CuO/ZnO Heterojunction Nanorod Arrays Prepared by Photochemical Method with Improved UV Detecting Performance

Abstract

:1. Introduction

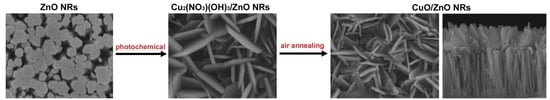

2. Experiment

3. Results and Discussion

3.1. Characteristics of Materials

3.2. UV Detecting Performance of CuO/ZnO Heterojunction NRs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Fu, Q.M.; He, D.C.; Yao, Z.C.; Peng, J.L.; Zhao, H.Y.; Tao, H.; Chen, Z.; Tu, Y.F.; Tian, Y.; Zhou, D.; et al. Self-powered ultraviolet photodetector based on ZnO nanorod arrays decorated with sea anemone-like CuO nanostructures. Mater. Lett. 2018, 222, 74–77. [Google Scholar] [CrossRef]

- Liang, Y.C.; Chang, C.W. Improvements of ethanol gas-sensing responses of ZnO-WO3 composite nanorods through annealing induced local phase transformation. Nanomaterials 2019, 9, 669. [Google Scholar] [CrossRef]

- Pietruszka, R.; Witkowski, B.; Gieraltowska, S.; Caban, P.; Wachnicki, L.; Zielony, E.; Gwozdz, K.; Bieganski, P.; Placzek-Popko, E.; Godlewski, M. New efficient solar cell structures based on zinc oxide nanorods. Sol. Energy Mater. Sol. Cells 2015, 143, 99–104. [Google Scholar] [CrossRef]

- Hatch, S.; Briscoe, J.; Dunn, S. A self-powered ZnO-nanorod/CuSCN UV photodetector exhibiting rapid response. Adv. Mater. 2013, 25, 867–871. [Google Scholar] [CrossRef]

- Khan, F.; Khan, W.; Kim, S.D. High performance ultraviolet light detection using nano-scale-fin isolation AlGaN/GaN heterostructure with ZnO nanorods. Nanomaterials 2019, 9, 440. [Google Scholar] [CrossRef]

- Game, O.; Singh, U.; Kumari, T.; Banpurkar, A.; Ogale, S. ZnO(N)-Spiro MeOTAD hybrid photodiode: An efficient self-powered fast-response UV (visible) photosensor. Nanoscale 2014, 6, 503–513. [Google Scholar] [CrossRef] [PubMed]

- Nam, G.; Leem, J.Y. Fast-response photoconductive ultraviolet light detectors fabricated using high-quality ZnO films obtained by plasma-assisted molecular beam epitaxy. Ceram. Int. 2017, 43, 11981–11985. [Google Scholar] [CrossRef]

- Ghosh, S.; Das, K.; Tripathy, N.; Bose, G.; Kim, D.; Lee, T.; Myoung, J.; Kar, J. Ultraviolet photodetection characteristics of zinc oxide thin films and nanostructures. IOP Conf. Ser. Mater. Sci. Eng. 2016, 115, 012035. [Google Scholar] [CrossRef]

- Cao, Y.; Deng, S.; Hu, Q.; Zhong, Q.; Luo, Q.; Yuan, L.; Zhou, J. Three-dimensional ZnO porous films for self-cleaning ultraviolet photodetectors. RSC Adv. 2015, 5, 85969–85973. [Google Scholar] [CrossRef]

- Mridha, S.; Basak, D. ZnO/polyaniline based inorganic/organic hybrid structure: Electrical and photoconductivity properties. Appl. Phys. Lett. 2008, 92, 142111. [Google Scholar] [CrossRef]

- Rajan, A.; Kaur, G.; Paliwal, A.; Yadav, H.; Gupta, V.; Tomar, M. Plasmonic assisted enhanced photoresponse of metal nanoparticle loaded ZnO thin film ultraviolet photodetectors. J. Phys. D Appl. Phys. 2014, 47, 425102. [Google Scholar] [CrossRef]

- Panigrahi, S.; Basak, D. Core-shell TiO2@ZnO nanorods for efficient ultraviolet photodetection. Nanoscale 2011, 3, 2336–2341. [Google Scholar] [CrossRef]

- Dao, T.; Dang, C.; Han, G.; Hoang, C.; Narayanamurti, W.; Nagao, T. Chemically synthesized nanowire TiO2/ZnO core-shell p-n junction array for high sensitivity ultraviolet photodetector. Appl. Phys. Lett. 2013, 103, 193119. [Google Scholar] [CrossRef]

- Dai, W.; Pan, X.; Chen, S.; Chen, C.; Wen, Z.; Zhang, H.; Ye, Z. Honeycomb-like NiO/ZnO heterostructured nanorods: Photochemical synthesis, characterization, and enhanced UV detection performance. J. Mater. Chem. C 2014, 2, 4606–4614. [Google Scholar] [CrossRef]

- Wang, T.; Jiao, Z.; Chen, T.; Li, Y.; Ren, W.; Lin, S.; Lu, G.; Ye, J.; Bi, Y. Vertically aligned ZnO nanowire arrays tip-grafted with silver nanoparticles for photoelectrochemical applications. Nanoscale 2013, 5, 7552–7557. [Google Scholar] [CrossRef]

- Chen, T.; Lee, K.; Chang, S.; Chang, S.; Chang, P. Effect of surface modification by self-assembled monolayer on the ZnO film ultraviolet sensor. Appl. Phys. Lett. 2013, 103, 022101. [Google Scholar] [CrossRef]

- Kargar, A.; Jing, Y.; Kim, S.; Riley, C.; Pan, X.; Wang, D. ZnO/CuO heterojunction branched nanowires for photoelectrochemical hydrogen generation. ACS Nano 2013, 7, 11112–11120. [Google Scholar] [CrossRef]

- Juan, Y.; Chang, S.; Hsueh, H.; Wang, S.; Cheng, T.; Huang, S.; Hsueh, T.; Yeh, Y.; Hsu, C. Electron field emitters made of 3-D CuO nanowires on flexible silicon substrate fabricated by heating Cu rods with through silicon via process. RSC Adv. 2016, 6, 47292–47297. [Google Scholar] [CrossRef]

- Yu, J.; Zhuang, S.; Xu, X.; Zhu, W.; Feng, B.; Hu, J. Photogenerated electron reservoir in hetero-p-n CuO-ZnO nanocomposite device for visible-light-driven photocatalytic reduction of aqueous Cr(VI). J. Mater. Chem. A 2015, 3, 1199–1207. [Google Scholar] [CrossRef]

- Liu, C.; Meng, F.L.; Zhang, L.; Zhang, D.T.; Wei, S.T.; Qi, K.; Fan, J.C.; Zhang, H.Y.; Cui, X.Q. CuO/ZnO heterojunction nanoarrays for enhanced photoelectrochemical water oxidation. Appl. Surf. Sci. 2019, 469, 276–282. [Google Scholar] [CrossRef]

- Chang, Y.C.; Guo, J.Y.; Chen, C.M.; Di, H.W.; Hsu, C.C. Construction of CuO/In2S3/ZnO heterostructure arrays for enhanced photocatalytic efficiency. Nanoscale 2017, 9, 13235–13244. [Google Scholar] [CrossRef] [PubMed]

- Vuong, N.; Chinh, N.; Huy, B.; Lee, Y. CuO-decorated ZnO hierarchical nanostructures as efficient and established sensing materials for H2S gas sensor. Sci. Rep. 2016, 6, 26736. [Google Scholar] [CrossRef]

- Mridha, S.; Basak, D. Investigation of a p-CuO/n-ZnO thin film heterojunction for H2 gas-sensor applications. Semicond. Sci. Technol. 2006, 21, 928–932. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, K.; Xu, D.; Yang, G.; Huang, H.; Nie, F.; Liu, C.; Yang, S. CuO nanostructures: Synthesis, characterization growth mechanisms, fundamental properties, and applications. Prog. Mater. Sci. 2014, 60, 208–337. [Google Scholar] [CrossRef]

- Mansournia, M.; Ghaderi, L. CuO@ZnO core@shell nanocomposites: Novel hydrothermal synthesis and enhancement in photocatalytic property. J. Alloy Compd. 2017, 691, 171–177. [Google Scholar] [CrossRef]

- Pal, S.; Maiti, S.; Maiti, U.; Chattopadhyay, K. Low temperature solution processed ZnO/CuO heterojunction photocatalyst for visible light induced photo-degradation of organic pollutants. CrystEngComm 2015, 17, 1464–1476. [Google Scholar] [CrossRef]

- Kim, S.; Lee, Y.; Gu, A.; You, C.; Oh, K.; Lee, S.; Im, Y. Synthesis of vertically conformal ZnO/CuO core-shell nanowire arrays by electrophoresis-assisted electroless deposition. J. Phys. Chem. C 2014, 118, 7377–7385. [Google Scholar] [CrossRef]

- Wang, S.; Hsiao, C.; Chang, S.; Member, S.; IEEE; Jiao, Z.; Young, S.; Hung, S.; Huang, B. ZnO branched nanowires and the p-CuO/n-ZnO heterojunction nanostructured photodetector. IEEE Trans. Nanotechnol. 2012, 12, 263–267. [Google Scholar] [CrossRef]

- Park, Y.; Yang, J.; Ryu, B.; Cho, J.; Cuong, T.; Hong, C. Solution-processed multidimensional ZnO/CuO heterojunction as ultraviolet sensing. Opt. Mater. Express 2015, 5, 1752–1758. [Google Scholar] [CrossRef]

- Wu, J.; Chen, W.; Chang, Y.; Chen, Y.; Hang, D.; Liang, C.; Lu, J. Fabrication and photoresponse of ZnO nanowires/CuO coaxial heterojunction. Nanoscale Res. Lett. 2013, 8, 387. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, X.; Li, B. ZnO-coated CuO nanowire arrays: Fabrications, optoelectronic properties, and photovoltaic applications. Opt. Express 2011, 19, 11271–11279. [Google Scholar] [CrossRef]

- Park, G.; Hwang, S.; Lim, J.; Joo, J. Growth behavior and electrical performance of Ga-doped ZnO nanorods/p-Si heterojunction diodes prepared using a hydrothermal method. Nanoscale 2014, 6, 1840–1847. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Li, J.; Shirolkar, M.; Li, M.; Wang, H. Oxygen interstitial mediated effective doping of Al in ZnO:Al films prepared by magnetron sputtering. Mater. Lett. 2016, 179, 146–149. [Google Scholar] [CrossRef]

- Wofl, S.; Feldmann, C. Cu2X(OH)3 (X = Cl−, NO3−): Synthesis of nanoparticles and its application for room temperature deposition/printing of conductive copper thin films. J. Mater. Chem. 2010, 20, 7694–7699. [Google Scholar]

- Ramesh, T.N.; Madhu, T.L. Thermal Decomposition Studies of Layered Metal Hydroxynitrates (Metal: Cu, Zn, Cu/Co, and Zn/Co). Int. J. Inorg. Chem. 2015, 10, 536470. [Google Scholar] [CrossRef]

- Guo, H.; Zhu, Q.; Wu, X.; Jiang, Y.; Xie, X.; Xu, A. Oxygen deficient ZnO1-x nanosheets with high visible light photocatalytic activity. Nanoscale 2015, 7, 7216–7223. [Google Scholar] [CrossRef] [PubMed]

- Akhavan, O.; Azimirad, R.; Safa, S.; Hasani, E. CuO/Cu(OH)2 hierarchical nanostructures as bactericidal photocatalysts. J. Mater. Chem. 2011, 21, 9634–9640. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, X.; Sun, Y.; Yang, S.; Song, X.; Yang, Z. Hierarchical CuO nanoflowers: Water-required synthesis and their application in a nonenzymatic glucose biosensor. Phys. Chem. Chem. Phys. 2013, 15, 10904–10913. [Google Scholar] [CrossRef]

- Bao, J.; Shalish, I.; Su, Z.; Guiwitz, R.; Capasso, F.; Wang, X.; Ren, Z. Photoinduced oxygen release and persistent photoconductivity in ZnO nanowires. Nanoscale Res. Lett. 2011, 6, 404. [Google Scholar] [CrossRef]

- Bartolomeo, A.D.; Genovese, L.; Foller, T.; Giubileo, F.; Luongo, G.; Croin, L.; Liang, S.J.; Ang, L.K.; Schleberger, M. Electrical transport and persistent photoconductivity in monolayer MoS2 phototransistors. Nanotechnology 2017, 28, 214002. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.G.; Zhang, X.W.; Fu, Z.; Yang, X.L.; Wu, J.L.; Wu, G.S.; Gong, L.; Chu, P.K. Persistent photoconductivity in ZnO nanostructures induced by surface oxygen vacancy. Rapid Res. Lett. 2012, 6, 117–119. [Google Scholar] [CrossRef]

| Samples | Idark (A) | Iph (A) | Photosensitivity | τr (s) | τd(s) |

|---|---|---|---|---|---|

| ZnO | 121 | 174 | 1.4 | 9 | 190 |

| CuO/ZnO | 0.002 | 0.142 | 71 | 6 | 7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhao, T.; M. Shirolkar, M.; Li, M.; Wang, H.; Li, H. CuO/ZnO Heterojunction Nanorod Arrays Prepared by Photochemical Method with Improved UV Detecting Performance. Nanomaterials 2019, 9, 790. https://doi.org/10.3390/nano9050790

Li J, Zhao T, M. Shirolkar M, Li M, Wang H, Li H. CuO/ZnO Heterojunction Nanorod Arrays Prepared by Photochemical Method with Improved UV Detecting Performance. Nanomaterials. 2019; 9(5):790. https://doi.org/10.3390/nano9050790

Chicago/Turabian StyleLi, Jieni, Tingting Zhao, Mandar M. Shirolkar, Ming Li, Haiqian Wang, and Henan Li. 2019. "CuO/ZnO Heterojunction Nanorod Arrays Prepared by Photochemical Method with Improved UV Detecting Performance" Nanomaterials 9, no. 5: 790. https://doi.org/10.3390/nano9050790