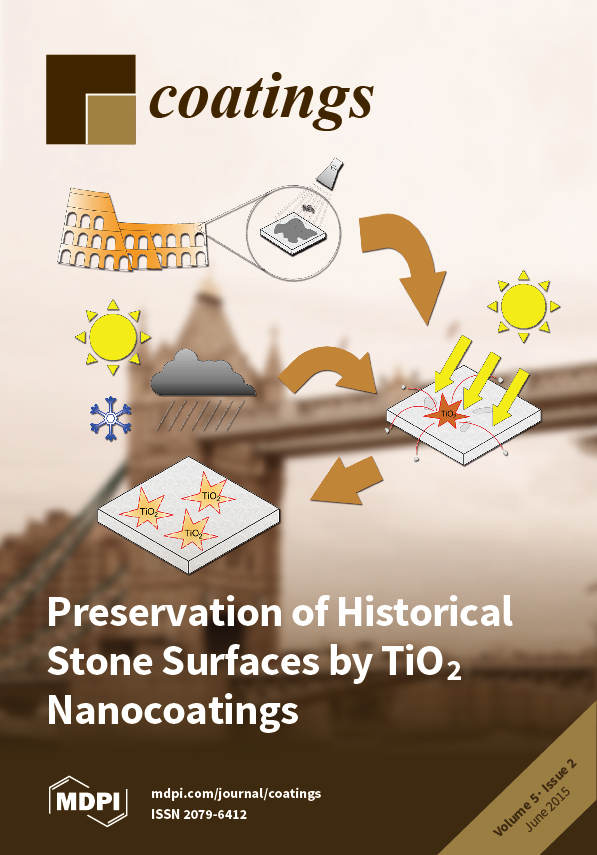

We proposed the application of titanium dioxide (TiO

2) for the preservation of historical (architectural, monumental, archaeological) stone surfaces. Solar light can activate the photocatalytic effect of TiO

2 nanoparticles: heterogeneous photocatalysis is the key factor for the development of self-cleaning, depolluting

[...] Read more.

We proposed the application of titanium dioxide (TiO

2) for the preservation of historical (architectural, monumental, archaeological) stone surfaces. Solar light can activate the photocatalytic effect of TiO

2 nanoparticles: heterogeneous photocatalysis is the key factor for the development of self-cleaning, depolluting and biocidal treatments able to photochemically degrade external damaging materials and prolong the durability of treated substrates, maintaining their original aspect and limiting ordinary cleaning activities. In this study, TiO

2 nanoparticles dispersed in an aqueous colloidal suspension were applied directly on travertine, a light-colored limestone, by spray-coating in order to obtain a nanometric film on stone samples. To assess the feasibility of use of TiO

2, we studied the characteristics of the nanocoating-stone system by monitoring the microscopic features of the coatings, the aesthetical changes induced to coated surfaces and the self-cleaning efficiency. We also monitored the self-cleaning ability over time during an accelerated ageing process to evaluate the durability of TiO

2-based treatments. We confirmed both compatibility and effectiveness of TiO

2 coating in the short term, anyway its efficiency decreased after artificial ageing. Further studies are necessary to better evaluate and eventually improve the stability of self-cleaning efficiency over prolonged time for outdoor stone surfaces.

Full article