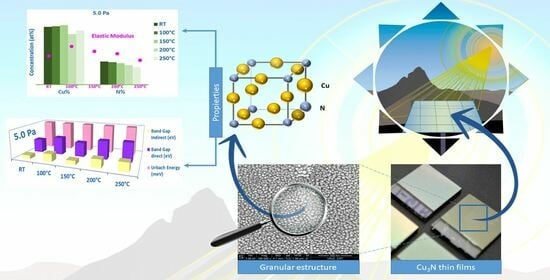

Effects of Deposition Temperature and Working Pressure on the Thermal and Nanomechanical Performances of Stoichiometric Cu3N: An Adaptable Material for Photovoltaic Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Structural Properties

3.1.1. X-ray Diffraction Analysis

3.1.2. RBS and Raman

3.1.3. Scanning Electron Microscopy Analysis

3.2. Nanomechanical Properties

Nanoindentation

3.3. Optical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McEvoy, A.; Castaner, L.; Markvart, T. Solar Cells: Materials, Manufacture and Operation; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Smith, W. Effect of Light on Selenium. Nature 1873, 7, 303. [Google Scholar]

- Fritts, C.E. On the Fritts selenium cells and batteries. J. Frankl. Inst. 1885, 119, 221–232. [Google Scholar] [CrossRef]

- Klassen, S. The photoelectric effect: Reconstructing the story for the physics classroom. Sci. Educ. 2011, 20, 719–731. [Google Scholar] [CrossRef]

- Kingsbury, E.F.; Ohl, R.S. Photoelectric properties of ionically bombarded silicon. Bell Syst. Tech. J. 1952, 31, 802–815. [Google Scholar] [CrossRef]

- Wohlgemuth, J.; Lindmayer, J.; Scheinine, A. Non-Reflecting Vertical Junction Silicon Solar Cell Optimization; Interim Report; Solarex Corp.: Rockville, MD, USA, 1977. [Google Scholar]

- Lindmayer, J.; Anderson, J.; Clifford, A.; Lafky, W.; Scheinine, A.; Wihl, M.; Wrigley, C. Solar Breeder: Energy Payback Time for Silicon Photovoltaic Systems; First Quarterly Report, 20 December 1976–20 March 1977; Solarex Corp.: Rockville, MD, USA, 1977. [Google Scholar]

- dos Santos, S.A.A.; Torres, J.P.N.; Fernandes, C.A.; Lameirinhas, R.A.M. The impact of aging of solar cells on the performance of photovoltaic panels. Energy Convers. Manag. X 2021, 10, 100082. [Google Scholar] [CrossRef]

- Simya, O.; Radhakrishnan, P.; Ashok, A.; Kavitha, K.; Althaf, R. Engineered nanomaterials for energy applications. In Handbook of Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 751–767. [Google Scholar]

- NREL. Best Research-Cell Efficiency Chart. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 7 August 2023).

- Marques Lameirinhas, R.A.; Torres, J.P.N.; de Melo Cunha, J.P. A photovoltaic technology review: History, fundamentals and applications. Energies 2022, 15, 1823. [Google Scholar] [CrossRef]

- Van Trinh, P.; Anh, N.N.; Cham, N.T.; Van Hao, N.; Thang, B.H.; Van Chuc, N.; Thanh, C.T.; Minh, P.N.; Fukata, N. Enhanced power conversion efficiency of an n-Si/PEDOT: PSS hybrid solar cell using nanostructured silicon and gold nanoparticles. RSC Adv. 2022, 12, 10514–10521. [Google Scholar] [CrossRef]

- Chavan, R.D.; Wolska-Pietkiewicz, M.; Prochowicz, D.; Jędrzejewska, M.; Tavakoli, M.M.; Yadav, P.; Hong, C.K.; Lewiński, J. Organic Ligand-Free ZnO Quantum Dots for Efficient and Stable Perovskite Solar Cells. Adv. Funct. Mater. 2022, 32, 2205909. [Google Scholar] [CrossRef]

- Wu, C.; Wang, K.; Batmunkh, M.; Bati, A.S.; Yang, D.; Jiang, Y.; Hou, Y.; Shapter, J.G.; Priya, S. Multifunctional nanostructured materials for next generation photovoltaics. Nano Energy 2020, 70, 104480. [Google Scholar] [CrossRef]

- Adak, D.; Bhattacharyya, R.; Barshilia, H.C. A state-of-the-art review on the multifunctional self-cleaning nanostructured coatings for PV panels, CSP mirrors and related solar devices. Renew. Sustain. Energy Rev. 2022, 159, 112145. [Google Scholar] [CrossRef]

- Kim, M.; Kang, T.-W.; Kim, S.H.; Jung, E.H.; Park, H.H.; Seo, J.; Lee, S.-J. Antireflective, self-cleaning and protective film by continuous sputtering of a plasma polymer on inorganic multilayer for perovskite solar cells application. Sol. Energy Mater. Sol. Cells 2019, 191, 55–61. [Google Scholar] [CrossRef]

- El-Ballouli, A.a.O.; Bakr, O.M.; Mohammed, O.F. Compositional, processing, and interfacial engineering of nanocrystal-and quantum-dot-based perovskite solar cells. Chem. Mater. 2019, 31, 6387–6411. [Google Scholar] [CrossRef]

- Booth, R.E.; Schrickx, H.M.; Hanby, G.; Liu, Y.; Qin, Y.; Ade, H.; Zhu, Y.; O’Connor, B.T. Silver Nanowire Composite Electrode Enabling Highly Flexible, Robust Organic Photovoltaics. Solar RRL 2022, 6, 2200264. [Google Scholar] [CrossRef]

- Sène, A.; Ndiaye, C.N.; Thiaw, L. Absorption optimization in nano-structured optical thin films: Application to photovoltaic solar cells. In Proceedings of the 2022 IEEE International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Tunis, Tunisia, 26–28 October 2022; pp. 1–6. [Google Scholar]

- Grohol, M.; Veeh, C. Study on the Critical Raw Materials for the EU 2023. In Final Report DG GROW; ISO: Geneva, Switzerland, 2023. [Google Scholar]

- Maruyama, T.; Morishita, T. Copper nitride and tin nitride thin films for write-once optical recording media. Appl. Phys. Lett. 1996, 69, 890–891. [Google Scholar] [CrossRef]

- Alyousef, H.A.; Hassan, A.; Zakaly, H.M. Exploring the Impact of Substrate Placement on Cu3N Thin Films as a Solar Cell Window Layer: Structural and Optical Attributes. Mater. Today Commun. 2023, 35, 106183. [Google Scholar] [CrossRef]

- Sakalley, S.; Saravanan, A.; Cheng, W.-C.; Chen, S.-C.; Sun, H.; Liao, M.-H.; Huang, B.-R. Cu3N thin film synthesized by selective in situ substrate heating during high power impulse magnetron sputtering for augmenting UV photodetection. Sens. Actuators A Phys. 2023, 350, 114137. [Google Scholar] [CrossRef]

- Chen, L.N.; Leng, J.F.; Yang, Z.X.; Meng, Z.C.; Sun, B. Influence of sputtering power on the structure, optical and electric properties of Cu3N films. In Materials Science Forum; Trans Tech Publications Ltd.: Baech, Switzerland, 2015; pp. 596–600. [Google Scholar]

- Ghoohestani, M.; Karimipour, M.; Javdani, Z. The effect of pressure on the physical properties of Cu3N. Phys. Scr. 2014, 89, 035801. [Google Scholar] [CrossRef]

- Sahoo, G.; Meher, S.; Jain, M.K. Room temperature growth of high crystalline quality Cu3N thin films by modified activated reactive evaporation. Mater. Sci. Eng. B 2015, 191, 7–14. [Google Scholar] [CrossRef]

- Caskey, C.M.; Richards, R.M.; Ginley, D.S.; Zakutayev, A. Thin film synthesis and properties of copper nitride, a metastable semiconductor. Mater. Horiz. 2014, 1, 424–430. [Google Scholar] [CrossRef]

- Fioretti, A.N.; Schwartz, C.P.; Vinson, J.; Nordlund, D.; Prendergast, D.; Tamboli, A.C.; Caskey, C.M.; Tuomisto, F.; Linez, F.; Christensen, S.T. Understanding and control of bipolar self-doping in copper nitride. J. Appl. Phys. 2016, 119, 181508. [Google Scholar] [CrossRef]

- Matsuzaki, K.; Okazaki, T.; Lee, Y.-S.; Hosono, H.; Susaki, T. Controlled bipolar doping in Cu3N (100) thin films. Appl. Phys. Lett. 2014, 105, 222102. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Lee, P.-I.; Sakalley, S.; Wen, C.-K.; Cheng, W.-C.; Sun, H.; Chen, S.-C. Enhanced Electrical Properties of Copper Nitride Films Deposited via High Power Impulse Magnetron Sputtering. Nanomaterials 2022, 12, 2814. [Google Scholar] [CrossRef] [PubMed]

- Zakutayev, A.; Caskey, C.M.; Fioretti, A.N.; Ginley, D.S.; Vidal, J.; Stevanovic, V.; Tea, E.; Lany, S. Defect Tolerant Semiconductors for Solar Energy Conversion. J. Phys. Chem. Lett. 2014, 5, 1117–1125. [Google Scholar] [CrossRef] [PubMed]

- Meymian, M.R.Z.; Heravi, A.D.; Mehr, A.K. Influence of bias voltage on optical and structural characteristics of Cu3N films deposited by reactive RF magnetron sputtering in a pure nitrogen atmosphere. Mater. Sci. Semicond. Process. 2020, 112, 104995. [Google Scholar] [CrossRef]

- Khalaf, M.K.; Saud, N.; Muhammed, M.S. Plasma Diagnostics and Characterizations of Reactive Magnetron Sputtered Copper Nitride Thin Films. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 072029. [Google Scholar]

- Ji, A.L.; Huang, R.; Du, Y.; Li, C.R.; Wang, Y.Q.; Cao, Z.X. Growth of stoichiometric Cu3N thin films by reactive magnetron sputtering. J. Cryst. Growth 2006, 295, 79–83. [Google Scholar] [CrossRef]

- Yamada, N.; Kondo, Y.; Ino, R. Low-temperature fabrication and performance of polycrystalline CuI films as transparent p-type semiconductors. Phys. Status Solidi (A) 2019, 216, 1700782. [Google Scholar] [CrossRef]

- Okrasa, S.; Wilczopolska, M.; Strzelecki, G.; Nowakowska-Langier, K.; Chodun, R.; Minikayev, R.; Król, K.; Skowronski, L.; Namyślak, K.; Wicher, B. The influence of thermal stability on the properties of Cu3N layers synthesized by pulsed magnetron sputtering method. Thin Solid Films 2021, 735, 138889. [Google Scholar] [CrossRef]

- Gonzalez-Arrabal, R.; Gordillo, N.; Martin-Gonzalez, M.S.; Ruiz-Bustos, R.; Agulló-López, F. Thermal Stability of Copper Nitride Thin Films: The Role of Nitrogen Migration. J. Appl. Phys. 2010, 107, 103513. [Google Scholar] [CrossRef]

- Xiao, J.; Qi, M.; Cheng, Y.; Jiang, A.; Zeng, Y.; Ma, J. Influences of nitrogen partial pressure on the optical properties of copper nitride films. RSC Adv. 2016, 6, 40895–40899. [Google Scholar] [CrossRef]

- Figueira, C.; Rosario, G.D.; Pugliese, D.; Rodríguez-Tapiador, M.; Fernández, S. Effect of Argon on the Properties of Copper Nitride Fabricated by Magnetron Sputtering for the Next Generation of Solar Absorbers. Materials 2022, 15, 8973. [Google Scholar] [CrossRef]

- Rodríguez-Tapiador, M.; Merino, J.; Jawhari, T.; Muñoz-Rosas, A.; Bertomeu, J.; Fernández, S. Impact of the RF Power on the Copper Nitride Films Deposited in a Pure Nitrogen Environment for Applications as Eco-Friendly Solar Absorber. Materials 2023, 16, 1508. [Google Scholar] [CrossRef]

- Rodríguez-Tapiador, M.; Asensi, J.; Roldán, M.; Merino, J.; Bertomeu, J.; Fernández, S. Copper Nitride: A Versatile Semiconductor with Great Potential for Next-Generation Photovoltaics. Coatings 2023, 13, 1094. [Google Scholar] [CrossRef]

- Márquez, E.; Blanco, E.; García-Gurrea, M.; Cintado Puerta, M.; Domínguez de la Vega, M.; Ballester, M.; Mánuel, J.; Rodríguez-Tapiador, M.; Fernández, S. Optical Properties of Reactive RF Magnetron Sputtered Polycrystalline Cu3N Thin Films Determined by UV/Visible/NIR Spectroscopic Ellipsometry: An Eco-Friendly Solar Light Absorber. Coatings 2023, 13, 1148. [Google Scholar] [CrossRef]

- Redondo-Cubero, A.; Borge, M.; Gordillo, N.; Gutiérrez, P.; Olivares, J.; Pérez Casero, R.; Ynsa, M. Current status and future developments of the ion beam facility at the centre of micro-analysis of materials in Madrid. Eur. Phys. J. Plus 2021, 136, 175. [Google Scholar] [CrossRef]

- Gordillo, N.; Gonzalez-Arrabal, R.; Martin-Gonzalez, M.S.; Olivares, J.; Rivera, A.; Briones, F.; Agulló-López, F.; Boerma, D.O. DC triode sputtering deposition and characterization of N-rich copper nitride thin films: Role of chemical composition. J. Cryst. Growth 2008, 310, 4362–4367. [Google Scholar] [CrossRef]

- Matej, M. SIMNRA User’s Guide; Max-Planck-Institut Für Plasmaphysik: Garching, Germany, 1997. [Google Scholar]

- Fallberg, A.; Ottosson, M.; Carlsson, J.-O. Phase stability and oxygen doping in the Cu–N–O system. J. Cryst. Growth 2010, 312, 5. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.; Yuan, X.; Wu, Z.; Miao, B.; Yan, P. Copper nitride (Cu3N) thin films deposited by RF magnetron sputtering. J. Cryst. Growth 2006, 286, 407–412. [Google Scholar] [CrossRef]

- Hadian, F.; Rahmati, A.; Movla, H.; Khaksar, M. Reactive DC magnetron sputter deposited copper nitride nano-crystalline thin films: Growth and characterization. Vacuum 2012, 86, 1067–1072. [Google Scholar] [CrossRef]

- Xiao, J.; Li, Y.; Jiang, A. Structure, optical property and thermal stability of copper nitride films prepared by reactive radio frequency magnetron sputtering. J. Mater. Sci. Technol. 2011, 27, 403–407. [Google Scholar] [CrossRef]

- Williamson, G.; Smallman, R., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Akl, A.; Hassanien, A. Microstructure characterization of Al-Mg alloys by X-ray diffraction line profile analysis. Int. J. 2014, 2, 1–9. [Google Scholar]

- Pierson, J. Structure and properties of copper nitride films formed by reactive magnetron sputtering. Vacuum 2002, 66, 59–64. [Google Scholar] [CrossRef]

| Working Pressure: 3.5 Pa | |||||

| Substrate temperature (°C) | RT | 100 | 150 | 200 | 250 |

| Film thickness (nm) | 91 ± 6 | 132 ± 20 | 128 ± 18 | 110 ± 15 | 85 ± 3 |

| Deposition rate (nm/min) | 3.03 | 4.40 | 4.27 | 3.67 | 2.83 |

| Working Pressure: 5.0 Pa | |||||

| Substrate temperature (°C) | RT | 100 | 150 | 200 | 250 |

| Film thickness (nm) | 85 ± 5 | 132 ± 21 | 119 ± 16 | 118 ± 15 | 88 ± 5 |

| Deposition rate (nm/min) | 2.83 | 4.40 | 3.97 | 3.93 | 2.93 |

| Working Pressure: 3.5 Pa | |||||||

| T substrate (°C) | Preferred orientation | FWHM (°) | Lattice constant a (nm) | τ (nm) | ε | δ (lines/nm2) | Nc (nm−2) |

| RT | (100) | 0.2460 | 0.3826 | 33 | 5.22 × 10−3 | 9.20 × 10−4 | 1.07 × 10−5 |

| 100 | (100) | 0.1573 | 0.3820 | 52 | 3.33 × 10−3 | 3.76 × 10−4 | 2.79 × 10−6 |

| 150 | (100) | 0.1378 | 0.3822 | 59 | 2.92 × 10−3 | 2.89 × 10−4 | 1.87 × 10−6 |

| 200 | (100) | 0.1181 | 0.3815 | 69 | 2.50 × 10−3 | 2.12 × 10−4 | 1.18 × 10−6 |

| 250 | (111) | 0.0590 | 0.3517 | 144 | 6.89 × 10−4 | 4.84 × 10−5 | 6.84 × 10−8 |

| Working Pressure: 5.0 Pa | |||||||

| T substrate (°C) | Preferred orientation | FWHM (°) | Lattice constant a (nm) | τ (nm) | ε | δ (lines/nm2) | Nc (nm−2) |

| RT | (100) | 0.2263 | 0.3832 | 36 | 4.81 × 10−3 | 7.79 × 10−4 | 8.32 × 10−6 |

| 100 | (100) | 0.1476 | 0.3810 | 55 | 3.12 × 10−3 | 3.31 × 10−4 | 2.30 × 10−6 |

| 150 | (100) | 0.1279 | 0.3838 | 63 | 2.72 × 10−3 | 2.49 × 10−4 | 1.51 × 10−6 |

| 200 | (100) | 0.1175 | 0.3815 | 69 | 2.48 × 10−3 | 2.10 × 10−4 | 1.16 × 10−6 |

| 250 | (100) | 0.0590 | 0.3823 | 137 | 1.25 × 10−3 | 5.29 × 10−5 | 1.47 × 10−7 |

| Working Pressure 3.5 Pa | |||||

| T substrate (°C) | Cu% | N% | O% | C% | Ratio Cu/N |

| RT | 73.5 | 26.5 | - | - | 2.8 |

| 100 | 74.1 | 25.9 | - | - | 2.9 |

| 150 | 73.3 | 26.7 | - | - | 2.7 |

| 200 | 70 | 30 | - | - | 2.3 |

| 250 | 76 | 12 | 12 | - | 6.3 |

| Working Pressure 5.0 Pa | |||||

| T substrate (°C) | Cu% | N% | O% | C% | Ratio Cu/N |

| RT | 71.3 | 28.7 | - | - | 2.5 |

| 100 | 72.1 | 27.9 | - | - | 2.6 |

| 150 | 73.4 | 26.6 | - | - | 2.8 |

| 200 | 62.4 | 24 | 13.6 | - | 2.6 |

| 250 | 67 | 21.5 | 1.0 | 10.5 | 3.6 |

| Working Pressure 3.5 Pa | ||

| T substrate (°C) | Raman Shift (cm−1) | Microstrain |

| RT | 628 ± 3.4 | 5.22 × 10−3 |

| 100 | 632 ± 0.6 | 3.33 × 10−3 |

| 150 | 632 ± 0.6 | 2.92 × 10−3 |

| 200 | 633 ± 1.6 | 2.50 × 10−3 |

| 250 | 632 ± 0.6 | 6.89 × 10−4 |

| Working Pressure 5.0 Pa | ||

| T substrate (°C) | Raman Shift (cm−1) | Microstrain |

| RT | 628 ± 4.2 | 4.81 × 10−3 |

| 100 | 627 ± 5.2 | 3.12 × 10−3 |

| 150 | 632 ± 0.2 | 2.72 × 10−3 |

| 200 | 637 ± 4.8 | 2.48 × 10−3 |

| 250 | 637 ± 4.8 | 1.25 × 10−3 |

| Working Pressure 3.5 Pa | ||

| T substrate (°C) | Elastic modulus (GPa) | Hardness (GPa) |

| RT | 85.92 ± 4.74 | 4.55 ± 0.21 |

| 100 | 90.44 ± 5.11 | 4.47 ± 0.22 |

| 150 | 99.85 ± 9.86 | 4.36 ± 0.50 |

| 200 | 89.10 ± 3.87 | 3.81 ± 0.15 |

| 250 | 80.49 ± 7.87 | 1.40 ± 0.15 |

| Working Pressure 5.0 Pa | ||

| T substrate (°C) | Elastic modulus (GPa) | Hardness (GPa) |

| RT | 78.66 ± 3.94 | 3.86 ± 0.21 |

| 100 | 85.97 ± 6.10 | 3.58 ± 0.21 |

| 150 | 82.19 ± 3.80 | 4.30 ± 0.19 |

| 200 | 80.43 ± 2.77 | 3.17 ± 0.19 |

| 250 | 75.46 ± 2.43 | 2.78 ± 0.09 |

| Working Pressure 3.5 Pa | ||||||

| T substrate (°C) | Refractive index | Urbach energy (meV) | Indirect bandgap (eV) | Direct bandgap (eV) | Transition energies (eV) | Absorption coeff. at 1 eV (cm−1) |

| RT | 2.43 | 305 | 1.66 | 2.29 | 2.20/2.50 | 1.1 × 103 |

| 100 | 2.59 | 246 | 1.46 | 2.13 | 1.90/2.35 | 6.6 × 102 |

| 150 | 2.54 | 343 | 1.62 | 2.26 | 2.22/2.47 | 9.1 × 103 |

| 200 | 2.33 | 316 | 1.81 | 2.38 | 2.37/2.57 | 2.2 × 103 |

| 250 | - | - | - | 1.94 | - | 1.6 × 105 |

| Working Pressure 5.0 Pa | ||||||

| T substrate (°C) | Refractive index | Urbach energy (meV) | Indirect bandgap (eV) | Direct bandgap (eV) | Transition energies (eV) | Absorption coeff. at 1 eV (cm−1) |

| RT | 2.59 | 211 | 1.50 | 2.10 | 1.88/2.30 | 1.2 × 103 |

| 100 | 2.34 | 285 | 1.76 | 2.33 | 2.26/2.52 | 7.1 × 103 |

| 150 | 2.48 | 268 | 1.49 | 2.14 | 1.97/2.36 | 1.2 × 103 |

| 200 | 2.26 | 263 (139) | 1.77 (1.37) | 2.37 | 2.24/2.56 | 2.6 × 102 |

| 250 | 2.15 | 215 (143) | 1.80 (1.38) | 2.41 | 2.20/2.62 | 1.2 × 102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Tapiador, M.I.; Jiménez-Suárez, A.; Lama, A.; Gordillo, N.; Asensi, J.M.; del Rosario, G.; Merino, J.; Bertomeu, J.; Agarwal, A.; Fernández, S. Effects of Deposition Temperature and Working Pressure on the Thermal and Nanomechanical Performances of Stoichiometric Cu3N: An Adaptable Material for Photovoltaic Applications. Nanomaterials 2023, 13, 2950. https://doi.org/10.3390/nano13222950

Rodríguez-Tapiador MI, Jiménez-Suárez A, Lama A, Gordillo N, Asensi JM, del Rosario G, Merino J, Bertomeu J, Agarwal A, Fernández S. Effects of Deposition Temperature and Working Pressure on the Thermal and Nanomechanical Performances of Stoichiometric Cu3N: An Adaptable Material for Photovoltaic Applications. Nanomaterials. 2023; 13(22):2950. https://doi.org/10.3390/nano13222950

Chicago/Turabian StyleRodríguez-Tapiador, M. I., A. Jiménez-Suárez, A. Lama, N. Gordillo, J. M. Asensi, G. del Rosario, J. Merino, J. Bertomeu, A. Agarwal, and S. Fernández. 2023. "Effects of Deposition Temperature and Working Pressure on the Thermal and Nanomechanical Performances of Stoichiometric Cu3N: An Adaptable Material for Photovoltaic Applications" Nanomaterials 13, no. 22: 2950. https://doi.org/10.3390/nano13222950