the 7th National Conference on FRP Composites in Infrastructure, Hangzhou, China, 15–16 October 2011. [Google Scholar]

- Bazli, M.; Heitzmann, M.; Hernandez, B.V. Hybrid fibre reinforced polymer and seawater sea sand concrete structures: A systematic review on short-term and long-term structural performance. Constr. Build. Mater. 2021, 301, 124335. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, J.; Liao, Q.; Duan, Z. Structural behavior of seawater sea-sand concrete shear wall reinforced with GFRP bars. Eng. Struct. 2019, 189, 458–470. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.-L.; Xian, G.; Wu, G.; Raman, R.S.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Limeira, J.; Agulló, L.; Etxeberria, M. Dredged marine sand as a new source for construction materials. Mater. De Construcción 2012, 62, 7–24. [Google Scholar]

- Peduzzi, P. Sand, rarer than one thinks. Environ. Dev. 2014, 11, 208–218. [Google Scholar]

- Wang, Z.; Zhao, X.-L.; Xian, G.; Wu, G.; Raman, R.S.; Al-Saadi, S. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars. Corros. Sci. 2018, 138, 200–218. [Google Scholar] [CrossRef]

- Han, L.-H.; Hou, C.; Wang, Q.-L. Square concrete filled steel tubular (CFST) members under loading and chloride corrosion: Experiments. J. Constr. Steel Res. 2012, 71, 11–25. [Google Scholar] [CrossRef]

- Hou, C.-C.; Han, L.-H.; Wang, Q.-L.; Hou, C. Flexural behavior of circular concrete filled steel tubes (CFST) under sustained load and chloride corrosion. Thin-Walled Struct. 2016, 107, 182–196. [Google Scholar] [CrossRef]

- Han, L.-H.; Hua, Y.-X.; Hou, C.; Wang, Q.-L. Circular Concrete-Filled Steel Tubes Subjected to Coupled Tension and Chloride Corrosion. J. Struct. Eng. 2017, 143, 04017134. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G.; Cheung, C.H.; Xiao, Y. FRP-confined concrete under axial cyclic compression. Cem. Concr. Compos. 2006, 28, 949–958. [Google Scholar] [CrossRef]

- Zhou, J.; Lin, G.; Teng, J. Compound concrete-filled FRP tubular columns under cyclic axial compression. Compos. Struct. 2021, 275, 114329. [Google Scholar] [CrossRef]

- Yu, T.; Hu, Y.; Teng, J. FRP-confined circular concrete-filled steel tubular columns under cyclic axial compression. J. Constr. Steel Res. 2014, 94, 33–48. [Google Scholar] [CrossRef]

- Wang, J.; Feng, P.; Hao, T.; Yue, Q. Axial compressive behavior of seawater coral aggregate concrete-filled FRP tubes. Constr. Build. Mater. 2017, 147, 272–285. [Google Scholar] [CrossRef]

- Shan, B.; Xu, C.; Lai, D.; Xiao, Y.; Li, T. Experimental research on compressive behavior of seawater and sea sand concrete-filled RPC tubes. Eng. Struct. 2020, 222, 111117. [Google Scholar] [CrossRef]

- Li, Y.-L.; Zhao, X.-L. Hybrid double tube sections utilising seawater and sea sand concrete, FRP and stainless steel. Thin-Walled Struct. 2020, 149, 106643. [Google Scholar] [CrossRef]

- Huang, Y.; Xiao, J.; Qin, L.; Li, P. Mechanical behaviors of GFRP tube confined recycled aggregate concrete with sea sand. Adv. Struct. Eng. 2020, 24, 1196–1207. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Zhao, X.-L.; Zhu, H.; Wei, Y.; Yan, Z. Mechanical properties of discrete BFRP needles reinforced seawater sea-sand concrete-filled GFRP tubular stub columns. Constr. Build. Mater. 2020, 244, 118330. [Google Scholar] [CrossRef]

- Li, Y.-L.; Zhao, X.-L.; Raman, R.S. Behaviour of seawater and sea sand concrete filled FRP square hollow sections. Thin-Walled Struct. 2020, 148, 106596. [Google Scholar] [CrossRef]

- Li, Y.-L.; Zhao, X.-L.; Raman, R.S. Durability of seawater and sea sand concrete and seawater and sea sand concrete-filled fibre-reinforced polymer/stainless steel tubular stub columns. Adv. Struct. Eng. 2020, 24, 1074–1089. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Bai, Y.; Raman, R.S.; Al-Saadi, S.; Haque, A. Durability of pultruded GFRP tubes subjected to seawater sea sand concrete and seawater environments. Constr. Build. Mater. 2020, 245, 118399. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X.; Raman, R.S. Mechanical properties of seawater and sea sand concrete-filled FRP tubes in artificial seawater. Constr. Build. Mater. 2018, 191, 977–993. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Raman, R.S.; Bai, Y.; Al-Saadi, S. Bond performance between FRP tubes and seawater sea sand concrete after exposure to seawater condition. Constr. Build. Mater. 2020, 265, 120342. [Google Scholar] [CrossRef]

- Guo, F.; Al-Saadi, S.; Raman, R.S.; Zhao, X. Durability of fiber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment. Corros. Sci. 2018, 141, 1–13. [Google Scholar] [CrossRef]

- Aly, T.; Elchalakani, M.; Thayalan, P.; Patnaikuni, I. Incremental collapse threshold for pushout resistance of circular concrete filled steel tubular columns. J. Constr. Steel Res. 2010, 66, 11–18. [Google Scholar] [CrossRef]

- Xue, J.; Li, H.; Ren, R.; Zhang, X. The bond behavior of steel reinforced recycled concrete under cyclic reversed load. Eng. Struct. 2021, 248, 113238. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, Y.; Li, S.; Xiao, L. Enhanced bond-slip behavior between recycled aggregate concrete and steel tubes under repeated loading. Structures 2021, 33, 1263–1282. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, R.; Shao, Y.; Zhang, X. Bond-slip behaviour of concrete-filled stainless steel circular hollow section tubes. J. Constr. Steel Res. 2017, 130, 248–263. [Google Scholar] [CrossRef]

- Oskouei, A.V.; Jafari, A.; Bazli, M.; Ghahri, R. Effect of different retrofitting techniques on in-plane behavior of masonry wallettes. Constr. Build. Mater. 2018, 169, 578–590. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Oskouei, A.V.; Bazli, L. Effect of Sequential Exposure to UV Radiation and Water Vapor Condensation and Extreme Temperatures on the Mechanical Properties of GFRP Bars. J. Compos. Constr. 2018, 22, 04017047. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Experiments and probabilistic models of bond strength between GFRP bar and different types of concrete under aggressive environments. Constr. Build. Mater. 2017, 148, 429–443. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Effect of harsh environments on mechanical properties of GFRP pultruded profiles. Compos. Part B Eng. 2016, 99, 203–215. [Google Scholar] [CrossRef]

- Jafari, A.; Bazli, M.; Ashrafi, H.; Oskouei, A.V.; Azhari, S.; Zhao, X.-L.; Gholipour, H. Effect of fibers configuration and thickness on tensile behavior of GFRP laminates subjected to elevated temperatures. Constr. Build. Mater. 2019, 202, 189–207. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Jafari, A.; Zhao, X.-L.; Gholipour, H.; Oskouei, A.V. Effect of thickness and reinforcement configuration on flexural and impact behaviour of GFRP laminates after exposure to elevated temperatures. Compos. Part B Eng. 2018, 157, 76–99. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Najafabadi, E.P.; Oskouei, A.V. The effect of mechanical and thermal properties of FRP bars on their tensile performance under elevated temperatures. Constr. Build. Mater. 2017, 157, 1001–1010. [Google Scholar] [CrossRef]

- Khaneghahi, M.H.; Najafabadi, E.P.; Bazli, M.; Oskouei, A.V.; Zhao, X.-L. The effect of elevated temperatures on the compressive section capacity of pultruded GFRP profiles. Constr. Build. Mater. 2020, 249, 118725. [Google Scholar] [CrossRef]

- Bazli, M.; Abolfazli, M. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers 2020, 12, 2600. [Google Scholar] [CrossRef]

- Nässén, J.; Hedenus, F.; Karlsson, S.; Holmberg, J. Concrete vs. wood in buildings–An energy system approach. Build. Environ. 2012, 51, 361–369. [Google Scholar] [CrossRef]

- Bazli, M. Mechanical and Microstructural Properties of Different FRP Composites under Various Environmental Conditions. Ph. D. Thesis, Monash University, Melbourne, VI, Australia, 2020. [Google Scholar]

- Li, J.; Rismanchi, B.; Ngo, T. Feasibility study to estimate the environmental benefits of utilising timber to construct high-rise buildings in Australia. Build. Environ. 2018, 147, 108–120. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Hamada, H.; Yamaji, T. Performance of seawater-mixed concrete in the tidal environment. Cem. Concr. Res. 2004, 34, 593–601. [Google Scholar] [CrossRef]

- Johansson, M.; Gylltoft, K. Mechanical Behavior of Circular Steel–Concrete Composite Stub Columns. J. Struct. Eng. 2002, 128, 1073–1081. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J. Stress–strain model for FRP-confined concrete under cyclic axial compression. Eng. Struct. 2009, 31, 308–321. [Google Scholar] [CrossRef]

- Murcia-Delso, J.; Stavridis, A.; Shing, P.B. Bond Strength and Cyclic Bond Deterioration of Large-Diameter Bars. ACI Struct. J. 2013, 110, 659–670. [Google Scholar]

- Akbas, T.T.; Celik, O.C.; Yalcin, C.; Ilki, A. Monotonic and Cyclic Bond Behavior of Deformed CFRP Bars in High Strength Concrete. Polymers 2016, 8, 211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Gao, X.; Zhang, P. Experimental investigation on the bond of reinforcing bars in high performance concrete under cyclic loading. Mater. Struct. 2007, 40, 1027–1044. [Google Scholar] [CrossRef]

- Shen, D.; Wen, C.; Zhu, P.; Li, M.; Ojha, B.; Li, C. Bond behavior between basalt fiber-reinforced polymer bars and concrete under cyclic loading. Constr. Build. Mater. 2020, 258, 119518. [Google Scholar] [CrossRef]

- Feng, R.; Chen, Y.; He, K.; Wei, J.; Chen, B.; Zhang, X. Push-out tests of concrete-filled stainless steel SHS tubes. J. Constr. Steel Res. 2018, 145, 58–69. [Google Scholar] [CrossRef]

- Tao, Z.; Song, T.-Y.; Uy, B.; Han, L.-H. Bond behavior in concrete-filled steel tubes. J. Constr. Steel Res. 2016, 120, 81–93. [Google Scholar] [CrossRef]

- Cai, J.; Hao, H.; Ozbakkaloglu, T.; Zhang, Y.; Pan, J. Behavior of geopolymeric recycled aggregate concrete-filled FRP tube (GRACFFT) columns under lateral cyclic loading. Eng. Struct. 2020, 222, 111047. [Google Scholar] [CrossRef]

- Yuan, J.S.; Hadi, M.N. Bond-slip behaviour between GFRP I-section and concrete. Compos. Part B Eng. 2017, 130, 76–89. [Google Scholar] [CrossRef] [Green Version]

- Yuan, J.S.; Hadi, M.N.S. Friction coefficient between FRP pultruded profiles and concrete. Mater. Struct. 2018, 51, 120. [Google Scholar] [CrossRef] [Green Version]

- Ji, G.; Ouyang, Z.; Li, G. Experimental investigation into the interfacial shear strength of AGS-FRP tube confined concrete pile. Eng. Struct. 2009, 31, 2309–2316. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Kasal, B. Experimental study and numerical simulation on bond between FFRP and CFRC components. J. Reinf. Plast. Compos. 2016, 36, 305–320. [Google Scholar] [CrossRef]

- Yang, S.; Yang, C.; Huang, M.; Liu, Y.; Jiang, J.; Fan, G. Study on bond performance between FRP bars and seawater coral aggregate concrete. Constr. Build. Mater. 2018, 173, 272–288. [Google Scholar] [CrossRef]

- Roeder, C.W.; Cameron, B.; Brown, C.B. Composite action in concrete filled tubes. J. Struct. Eng. 1999, 125, 477–484. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I. Investigation on variables affecting bond strength between FRP reinforcing bar and concrete by modified hinged beam tests. Compos. Struct. 2020, 242, 112185. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Xu, Y. Experimental study on the bond durability between steel-FRP composite bars (SFCBs) and sea sand concrete in ocean environment. Constr. Build. Mater. 2016, 115, 277–284. [Google Scholar] [CrossRef]

- Hunaiti, Y.M. Aging effect on bond strength in composite sections. J. Mater. Civ. Eng. 1994, 6, 469–473. [Google Scholar] [CrossRef]

| Reference | Research Type | Tube Type | Concrete Type | Structural Member | Testing Condition |

|---|---|---|---|---|---|

| [35] | Experimental and theoretical | GFRP | PC-SWC | Fully filled circular columns | Compression test |

| [18] | Experimental and theoretical | CFRP, BFRP | SB-SWSSC | Fully filled and double-skin circular columns | Compression test |

| [2] | Theoretical | GFRP, BFRP, CFRP | SB-SWSSC | Fully filled circular columns | Compression test |

| [36] | Experimental and theoretical | CFRP longitudinal and hoop bars | PC-SWSSC | Fully filled circular columns | Compression test |

| [20] | Experimental and theoretical | GFRP | SB-SWSSC | Fully filled and double-skin circular columns | Compression test |

| [37] | Experimental and theoretical | CFRP, BFRP | SB-SWSSC | Fully filled and double-skin circular columns | Compression test |

| [38] | Experimental, theoretical, and numerical | GFRP | PC-SSC | Fully filled circular columns | Compression test |

| [39] | Experimental and theoretical | GFRP | PC-SWSSC | Fully filled circular columns | Compression test and 4-point bending tests |

| [40] | Experimental and theoretical | GFRP, BFRP, CFRP | SB-SWSSC | Fully filled rectangular columns | Compression, 3-point and 4-point bending tests |

| [12] | Experimental and theoretical | GFRP, BFRP, CFRP | SB-SWSSC | Fully filled circular columns | Pushout tests |

| Reference | Tube Type | Concrete Type | Conditioning Type | Structural Member | Testing Condition |

|---|---|---|---|---|---|

| [41] | GFRP | SB-SWSSC | Indoor environment for 1 and 2.5 years | Fully filled circular tubes | Compression tests |

| [42] | GFRP | PC/SB-SWSSC | 30, 90, 180 days immersion in simulated SWSSC (inner side) and seawater (outer side) (25 °C, 40 °C) | Fully filled circular tubes | Compression and tension tests |

| [8] | GFRP, CFRP, BFRP | PC/SB-SWSSC | 30, 90, 180 days immersion in seawater (real concrete as inner side) | Fully filled and double-skin circular tubes | Compression and hoop tests |

| 30, 90, 180 days immersion in simulated SWSSC (inner side) and seawater (outer side) (23 °C, 40 °C) | Fully filled circular tubes | Compression and hoop tests | |||

| [43] | GFRP, CFRP, BFRP | SB-SWSSC | 30, 90, 180 days immersion in seawater (40 °C) | Fully filled and double-skin circular tubes | Compression and hoop tests |

| [44] | GFRP, CFRP, BFRP | SB-SWSSC | 30, 90, 180 days immersion in seawater (25 °C, 40 °C) | Fully filled circular tubes | Pushout tests |

| [45] | GFRP, CFRP, BFRP | PC/SB-SWSSC | Up to 180 days immersion in simulated normal and high-performance SWSSC (25 °C, 40 °C, 60 °C) | Coupon samples cut from tubes | Chemical analyses |

| Reference | [12] | [17] | [46] | [47] |

|---|---|---|---|---|

| Summary | Push out test to investigate chemical and mechanical bond strength and bond slip behaviour of FRP tubes and SWSSC with different fibre orientations, fibre types and diameter to thickness ratios | Push out test to investigate bond strength of pultruded FRP tubes filled with traditional concrete with and without interior sand coating. Analytical and finite element models were also developed | Pushout test of concrete filled steel tubes under static and variable repeated loading using varying strength and age of concrete. | Bond strength of recycled aggregate concrete reinforced with H-shaped steel column under reversed cyclic load |

| Concrete | SWSSC

| Traditional Concrete:

| Traditional concrete

| Recycled aggregate concrete |

| Tube | Filament wound (epoxy resin) and pultruded FRP (viylester resin)

| Pultruded FRP (viylester resin)

| Steel

| No tube—H-shaped steel |

| Materials, Parameters and Test |

|

|

|

|

| Number and Size of Samples |

|

|

| 14 samples—13 under cyclic load and 1 under static load each with different parameters |

| Test set-up |

|

|

|

|

| Collected Results |

|

|

|

|

| Cyclic Load Pattern | - | - |

|

|

| Reference | [19] | [69] | [44] | [70] |

| Summary | FRP confined concrete columns subjected to various tests including compression, bending and pushout tests using concrete of various strengths. | Stainless steel SHS of varying geometry subjected to static pushout loads to study the bond–slip behaviour along the tube and concrete interface | Pushout test of FRP concrete filled tubes of different FRP material under prolonged seawater exposure to investigate bond durability and changes in frictional and chemical bond resistance | Bond strength of circular and square concrete filled steel tubes under different parameters using a pushout test |

| Concrete | Traditional Portland cement-based concrete with 35, 50 and 80 MPa 28-day compressive strength | Traditional Portland cement-based concrete with compressive strengths between 32.3 and 51.7 MPa | SWSSC

| Traditional concrete and recycled aggregate concrete with concrete strength between 40.4 and 81.8 MPa |

| Tube | GFRP tube (viylester resin)

| Stainless steel SHS tubes

| Filament wound (epoxy resin) and pultruded FRP (viylester resin)

| Steel:

|

| Materials, Parameters and Test |

|

|

|

|

| Number and Size of Samples |

|

|

|

|

| Test set-up |

| Similar test set-up to [12] | Similar test set-up to [12] |

|

| Collected Results |

|

|

|

|

| Reference | Materials (Tube/Core) | Fibre Orientation | D/t Ratio | Bond Strength (MPa) |

|---|---|---|---|---|

| [12] | GFRP/SWSSC | 89° | 49, 25.5 | 0.65 (D/t 49) 1.21 |

| [12] | GFRP/SWSSC | Mixed (15°, 40° and 75°) | 49, 25.5 | 0.29 (D/t 49) 1.18 |

| [12] | CFRP/SWSSC | 89° | 49, 25.5 | 1.12 (D/t 49) 2.44 (D/t 25.5) |

| [12] | CFRP/SWSSC | Mixed (15°, 40° and 75°) | 49, 25.5 | 0.64 (D/t 49) 1.71 (D/t 25.5) |

| [12] | BFRP/SWSSC | 89° | 49, 25.5 | 0.35 (D/t 49) 0.99 (D/t 25.5) |

| [12] | BFRP/SWSSC | Mixed (15°, 40° and 75°) | 49, 25.5 | 0.26 (D/t 49) 0.82 (D/t 25.5) |

| [17] | GFRP/Concrete | N/A | 24, 31.7 | 0.03 (D/t 24) 0.023 (D/t 31.7) |

| [19] | GFRP/Normal strength concrete (35 MPa) | 54° | 20.3 | 0.42 |

| [19] | GFRP/Medium strength concrete (50 MPa) | 54° | 20.3 | 0.62 |

| [74] | GFRP/Normal strength concrete | 54° | 13, 8.8 | 2.08 (D/t 13) 2.64 (D/t 8.8) |

| [75] | FFRP1/Coir fibre-reinforced concrete | 0° and 89° | 100 mm/(6 layers of flax fabrics) | 0.64 |

| [13] | FFRP/Coconut fibre-reinforced concrete | 0° and 89° | 100 mm/(4 layers of flax fabric) | 0.315 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luck, J.D.; Bazli, M.; Rajabipour, A. Bond between Fibre-Reinforced Polymer Tubes and Sea Water Sea Sand Concrete: Mechanisms and Effective Parameters: Critical Overview and Discussion. Fibers 2022, 10, 8. https://doi.org/10.3390/fib10010008

Luck JD, Bazli M, Rajabipour A. Bond between Fibre-Reinforced Polymer Tubes and Sea Water Sea Sand Concrete: Mechanisms and Effective Parameters: Critical Overview and Discussion. Fibers. 2022; 10(1):8. https://doi.org/10.3390/fib10010008

Chicago/Turabian StyleLuck, Johanna Dorothea, Milad Bazli, and Ali Rajabipour. 2022. "Bond between Fibre-Reinforced Polymer Tubes and Sea Water Sea Sand Concrete: Mechanisms and Effective Parameters: Critical Overview and Discussion" Fibers 10, no. 1: 8. https://doi.org/10.3390/fib10010008