Airborne LTA Nanozeolites Characterization during the Manufacturing Process and External Sources Interaction with the Workplace Background

Abstract

:1. Introduction

2. Materials and Methods

- 1.

- 2.

- Field investigations to conduct a basic exposure assessment using easy to use and portable equipment to measure airborne NMs by real-time measurements and sampling for further off-line analysis. Simulations on trial materials are also performed in a laboratory setting.

- 3.

- Expert exposure assessment using all appropriate equipment and available characterization techniques to provide a definitive conclusion regarding the presence of airborne nanomaterials in the occupational setting.

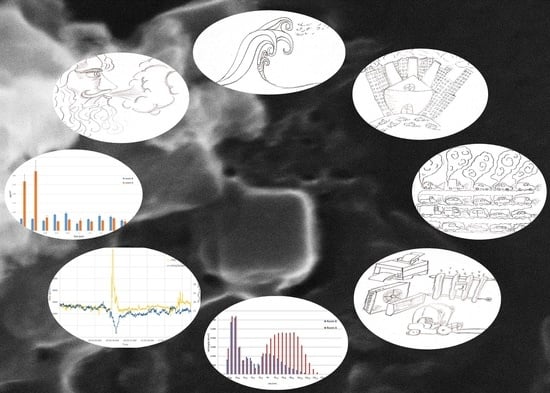

3. Results and Discussion

3.1. Real-Time Measurements

3.2. Off-Line Analysis

3.3. External Source Interactions with the Background

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Almeida, L.; Ramos, D. Health and safety concerns of textiles with nanomaterials. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 102002. [Google Scholar] [CrossRef]

- Gajanan, D.K.; Tijare, D.S.N.; Gajanan, K. Applications of nanomaterials. Mater. Today Proc. 2018, 5, 1093–1096. [Google Scholar] [CrossRef]

- Kranjc, E.; Drobne, D. Nanomaterials in plants: A review of hazard and applications in the agri-food sector. Nanomaterials 2019, 9, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mihalache, V.; Mercioniu, I.; Velea, A.; Palade, P. Effect of the process control agent in the ball-milled powders and SPS-consolidation temperature on the grain refinement, density and Vickers hardness of Fe14Cr ODS ferritic alloys. Powder Technol. 2019, 347, 103–113. [Google Scholar] [CrossRef]

- ISO/TS 80004-4:2011; Nanotechnologies-Vocabulary-Part 4: Nanostructured Materials. International Organization for Standardization (ISO): Geneva, Switzerland, 2011. Available online: https://www.iso.org/standard/52195.html (accessed on 20 January 2022).

- Research and Markets, I. Global Nanotechnology Market Outlook. 2022. Available online: https://www.researchandmarkets.com/reports/4991720/global-nanotechnology-market-outlook-2024 (accessed on 31 January 2022).

- Butter, M.; Fischer, N.; Gjsberts, G.; Hartmann, C.; de Heide, M.; van der Zee, F. Horizon 2020: Key Enabling Technologies (KETs), Booster for European Leadership in the Manufacturing Sector; Study for the ITRE Committee 2014, IP/A/ITRE/2013-01 PE 536.282; European Union: Brussels, Belgium, 2014. [Google Scholar]

- Kuhlbusch, T.A.J.; Wijnhoven, S.W.P.; Haase, A. Nanomaterial exposures for worker, consumer and the general public. NanoImpact 2018, 10, 11–25. [Google Scholar] [CrossRef]

- Boccuni, F.; Ferrante, R.; Tombolini, F.; Lega, D.; Antonini, A.; Alvino, A.; Pingue, P.; Beltram, F.; Sorba, L.; Piazza, V.; et al. Workers’ exposure to nano-objects with different dimensionalities in R&D laboratories: Measurement strategy and field studies. Int. J. Mol. Sci. 2018, 19, 349. [Google Scholar] [CrossRef] [Green Version]

- Schulte, P.A.; Leso, V.; Niang, M.; Iavicoli, I. Current state of knowledge on the health effects of engineered nanomaterials in workers: A systematic review of human studies and epidemiological investigations. Scand. J. Work. Environ. Health 2019, 45, 217–238. [Google Scholar] [CrossRef]

- Lux Research the Nanotech Report. Investment overview and Market research for Nanotechnology. 5th ed. 2007. Available online: https://members.luxresearchinc.com/report/1536 (accessed on 31 January 2022).

- Thomassen, L.; Napierska, D.; David, D.; Lievens, N.; Jammaere, J.; Lison, D.; Kirschhock, C.; Hoet, P.H.; Martens, J.A. Investigation of citotoxicity of nanozeolites A and Y. Nanotoxicology 2012, 6, 472–485. [Google Scholar] [CrossRef]

- Baerlocher, C.; McCusker, L.B.; Olson, D.H. Atlas of Zeolite Framework Types, 6th ed.; Elsevier Science: Amsterdam, The Netherlands, 2007; ISBN 9780444530646. Available online: https://www.sciencedirect.com/book/9780444530646 (accessed on 20 January 2022).

- Tosheva, L.; Valtchev, V.P. Nanozeolites: Synthesis, crystallization mechanism, and applications. Chem. Mater. 2005, 17, 2494–2513. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Kong, J.; Yang, P.; Tang, Y.; Liu, B. Efficient proteolysis system: A nanozeolite-derived microreactor. Small 2006, 2, 1170–1173. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, Y.; You, C.; Zhuang, J.; Wang, B.; Liu, B.; Kang, Y.; Tang, Y. Controlled nanozeolite-assembled electrode: Remarkable enzyme-immobilization ability and high sensitivity as biosensor. Chem.-A Eur. J. 2006, 12, 1137–1143. [Google Scholar] [CrossRef] [PubMed]

- Bandala, E.R.; Berli, M. Engineered nanomaterials (ENMs) and their role at the nexus of Food, Energy, and Water. Mater. Sci. Energy Technol. 2019, 2, 29–40. [Google Scholar] [CrossRef]

- Chanvirat, K.; Chaiear, N.; Choosong, T. Determinants of Respirable Crystalline Silica Exposure among Sand-stone Workers. Am. J. Public Health Res. 2018, 6, 44–50. [Google Scholar] [CrossRef]

- Murugadoss, S.; Lison, D.; Godderis, L.; Van Den Brule, S.; Mast, J.; Brassinne, F.; Sebaihi, N.; Hoet, P.H. Toxicology of silica nanoparticles: An update. Arch. Toxicol. 2017, 91, 2967–3010. [Google Scholar] [CrossRef]

- Mohamed, S.H.; El-Ansary, A.L.; El-Aziz, E.M.A. Determination of crystalline silica in respirable dust upon occupational exposure for Egyptian workers. Ind. Health 2018, 56, 255–263. [Google Scholar] [CrossRef] [Green Version]

- Rafieepour, A.; Azari, M.R.; Jaktaji, J.P.; Khodagholi, F.; Peirovi, H.; Mehrabi, Y.; Mohammadian, Y. The Effect of Particle Size on the Cytotoxicity of Amorphous Silicon Dioxide: An In Vitro Toxicological Study. Asian Pacific J. Cancer Prev. 2021, 22, 325–332. [Google Scholar] [CrossRef]

- Keramydas, D.; Bakakos, P.; Alchanatis, M.; Papalexis, P.; Konstantakopoulos, I.; Tavernaraki, K.; Dracopoulos, V.; Papadakis, A.; Pantazi, E.; Chelidonis, G.; et al. Investigation of the health effects on workers exposed to respirable crystalline silica during outdoor and underground construction projects. Exp. Ther. Med. 2020, 20, 882–889. [Google Scholar] [CrossRef]

- Di Cristo, L.; Boccuni, F.; Iavicoli, S.; Sabella, S. A human-relevant 3d in vitro platform for an effective and rapid simulation of workplace exposure to nanoparticles: Silica nanoparticles as case study. Nanomaterials 2020, 10, 1761. [Google Scholar] [CrossRef]

- Byrne, J.D.; Baugh, J.A. The significance of nanoparticles in particle-induced pulmonary fibrosis. McGill J. Med. 2008, 11, 43–50. [Google Scholar] [CrossRef]

- Kihara, T.; Zhang, Y.; Hu, Y.; Mao, Q.; Tang, Y.; Miyake, J. Effect of composition, morphology and size of nanozeolite on its in vitro cytotoxicity. J. Biosci. Bioeng. 2011, 111, 725–730. [Google Scholar] [CrossRef]

- Męczyńska-Wielgosz, S.; Piotrowska, A.; Majkowska-Pilip, A.; Bilewicz, A.; Kruszewski, M. Effect of Surface Functionalization on the Cellular Uptake and Toxicity of Nanozeolite A. Nanoscale Res. Lett. 2016, 11, 123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hejazy, M.; Moradi, M.; Akbari, G.; Amini, M.R. Investigation on the teratogenic and embryotoxic effects of nanozeolite on chick embryos model. Nanomed. Res. J. 2018, 3, 169–173. [Google Scholar] [CrossRef]

- OECD Harmonized tiered approach to measure and assess the potential exposure to airborne emissions of engineered nano-objects and their agglomerates and aggregates at workplaces. Ser. Saf. Manuf. Nanomater. 2015, 55, 1–51.

- OECD Strategies, Techniques and Sampling Protocols for Determining the Concentrations of Manufactured Nanomaterials in Air at the Workplace. Ser. Saf. Manuf. Nanomater. 2017, 82, 1–155.

- Cavallo, D.; Ursini, C.L.; Fresegna, A.M.; Ciervo, A.; Maiello, R.; Del Frate, V.; Iavicoli, S. Cyto-genotoxic and inflammatory effects of commercial Linde Type A (LTA) nanozeolites on human alveolar epithelial cells. J. Appl. Toxicol. 2020, 40, 592–599. [Google Scholar] [CrossRef] [PubMed]

- Tombolini, F.; Boccuni, F.; Ferrante, R.; Natale, C.; Marasco, L.; Mantero, E.; Del Rio Castillo, A.E.; Leoncino, L.; Pellegrini, V.; Sabella, S.; et al. An integrated and multi-technique approach to characterize airborne graphene flakes in the workplace during production phases. Nanoscale 2021, 13, 3841–3852. [Google Scholar] [CrossRef]

- Maynard, A.D.; Aitken, R.J. Assessing exposure to airborne nanomaterials: Current abilities and future requirements. Nanotoxicology 2007, 1, 26–41. [Google Scholar] [CrossRef]

- Hristozov, D.; Malsch, I. Hazards and Risks of engineered nanoparticles for the environment and human health. Sustainability 2009, 1, 1161–1194. [Google Scholar] [CrossRef] [Green Version]

- Brouwer, D. Exposure to manufactured nanoparticles in different workplaces. Toxicology 2010, 269, 120–127. [Google Scholar] [CrossRef]

- Van Broekhuizen, P.; Van Broekhuizen, F.; Cornelissen, R.; Reijnders, L. Workplace exposure to nanoparticles and the application of provisional nanoreference values in times of uncertain risks. J. Nanoparticle Res. 2012, 14, 770. [Google Scholar] [CrossRef]

- Bouillard, J.; Vignes, A. Nano-Evaluris: An inhalation and explosion risk evaluation method for nanoparticle use. Part I: Description of the methodology. J. Nanoparticle Res. 2014, 16, 2149. [Google Scholar] [CrossRef] [Green Version]

- Luyts, K.; Napierska, D.; Nemery, B.; Hoet, P.H.M. How physico-chemical characteristics of nanoparticles cause their toxicity: Complex and unresolved interrelations. Environ. Sci. Process. Impacts 2013, 15, 23–38. [Google Scholar] [CrossRef] [PubMed]

- Landsiedel, R.; Ma-Hock, L.; Wiench, K.; Wohlleben, W.; Sauer, U.G. Safety assessment of nanomaterials using an advanced decision-making framework, the DF4nanoGrouping. J. Nanoparticle Res. 2017, 19, 1–21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brouwer, D.; Markus, B.V.D.; Berges, M.; Jankowska, E.; Bard, D.; Mark, D. From workplace air measurement results toward estimates of exposure? Development of a strategy to assess exposure to manufactured nano-objects to manufactured nano-objects. J. Nanoparticle Res. 2009, 11, 1687–1881. [Google Scholar] [CrossRef]

- IUTA; BAuA; BG-RCI; IFA; TUD. Tiered Approach to an Exposure Measurement and Assessment of Nanoscale Aerosols Released from Engineered Nanomaterials in Workplace Operations. 2011. Available online: https://www.vci.de/vci/downloads-vci/tiered-approach.pdf (accessed on 20 January 2022).

- Human Respiratory Tract Model for Radiological Protection; A Report of a Task Group of the International Commission on Radiological Protection; Pergamon Press: Oxford, UK, 1994; Volume 24.

- Schmid, O.; Stoeger, T. Surface area is the biologically most effective dose metric for acute nanoparticle toxicity in the lung. J. Aerosol Sci. 2016, 99, 133–143. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.H.; Kim, J.B.; Ji, J.H.; Lee, S.B.; Bae, G.N. Nanoparticle formation in a chemical storage room as a new incidental nanoaerosol source at a nanomaterial workplace. J. Hazard. Mater. 2015, 298, 36–45. [Google Scholar] [CrossRef]

- Ferrante, R.; Boccuni, F.; Tombolini, F.; Iavicoli, S. Measurement techniques of exposure to nanomaterials in workplaces. In Nanotechnology in Eco-Efficient Construction; Pacheco-Torgal, M.V.F., Diamanti, A., Nazari, C.G., Granqvist, A., Pruna, S.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 785–813. ISBN 5856420187. [Google Scholar] [CrossRef]

- Asbach, C.; Fissan, H.; Stahlmecke, B.; Kuhlbusch, T.A.J.; Pui, D.Y.H. Conceptual limitations and extensions of lung-deposited Nanoparticle Surface Area Monitor (NSAM). J. Nanoparticle Res. 2009, 11, 101–109. [Google Scholar] [CrossRef]

- Kuhlbusch, T.A.J.; Asbach, C.; Fissan, H.; Göhler, D.; Stintz, M. Nanoparticle exposure at nanotechnology workplaces: A review. Part. Fibre Toxicol. 2011, 8, 22. [Google Scholar] [CrossRef] [Green Version]

- Brouwer, D.; Berges, M.; Virji, M.A.; Fransman, W.; Bello, D.; Hodson, L.; Gabriel, S.; Tielemans, E. Harmonization of measurement strategies for exposure to manufactured nano-objects; Report of a workshop. Ann. Occup. Hyg. 2012, 56, 1–9. [Google Scholar] [CrossRef]

- Asbach, C.; Kaminski, H.; Von Barany, D.; Kuhlbusch, T.A.J.; Monz, C.; Dziurowitz, N.; Pelzer, J.; Vossen, K.; Berlin, K.; Dietrich, S.; et al. Comparability of portable nanoparticle exposure monitors. Ann. Occup. Hyg. 2012, 56, 606–621. [Google Scholar] [CrossRef]

- Fonseca, A.S.; Maragkidou, A.; Viana, M.; Querol, X.; Hämeri, K.; de Francisco, I.; Estepa, C.; Borrell, C.; Lennikov, V.; de la Fuente, G.F. Process-generated nanoparticles from ceramic tile sintering: Emissions, exposure and environmental release. Sci. Total Environ. 2016, 565, 922–932. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boccuni, F.; Ferrante, R.; Tombolini, F.; Iavicoli, S.; Pelliccioni, A. Relationship between indoor high frequency size distribution of ultrafine particles and their metrics in a university site. Sustainability 2021, 13, 5504. [Google Scholar] [CrossRef]

- Ferrante, R.; Ursini, C.L.; Boccuni, F.; Tombolini, F.; Fresegna, A.M.; Ciervo, A.; Maiello, R.; Iavicoli, S.; Cavallo, D. Occupational exposure to LTA Nanozeolites: Strategies of exposure monitoring and toxicity evaluation. J. Phys. Conf. Ser. 2019, 1323, 012009. [Google Scholar] [CrossRef]

- Kittelson, D.B. Engines and nanoparticles: A review. J. Aerosol Sci. 1998, 29, 575–588. [Google Scholar] [CrossRef]

- Kumar, P.; Robins, A.; Vardoulakis, S.; Britter, R. A review of the characteristics of nanoparticles in the urban atmosphere and the prospects for developing regulatory controls. Atmos. Environ. 2010, 44, 5035–5052. [Google Scholar] [CrossRef] [Green Version]

- Bukowiecki, N.; Kittelson, D.B.; Watts, W.F.; Burtscher, H.; Weingartner, E.; Baltensperger, U. Real-time characterization of ultrafine and accumulation mode particles in ambient combustion aerosols. J. Aerosol Sci. 2002, 33, 1139–1154. [Google Scholar] [CrossRef]

- Garbarino, J.; Leslie, K.K.; Cree, M.E. Determination of Elements in Natural-Water, Biota, Sediment, and Soil Samples Using Collision/Reaction Cell Inductively Coupled Plasma—Mass Spectrometry. In Geological Survey Techniques and Methods; National Water Quality Laboratory: Denver, CO, USA, 2006; Book 5, Secetion B, Chapter 1; pp. 1–87. Available online: https://pubs.usgs.gov/tm/2006/tm5b1/PDF/TM5-B1.pdf (accessed on 20 January 2022).

- WHO Guidelines on Protecting Workers from Potential Risk of Manufactured Nanomaterials; World Health Organization: Geneva, Switzerland, 2017.

- Tsai, S.J.; Ashter, A.; Ada, E.; Mead, J.L.; Barry, C.F.; Ellenbecker, M.J. Airborne nanoparticle release associated with the compounding of nanocomposites using nanoalumina as fillers. Aerosol Air Qual. Res. 2008, 8, 160–177. [Google Scholar] [CrossRef]

- Schulte, P.A.; Roth, G.; Hodson, L.L.; Murashov, V.; Hoover, M.D.; Zumwalde, R.; Kuempel, E.D.; Geraci, C.L.; Stefaniak, A.B.; Castranova, V.; et al. Taking stock of the occupational safety and health challenges of nanotechnology: 2000–2015. J. Nanoparticle Res. 2016, 18, 159. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Chen, J.; Wang, Q.; Qin, Q.; Ye, J.; Han, Y.; Li, L.; Zhen, W.; Zhi, Q.; Zhang, Y.; et al. Increased secondary aerosol contribution and possible processing on polluted winter days in China. Environ. Int. 2019, 127, 78–84. [Google Scholar] [CrossRef]

- Rim, D.; Persily, A.; Emmerich, S.; Dols, W.S.; Wallace, L. Multi-zone modeling of size-resolved outdoor ultrafine particle entry into a test house. Atmos. Environ. 2013, 69, 219–230. [Google Scholar] [CrossRef]

| Phases | Processing Time | No. of Workers | Physical State | |

|---|---|---|---|---|

| 0 | Cleaning | 10 min | ||

| 0.1 | Generic cleaning phase (compressed air involved) | 2 | Powder form (in processing residues) | |

| 1 | Synthesis | 24 h | ||

| 1.1 | Preparation (surface and equipment cleaning) | 10 min | 1 | Powder form (in processing residues) |

| 1.2 | Bulk matter dispersed in aqueous solution | 1 | Liquid suspension | |

| 1.3 | Liquid suspension distribution in closed bins | 1 h 30 min | 1 | Liquid suspension |

| 2 | Drying | 48 h | ||

| 2.1 | Preparation (surface and equipment cleaning) | 10 min | 2 | Powder form (in processing residues) |

| 2.2 | Closed system employed: spray drying or freeze drying | 2 h | 2 | Liquid suspension |

| 2.3 | Sublimation | 1 h | 2 | Powder form |

| 3 | Surface Modification | 24 h | ||

| 3.1 | Preparation (surface and equipment cleaning), transfer of incoming materials | 1 h | 1 | Powder form (in processing residues) and liquid suspension |

| 3.2 | Start phase (bulk matter suspension in organic solvent) | 30 min | 1 | Liquid suspension |

| 3.3 | Finish phase (transfer of incoming materials and equipment cleaning) | 30 min | 1 | Powder form |

| 3.4 | Laboratory oven drying in specific bins | 12 h * | 1 | Powder form |

| 4 | Activation | 24 h | ||

| 4.1 | 200 °C vacuum treatment | 2 | Powder form | |

| Instrument | Class | Principle of Operation | Output | Size Range (nm) | Time Resolution (s) | Flow (L/min) | Detection Limits | Accuracy |

|---|---|---|---|---|---|---|---|---|

| CPC TSI Inc. Mod. 3007 | Real time | Optical detection | PNC (#/cm3) | 10–1000 | 1 | 0.7 | 1–1 × 105 #/cm3 | ±20% |

| FMPS TSI Inc. Mod. 3091 | Real time | Electrical mobility | PNC (#/cm3) Size distribution | 5.6–560 | 1 | 10 | Small part.: 100–1 × 107 #/cm3 Large part.: 1–1 × 105 #/cm3 | ±15% MDC * |

| NSAM TSI Inc. Mod. 3550 | Real time | Diffusion charging | Surface area running avg (µm²/cm³) and total (µm²) TB or A fractions | 10–1000 | 1 | 2.5 | TB: 0–2500 μm2/cm3 A: 0–10,000 μm2/cm3 | ±20% |

| PAS2000 EcoChem Inc. | Real time | Photoelectric Ionization | p-PAH (ng/m3) | 10–1000 | 10 | 2 | >3 ng/m3 | ±30% |

| nanoMOUDI MSP Mod. 122 R | Time-integrated area sampler | Aerodynamic diameter | Particle gravimetric mass Size distribution Samples for off-line analysis | 10–18,000 | - | 30 | - | - |

| SIOUTAS SKC Ltd. | Time-integrated personal sampler | Aerodynamic diameter | Particle gravimetric mass Size distribution Samples for off-line analysis | 250–2500 | - | 9 | - | - |

| Technical name | Submicrometer LTA Zeolite |

| Physical state | Powder, dispersion in organic matrix |

| Chemical composition and surface coating | Na8 Al8 Si8 O32 with surface aromatic silanes coating based |

| Crystalline structure | Orderly crystalline structure |

| Physical shape/aspect | Cubic shape |

| Dimensions | 60% n/n < 100 nm determined by dynamic light scattering (DLS) analysis |

| Surface area | 819.6 m2/g determined by Brunauer–Emmett–Teller (BET) analysis |

| Density | 1.8 g/cm3 |

| Porosity | 0.4352 cm3/g Total pore volume determined by BET analysis |

| Bkg FF 13:00–17:00 | Bkg NF 14:42–15:00 | |||

|---|---|---|---|---|

| Mean Value | Std.Dev. | Mean Value | Std.Dev. | |

| PNC (#/cm3) | 956 | 155 | 4423 | 243 |

| Davg (nm) | 36 | 3 | 65 | 2 |

| LDSA (µm2/cm3) | 3.3 | 0.6 | 19.9 | 0.7 |

| p-PAH (ng/m3) | 1.5 | 0.7 | 2.3 | 0.7 |

| Room A | Room B | |||

|---|---|---|---|---|

| Mean Value | Std.Dev. | Mean Value | Std.Dev. | |

| LDSA (µm²/cm³) | 23 | 5 | 6 | 3 |

| T (°C) | 23.5 | 0.5 | 20.7 | 0.6 |

| RH (%) | 44 | 7 | 24 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrante, R.; Boccuni, F.; Tombolini, F.; Natale, C.; Lega, D.; Antonini, A.; Iavicoli, S. Airborne LTA Nanozeolites Characterization during the Manufacturing Process and External Sources Interaction with the Workplace Background. Nanomaterials 2022, 12, 1448. https://doi.org/10.3390/nano12091448

Ferrante R, Boccuni F, Tombolini F, Natale C, Lega D, Antonini A, Iavicoli S. Airborne LTA Nanozeolites Characterization during the Manufacturing Process and External Sources Interaction with the Workplace Background. Nanomaterials. 2022; 12(9):1448. https://doi.org/10.3390/nano12091448

Chicago/Turabian StyleFerrante, Riccardo, Fabio Boccuni, Francesca Tombolini, Claudio Natale, Daniela Lega, Alessandra Antonini, and Sergio Iavicoli. 2022. "Airborne LTA Nanozeolites Characterization during the Manufacturing Process and External Sources Interaction with the Workplace Background" Nanomaterials 12, no. 9: 1448. https://doi.org/10.3390/nano12091448