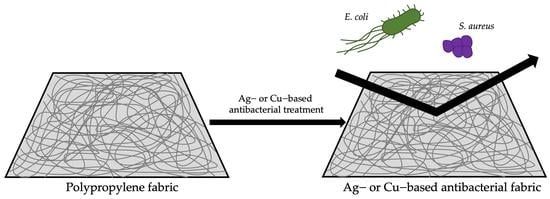

Efficacy Evaluation of Cu- and Ag-Based Antibacterial Treatments on Polypropylene Fabric and Comparison with Commercial Products

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Antibacterial Treatments Development

2.3. Identification and Selection of Mask Commercial Samples

2.4. Morphological and Elemental Analysis

2.5. Crystalline Structures Investigation

2.6. Hydrophobicity Degree

2.7. Antibacterial Agent Content

2.8. Antibacterial Activity

2.9. Statistical Analysis

3. Results

3.1. Morphological and Elemental Analysis

3.2. Crystalline Structures Investigation

3.3. Hydrophobicity Degree

3.4. Antibacterial Agent Content

3.5. Antibacterial Activity

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, M.; Liu, H.; Wang, X.; Hu, X.; Huang, Y.; Liu, X.; Brenan, K.; Mecha, J.; Nirmalan, M.; Lu, J.R. A Technical Review of Face Mask Wearing in Preventing Respiratory COVID-19 Transmission. Curr. Opin. Colloid. Interface Sci. 2021, 52, 101417. [Google Scholar] [CrossRef] [PubMed]

- Tirupathi, R.; Bharathidasan, K.; Palabindala, V.; Salim, S.A.; Al-Tawfiq, J.A. Comprehensive Review of Mask Utility and Challenges during the COVID-19 Pandemic. Infez. Med. 2020, 28, 57–63. [Google Scholar] [PubMed]

- Selvaranjan, K.; Navaratnam, S.; Rajeev, P.; Ravintherakumaran, N. Environmental Challenges Induced by Extensive Use of Face Masks during COVID-19: A Review and Potential Solutions. Environ. Chall. 2021, 3, 100039. [Google Scholar] [CrossRef]

- UNI EN 14683:2019 − Maschere Facciali Ad Uso Medico-Requisiti e Metodi Di Prova. Available online: https://store.uni.com/catalogo/uni-en-14683-2019-292195?josso_back_to=https://store.uni.com/josso-security-check.php&josso_cmd=login_optional&josso_partnerapp_host=store.uni.com (accessed on 6 April 2022).

- UNI EN 149:2009 − Dispositivi Di Protezione Delle Vie Respiratorie-Semimaschere Filtranti Antipolvere-Requisiti, Prove, Marcatura. Available online: https://store.uni.com/catalogo/uni-en-149-2009 (accessed on 6 April 2022).

- PdR UNI 90:2020—Maschere Di Comunità. Available online: https://store.uni.com/uni-pdr-90-1-2020 (accessed on 6 April 2022).

- Pullangott, G.; Kannan, U.; Gayathri, S.; Kiran, D.V.; Maliyekkal, S.M. A Comprehensive Review on Antimicrobial Face Masks: An Emerging Weapon in Fighting Pandemics. RSC Adv. 2021, 11, 6544–6576. [Google Scholar] [CrossRef]

- Xu, E.G.; Ren, Z.J. Preventing Masks from Becoming the next Plastic Problem. Front. Environ. Sci. Eng. 2021, 15, 6–8. [Google Scholar] [CrossRef]

- Hu, T.; Shen, M.; Tang, W. Wet Wipes and Disposable Surgical Masks Are Becoming New Sources of Fiber Microplastic Pollution during Global COVID-19. Environ. Sci. Pollut. Res. 2022, 29, 284–292. [Google Scholar] [CrossRef]

- Chen, X.; Chen, X.; Liu, Q.; Zhao, Q.; Xiong, X.; Wu, C. Used Disposable Face Masks Are Significant Sources of Microplastics to Environment. Environ. Pollut. 2021, 285, 117485. [Google Scholar] [CrossRef]

- Aboubakr, H.A.; Sharafeldin, T.A.; Goyal, S.M. Stability of SARS-CoV-2 and Other Coronaviruses in the Environment and on Common Touch Surfaces and the Influence of Climatic Conditions: A Review. Transbound. Emerg. Dis. 2021, 68, 296–312. [Google Scholar] [CrossRef]

- Valdez-Salas, B.; Beltran-Partida, E.; Cheng, N.; Salvador-Carlos, J.; Valdez-Salas, E.A.; Curiel-Alvarez, M.; Ibarra-Wiley, R. Promotion of Surgical Masks Antimicrobial Activity by Disinfection and Impregnation with Disinfectant Silver Nanoparticles. Int. J. Nanomed. 2021, 16, 2689–2702. [Google Scholar] [CrossRef]

- Blevens, M.S.; Pastrana, H.F.; Mazzotta, H.C.; Tsai, C.S.-J. Cloth Face Masks Containing Silver: Evaluating the Status. ACS Chem. Health Saf. 2021, 28, 171–182. [Google Scholar] [CrossRef]

- Borkow, G.; Melamed, E. Copper, an Abandoned Player Returning to the Wound Healing Battle. Recent. Adv. Wound Health 2022. [Google Scholar] [CrossRef]

- Kumar, S.; Karmacharya, M.; Joshi, S.R.; Gulenko, O.; Park, J.; Kim, G.-H.; Cho, Y.-K. Photoactive Antiviral Face Mask with Self-Sterilization and Reusability. Nano Lett. 2021, 21, 337–343. [Google Scholar] [CrossRef] [PubMed]

- Picca, R.A.; Paladini, F.; Sportelli, M.C.; Pollini, M.; Giannossa, L.C.; Di Franco, C.; Panico, A.; Mangone, A.; Valentini, A.; Cioffi, N. Combined Approach for the Development of Efficient and Safe Nanoantimicrobials: The Case of Nanosilver-Modified Polyurethane Foams. ACS Biomater. Sci. Eng. 2017, 3, 1417–1425. [Google Scholar] [CrossRef]

- Alexander, J.W. History of the Medical Use of Silver. Surg. Infect. 2009, 10, 289–294. [Google Scholar] [CrossRef]

- Dollwet, H.H.A.; Sorenson, J.R.J. Historic Uses of Copper Compounds in Medicine. Trace Elem. Med. 1985, 2, 80–87. [Google Scholar]

- Jung, S.; Yang, J.-Y.; Byeon, E.-Y.; Kim, D.-G.; Lee, D.-G.; Ryoo, S.; Lee, S.; Shin, C.-W.; Jang, H.W.; Kim, H.J.; et al. Copper-Coated Polypropylene Filter Face Mask with SARS-CoV-2 Antiviral Ability. Polymers 2021, 13, 1367. [Google Scholar] [CrossRef] [PubMed]

- Borkow, G.; Gabbay, J. Copper as a Biocidal Tool. Curr. Med. Chem. 2005, 12, 2163–2175. [Google Scholar] [CrossRef]

- Gomes, I.B.; Simões, M.; Simões, L.C. Copper Surfaces in Biofilm Control. Nanomaterials 2020, 10, 2491. [Google Scholar] [CrossRef] [PubMed]

- Hiragond, C.B.; Kshirsagar, A.S.; Dhapte, V.V.; Khanna, T.; Joshi, P.; More, P.V. Enhanced Anti-Microbial Response of Commercial Face Mask Using Colloidal Silver Nanoparticles. Vacuum 2018, 156, 475–482. [Google Scholar] [CrossRef]

- Borkow, G.; Okon-Levy, N.; Gabbay, J. Copper Oxide Impregnated Wound PL. Wounds 2010, 22, 301–310. [Google Scholar]

- Sportelli, M.C.; Picca, R.A.; Ronco, R.; Bonerba, E.; Tantillo, G.; Pollini, M.; Sannino, A.; Valentini, A.; Cataldi, T.R.I.; Cioffi, N. Investigation of Industrial Polyurethane Foams Modified with Antimicrobial Copper Nanoparticles. Materials 2016, 9, 544. [Google Scholar] [CrossRef] [PubMed]

- Pollini, M.; Paladini, F.; Licciulli, A.; Maffezzoli, A.; Sannino, A. Engineering Nanostructured Silver Coatings for Antimicrobial Applications. In Nano-Antimicrobials; Springer: Berlin/Heidelberg, Germany, 2012; pp. 313–336. [Google Scholar]

- Cooper, I.R.; Pollini, M.; Paladini, F. The Potential of Photo-Deposited Silver Coatings on Foley Catheters to Prevent Urinary Tract Infections. Mater. Sci. Eng. C 2016, 69, 414–420. [Google Scholar] [CrossRef] [PubMed]

- Sportelli, M.C.; Picca, R.A.; Paladini, F.; Mangone, A.; Giannossa, L.C.; Franco, C.D.; Gallo, A.L.; Valentini, A.; Sannino, A.; Pollini, M.; et al. Spectroscopic Characterization and Nanosafety of Ag-Modified Antibacterial Leather and Leatherette. Nanomaterials 2017, 7, 203. [Google Scholar] [CrossRef]

- Raho, R.; Paladini, F.; Lombardi, F.A.; Boccarella, S.; Zunino, B.; Pollini, M. In-Situ Photo-Assisted Deposition of Silver Particles on Hydrogel Fibers for Antibacterial Applications. Mater. Sci. Eng. C 2015, 55, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Sagripanti, J.-L.; Goering, P.L.; Lamanna, A. Interaction of Copper with DNA and Antagonism by Other Metals. Toxicol. Appl. Pharmacol. 1991, 110, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Arendsen, L.P.; Thakar, R.; Sultan, A.H. The Use of Copper as an Antimicrobial Agent in Health Care, Including Obstetrics and Gynecology. Clin. Microbiol. Rev. 2019, 32, e00125-18. [Google Scholar] [CrossRef]

- Salah, I.; Parkin, I.P.; Allan, E. Copper as an Antimicrobial Agent: Recent Advances. RSC Adv. 2021, 11, 18179–18186. [Google Scholar] [CrossRef]

- Anees Ahmad, S.; Sachi Das, S.; Khatoon, A.; Tahir Ansari, M.; Afzal, M.; Saquib Hasnain, M.; Kumar Nayak, A. Bactericidal Activity of Silver Nanoparticles: A Mechanistic Review. Mater. Sci. Energy Technol. 2020, 3, 756–769. [Google Scholar] [CrossRef]

- Yin, I.X.; Zhang, J.; Zhao, I.S.; Mei, M.L.; Li, Q.; Chu, C.H. The Antibacterial Mechanism of Silver Nanoparticles and Its Application in Dentistry. Int. J. Nanomed. 2020, 15, 2555–2562. [Google Scholar] [CrossRef]

- Franci, G.; Falanga, A.; Galdiero, S.; Palomba, L.; Rai, M.; Morelli, G.; Galdiero, M. Silver Nanoparticles as Potential Antibacterial Agents. Molecules 2015, 20, 8856–8874. [Google Scholar] [CrossRef]

- Morones, J.R.; Elechiguerra, J.L.; Camacho, A.; Holt, K.; Kouri, J.B.; Ramírez, J.T.; Yacaman, M.J. The Bactericidal Effect of Silver Nanoparticles. Nanotechnology 2005, 16, 2346–2353. [Google Scholar] [CrossRef]

- Silvia, G.; Pagani, I.; Poli, G.; Pal, S.; Licciulli, A.; Perboni, S.; Vicenzi, E. Rapid Inactivation of SARS-CoV-2 by Coupling Tungsten Trioxide (WO3) Photocatalyst with Copper Nanoclusters. J. Nanotechnol. Nanomater. 2020, 1, 109–115. [Google Scholar] [CrossRef]

- Gallo, N.; Natali, M.L.; Curci, C.; Picerno, A.; Gallone, A.; Vulpi, M.; Vitarelli, A.; Ditonno, P.; Cascione, M.; Sallustio, F.; et al. Analysis of the Physico-Chemical, Mechanical and Biological Properties of Crosslinked Type-I Collagen from Horse Tendon: Towards the Development of Ideal Scaffolding Material for Urethral Regeneration. Materials 2021, 14, 7648. [Google Scholar] [CrossRef] [PubMed]

- Borkow, G.; Salvatori, R.; Kanmukhla, V.K. Drastic Reduction of Bacterial, Fungal and Viral Pathogen Titers by Cuprous Oxide Impregnated Medical Textiles. J. Funct. Biomater. 2021, 12, 9. [Google Scholar] [CrossRef]

- Gawish, S.M.; Mosleh, S. Antimicrobial Polypropylene Loaded by Silver Nano Particles. Fibers Polym. 2020, 21, 19–23. [Google Scholar] [CrossRef]

- Zhu, S.; Kang, Z.; Wang, F.; Long, Y. Copper Nanoparticle Decorated Non-Woven Polypropylene Fabrics with Durable Superhydrophobicity and Conductivity. Nanotechnology 2021, 32, 035701. [Google Scholar] [CrossRef]

- Whyte, H.E.; Joubert, A.; Leclerc, L.; Sarry, G.; Verhoeven, P.; Le Coq, L.; Pourchez, J. Reusability of Face Masks: Influence of Washing and Comparison of Performance between Medical Face Masks and Community Face Masks. Environ. Technol. Innov. 2022, 28, 102710. [Google Scholar] [CrossRef]

- Varanges, V.; Caglar, B.; Lebaupin, Y.; Batt, T.; He, W.; Wang, J.; Rossi, R.M.; Richner, G.; Delaloye, J.-R.; Michaud, V. On the Durability of Surgical Masks after Simulated Handling and Wear. Sci. Rep. 2022, 12, 4938. [Google Scholar] [CrossRef]

- Cho, D.; Zhou, H.; Cho, Y.; Audus, D.; Joo, Y.L. Structural Properties and Superhydrophobicity of Electrospun Polypropylene Fibers from Solution and Melt. Polymer 2010, 51, 6005–6012. [Google Scholar] [CrossRef]

- Chu, C.; Hu, X.; Yan, H.; Sun, Y. Surface Functionalization of Nanostructured Cu/Ag-Deposited Polypropylene Fiber by Magnetron Sputtering. e-Polymers 2021, 21, 140–150. [Google Scholar] [CrossRef]

- Jardón-Maximino, N.; Cadenas-Pliego, G.; Ávila-Orta, C.A.; Comparán-Padilla, V.E.; Lugo-Uribe, L.E.; Pérez-Alvarez, M.; Tavizón, S.F.; Santillán, G.d.J.S. Antimicrobial Property of Polypropylene Composites and Functionalized Copper Nanoparticles. Polymers 2021, 13, 1694. [Google Scholar] [CrossRef] [PubMed]

- Balagna, C.; Perero, S.; Percivalle, E.; Nepita, E.V.; Ferraris, M. Virucidal Effect against Coronavirus SARS-CoV-2 of a Silver Nanocluster/Silica Composite Sputtered Coating. Open. Ceram. 2020, 1, 100006. [Google Scholar] [CrossRef]

- Lv, X.; Wang, P.; Bai, R.; Cong, Y.; Suo, S.; Ren, X.; Chen, C. Inhibitory Effect of Silver Nanomaterials on Transmissible Virus-Induced Host Cell Infections. Biomaterials 2014, 35, 4195–4203. [Google Scholar] [CrossRef] [PubMed]

| Mask Type | Antibacterial Treatment | Company | Product Name | Code | Material |

|---|---|---|---|---|---|

| Prototypes | Silver | Unisalento | Ag | SIL | PP |

| Copper | Nanohub/Unisalento | Cu | COP | PP | |

| Surgical mask | Silver | – | – | – | – |

| Copper | Olvitech | Copper Oxide Medical Mask | OLV | PP | |

| Personal Protective Equipment | Silver | ARGO Industries | FFP2 Washable mask | ARG | Cotton/PE |

| Copper | Respilon | VK RespiPro | RES | PP | |

| Community face covering | Silver | Absolutex | ACM | ABS | PE |

| Copper | Primeway | P29 | PRI | PU |

| Sample | 0 W | 3 W | 10 W |

|---|---|---|---|

| SIL | 2.61 ÷ 2.83% | 2.45 ÷ 2.52% | 2.44 ÷ 2.48% |

| COP | 6.47 ÷ 6.89% | 1.16 ÷ 1.75% | 1.51 ÷ 1.65% |

| ARG | 0.21 ÷ 0.29% | 0.20 ÷ 0.28% | 0.01 ÷ 0.03% |

| ABS | 0.92 ÷ 1.06% | 0.55 ÷ 0.63% | 0.31 ÷ 0.39% |

| OLV | 0.90 ÷ 1.02% | 0.74 ÷ 0.86% | 0.74 ÷ 0.76% |

| RES | 1.62 ÷ 1.68% | 1.42 ÷ 1.58% | 0.84 ÷ 0.96% |

| PRI | 0.30 ÷ 0.40% | 0.25 ÷ 0.35% | 0.20 ÷ 0.30% |

| Mask Type | 0 W | 3 W | 10 W |

|---|---|---|---|

| PP | 134 ± 2° | 117 ± 11° | 103 ± 4° |

| SIL | 127 ± 2° | 110 ± 15° | 104 ± 4° |

| COP | 124 ± 6° | 122 ± 3° | 118 ± 7° |

| OLV | 104 ± 10° | 120 ± 5° | 114 ± 4° |

| ARG | 128 ± 13° | 118 ± 9° | 122 ± 10° |

| RES | 129 ± 7° | 119 ± 8° | 117 ± 8° |

| ABS | 0 ± 0° | 0 ± 0° | 0 ± 0° |

| PRI | 0 ± 0° | 0 ± 0° | 0 ± 0° |

| Mask Type | 0 W | 3 W | 10 W |

|---|---|---|---|

| SIL | 4.0 ± 0.7 | 3.6 ± 0.6 | 3.6 ± 0.3 |

| COP | 4.5 ± 1.4 | 4.0 ± 0.4 | 2.1 ± 0.9 |

| OLV | 3.8 ± 0.3 | 3.0 ± 1.1 | 2.7 ± 0.7 |

| ARG | 0.4 ± 0.2 | 0.2 ± 0.1 | 0.2 ± 0.1 |

| RES | 3.5 ± 0.6 | 2.3 ± 0.9 | 2.0 ± 0.3 |

| ABS | 0.9 ± 0.2 | 0.7 ± 0.5 | 0.5 ± 0.2 |

| PRI | 1.5 ± 0.8 | 1.1 ± 0.4 | 0.8 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallo, N.; Iaconisi, G.N.; Pollini, M.; Paladini, F.; Pal, S.; Nobile, C.; Capobianco, L.; Licciulli, A.; Buonocore, G.G.; Mansi, A.; et al. Efficacy Evaluation of Cu- and Ag-Based Antibacterial Treatments on Polypropylene Fabric and Comparison with Commercial Products. Coatings 2023, 13, 919. https://doi.org/10.3390/coatings13050919

Gallo N, Iaconisi GN, Pollini M, Paladini F, Pal S, Nobile C, Capobianco L, Licciulli A, Buonocore GG, Mansi A, et al. Efficacy Evaluation of Cu- and Ag-Based Antibacterial Treatments on Polypropylene Fabric and Comparison with Commercial Products. Coatings. 2023; 13(5):919. https://doi.org/10.3390/coatings13050919

Chicago/Turabian StyleGallo, Nunzia, Giorgia Natalia Iaconisi, Mauro Pollini, Federica Paladini, Sudipto Pal, Concetta Nobile, Loredana Capobianco, Antonio Licciulli, Giovanna Giuliana Buonocore, Antonella Mansi, and et al. 2023. "Efficacy Evaluation of Cu- and Ag-Based Antibacterial Treatments on Polypropylene Fabric and Comparison with Commercial Products" Coatings 13, no. 5: 919. https://doi.org/10.3390/coatings13050919