Large-Area Nanopillar Arrays by Glancing Angle Deposition with Tailored Magnetic Properties

Abstract

:1. Introduction

2. Methods

2.1. Synthesis

2.2. Characterization

2.3. Micromagnetic Simulations

3. Results

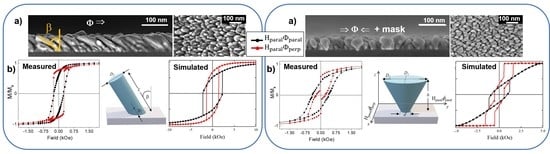

3.1. Structural and Morphological Results

3.2. Hysteresis Loops

3.3. FORC Diagrams

4. Micromagnetic Simulations and Discussion

4.1. Micromagnetic Simulations

4.2. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Micromagnetic Simulatioms

Appendix A.1. Isolated Conical Nanostructure without Magnetocrystalline Anisotropy

Appendix A.2. Dipolar Interaction

Appendix A.3. Variation of Magnetocrystalline Anisotropy

References

- Robbie, K.; Friedrich, L.J.; Dew, S.K.; Smy, T.; Brett, M.J. Fabrication of thin films with highly porous microstructures. J. Vac. Sci. Technol. A 1995, 13, 1032. [Google Scholar] [CrossRef]

- Robbie, K.; Brett, M.J. Sculptured thin films and glancing angle deposition: Growth mechanics and applications. J. Vac. Sci. Technol. A 1997, 15, 1460. [Google Scholar] [CrossRef]

- Sit, J.C.; Vick, D.; Robbie, K.; Brett, M.J. Thin film microstructure control using glancing angle deposition by sputtering. J. Mater. Res. 1999, 14, 1197–1199. [Google Scholar] [CrossRef]

- Lakhtakia, A.; Messier, R. Sculptured thin films. In Nanoengineered Morphology and Optics; SPIE Press: Bellingham, WA, USA, 2005. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–152. [Google Scholar] [CrossRef] [Green Version]

- Hawkeye, M.M.; Taschuk, M.T.; Brett, M.J. Glancing Angle Deposition of Thin Films: Engineering the Nanoscale; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Ziegler, N.; Sengstock, C.; Mai, V.; Schildhauer, T.A.; Köller, M.; Ludwig, A. Glancing-Angle Deposition of Nanostructures on an Implant Material Surface. Nanomaterials 2019, 9, 60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alvarez, R.; Muñoz-Piña, S.; González, M.U.; Izquierdo-Barba, I.; Fernández-Martínez, I.; Rico, V.; Arcos, D.; García-Valenzuela, A.; Palmero, A.; Vallet-Regi, M.; et al. Antibacterial Nanostructured Ti Coatings by Magnetron Sputtering: From Laboratory Scales to Industrial Reactors. Nanomaterials 2019, 9, 1217. [Google Scholar] [CrossRef] [Green Version]

- Knorr, T.G.; Hoffman, R.W. Dependence of Geometric Magnetic Anisotropy in Thin Iron Films. Phys. Rev. 1959, 113, 1039–1046. [Google Scholar] [CrossRef]

- Smith, D.O.; Cohen, M.S.; Weiss, G.P. Oblique-Incidence Anisotropy in Evaporated Permalloy Films. J. Appl. Phys. 1959, 31, 1755–1762. [Google Scholar] [CrossRef]

- Okamoto, K.; Hashimoto, T.; Hara, K.; Kamiya, M.; Fujiwara, H. Columnar structure and texture of iron films prepared at various evaporation rates. Thin Solid Film. 1987, 147, 299–311. [Google Scholar] [CrossRef]

- Hara, K.; Kamiya, M.; Itoh, K.; Okamoto, K.; Hashimoto, T. Magnetic anisotropy in iron films deposited by sputtering. J. Magn. Magn. Mater. 1988, 75, 366–370. [Google Scholar] [CrossRef]

- Itoh, K.; Hara, K.; Kamiya, M.; Okamoto, K.; Hashimoto, T.; Fujiwara, H. Texture in cobalt films deposited obliquely by sputtering. J. Magn. Magn. Mater. 1994, 134, 199–207. [Google Scholar] [CrossRef]

- Liu, F.; Umlor, M.T.; Shen, L.; Weston, J.; Eads, W.; Barnard, J.A.; Mankey, G.J. The growth of nanoscale structured iron films by glancing angle deposition. J. Appl. Phys. 1999, 85, 5486–5488. [Google Scholar] [CrossRef]

- Dick, B.; Brett, M.J.; Smy, T.J.; Freeman, M.R.; Malac, M.; Egerton, R.F. Periodic magnetic microstructures by glancing angle deposition. J. Vac. Sci. Technol. A 2000, 18, 1838. [Google Scholar] [CrossRef]

- Lisfi, A.; Lodder, J.C. Magnetic domains in Co thin films obliquely sputtered on a polymer substrate. Phys. Rev. B 2001, 63, 174441. [Google Scholar] [CrossRef] [Green Version]

- Tang, F.; Liu, D.-L.; Ye, D.-X.; Zhao, Y.-P.; Lu, T.-M.; Wang, G.-C.; Vijayaraghavan, A. Magnetic properties of Co nanocolumns fabricated by oblique-angle deposition. J. Appl. Phys. 2003, 93, 4194–4200. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Dong, C.; Wang, W.; Wang, Z.; Chai, G.; Jiang, C.; Xue, D. Observation of rotatable stripe domain in permalloy films with oblique sputtering. J. Appl. Phys. 2012, 112, 093907. [Google Scholar] [CrossRef]

- Quirós, C.; Peverini, L.; Díaz, J.; Alija, A.; Blanco, C.; Vélez, M.; Robach, O.; Ziegler, E.; Alameda, J.M. Asymmetric grazing incidence small angle x-ray scattering and anisotropic domain wall motion in obliquely grown nanocrystalline Co films. Nanotechnology 2014, 25, 335704. [Google Scholar] [CrossRef]

- Lisfi, A.; Lodder, J.C.; Wormeester, H.; Poelsema, B. Reorientation of magnetic anisotropy in obliquely sputtered metallic thin films. Phys. Rev. B 2002, 66, 174420. [Google Scholar] [CrossRef] [Green Version]

- Umlor, M.T. Uniaxial magnetic anisotropy in cobalt films induced by oblique deposition of an ultrathin cobalt underlayer. Appl. Phys. Lett. 2005, 87, 082505. [Google Scholar] [CrossRef]

- Bubendorff, J.L.; Zabrocki, S.; Garreau, G.; Hajjar, S.; Jaafar, R.; Berling, D.; Mehdaoui, A.; Pirri, C.; Gewinner, G. Origin of the magnetic anisotropy in ferromagnetic layers deposited at oblique incidence. Europhys. Lett. 2006, 75, 119–125. [Google Scholar] [CrossRef]

- Solovev, P.N.; Izotov, A.V.; Belyaev, B.A. Microstructural and magnetic properties of thin obliquely deposited films: A simulation approach. J. Magn. Magn. Mater. 2017, 429, 45–51. [Google Scholar] [CrossRef]

- Morrow, P.; Tang, X.-T.; Parker, T.C.; Shima, M.; CWang, G. Magnetoresistance of oblique angle deposited multilayered Co/Cu nanocolumns measured by a scanning tunnelling microscope. Nanotechnology 2008, 19, 065712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schlage, K.; Bocklage, L.; Erb, D.; Comfort, J.; Wille, H.-C.; Röhlsberger, R. Spin-Structured Multilayers: A New Class of Materials for Precision Spintronics. Adv. Funct. Mater. 2016, 26, 7423–7430. [Google Scholar] [CrossRef] [Green Version]

- Ali, Z.; Basaula, D.; Zhou, W.; Brock, J.; Khan, M.; Eid, K.F. Controlling the charge transport mode in permalloy films using oblique angle deposition. J. Magn. Magn. Mater. 2019, 484, 430–436. [Google Scholar] [CrossRef]

- Schmidt, D.; Kjerstad, A.C.; Hofmann, T.; Skomski, R.; Schubert, E.; Schubert, M. Optical, structural, and magnetic properties of cobalt nanostructure thin films. J. Appl. Phys. 2009, 105, 113508. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, D.; Hofmann, T.; Herzinger, C.M.; Schubert, E.; Schubert, M. Magneto-optical properties of cobalt slanted columnar thin films. Appl. Phys. Lett. 2010, 96, 091906. [Google Scholar] [CrossRef] [Green Version]

- Kar, A.K.; Morrow, P.; Tang, X.-T.; Parker, T.C.; Li, H.; Dai, J.-Y.; Shima, M.; Wang, G.-C. Epitaxial multilayered Co/Cu ferromagnetic nanocolumns grown by oblique angle deposition. Nanotechnology 2007, 18, 295702. [Google Scholar] [CrossRef] [Green Version]

- Thomas, S.; Al-Harthi, S.H.; Al-Omari, I.A.; Ramanujan, R.V.; Swaminathan, V.; Anantharaman, M.R. Influence of substrate topography on the growth and magnetic properties of obliquely deposited amorphous nanocolumns of Fe–Ni. J. Phys. D: Appl. Phys. 2009, 42, 215005. [Google Scholar] [CrossRef]

- Su, H.; Natarajarathinam, A.; Gupta, S. Nanorods of Co/Pd multilayers fabricated by glancing angle deposition for advanced media. J. Appl. Phys. 2013, 113, 203901. [Google Scholar] [CrossRef]

- Keller, A.; Peverini, L.; Grenzer, J.; Kovacs, G.J.; Mucklich, A.; Facsko, S. Polycrystalline Ni thin films on nanopatterned Si substrates: From highly conformal to nonconformal anisotropic growth. Phys. Rev. B 2011, 84, 035423. [Google Scholar] [CrossRef]

- Hajihoseini, H.; Kateb, M.; Ingvarsson, S.P.; Gudmundsson, J.T. Oblique angle deposition of nickel thin films by high-power impulse magnetron sputtering. Beilstein J. Nanotechnol. 2019, 10, 1914–1921. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, R.; Garcia-Valenzuela, A.; Rico, V.; Garcia-Martin, J.M.; Cotrino, J.; Gonzalez-Elipe, A.R.; Palmero, A. Kinetic energy-induced growth regimes of nanocolumnar Ti thin films deposited by evaporation and magnetron sputtering. Nanotechnology 2019, 30, 475603. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alvarez, R.; García-Martín, J.M.; Macías-Montero, M.; González-García, L.; González, J.C.; Rico, V.; Perlich, J.; Cotrino, J.; González-Elipe, A.R.; Palmero, A. Growth regimes of porous gold thin films deposited by magnetron sputtering at oblique incidence: From compact to columnar microstructures. Nanotechnology 2013, 24, 045604. [Google Scholar] [CrossRef] [Green Version]

- Alvarez, R.; Garcia-Martin, J.M.; Lopez-Santos, M.C.; Rico, V.; Ferrer, F.J.; Cotrino, J.; Gonzalez-Elipe, A.R.; Palmero, A. On the Deposition Rates of Magnetron Sputtered Thin Films at Oblique Angles. Plasma Process. Polym. 2014, 11, 571–576. [Google Scholar] [CrossRef] [Green Version]

- García-Valenzuela, A.; Alvarez, R.; Rico, V.; Cotrino, J.; González-Elipe, A.R.; Palmero, A. Growth of nanopillar porous TiO2 thin films by magnetron sputtering using particle collimators. Surf. Coat. Technol. 2018, 343, 172–177. [Google Scholar] [CrossRef]

- Troncoso, G.; García-Martín, J.M.; González, M.U.; Morales, C.; Fernández-Castro, M.; Soler-Morala, J.; Galán, L.; Soriano, L. Silver nanopillar coatings grown by glancing angle magnetron sputtering for reducing multipactor effect in spacecrafts. Appl. Surf. Sci. 2020, 526, 146699. [Google Scholar] [CrossRef]

- Nieuwenhuizen, J.M.; Haanstra, H.B. Microfractography of thin films. Philips Tech. Rev. 1966, 27, 87–91. [Google Scholar]

- Hodgkinson, I.; Wu, Q.H.; Hazel, J. Empirical equations for the principal refractive indices and column angle of obliquely deposited films of tantalum oxide, titanium oxide, and zirconium oxide. Appl. Opt. 1998, 37, 2653–2659. [Google Scholar] [CrossRef]

- Tait, R.N.; Smy, T.; Brett, M.J. Modelling and characterization of columnar growth in evaporated films. Thin Solid Film. 1993, 226, 196–201. [Google Scholar] [CrossRef]

- Hagemeyer, A.; Richter, H.J.; Hibst, H.; Maier, V.; Marosi, L. Crystallographic texture and morphology of obliquely deposited Co-Cr magnetic thin films on flexible polymeric substrates. Thin Solid Film. 1993, 230, 199–202. [Google Scholar] [CrossRef]

- Nakhodkin, N.G.; Shaldervan, A.I. Effect of vapour incidence angles on profile and properties of condensed films. Thin Solid Film. 1972, 10, 109–122. [Google Scholar] [CrossRef]

- Hashimoto, T.; Okamoto, K.; Hara, K.; Kamiya, M.; Fujiwara, H. Columnar structure and texture of iron films evaporated at oblique incidence. Thin Solid Film. 1982, 91, 145–154. [Google Scholar] [CrossRef]

- Lintymer, J.; Gavoille, J.; Martin, N.; Takadoum, J. Glancing angle deposition to modify microstructure and properties of sputter deposited chromium thin films. Surf. Coat. Technol. 2003, 174–175, 316–323. [Google Scholar] [CrossRef]

- Vitrey, A.; Alvarez, R.; Palmero, A.; González, M.U.; García-Martín, J.M. Fabrication of black-gold coatings by glancing angle deposition with sputtering. Beilstein J. Nanotechnol. 2017, 8, 434–439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gradmann, U. Magnetism in Ultrathin Transition Metal. In Handbook of Magnetic Materials; Buschow, K.H.J., Ed.; Elsevier Science Publishers: Amsterdam, The Netherlands, 1993; Volume 7, Chapter 1; pp. 1–96, Review: Magnetic fundamental properties in continuous thin films: Methods, magnetic anisotropy, temperature dependance of magnetization, ground state properties (interface magnetization), metastable phases. [Google Scholar]

- O’Handley, R.C. Modern Magnetic Materials: Principles and Applications; John Willey and Sons: Hoboken, NJ, USA, 2000; pp. 303–306. [Google Scholar]

- Raposo, V.; García, J.M.; González, J.M.; Vázquez, M. Long-range magnetostatic interactions in arrays of nanowires. J. Magn. Magn. Mat. 2000, 222, 227–232. [Google Scholar] [CrossRef]

- Cohen, M.S. Anisotropy in permalloy films evaporated at grazing incidence. J. Appl. Phys. 1961, 32, S87–S88. [Google Scholar] [CrossRef]

- König, H.; Hellwig, G. Über die Struktur schräg aufgedampfter Schichten und ihr EinfluB auf die Entwicklung submikroskopischer Oberflächenrauhigkeiten. Optik 1950, 6, 111–124. [Google Scholar]

- Alvarez, R.; Garcia-Martin, J.M.; Garcia-Valenzuela, A.; Macias-Montero, M.; Ferrer, F.J.; Santiso, J.; Rico, V.; Cotrino, J.; Gonzalez-Elipe, A.R.; Palmero, A. Nanostructured Ti thin films by magnetron sputtering at oblique angles. J. Phys. D. Appl. Phys. 2015, 49, 45303. [Google Scholar] [CrossRef] [Green Version]

| Particular Growth Conditions | (nm) | (%) | (°) | (nm) | (nm) | ||

|---|---|---|---|---|---|---|---|

| NR | No azimuthal rotation of the substrate | 76 | 50 | 58 | 125 | 31 | |

| NR-mask | No azimuthal rotation of the substrate and use of mask (atoms coming from one side) | 59 | 69 | 58 | 87 | 16 | |

| R | Azimuthal rotation of the substrate | 60 | 28 | 0 | 60 | 33 | |

| R-mask | Azimuthal rotation of the substrate and use of mask (atoms coming from the two sides, alternatively) | 55 | 42 | 0 | 55 | Dtop = 41 | Dbase = 14 |

| Thin film | Not GLAD | 25 | 0 | - | - | - | - |

| NR | 238 | 263 | 415 | 592 | 17,900 | 0.60 | 0.77 | 0.006 |

| NR-mask | 522 | 295 | 791 | 363 | 16,000 | 0.76 | 0.40 | 0.22 |

| R | 198 | 189 | 85 | 856 | 15,000 | 0.60 | 0.60 | 0.13 |

| R-mask | 400 | 215 | 35 | 683 | 10,100 | 0.43 | 0.60 | 0.21 |

| Thin Film | 15 | 15 | 375 | 1190 | 18,000 | 0.95 | 0.95 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navarro, E.; González, M.U.; Béron, F.; Tejo, F.; Escrig, J.; García-Martín, J.M. Large-Area Nanopillar Arrays by Glancing Angle Deposition with Tailored Magnetic Properties. Nanomaterials 2022, 12, 1186. https://doi.org/10.3390/nano12071186

Navarro E, González MU, Béron F, Tejo F, Escrig J, García-Martín JM. Large-Area Nanopillar Arrays by Glancing Angle Deposition with Tailored Magnetic Properties. Nanomaterials. 2022; 12(7):1186. https://doi.org/10.3390/nano12071186

Chicago/Turabian StyleNavarro, Elena, María Ujué González, Fanny Béron, Felipe Tejo, Juan Escrig, and José Miguel García-Martín. 2022. "Large-Area Nanopillar Arrays by Glancing Angle Deposition with Tailored Magnetic Properties" Nanomaterials 12, no. 7: 1186. https://doi.org/10.3390/nano12071186