1. Introduction

Nanomaterials have been implemented in a variety of applications for water treatment. Their attractiveness can be attributed to their extraordinary properties, such as high surface area for adsorption, high activity for (photo) catalysis, antimicrobial properties for disinfection and biofouling control, superparamagnetism for particle separation, and other unique optical and electronic properties that find use in novel treatment processes and sensors for water quality monitoring. Additionally, several studies on water treatment technology showed promising benefits of applying nanomaterials in terms of their performance, cost effectiveness, and environmental acceptability [

1,

2,

3]. In the adsorption process, carbon nanomaterials (CNMs), well-known adsorbents for water treatment with high specific surface area, have recently received close attention from many researchers for the adsorption of various kinds of aquatic pollutants, including endocrine-disrupting compounds (EDCs). Graphene oxide (GO), a carbon-based hexagonal structure decorated with the largest, as compared to other CNMs, proportion of oxygen-containing functional groups (OCFGs), has proved to be a remarkable candidate for the adsorption of various contaminants in water, including heavy metals (Cd

2+, Zn

2+, Pb

2+, Cu

2+, Cr

6+, etc.), dyes (methyl blue, methyl violet, rhodamine B, orange G, etc.), and pharmaceutical antibiotics (tetracycline, oxytetracycline, doxycycline, etc.). The large constituent of OCFGs (hydroxyl, carbonyl, carboxyl, epoxy, and alkoxy) provides a strong negative charge for GO, activating the electrostatic interactions with the positively-charged adsorbates. These interactions also comprise the hydrogen bonding between the hydrogen atom and the highly electronegative atoms (oxygen, nitrogen, and fluorine). Furthermore, similarly to other CNMs, GO is also composed of sp

2 hybridized benzene rings that are able to build π–π interactions with the benzene rings of adsorbate, and even to create the cation–π bonding with metal ions/protonated amino groups. This unique capacity promotes the excellence of GO as a novel adsorbent for the removal of aquatic contaminants. Another advantage of this material is that it can be synthesized from low-cost graphite [

4].

Bisphenol A (BPA, C

15H

16O

2), a phenolic compound, is considered to be one of EDCs that can cause harmful effects on human and wildlife endocrine systems, even at extremely low concentrations. This compound is widely used as a component in industrial products, such as plastic, food cans, epoxy resin, and flame retardants. It is a major contaminant in the municipal wastewater and can also be extensively found in industrial wastewater, sewage treatment effluent, ground water, surface water, landfill leachate, blackish water, and seawater [

5,

6,

7]. The pathways through which BPA gets from these water sources to the human body are possibly from drinking water and reuse water for agricultural purposes [

8]. In order to cut off these pathways, a proper, economically-viable treatment process that can ensure a highly-efficient removal of BPA is urgently required.

Cortés-Arriagada et al. [

9] investigated the adsorption of BPA on graphene and GO using the density functional theory (DFT) method. At the basal plane of GO, the highest adsorption energy was obtained from the binding between BPA and hydroxyl groups. At the edges of GO, valuable energies were obtained from two cases (BPA–carbonyl groups and BPA–carboxyl groups), while the outcome of the binding with hydroxyl groups was insignificant. The adsorption energies were found to be higher at the basal plane as compared to the edge, which may be explained by the support of π–π interactions. However, from the comparison of the adsorption energies in both adsorbents, it can be inferred that the adsorption energies of BPA onto GO are either higher than, or comparable to, that of BPA onto graphene. The resembling consequence was also reported by Jin et al. [

10]. These computational studies provide valuable evidence in support of the use of GO as an effective adsorbent for the adsorption of BPA. By contrast, the results gathered from experimental studies remain inconclusive. The studies on the adsorption of some aromatic compounds (including BPA) that definitely have no positive charge in the molecules showed that the use of GO is ineffective. Specifically, it was demonstrated that the adsorption of these compounds is strongly induced by π–π interactions, rather than by the electrostatic interactions, including hydrogen bonding. Thus, the functional groups on GO seem to hinder π–π interactions. This conclusion is consistent with several previous studies that observed the enhancement of adsorption efficiency after the reduction of GO. The reduction process will eliminate OCFGs and restore the sp

2-hybridized structure that improves the potential of π–π interactions [

11].

Since, considering the discrepancy between the results of computational and experimental studies, the adsorption behavior of BPA onto GO remains questionable, further research is needed to resolve this confusion.

In the present study, we experimentally investigated the GO adsorption of BPA. To this end, the fundamental examinations including kinetic and isotherm models were examined. The effects of various factors (such as contact time, initial BPA concentration, GO dosage, pH, and temperature) on the removal efficiency were systematically explored. Finally, the evaluation of the experimental results was performed to get a clear understanding of the adsorption characteristics.

3. Discussion

To classify the types of OCFGs on the GO surface, Fourier transform infrared spectroscopy (FTIR) analysis is necessary. The FTIR results of graphite and GO are illustrated in

Figure 9. Each peak in FTIR results displays the appearance of different functional groups on the surface of the materials. Compared to graphite (as data referred from elsewhere), the peak intensities of GO are distinctly enhanced, demonstrating the success of oxidization. The cooperation among KMnO

4, H

2SO

4, and H

3PO

4 destroys the π–orbital system of graphite and inserts diverse types of OCFGs into the carbon skeleton [

41]. The obvious peak at 3419 cm

−1 represents the existence of the hydroxyl group (O–H). The following peak at 1720 cm

−1 is attributed to the carbonyl group (C=O). The formation of aromatic bonds (C=C) corresponds to the peak at 1619 cm

−1. The evidence for the carboxyl group (O=C–OH) can be explained by the peak at 1384 cm

−1. The next peak at 1227 cm

−1 is considered as the epoxy group (C–O–C). The last peak at 1052 cm

−1 is considered as the alkoxy group (C–O). These results are congruent with those reported in previous studies, which convincingly demonstrates the attainment of our synthesized GO [

42,

43].

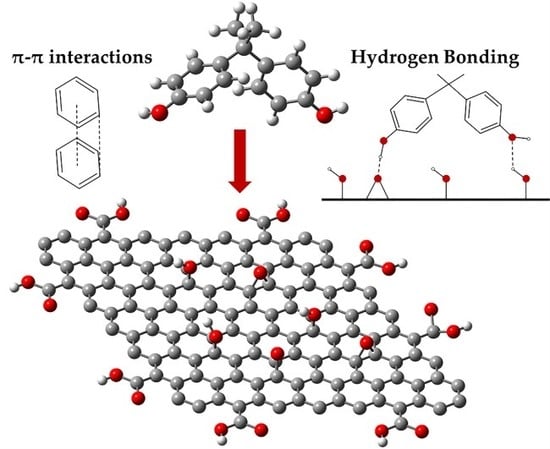

After the adsorption of BPA, the peak intensities were modified in the whole range assigned to the interactions between BPA and GO. The interactions between BPA and OCFGs were affirmed by the change of peaks from 3419 cm

−1, 1720 cm

−1, 1227 cm

−1, 1052 cm

−1 to 3418 cm

−1, 1733 cm

−1, 1228 cm

−1, and 1065 cm

−1, respectively. These moves may represent the hydrogen bonding formed between the hydroxyl groups of BPA and OCFGs of GO. As evidenced by the shift of the band from 1619 cm

−1 to 1623 cm

−1, π–π interactions also played a role in the adsorption. These interactions existed between the benzene rings of both the adsorbate and the adsorbent. The FTIR result reveals that the adsorption of BPA onto GO is held by both hydrogen bonding and π–π interactions. The schematic of both adsorption interactions is shown in

Figure 10. The appearance of OCFGs appears to be helpful for adsorption. This result is also supported by the analogous structures of the adsorbate and the adsorbent. The structure of BPA consists of hydrophilic hydroxyl groups and hydrophobic benzene rings. This amphiphilic property is similar to GO which contains hydrophilic functional groups and a hydrophobic basal plane. The compatibility of properties in the adsorbate and the adsorbent may lead to a strong adsorption [

35]. Additionally, since the length of BPA molecule is 0.94 nm and the average pore size of GO varies in the range from 2.3 to 5 nm, this pore size is sufficient for the BPA molecules to enter and be adsorbed on the adsorption sites [

28,

44,

45]. The high performance of GO is confirmed not only by these explanations, but also by some previous computational studies [

9,

10]. The adsorption energy of BPA onto GO obtained by the DFT study is higher than that onto graphene. The adsorption of GO regarding the collaboration between hydrogen bonding and π–π interactions is shown to be stronger than the adsorption by only π–π interactions of graphene [

9]. This confident evidence suggests that GO is the most suitable adsorbent for the removal of BPA as compared to other CNMs that contain a lower proportion of OCFGs. By contrast, the efficiency of GO for the removal of some aromatic pollutants that are free from positive charge was found to be the lowest among CNMs in previous experimental studies [

11]. The reason behind this ineffectiveness may point to a large number of functional groups on the surface. This reason was investigated by Wang et al. [

11] who studied the correlation between the reduction degree of GO and the adsorption efficiency of phenolic compounds. After the reduction of GO, the increment of π–π interactions alongside with adsorption performance was found. In other words, a lower number of OCFGs results in a higher adsorption efficiency. This means that π–π interactions are dominant interactions for the adsorption of phenolic compounds. Thus, the occurrence of OCFGs appears to hinder the potential of π–π interactions. The interpretations in both computational studies and experimental studies are definitely mutually contradictory.

In our study, the maximum adsorption capacity of BPA onto GO amounted to 49.26 mg/g. This capacity is quite low as compared to other CNMs, according to previous studies (81.3–96.2 mg/g for rGO, 71–111 mg/g for CNTs, and 182 mg/g for graphene) [

33,

34,

40]. Among CNMs, GO contains the highest number of OCFGs, followed by rGO, CNTs, and graphene. Thus, the adsorption capacity seems to increase with decreasing the number of OCFGs. Our results support the inference of other experimental studies that showed that GO is an ineffective material for the removal of BPA. Thus, the logical clarification is necessary in order to enhance the reliability of this summary. The possible issue may relate to the interference of water molecules. The competitive adsorption of a solvent is a common phenomenon in the solid–liquid adsorption system [

35]. In aqueous solution, the adsorption may be hindered by the formation of hydrogen bonding between water molecules and OCFGs (see

Figure 11A). Additionally, OCFGs can possibly bond with other surrounding functional groups located in the same GO sheet or in the neighboring sheets (see

Figure 11B). These unwanted H-bonds have a large-scale effect on the adsorption efficiency of GO by sealing the high-adsorption-energy binding sites. Instead of enhancing the efficiency, the occurrence of OCFGs has a negative effect on the adsorption by reducing the efficiency and obstructing the formation of π–π interactions, which is supposed to be the main interaction for the adsorption on CNMs. Accordingly, GO that contains a high proportion of OCFGs seems to be critically affected by these phenomena. Compared to other CNMs, these effects are almost meaningless [

46]. The conclusion was also declared by several molecular dynamics studies that demonstrated a plentiful hydrogen bonding between OCFGs and water molecules, as well as the intra/inter-layer H bonds among OCFGs on the GO surface [

47,

48]. In computational studies revealing the suitability of GO for the BPA adsorption, the DFT studies were performed without considering the aforementioned issues. Even though the adsorption energy was found to be higher in GO, this investigation cannot be used to illustrate the adsorption behavior in reality. Up to now, our study has clearly emphasized that the efficiency of GO for adsorption of BPA in water is low. Thus, some specific modifications on the GO surface should be applied in order to improve its adsorption performance. A better efficiency after modification of adsorbents was confirmed in several previous studies [

37,

49,

50].

4. Materials and Methods

4.1. Materials

Graphite powder (500 mg) was purchased from Kanto Chemical. Co., Inc, (Chuo-ku, Tokyo, Japan). Other chemicals (99% BPA, KMnO4 flake, 98% H2SO4, 85% H3PO4, 34.5% H2O2, 35% HCl, Acetone, and deionized (DI) water) were ordered from Daejung Chemical and Metals Co., Ltd. (Siheung-city, Gyonggi-do, Korea). The BPA stock solution (60 mg/L) was prepared in DI water by shaking overnight without mixing with other chemicals to avoid the co-solvent effect. The stock solution was further diluted to the required concentrations before use.

4.2. Synthesis of Graphene Oxide

4.2.1. Oxidation of Graphite

GO was synthesized following the Improved Hummers’ method [

51]. A 9:1 mixture of concentrated H

2SO

4/H

3PO

4 (360:40 mL) was added to a 1:6 mixture of graphite powder/KMnO

4 (3:18 g). In accordance with the intense exothermicity of this reaction, both mixtures need to be cooled in a fridge before mixing to avoid an explosion due to the occurrence of the strong oxidant Mn

2O

7. This oxidant is known to detonate at the temperature over 55 °C [

52]. The exothermic reaction of mixing will heat up the temperature of solution to 35–40 °C. The reaction was then heated to 50 °C and stirred for 12 h by using a magnetic stirrer to ensure the complete oxidation reaction of graphite. The mixture was then cooled down to room temperature and poured onto ice (made from 400 mL of DI water) followed by adding 3 ml of 30% H

2O

2 to reduce the residual permanganate and manganese dioxide [

53]. The bright yellow solution was received as the final product.

4.2.2. Washing the Oxidized Graphite

The final solution was repeatedly washed to remove the byproducts (e.g., potassium-containing compounds) that can cause an acute explosion and combustion [

54]. The washing process was started with the filtering of the mixture through a 45 µm testing sieve (Chung Gye Sang Gong Sa, Seoul, Korea), followed by the centrifugation of the filtrate at 4000 rpm for 3 h; then, the supernatant was decanted away. The remaining settling was then washed in succession with 200 mL of DI water, 200 mL of 30% HCl (2 times), and 200 mL of Acetone (five times) [

54]. For each wash, the mixture was again filtered through the testing sieve and centrifuged as mentioned above. After the washing process, the color of sediment turned to dark brown. Finally, the product was filtered over the polytetrafluoroethylene (PTFE) membrane with a pore size of 0.45 µm. The GO paste attached to the filter was vacuum-dried overnight at room temperature, which let us obtain 5.8 g of the GO powder. The particle size of the GO powder was controlled to be below 0.2 mm.

4.3. Characteristic Analysis of the Synthesized Graphene Oxide

The synthesized GO was characterized by powder X-ray diffraction (XRD) on a Bruker D8-advance X-ray diffractometer (Bruker AXS GmbH, Karlsruhe, Germany) at 40 kV and 40 mA for monochromatized Cu Kα (λ = 0.1541 nm) radiation. The XRD data were collected in a 2θ range from 5° to 70°. The Fourier transform infrared (FTIR) spectra were recorded on an FTIR-6300 (JASCO, Hachioji, Tokyo, Japan spectrometer in the transmittance mode. The range of the detectable signal was 4000–400 cm−1 with the resolution of 4 cm−1. The morphology energy-dispersive X-ray spectroscopy (EDS) of both samples was inspected using a scanning electron microscope (SEM, JSM-6510, JEOL Ltd., Akishima, Tokyo, Japan) equipped with an energy-dispersive X-ray analyzer (EDX, Oxford INCA, Oxford Instruments, Abingdon, Oxfordshire, UK).

4.4. Batch Adsorption Experiments

To clarify the adsorption characteristics, batch experiments for adsorption kinetics, isotherms including the effects of various parameters are necessary. Each experiment was performed using a series of volumetric flasks containing 50 mL of the BPA solution. The experimental conditions in each experiment are specified in

Table 5. The samples were shaken in a shaking incubator (JEIO TECH, SI-900R, Geumcheon-gu, Seoul, Korea) with constant agitation (200 rpm).

After the adsorption experiments, the samples were centrifuged at 5000 rpm for 20 min to separate GO from the samples. The supernatants were taken out and centrifuged again at 13,000 rpm for 20 min to remove the residual GO in the samples. The BPA concentration in the samples was measured by high-performance liquid chromatography (HPLC, Shimadzu, Kyoto, Japan) system with a 150 mm × 4.6 mm, 3.5 µm Agilent Zorbax SB-C18 column (Agilent, Santa Clara, CA, USA). The UV-VIS detector (SPD-20A, Shimadzu, Kyoto, Japan) was operated at 280 nm. The mobile phase was 1.0 mL/min of 70% methanol and 30% deionized water. To warrant the accuracy of the results, the experiments were completed at least three times. The adsorption capacity (mg/g) was calculated using Equation (7):

where C

0 and C

e are the concentrations of BPA in the solution (mg/L) at the initial stage and at equilibrium, respectively; V is the volume of solution (L); and m is the adsorbent mass (g).

5. Conclusions

In the present study, the adsorption characteristics of BPA on GO in aqueous solution were investigated. The adsorption reached equilibrium within 30 min, indicating the rapid adsorption of BPA on GO. The increment of adsorption capacity after increasing the initial BPA concentration could be illustrated by the support of the driving force which overcame the mass transfer resistance between the aqueous and the solid phases. The reverse result was obtained after increasing the adsorbent dosage. This pattern can be explained by the aggregation and overlapping of the adsorbent particles that obstructed the adsorption. By varying the pH of the solution, the adsorption efficiency was constantly high in the acidic pH range, but dramatically decreased when the pH increased above 8. This trend could be explained by the deprotonation of the BPA molecules that cause the electrostatic repulsion with the GO surface. The adsorption process proved to be exothermic and spontaneous, according to the thermodynamic study. The adsorption kinetics of BPA on GO could be described by the pseudo-second-order model covering the three stages of adsorption, including film diffusion, intraparticle diffusion, and the equilibrium stage. The equilibrium sorption of BPA could be properly fitted by both the Langmuir and the Freundlich isotherms, as suggested by the existence of both monolayer and multilayer adsorption. It may be explained by the nature of BPA molecules and the defect of the GO surface. By consulting the results of other experimental and computational studies, the BPA adsorption onto GO in the aqueous solution was demonstrated to be driven by π–π interactions, rather than by hydrogen bonding. The appearance of OCFGs on GO was found to hinder the adsorption for two reasons. First, the possibility of formation of hydrogen bond between the water molecules and OCFGs will create competition for adsorption of the adsorbate. Second, hydrogen bonding also can be formed among OCFGs on the GO surface by bonding within the GO sheet (intra-layer H-bonds) and by bonding with the nearby sheets (inter-layer H-bonds). These effects should be considered in further computational studies in order to achieve a clear and reliable understanding of the adsorption mechanisms. As it becomes obvious from the discussion above, even though the use of GO is ineffective for the BPA adsorption, suitable modifications of the GO surface may lead to further development of a novel adsorbent that is appropriate for the removal of BPA.