A Comparison of the Performance of Two Kinds of Waterborne Coatings on Bamboo and Bamboo Scrimber

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Waterborne Coatings

2.3. Fabrication of Bamboo Scrimber

2.4. Coating

2.5. Film Physical Properties

2.6. Characterizations of Basic Properties and Structures

3. Results and Discussion

3.1. Chemical Synthesis and Curing Process

3.2. Chemical Analysis

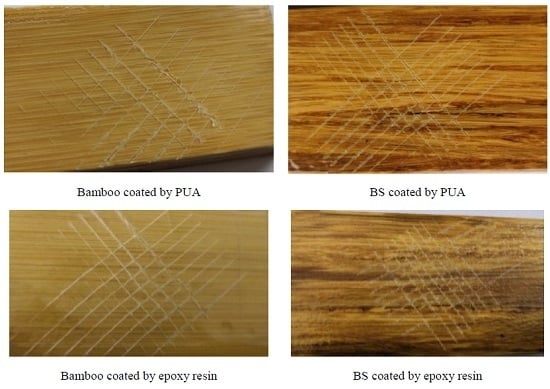

3.3. Morphologies

3.4. Surface Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xie, Y.; Xie, G.; Yao, Q. Present situation and outlook of bamboo resource utilization in China. Chin. J. Trop. Agric. 2004, 6, 46–52. [Google Scholar]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Mahdavi, M.; Clouston, P.L.; Arwade, S.R. A low-technology approach toward fabrication of laminated bamboo lumber. Constr. Build. Mater. 2012, 29, 257–262. [Google Scholar] [CrossRef]

- Shangguan, W.; Zhong, Y.; Xing, X.; Zhao, R.; Ren, H. 2D model of strength parameters for bamboo scrimber. BioResources 2014, 9, 7073–7085. [Google Scholar] [CrossRef]

- Shangguan, W.; Gong, Y.; Zhao, R.; Ren, H. Effects of heat treatment on the properties of bamboo scrimber. J. Wood Sci. 2016, 62, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Meng, F.; Yu, Y.; Zhang, Y.; Yu, W.; Gao, J. Surface chemical composition analysis of heat-treated bamboo. Appl. Surf. Sci. 2016, 371, 383–390. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Wei, Y.; Ji, X.; Duan, M.; Li, G. Flexural performance of bamboo scrimber beams strengthened with fiber-reinforced polymer. Constr. Build. Mater. 2017, 142, 66–82. [Google Scholar] [CrossRef]

- Zhong, Y.; Wu, G.; Ren, H.; Jiang, Z. Bending properties evaluation of newly designed reinforced bamboo scrimber composite beams. Constr. Build. Mater. 2017, 143, 61–70. [Google Scholar] [CrossRef]

- Meng, F.; Liu, R.; Zhang, Y.; Huang, Y.; Yu, Y.; Yu, W. Improvement of the water repellency, dimensional stability, and biological resistance of bamboo-based fiber reinforced composites. Polym. Compos. 2019, 40, 506–513. [Google Scholar] [CrossRef]

- Amada, S.; Ichikawa, Y.; Munekata, T.; Nagase, Y.; Shimizu, H. Fiber texture and mechanical graded structure of bamboo. Compos. Part B Eng. 1997, 28, 13–20. [Google Scholar] [CrossRef]

- Sulastiningsih, I.M.; Nurwati. Physical and mechanical properties of laminated bamboo board. J. Trop. For. Sci. 2009, 3, 246–251. [Google Scholar]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Liptáková, E.; Kúdela, J.; Sarva, J. Study of the system wood-coating material. I. wood-liquid coating material. Holzforschung 2000, 2, 189–196. [Google Scholar] [CrossRef]

- Schaller, C.; Rogez, D. New approaches in wood coating stabilization. J. Coat. Technol. Res. 2007, 4, 401–409. [Google Scholar] [CrossRef]

- Long, L.; Xu, J.; Wan, X. Surface modification of nano-alumina and its application in preparing polyacrylate water-based wood coating. J. Polym. Eng. 2013, 33, 767–774. [Google Scholar] [CrossRef]

- Liptáková, E.; Kúdela, J. Study of the system wood-coating material. Part 2. Wood-solid coating material. Holzforschung 2002, 5, 547–557. [Google Scholar] [CrossRef]

- Queant, C.; Blanchet, P.; Landry, V.; Schorr, D. Effect of adding UV absorbers embedded in carbonate calcium templates covered with light responsive polymer into a clear wood coating. Coatings 2018, 8, 265. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M. Novel attribute of organic–inorganic hybrid coatings for protection and preservation of materials (stone and wood) belonging to cultural heritage. Coatings 2018, 8, 319. [Google Scholar] [CrossRef]

- Li, C.; Xiao, H.; Wang, X.; Zhao, T. Development of green waterborne UV-curable vegetable oil-based urethane acrylate pigment prints adhesive: Preparation and application. J. Clean. Prod. 2018, 180, 272–279. [Google Scholar] [CrossRef]

- ISO 15528:2000 Paints, Varnishes and Raw Materials for Paints and Varnishes-Sampling; ISO: Geneva, Switzerland, 2000.

- Xu, J.; Wu, H.; Liu, R. Preparation and properties of light-resistant UV ink modified with nano-TiO2 on wood substrate. Surf. Eng. 2018. [Google Scholar] [CrossRef]

- ISO 2409-2013 Paints and Varnishes-Cross-Cut Test; ISO: Geneva, Switzerland, 2013.

- ISO 7784-2-2016 Paints and Varnishes—Determination of Resistance to Abrasion—Part 2: Method With Abrasive Rubber Wheels and Rotating Test Specimen; ISO: Geneva, Switzerland, 2016.

- ISO 15184-2012 Paints and Varnishes—Determination of Film Hardness by Pencil Test; ISO: Geneva, Switzerland, 2012.

- Mandla, A.T.; Peter, K.; Mark, R.V. Surface chemistry and moisture sorption properties of wood coated with multifunctional alkoxysilanes by sol-gel process. J. Appl. Polym. Sci. 2003, 88, 2828–2841. [Google Scholar]

- Ray, A.K.; Das, S.K.; Mondal, S.; Ramachandrarao, P. Microstructural characterization of bamboo. J. Mater. Sci. 2004, 39, 1055–1060. [Google Scholar] [CrossRef]

- Sun, R.H.; Li, X.J.; Hou, R.G.; Qiao, J.Z. Effects of high temperature heat treatment on FTIR and XRD characteristics of bamboo bundles. J. Cent. Sout. Fore. Tech. 2013, 2, 97–100. [Google Scholar]

- Rao, J.; Bao, L.; Wang, B.; Fan, M.; Feo, L. Plasma surface modification and bonding enhancement for bamboo composites. Compos. Part B Eng. 2018, 138, 157–167. [Google Scholar] [CrossRef]

- Kocaefe, D.; Huang, X.; Kocaefe, Y.; Boluk, Y. Quantitative characterization of chemical degradation of heat-treated wood surfaces during artificial weathering using XPS. Surf. Interface Analy. 2013, 45, 639–649. [Google Scholar] [CrossRef]

- Gironès, J.; Méndez, J.A.; Boufi, S.; Vilaseca, F.; Mutjé, P. Effect of silane coupling agents on the properties of pine fibers/polypropylene composites. J. Appl. Polym. Sci. 2007, 103, 3706–3717. [Google Scholar] [CrossRef]

- Zou, L.; Jin, H.; Lu, W.Y.; Li, X. Nanoscale structural and mechanical characterization of the cell wall of bamboo fibers. Mater. Sci. Eng. C 2008, 29, 1375–1379. [Google Scholar] [CrossRef]

- Meincken, M.; Evans, P.D. Nanoscale characterization of wood photodegradation using atomic force microscopy. Eur. J. Wood Prod. 2009, 67, 229–231. [Google Scholar] [CrossRef]

| Reagent | Type | Abbreviation | Manufacturer |

|---|---|---|---|

| Ammonium persulfate | Initiator | APS | 1 |

| Acrylic acid | Monomer | AA | 1 |

| Styrene | Monomer | ST | 1 |

| Ethyl acrylate | Monomer | EA | 1 |

| Hydroxyethyl acrylate | Monomer | HEA | 1 |

| Toluene-2,4-diisocyanate | Monomer | TDI | 1 |

| Polyethylene glycol (Mn: 400) | Monomer | PEG-400 | 1 |

| Dibutyltin dilaurate | Catalyzer | DBTD | 1 |

| γ-aminopropyl triethoxysilane | Silane | KH550 | 2 |

| Polyether siloxane copolymer composition | Defoamer agent | – | 3 |

| Phenolic epoxy resin | Resin | – | 4 |

| Ethanol | Solvent | – | 3 |

| Ethylene glycol monobutyl ether | Solvent | – | 3 |

| N-methyl-2-pyrrolidone | Solvent | – | 3 |

| Diethanolamine | Modifier | – | 3 |

| Glacial acetic acid | Neutralization reagent | – | 3 |

| Samples | Element Content (%) | ||

|---|---|---|---|

| C | O | N | |

| Bamboo | 70.35 | 26.63 | 3.02 |

| BS | 78.37 | 19.01 | 2.62 |

| Bamboo coated with PUA | 74.77 | 20.43 | 4.81 |

| BS coated with PUA | 74.21 | 17.61 | 8.18 |

| Bamboo coated with the epoxy coating | 81.19 | 17.06 | 1.75 |

| BS coated with the epoxy coating | 78.56 | 19.86 | 1.58 |

| Samples | Element Content (%) | |||

|---|---|---|---|---|

| C1 | C2 | C3 | C4 | |

| Bamboo | 54.82 | 34.78 | 10.40 | 0 |

| BS | 72.51 | 19.35 | 8.14 | 0 |

| Bamboo coated with PUA | 68.81 | 18.96 | 12.23 | 0 |

| BS coated with PUA | 66.09 | 22.42 | 7.58 | 3.91 |

| Bamboo coated with the epoxy coating | 75.10 | 20.39 | 0 | 4.51 |

| BS coated with the epoxy coating | 69.35 | 25.23 | 0 | 5.43 |

| Samples | Adhesion Level | Hardness | Abrasion Value (g/100r) | Dry Film Thickness (μm) | Roughness (nm) |

|---|---|---|---|---|---|

| Glass pane coated with PUA | – | 4H | 0.168 | – | 0.65 |

| Bamboo coated with PUA | 2 | H | 0.088 | 10.6 | 1.35 |

| BS coated with PUA | 2 | H | 0.092 | 13.9 | 1.41 |

| Glass pane coated with the epoxy coating | – | 2H | 0.188 | – | 0.72 |

| Bamboo coated with the epoxy coating | 1 | HB | 0.075 | 8.7 | 1.89 |

| BS coated with the epoxy coating | 2 | HB | 0.122 | 15.4 | 2.79 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Liu, R.; Wu, H.; Qiu, H.; Yu, Y.; Long, L.; Ni, Y. A Comparison of the Performance of Two Kinds of Waterborne Coatings on Bamboo and Bamboo Scrimber. Coatings 2019, 9, 161. https://doi.org/10.3390/coatings9030161

Xu J, Liu R, Wu H, Qiu H, Yu Y, Long L, Ni Y. A Comparison of the Performance of Two Kinds of Waterborne Coatings on Bamboo and Bamboo Scrimber. Coatings. 2019; 9(3):161. https://doi.org/10.3390/coatings9030161

Chicago/Turabian StyleXu, Jianfeng, Ru Liu, Huagui Wu, Hongyun Qiu, Yanglun Yu, Ling Long, and Yonghao Ni. 2019. "A Comparison of the Performance of Two Kinds of Waterborne Coatings on Bamboo and Bamboo Scrimber" Coatings 9, no. 3: 161. https://doi.org/10.3390/coatings9030161