N-Type Printed Organic Source-Gated Transistors with High Intrinsic Gain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Device Fabrication

2.3. Transistor Characteristics

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, H.; Iino, H.; Hanna, J.I. Scalable Ultrahigh-Speed Fabrication of Uniform Polycrystalline Thin Films for Organic Transistors. ACS Appl. Mater. Interfaces 2020, 12, 29497–29504. [Google Scholar] [CrossRef]

- Larsen, C.; Lundberg, P.; Tang, S.; Rafols-Ribe, J.; Sandstrom, A.; Mattias Lindh, E.; Wang, J.; Edman, L. A tool for identifying green solvents for printed electronics. Nat. Commun. 2021, 12, 4510. [Google Scholar] [CrossRef]

- Ho, D.; Lee, J.; Park, S.; Park, Y.; Cho, K.; Campana, F.; Lanari, D.; Facchetti, A.; Seo, S.; Kim, C.; et al. Green solvents for organic thin-film transistor processing. J. Mater. Chem. C 2020, 8, 5786–5794. [Google Scholar] [CrossRef]

- Lee, J.; Park, S.A.; Ryu, S.U.; Chung, D.; Park, T.; Son, S.Y. Green-solvent-processable organic semiconductors and future directions for advanced organic electronics. J. Mater. Chem. A 2020, 8, 21455–21473. [Google Scholar] [CrossRef]

- Sugiyama, M.; Uemura, T.; Kondo, M.; Akiyama, M.; Namba, N.; Yoshimoto, S.; Noda, Y.; Araki, T.; Sekitani, T. An ultraflexible organic differential amplifier for recording electrocardiograms. Nat. Electron. 2019, 2, 351–360. [Google Scholar] [CrossRef]

- Su, Y.; Ma, C.; Chen, J.; Wu, H.; Luo, W.; Peng, Y.; Luo, Z.; Li, L.; Tan, Y.; Omisore, O.M.; et al. Printable, Highly Sensitive Flexible Temperature Sensors for Human Body Temperature Monitoring: A Review. Nanoscale Res. Lett. 2020, 15, 200. [Google Scholar] [CrossRef]

- Wu, J.; Sun, Y.M.; Wu, Z.; Li, X.; Wang, N.; Tao, K.; Wang, G.P. Carbon Nanocoil-Based Fast-Response and Flexible Humidity Sensor for Multifunctional Applications. ACS Appl. Mater. Interfaces 2019, 11, 4242–4251. [Google Scholar] [CrossRef]

- Ha, K.H.; Huh, H.; Li, Z.; Lu, N. Soft Capacitive Pressure Sensors: Trends, Challenges, and Perspectives. ACS Nano 2022, 16, 3442–3448. [Google Scholar] [CrossRef]

- He, Z.; Dai, D.S.H.S.; Chen, M.; Zou, D.; Chik, G.K.K.; Rafael, R.; Lee, K.H.; Piao, Y.; Zhang, S.; Cheng, X.; et al. Van der Waals Assembled Solution-processed Organic Monolayer Single-Crystal Transistor for Electrocardiograph Sensing. Adv. Funct. Mater. 2022, 32, 2205129. [Google Scholar] [CrossRef]

- Boudinet, D.; Benwadih, M.; Qi, Y.; Altazin, S.; Verilhac, J.-M.; Kroger, M.; Serbutoviez, C.; Gwoziecki, R.; Coppard, R.; Le Blevennec, G.; et al. Modification of gold source and drain electrodes by self-assembled monolayer in staggered n- and p-channel organic thin film transistors. Org. Electron. 2010, 11, 227–237. [Google Scholar] [CrossRef]

- Dallaire, N.J.; Brixi, S.; Claus, M.; Blawid, S.; Lessard, B.H. Benchmarking contact quality in N-type organic thin film transistors through an improved virtual-source emission-diffusion model. Appl. Phys. Rev. 2022, 9, 011418. [Google Scholar] [CrossRef]

- Bürgi, L.; Richards, T.J.; Friend, R.H.; Sirringhaus, H. Close look at charge carrier injection in polymer field-effect transistors. J. Appl. Phys. 2003, 94, 6129–6137. [Google Scholar] [CrossRef]

- Hamadani, B.H.; Natelson, D. Nonlinear charge injection in organic field-effect transistors. J. Appl. Phys. 2005, 97, 064508. [Google Scholar] [CrossRef] [Green Version]

- Gundlach, D.J.; Zhou, L.; Nichols, J.A.; Jackson, T.N.; Necliudov, P.V.; Shur, M.S. An experimental study of contact effects in organic thin film transistors. J. Appl. Phys. 2006, 100, 024509. [Google Scholar] [CrossRef]

- Bolognesi, A.; Di Carlo, A.; Lugli, P. Influence of carrier mobility and contact barrier height on the electrical characteristics of organic transistors. Appl. Phys. Lett. 2002, 81, 4646–4648. [Google Scholar] [CrossRef]

- Shannon, J.M.; Gerstner, E.G. Source-gated thin-film transistors. IEEE Electron Device Lett. 2003, 24, 405–407. [Google Scholar] [CrossRef]

- Sporea, R.A.; Trainor, M.J.; Young, N.D.; Shannon, J.M.; Silva, S.R.P. Intrinsic Gain in Self-Aligned Polysilicon Source-Gated Transistors. IEEE Trans. Electron Devices 2010, 57, 2434–2439. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Choi, H.W.; Cheng, X.; Ma, H.; Hasko, D.; Nathan, A. Printed subthreshold organic transistors operating at high gain and ultralow power. Science 2019, 363, 719–723. [Google Scholar] [CrossRef] [Green Version]

- Mariucci, L.; Rapisarda, M.; Valletta, A.; Jacob, S.; Benwadih, M.; Fortunato, G. Current spreading effects in fully printed p-channel organic thin film transistors with Schottky source–drain contacts. Org. Electron. 2013, 14, 86–93. [Google Scholar] [CrossRef]

- Georgakopoulos, S.; Sporea, R.A.; Shkunov, M. Polymer source-gated transistors with low saturation voltage. J. Mater. Chem. C 2022, 10, 1282–1288. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, Z.G.; Xue, L.; Min, J.; Zhang, J.; Wei, Z.; Li, Y. All-Polymer Solar Cells Based on Absorption-Complementary Polymer Donor and Acceptor with High Power Conversion Efficiency of 8.27%. Adv. Mater. 2016, 28, 1884–1890. [Google Scholar] [CrossRef]

- Sporea, R.A.; Trainor, M.J.; Young, N.D.; Guo, X.; Shannon, J.M.; Silva, S.R.P. Performance trade-offs in polysilicon source-gated transistors. Solid-State Electron. 2011, 65-66, 246–249. [Google Scholar] [CrossRef] [Green Version]

- Sawada, T.; Yamamura, A.; Sasaki, M.; Takahira, K.; Okamoto, T.; Watanabe, S.; Takeya, J. Correlation between the static and dynamic responses of organic single-crystal field-effect transistors. Nat. Commun. 2020, 11, 4839. [Google Scholar] [CrossRef]

- Sporea, R.A.; Trainor, M.J.; Young, N.D.; Shannon, J.M.; Silva, S.R.P. Field Plate Optimization in Low-Power High-Gain Source-Gated Transistors. IEEE Trans. Electron Devices 2012, 59, 2180–2186. [Google Scholar] [CrossRef] [Green Version]

- Bestelink, E.; Zschieschang, U.; Bandara, R.M.I.; Klauk, H.; Sporea, R.A. The Secret Ingredient for Exceptional Contact-Controlled Transistors. Adv. Electron. Mater. 2021, 8, 2101101. [Google Scholar] [CrossRef]

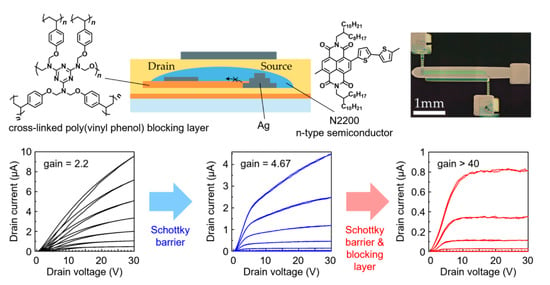

| Device I | Device II | Device III | |

|---|---|---|---|

| Output resistance (MΩ·cm) | 0.69 ± 0.06 | 2.1 ± 0.1 | >100 |

| Transconductance (µS/cm) | 3.2 ± 0.5 | 2.2 ± 0.1 | 0.4 ± 0.1 |

| Intrinsic gain (-) | 2.2 ± 0.4 | 4.67 ± 0.04 | >40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hemmi, Y.; Ikeda, Y.; Sporea, R.A.; Takeda, Y.; Tokito, S.; Matsui, H. N-Type Printed Organic Source-Gated Transistors with High Intrinsic Gain. Nanomaterials 2022, 12, 4441. https://doi.org/10.3390/nano12244441

Hemmi Y, Ikeda Y, Sporea RA, Takeda Y, Tokito S, Matsui H. N-Type Printed Organic Source-Gated Transistors with High Intrinsic Gain. Nanomaterials. 2022; 12(24):4441. https://doi.org/10.3390/nano12244441

Chicago/Turabian StyleHemmi, Yudai, Yuji Ikeda, Radu A. Sporea, Yasunori Takeda, Shizuo Tokito, and Hiroyuki Matsui. 2022. "N-Type Printed Organic Source-Gated Transistors with High Intrinsic Gain" Nanomaterials 12, no. 24: 4441. https://doi.org/10.3390/nano12244441