Effect of Mn2+/Zn2+/Fe3+ Oxy(Hydroxide) Nanoparticles Doping onto Mg-Al-LDH on the Phosphate Removal Capacity from Simulated Wastewater

Abstract

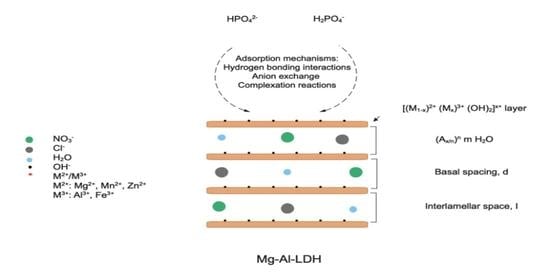

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Mn2+/Zn2+/Fe3+/Mg-Al-LDH Composite Adsorbent

2.3. Physicochemical Characterization of Materials

2.4. Batch Adsorption Studies

2.4.1. Effect of pH on Phosphate Adsorption

2.4.2. Maximum Phosphate Adsorption Capacity

2.4.3. Adsorption Thermodynamics

2.4.4. Kinetic Behavior of Phosphate Adsorption

2.4.5. Phosphate Adsorption Influenced by Competing Ions

2.4.6. Desorption of Phosphate Loaded Mn2+/Zn2+/Fe3+/Mg-Al-LDH

2.4.7. Phosphate Speciation of Loaded Mn2+/Zn2+/Fe3+/Mg-Al-LDH

3. Results

3.1. Characterization

3.2. Effect of pH

3.3. Phosphate Adsorption Isotherms

3.4. Phosphate Adsorption Kinetics

3.5. Influence of Competing Ions

3.6. Phosphate Speciation

3.7. Adsorption–Desorption Cycles

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, F.; Ansari, A.A. Eutrophication: An Ecological Vision. Bot. Rev. 2005, 71, 449–482. [Google Scholar] [CrossRef]

- Guaya, D.; Jiménez, R.; Sarango, J.; Valderrama, C.; Cortina, J.L. Iron-Doped Natural Clays: Low-Cost Inorganic Adsorbents for Phosphate Recovering from Simulated Urban Treated Wastewater. J. Water Process Eng. 2021, 43, 102274. [Google Scholar] [CrossRef]

- Guaya, D.; Hermassi, M.; Valderrama, C.; Farran, A.; Cortina, J.L. Recovery of Ammonium and Phosphate from Treated Urban Wastewater by Using Potassium Clinoptilolite Impregnated Hydrated Metal Oxides as N-P-K Fertilizer. J. Env. Chem. Eng. 2016, 4, 3519–3526. [Google Scholar] [CrossRef]

- United Nations. Sustainable Development Goals. Available online: http://www.undp.org/content/undp/en/home/sustainable-development-goals.html (accessed on 24 September 2022).

- Guaya, D.; Cobos, H.; Camacho, J.; López, C.M.; Valderrama, C.; Cortina, J.L. LTA and FAU-X Iron-Enriched Zeolites: Use for Phosphate Removal from Aqueous Medium. Materials 2022, 15, 5418. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Son, N.; Kang, M. Synergistic Sorption Performance of Karaya Gum Crosslink Poly(Acrylamide-Co-Acrylonitrile) @ Metal Nanoparticle for Organic Pollutants. Int. J. Biol. Macromol. 2022, 210, 300–314. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.-H.; Lundehøj, L.; Nielsen, U.G. An Investigation of the Phosphate Removal Mechanism by MgFe Layered Double Hydroxides. Appl. Clay Sci. 2020, 189, 105521. [Google Scholar] [CrossRef]

- Almasri, D.A.; Saleh, N.B.; Atieh, M.A.; McKay, G.; Ahzi, S. Adsorption of Phosphate on Iron Oxide Doped Halloysite Nanotubes. Sci. Rep. 2019, 9, 3232. [Google Scholar] [CrossRef]

- Li, S.-S.; Jiang, M.; Jiang, T.-J.; Liu, J.-H.; Guo, Z.; Huang, X.-J. Competitive Adsorption Behavior toward Metal Ions on Nano-Fe/Mg/Ni Ternary Layered Double Hydroxide Proved by XPS: Evidence of Selective and Sensitive Detection of Pb(II). J. Hazard Mater. 2017, 338, 1–10. [Google Scholar] [CrossRef]

- Qiu, H.; Ye, M.; Zeng, Q.; Li, W.; Fortner, J.; Liu, L.; Yang, L. Fabrication of Agricultural Waste Supported UiO-66 Nanoparticles with High Utilization in Phosphate Removal from Water. Chem. Eng. J. 2019, 360, 621–630. [Google Scholar] [CrossRef]

- Guaya, D.; Valderrama, C.; Farran, A.; Armijos, C.; Cortina, J.L. Simultaneous Phosphate and Ammonium Removal from Aqueous Solution by a Hydrated Aluminum Oxide Modified Natural Zeolite. Chem. Eng. J. 2015, 271, 204–213. [Google Scholar] [CrossRef]

- Pandey, S.; Son, N.; Kim, S.; Balakrishnan, D.; Kang, M. Locust Bean Gum-Based Hydrogels Embedded Magnetic Iron Oxide Nanoparticles Nanocomposite: Advanced Materials for Environmental and Energy Applications. Env. Res. 2022, 214, 114000. [Google Scholar] [CrossRef] [PubMed]

- Pontes-Neto, J.G.; Lyra, M.A.M.; Soares, M.F.L.R.; Chaves, L.L.; Soares-Sobrinho, J.L. Intercalation of Olanzapine into CaAl and NiAl Layered Double Hydroxides for Dissolution Rate Improvement: Synthesis, Characterization and in Vitro Toxicity. J. Drug Deliv. Sci. Technol. 2019, 52, 986–996. [Google Scholar] [CrossRef]

- Guaya, D.; Valderrama, C.; Farran, A.; Sauras, T.; Cortina, J.L. Valorisation of N and P from Waste Water by Using Natural Reactive Hybrid Sorbents: Nutrients (N,P,K) Release Evaluation in Amended Soils by Dynamic Experiments. Sci. Total Environ. 2018, 612, 728–738. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dias, A.C.; Fontes, M.P.F. Arsenic (V) Removal from Water Using Hydrotalcites as Adsorbents: A Critical Review. Appl. Clay Sci. 2020, 191, 105615. [Google Scholar] [CrossRef]

- Goh, K.-H.; Lim, T.-T.; Dong, Z. Application of Layered Double Hydroxides for Removal of Oxyanions: A Review. Water Res. 2008, 42, 1343–1368. [Google Scholar] [CrossRef] [PubMed]

- Luengo, C.V.; Volpe, M.A.; Avena, M.J. High Sorption of Phosphate on Mg-Al Layered Double Hydroxides: Kinetics and Equilibrium. J. Env. Chem. Eng. 2017, 5, 4656–4662. [Google Scholar] [CrossRef]

- Kuzawa, K.; Jung, Y.-J.; Kiso, Y.; Yamada, T.; Nagai, M.; Lee, T.-G. Phosphate Removal and Recovery with a Synthetic Hydrotalcite as an Adsorbent. Chemosphere 2006, 62, 45–52. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zhu, Z.; Qiu, Y.; Zhao, J. Adsorption of Arsenate on Cu/Mg/Fe/La Layered Double Hydroxide from Aqueous Solutions. J. Hazard Mater. 2012, 239–240, 279–288. [Google Scholar] [CrossRef]

- Novillo, C.; Guaya, D.; Allen-Perkins Avendaño, A.; Armijos, C.; Cortina, J.L.; Cota, I. Evaluation of Phosphate Removal Capacity of Mg/Al Layered Double Hydroxides from Aqueous Solutions. Fuel 2014, 138, 72–79. [Google Scholar] [CrossRef]

- Yan, H.; Chen, Q.; Liu, J.; Feng, Y.; Shih, K. Phosphorus Recovery through Adsorption by Layered Double Hydroxide Nano-Composites and Transfer into a Struvite-like Fertilizer. Water Res. 2018, 145, 721–730. [Google Scholar] [CrossRef]

- Cheng, X.; Ye, J.; Sun, D.; Chen, A. Influence of Synthesis Temperature on Phosphate Adsorption by Zn-Al Layered Double Hydroxides in Excess Sludge Liquor. Chin. J. Chem. Eng. 2011, 19, 391–396. [Google Scholar] [CrossRef]

- Ogata, F.; Nagai, N.; Kishida, M.; Nakamura, T.; Kawasaki, N. Interaction between Phosphate Ions and Fe-Mg Type Hydrotalcite for Purification of Wastewater. J. Env. Chem. Eng. 2019, 7, 102897. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, Z.; Qiu, Y.; Zhao, J. Synthesis of Mesoporous Cu/Mg/Fe Layered Double Hydroxide and Its Adsorption Performance for Arsenate in Aqueous Solutions. J. Environ. Sci. 2013, 25, 944–953. [Google Scholar] [CrossRef]

- Ma, W.; Chen, Y.; Zhang, W.; Zhao, W. Performance and Mechanism of Mg-Ca-Fe Hydrotalcite-like Compounds for Fluoride Removal from Aqueous Solution. J. Fluor. Chem. 2017, 200, 153–161. [Google Scholar] [CrossRef]

- Zhou, H.; Tan, Y.; Yang, Y.; Zhang, Y.; Lei, X.; Yuan, D. Application of FeMgMn Layered Double Hydroxides for Phosphate Anions Adsorptive Removal from Water. Appl. Clay Sci. 2021, 200, 105903. [Google Scholar] [CrossRef]

- Sipos, P.; Berkesi, O.; Tombácz, E.; St. Pierre, T.G.; Webb, J. Formation of Spherical Iron(III) Oxyhydroxide Nanoparticles Sterically Stabilized by Chitosan in Aqueous Solutions. J. Inorg. Biochem. 2003, 95, 55–63. [Google Scholar] [CrossRef]

- McCrady, M.H. American Journal of Public Health and the Nations Health. In Standard Methods for the Examination of Water and Wastewater, 12th ed.; American Public Health Association: New York, NY, USA, 2011. [Google Scholar]

- Limousin, G.; Gaudet, J.-P.; Charlet, L.; Szenknect, S.; Barthès, V.; Krimissa, M. Sorption Isotherms: A Review on Physical Bases, Modeling and Measurement. Appl. Geochem. 2007, 22, 249–275. [Google Scholar] [CrossRef]

- Liang, X.; Zang, Y.; Xu, Y.; Tan, X.; Hou, W.; Wang, L.; Sun, Y. Sorption of Metal Cations on Layered Double Hydroxides. Colloids Surf. A Phys. Eng. Asp. 2013, 433, 122–131. [Google Scholar] [CrossRef]

- Tran, H.N.; You, S.-J.; Hosseini-Bandegharaei, A.; Chao, H.-P. Mistakes and Inconsistencies Regarding Adsorption of Contaminants from Aqueous Solutions: A Critical Review. Water Res. 2017, 120, 88–116. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, X. The Unit Problem in the Thermodynamic Calculation of Adsorption Using the Langmuir Equation. Chem. Eng. Commun. 2014, 201, 1459–1467. [Google Scholar] [CrossRef]

- Valderrama, C.; Barios, J.I.; Caetano, M.; Farran, A.; Cortina, J.L. Kinetic Evaluation of Phenol/Aniline Mixtures Adsorption from Aqueous Solutions onto Activated Carbon and Hypercrosslinked Polymeric Resin (MN200). React. Funct. Polym. 2010, 70, 142–150. [Google Scholar] [CrossRef]

- Hieltjes, A.H.M.; Lijklema, L. Fractionation of Inorganic Phosphates in Calcareous Sediments. J. Environ. Qual. 1980, 9, 405–407. [Google Scholar] [CrossRef]

- Wu, X.; Luo, B.; Chen, M.; Chen, F. Tunable Surface Charge of Fe, Mn Substituted Polyoxometalates/Hydrotalcites for Efficient Removal of Multiple Dyes. Appl. Surf. Sci. 2020, 509, 145344. [Google Scholar] [CrossRef]

- Jabłońska, M.; Arán, M.A.; Beale, A.M.; Delahay, G.; Petitto, C.; Nocuń, M.; Palkovits, R. Understanding the Origins of N2O Decomposition Activity in Mn(Fe)CoAlOx Hydrotalcite Derived Mixed Metal Oxides. Appl. Catal. B 2019, 243, 66–75. [Google Scholar] [CrossRef]

- Awual, M.R.; Hasan, M.M.; Asiri, A.M.; Rahman, M.M. Cleaning the Arsenic(V) Contaminated Water for Safe-Guarding the Public Health Using Novel Composite Material. Compos. B Eng. 2019, 171, 294–301. [Google Scholar] [CrossRef]

- Awual, M.R. Efficient Phosphate Removal from Water for Controlling Eutrophication Using Novel Composite Adsorbent. J. Clean. Prod. 2019, 228, 1311–1319. [Google Scholar] [CrossRef]

- Awual, M.R.; Yaita, T.; Suzuki, S.; Shiwaku, H. Ultimate Selenium(IV) Monitoring and Removal from Water Using a New Class of Organic Ligand Based Composite Adsorbent. J. Hazard Mater. 2015, 291, 111–119. [Google Scholar] [CrossRef]

- Koilraj, P.; Kannan, S. Phosphate Uptake Behavior of ZnAlZr Ternary Layered Double Hydroxides through Surface Precipitation. J. Colloid Interface Sci. 2010, 341, 289–297. [Google Scholar] [CrossRef]

- Seida, Y.; Nakano, Y. Removal of Phosphate by Layered Double Hydroxides Containing Iron. Water Res. 2002, 36, 1306–1312. [Google Scholar] [CrossRef]

- Awual, M.R.; Shenashen, M.A.; Jyo, A.; Shiwaku, H.; Yaita, T. Preparing of Novel Fibrous Ligand Exchange Adsorbent for Rapid Column-Mode Trace Phosphate Removal from Water. J. Ind. Eng. Chem. 2014, 20, 2840–2847. [Google Scholar] [CrossRef]

- Awual, M.R.; Hasan, M.M.; Khaleque, M.A. Efficient Selenium(IV) Detection and Removal from Water by Tailor-Made Novel Conjugate Adsorbent. Sens. Actuators B Chem. 2015, 209, 194–202. [Google Scholar] [CrossRef]

- Khitous, M.; Salem, Z.; Halliche, D. Removal of Phosphate from Industrial Wastewater Using Uncalcined MgAl-NO3 Layered Double Hydroxide: Batch Study and Modeling. Desalination Water Treat. 2016, 57, 15920–15931. [Google Scholar] [CrossRef]

- Guaya, D.; Valderrama, C.; Farran, A.; Cortina, J.L. Modification of a Natural Zeolite with Fe(III) for Simultaneous Phosphate and Ammonium Removal from Aqueous Solutions. J. Chem. Technol. Biotechnol. 2016, 91, 1737–1746. [Google Scholar] [CrossRef]

- Guaya, D.; Valderrama, C.; Farran, A.; Cortina, J.L. Simultaneous Nutrients (N,P) Removal by Using a Hybrid Inorganic Sorbent Impregnated with Hydrated Manganese Oxide. J. Environ. Chem. Eng. 2017, 5, 1516–1525. [Google Scholar] [CrossRef]

- Deng, L.; Shi, Z. Synthesis and Characterization of a Novel Mg–Al Hydrotalcite-Loaded Kaolin Clay and Its Adsorption Properties for Phosphate in Aqueous Solution. J. Alloys Compd. 2015, 637, 188–196. [Google Scholar] [CrossRef]

- Das, J.; Patra, B.S.; Baliarsingh, N.; Parida, K.M. Adsorption of Phosphate by Layered Double Hydroxides in Aqueous Solutions. Appl. Clay Sci. 2006, 32, 252–260. [Google Scholar] [CrossRef]

- Kamiyango, M.; Sajidu, S.; Masamba, W. Removal of Phosphate Ions from Aqueous Solutions Using Bauxite Obtained from Mulanje, Malawi. Afr. J. Biotechnol. 2011, 10, 11972–11982. [Google Scholar] [CrossRef]

| Material | C (%) | O (%) | Mg (%) | Al (%) | P (%) | Cl (%) | Mn (%) | Fe (%) | Zn (%) |

|---|---|---|---|---|---|---|---|---|---|

| Mg-Al-LDH | 9.2 ± 0.2 | 61.0 ± 0.5 | 19.4 ± 0.2 | 10.4 ± 0.3 | - | - | - | - | - |

| Mn2+/Zn2+/Fe3+/Mg-Al-LDH | 8.4 ± 0.3 | 45.5 ± 0.5 | 12.7 ± 0.1 | 10.2 ± 0.3 | - | 9.4 ± 0.5 | 3.5 ± 0.3 | 7.2 ± 0.4 | 3.2 ± 0.3 |

| P-loaded Mn2+/Zn2+/Fe3+/Mg-Al-LDH | 8.5 ± 0.4 | 59.1 ± 0.4 | 11.4 ± 0.2 | 10.4 ± 0.3 | 3.2 ± 0.3 | 0.7 ± 0.2 | 1.7 ± 0.2 | 3.0 ± 0.3 | 2.1 ± 0.3 |

| Adsorbent | Description | Nomenclature | (mg∙g−1) | Condition | Ref. |

|---|---|---|---|---|---|

| Parent Mg-Al-LDH | Synthetized Mg-Al-LDH | Mg-Al-LDH | 65.3 | 20 °C, pH 7.5 | This study |

| Mn2+/Zn2+/Fe3+/Mg (oxy)hydroxide nanoparticles supported onto parent Mg-Al-LDH | Metals (oxy)hydroxide nanoparticles supported onto parent Mg-Al-LDH | Mn2+/Zn2+/Fe3+/Mg-Al-LDH | 82.3 | ||

| FeMgMn-LDH | FeMgMn-LDH synthesized in a single co-precipitation step. | FeMg2Mn-LDH | 34.3 | 25 °C, pH 6.5 | [26] |

| MgAl-NO3-LDH | Synthetized Mg-Al-LDH in a single co-precipitation step. | MgAl-NO3-LDH | 64.1 | 25 °C, pH 6 | [44] |

| MgAl-Cl-LDH | Synthetized Mg-Al-LDH in a single co-precipitation step. | Mg-Al LDH | 69.8 | 25 °C, pH 5 | [17] |

| Fe-Mg-LDH | Purchased Fe-HT3.0 and Fe-HT5.0 | Fe-Mg-LDH | 58.3 | - | [23] |

| Zn-Al-LDH | Zn-Al-LDH synthesized in a single co-precipitation step. | Zn-Al-70-LDH | 20.7 | 25 °C, pH 6.8 | [22] |

| Natural clays | Natural form of clays | C1 | 21.4 | 20 °C, pH 7.0 | [2] |

| C2 | 20.9 | ||||

| Iron-doped clays | C1-Fe | 38.0 | |||

| C2-Fe | 37.6 | ||||

| Hydrothermally synthesized zeolites | Iron-doped zeolites | LTA-Fe | 18.5 | 20 °C, pH 7.0 | [5] |

| FAU-X-Fe | 17.5 | ||||

| Natural zeolites | Al/Fe/Mn doped clinoptilolite | ZN | 0.6 | 20 °C, pH 7.0 | [11] |

| Z-Al | 7.0 | ||||

| Z-Fe | 3.4 | [45] | |||

| Z-Mn | 5.6 | [46] |

| Temperature (K) | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|

(mg·g−1) | (L·mg−1) | R2 | n | (mg·g−1) | R2 | |

| 293.15 | 82.34 | 0.03 | 0.99 | 3.10 | 8.65 | 0.73 |

| 298.15 | 86.45 | 0.04 | 0.99 | 3.23 | 9.13 | 0.75 |

| 303.15 | 87.98 | 0.05 | 0.99 | 3.45 | 10.1 | 0.77 |

| Temperature (K) | R2 | ||||

|---|---|---|---|---|---|

| (kJ·mol−1) | (kJ·mol−1·K−1) | (kJ·mol−1) | |||

| 293.15 | 11.97 | 0.99 | −29.18 | 0.23 | 37.77 |

| 298.15 | 12.26 | −30.39 | |||

| 303.15 | 12.48 | −31.46 |

| Model | Kinetic Parameters | Phosphate |

|---|---|---|

| Pseudo-first order | (mg·g−1) | 10.5 |

| (h−1) | 0.2 | |

| R2 | 0.76 | |

| Pseudo-second order | (mg·g−1) | 32.7 |

| (g·mg−1·h−1) | 0.19 | |

| R2 | 0.99 | |

| Intraparticle diffusion | (mg·g−1·h−1/2) | 29.7 |

| R2 | 0.77 | |

| (mg·g−1·h−1/2) | 1.9 | |

| R2 | 0.90 | |

| (mg·g−1·h−1/2) | 1.9 | |

| R2 | 0.95 | |

| HPDF Film diffusion | (m2·s−1) | 5.6 × 10−15 |

| R2 | 0.93 | |

| HPDM Particle diffusion | (m2·s−1) | 2.6 × 10−14 |

| R2 | 0.90 |

| Anion | (mg·g−1) | qmix/q0 |

|---|---|---|

| PO43− | 12.4 ± 0.3 | - |

| PO43− + NO3− | 17.6 ± 0.4 | 1.4 |

| PO43−+ SO42− | 11.7 ± 0.4 | 0.9 |

| PO43− + Cl− | 12.3 ± 0.5 | 1.0 |

| PO43− + HCO3− | 13.7 ± 0.4 | 1.1 |

| PO43− + All anions | 10.4 ± 0.6 | 0.8 |

| LB-P | (Fe + Zn + Mn)-P | (Mg)-P | R-P | |||||

|---|---|---|---|---|---|---|---|---|

| (mg·g−1) | (mg·g−1) | % | (mg·g−1) | % | (mg·g−1) | % | (mg·g−1) | % |

| 18.0 | 2.5 | 14 ± 1 | 9.2 | 51 ± 3 | 5.8 | 32 ± 2 | 0.5 | 3 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guaya, D.; Cobos, H.; Valderrama, C.; Cortina, J.L. Effect of Mn2+/Zn2+/Fe3+ Oxy(Hydroxide) Nanoparticles Doping onto Mg-Al-LDH on the Phosphate Removal Capacity from Simulated Wastewater. Nanomaterials 2022, 12, 3680. https://doi.org/10.3390/nano12203680

Guaya D, Cobos H, Valderrama C, Cortina JL. Effect of Mn2+/Zn2+/Fe3+ Oxy(Hydroxide) Nanoparticles Doping onto Mg-Al-LDH on the Phosphate Removal Capacity from Simulated Wastewater. Nanomaterials. 2022; 12(20):3680. https://doi.org/10.3390/nano12203680

Chicago/Turabian StyleGuaya, Diana, Hernán Cobos, César Valderrama, and José Luis Cortina. 2022. "Effect of Mn2+/Zn2+/Fe3+ Oxy(Hydroxide) Nanoparticles Doping onto Mg-Al-LDH on the Phosphate Removal Capacity from Simulated Wastewater" Nanomaterials 12, no. 20: 3680. https://doi.org/10.3390/nano12203680