Nanostructuration of YAG:Ce Coatings by ZnO Nanowires: A Smart Way to Enhance Light Extraction Efficiency

Abstract

:1. Introduction

2. Materials and Methods

2.1. Elaboration of YAG:Ce Coatings

2.2. Growth of ZnO Nanowires

2.3. Characterization Techniques

3. Results and Discussion

3.1. Structural and Morphological Studies

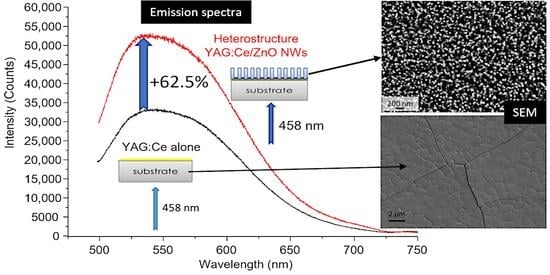

3.2. Optical Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khanna, V.K. Fundamentals of Solid-State Lighting: LEDs, OLEDs, and Their Applications in Illumination and Displays; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- McKittrick, J.; Shea-Rohwer, L.E. Review: Down Conversion Materials for Solid-State Lighting. J. Am. Ceram. Soc. 2014, 97, 1327–1352. [Google Scholar] [CrossRef]

- Piquette, A.; Bergbauer, W.; Galler, B.; Mishra, K.C. On Choosing Phosphors for Near-UV and Blue LEDs for White Light. ECS J. Solid State Sci. Technol. 2016, 5, R3146–R3159. [Google Scholar] [CrossRef]

- Khan, M.A.; Bian, P.; Qu, J.; Chen, H.; Liu, H.; Foley, M.; Yao, Y.; Ringer, S.P.; Zheng, R. Non-destructive analysis on nano-textured surface of the vertical LED for light enhancement. Ultramicroscopy 2019, 196, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Geng, C.; Wei, T.; Wang, X.; Shen, D.; Hao, Z.; Yan, Q. Enhancement of Light Output Power from LEDs Based on Monolayer Colloidal Crystal. Small 2014, 10, 1668–1686. [Google Scholar] [CrossRef]

- Gorsky, S.; Britton, W.A.; Chen, Y.; Montaner, J.; Lenef, A.; Raukas, M.; Negro, L.D. Engineered hyperuniformity for directional light extraction. APL Photonics 2019, 4, 110801. [Google Scholar] [CrossRef]

- Lenef, A.; Piquette, A.; Kelso, J. Thermodynamics of Light Extraction from Luminescent Materials. ECS J. Solid State Sci. Technol. 2018, 7, R3211–R3226. [Google Scholar] [CrossRef] [Green Version]

- Zhmakin, A.I. Enhancement of light extraction from light emitting diodes. Phys. Rep. 2011, 498, 189–241. [Google Scholar] [CrossRef]

- Leung, S.-F.; Zhang, Q.; Xiu, F.; Yu, D.; Ho, J.C.; Li, D.; Fan, Z. Light Management with Nanostructures for Optoelectronic Devices. J. Phys. Chem. Lett. 2014, 5, 1479–1495. [Google Scholar] [CrossRef]

- Li, Z.; Cao, K.; Li, J.; Tang, Y.; Xu, L.; Ding, X.; Yu, B. Investigation of Light-Extraction Mechanisms of Multiscale Patterned Arrays with Rough Morphology for GaN-Based Thin-Film LEDs. IEEE Access 2019, 7, 73890–73898. [Google Scholar] [CrossRef]

- Zelmon, D.E.; Small, D.L.; Page, R. Refractive-index measurements of undoped yttrium aluminum garnet from 0.4 to 5.0 μm. Appl. Opt. 1998, 37, 4933–4935. [Google Scholar] [CrossRef]

- Kim, J.S.; Eswaran, S.K.; Kwon, O.H.; Han, S.J.; Lee, J.H.; Cho, Y.S. Enhanced Luminescence Characteristics of Remote Yellow Silicate Phosphors Printed on Nanoscale Surface-Roughened Glass Substrates for White Light-Emitting Diodes. Adv. Opt. Mater. 2016, 4, 1081–1087. [Google Scholar] [CrossRef]

- Sun, H.; Piquette, A.; Raukas, M.; Moustakas, T.D. Enhancement of yellow light extraction efficiency of Y3Al5O12: Ce3+ ceramic converters using a 2-D TiO2 hexagonal-lattice nanocylinder photonic crystal layer. IEEE Photonics J. 2016, 8, 4500310. [Google Scholar] [CrossRef]

- Schnitzer, I.; Yablonovitch, E.; Caneau, C.; Gmitter, T.J.; Scherer, A. 30% external quantum efficiency from surface textured, thin-film light-emitting diodes. Appl. Phys. Lett. 1993, 63, 2174–2176. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Son, S.Y.; Singh, R.; Balasundaram, K.; Lee, J.; Singh, R. Analytical treatment of light extraction from textured surfaces using classical ray optics. Opt. Commun. 2011, 284, 4874–4878. [Google Scholar] [CrossRef]

- Fang, C.-Y.; Liu, Y.-L.; Lee, Y.-C.; Chen, H.-L.; Wan, D.-H.; Yu, C.-C. Nanoparticle Stacks with Graded Refractive Indices Enhance the Omnidirectional Light Harvesting of Solar Cells and the Light Extraction of Light-Emitting Diodes. Adv. Funct. Mater. 2013, 23, 1412–1421. [Google Scholar] [CrossRef]

- Sohn, K.-S.; Shin, N.; Kim, Y.-C.; Do, Y.R. Effect of corrugated substrates on light extraction efficiency and the mechanism of growth in pulsed laser deposited Y2O3:Eu3+ thin-film phosphors. Appl. Phys. Lett. 2004, 85, 55–57. [Google Scholar] [CrossRef]

- Youn, W.; Lee, J.; Xu, M.; Singh, R.; So, F. Corrugated Sapphire Substrates for Organic Light-Emitting Diode Light Extraction. ACS Appl. Mater. Interfaces 2015, 7, 8974–8978. [Google Scholar] [CrossRef]

- Devys, L.; Dantelle, G.; Revaux, A.; Kubytskyi, V.; Paget, D.; Benisty, H.; Gacoin, T. Extraction Length Determination in Patterned Luminescent Sol–Gel Films. Adv. Opt. Mater. 2014, 2, 81–87. [Google Scholar] [CrossRef]

- Yang, X.; Dev, K.; Wang, J.; Mutlugun, E.; Dang, C.; Zhao, Y.; Liu, S.; Tang, Y.; Tan, S.T.; Sun, X.W.; et al. Light Extraction Efficiency Enhancement of Colloidal Quantum Dot Light-Emitting Diodes Using Large-Scale Nanopillar Arrays. Adv. Funct. Mater. 2014, 24, 5977–5984. [Google Scholar] [CrossRef] [Green Version]

- Ding, P.; Shao, L.; Wang, J.; Li, Y.; Zeng, F.; Liang, E. Enhanced light extraction with silicon nanoantenna arrays for white light LED applications. Opt. Quantum Electron. 2017, 49, 194. [Google Scholar] [CrossRef]

- Gorsky, S.; Zhang, R.; Gok, A.; Wang, R.; Kebede, K.; Lenef, A.; Raukas, M.; Negro, L.D. Directional light emission enhancement from LED-phosphor converters using dielectric Vogel spiral arrays. APL Photonics 2018, 3, 126103. [Google Scholar] [CrossRef] [Green Version]

- Panda, D.; Tseng, T.-Y. One-dimensional ZnO nanostructures: Fabrication, optoelectronic properties, and device applications. J. Mater. Sci 2013, 48, 6849–6877. [Google Scholar] [CrossRef]

- Djurišić, A.B.; Leung, Y.H. Optical Properties of ZnO Nanostructures. Small 2006, 2, 944–961. [Google Scholar] [CrossRef]

- Jeong, H.; Salas-Montiel, R.; Lerondel, G.; Jeong, M.S. Ultraviolet, blue, and green InGaN-based light-emitting diodes functionalized with ZnO nanorods. J. Alloys Compd. 2017, 708, 612–618. [Google Scholar] [CrossRef]

- Jeong, H.; Park, D.J.; Lee, H.S.; Ko, Y.H.; Yu, J.S.; Choi, S.-B.; Lee, D.-S.; Suh, E.-K.; Jeong, M.S. Light-extraction enhancement of a GaN-based LED covered with ZnO nanorod arrays. Nanoscale 2014, 6, 4371–4378. [Google Scholar] [CrossRef]

- Soh, C.B.; Tay, C.B.; Chua, S.J.; Le, H.Q.; Ang, N.S.S.; Teng, J.H. Optimization of hydrothermal growth ZnO Nanorods for enhancement of light extraction from GaN blue LEDs. J. Cryst. Growth 2010, 312, 1848–1854. [Google Scholar] [CrossRef]

- Park, Y.J.; Song, H.; Ko, K.B.; Ryu, B.D.; Cuong, T.V.; Hong, C.-H. Nanostructural Effect of ZnO on Light Extraction Efficiency of Near-Ultraviolet Light-Emitting Diodes. J. Nanomater. 2016, 2016, 7947623. [Google Scholar] [CrossRef] [Green Version]

- Kwon, O.H.; Jang, J.W.; Park, S.-J.; Kim, J.S.; Hong, S.J.; Jung, Y.S.; Yang, H.; Kim, Y.J.; Cho, Y.S. Plasmonic-Enhanced Luminescence Characteristics of Microscale Phosphor Layers on a ZnO Nanorod-Arrayed Glass Substrate. ACS Appl. Mater. Interfaces 2019, 11, 1004–1012. [Google Scholar] [CrossRef]

- Layek, A.; Stanish, P.C.; Chirmanov, V.; Radovanovic, P.V. Hybrid ZnO-Based Nanoconjugate for Efficient and Sustainable White Light Generation. Chem. Mater. 2015, 27, 1021–1030. [Google Scholar] [CrossRef]

- Amara, N.; Martin, A.; Potdevin, A.; Riassetto, D.; Messaoud, M.; Réveret, F.; Chadeyron, G.; Bouaziz, J.; Langlet, M. ZnO nanowires/YAG:Ce functional heterostructure coatings with tunable optical properties. J. Alloys Compd. 2020, 842, 155708. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, X.; Gao, F.; Yang, L.; Liu, W. Stable white emission and color-tunable electroluminescence achieved from n-ZnO/p-GaN nano-heterojunction decorated with CsPbBr3 and CsPbI3 quantum dots. J. Lumin. 2022, 244, 118691. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Li, H.; Pan, L.; Lv, T.; Sun, Z.; Sun, C. Microwave-assisted synthesis of ZnO–Y3Al5O12:Ce3+ composites with enhanced visible light photocatalysis. J. Mater. Chem. 2012, 22, 16293–16298. [Google Scholar] [CrossRef]

- Zammouri, L.; Aboulaich, A.; Capoen, B.; Bouazaoui, M.; Sarakha, M.; Stitou, M.; Mahiou, R. Synthesis of YAG:Ce/ZnO core/shell nanoparticles with enhanced UV-visible and visible light photocatalytic activity and application for the antibiotic removal from aqueous media. J. Mater. Res. 2019, 34, 1318–1330. [Google Scholar] [CrossRef]

- Chao, K.; Xiao, Z.; Zhang, H.; Niu, W.; Xia, W.; Sang, S.; Xin, Y.; Li, Q.; Wu, S.; Zhang, S. The surface coating of YAG:Ce phosphors with ZnO nanoparticles for white LED. Mater. Sci. Forum 2011, 675–677, 1283–1286. [Google Scholar] [CrossRef]

- Yildirim, B.; Yasin Keskin, O.; Oguzlar, S.; Birlik, I.; Ak Azem, F.; Ertekin, K. Manipulation of brightness and decay kinetics of LuAG: Ce3+ and YAG: Ce3+ by simple metal oxides in polymeric matrices. Opt. Laser Technol. 2021, 142, 107226. [Google Scholar] [CrossRef]

- Sundarakannan, B.; Kottaisamy, M. Blue light excitable red emitting ZnO and its blend for high CRI white light emitting diodes applications. J. Lumin. 2022, 241, 118447. [Google Scholar] [CrossRef]

- Nyalosaso, J.L.; Potdevin, A.; Réveret, F.; Disseix, P.; Mahiou, R.; Chadeyron, G. Enhancement of light extraction in Y3Al5O12:Tb3+ thin films through nanopatterning. Chem. Eng. Sci. 2020, 213, 115416. [Google Scholar] [CrossRef]

- Potdevin, A.; Briois, V.; Caperaa, N.; Santilli, C.V.; Chadeyron, G.; Mahiou, R. A thorough spectroscopic study of luminescent precursor solution of Y3Al5O12:Tb3+: Influence of acetylacetone. RSC Adv. 2016, 6, 41962–41971. [Google Scholar] [CrossRef]

- Potdevin, A.; Chadeyron, G.; Boyer, D.; Mahiou, R. Sol-gel based YAG:Ce3+ powders for applications in LED devices. Phys. Status Solidi C 2007, 4, 65–69. [Google Scholar] [CrossRef]

- Potdevin, A.; Lechevallier, S.; Chadeyron, G.; Caperaa, N.; Boyer, D.; Mahiou, R. Waveguiding terbium-doped yttrium aluminum garnet coatings based on the sol-gel process. Thin Solid Films 2009, 517, 4610–4614. [Google Scholar] [CrossRef]

- Demes, T.; Ternon, C.; Riassetto, D.; Roussel, H.; Rapenne, L.; Gélard, I.; Jimenez, C.; Stambouli, V.; Langlet, M. New insights in the structural and morphological properties of sol-gel deposited ZnO multilayer films. J. Phys. Chem. Solids 2016, 95, 43–55. [Google Scholar] [CrossRef]

- Demes, T.; Ternon, C.; Riassetto, D.; Stambouli, V.; Langlet, M. Comprehensive study of hydrothermally grown ZnO nanowires. J. Mater. Sci. 2016, 51, 10652–10661. [Google Scholar] [CrossRef]

- Kodama, K.; Uchino, T. Variations in Decay Rate of Green Photoluminescence in ZnO under Above- and Below-Band-Gap Excitation. J. Phys. Chem. B 2014, 118, 23977–23985. [Google Scholar] [CrossRef]

- Willander, M.; Nur, O.; Zaman, S.; Zainelabdin, A.; Bano, N.; Hussain, I. Zinc oxide nanorods/polymer hybrid heterojunctions for white light emitting diodes. J. Phys. D Appl. Phys. 2011, 44, 224017. [Google Scholar] [CrossRef] [Green Version]

- Ren, Y.; Yuan, Z.; Fan, J.; Huang, W.; Shuai, C. Annealing temperature-dependent morphology, structure, and optical properties of well-aligned ZnO nanowire arrays. Appl. Phys. A 2018, 124, 655. [Google Scholar] [CrossRef]

- Sun, Y.; Gu, X.; Zhao, Y.; Wang, L.; Qiang, Y. Temperature-dependent photoluminescence analysis of ZnO nanowire array annealed in air. Superlattices Microstruct. 2018, 117, 520–526. [Google Scholar] [CrossRef]

- Greene, L.E.; Law, M.; Tan, D.H.; Montano, M.; Goldberger, J.; Somorjai, G.; Yang, P. General Route to Vertical ZnO Nanowire Arrays Using Textured ZnO Seeds. Nano Lett. 2005, 5, 1231–1236. [Google Scholar] [CrossRef]

- Syrrokostas, G.; Govatsi, K.; Yannopoulos, S.N. High-Quality, Reproducible ZnO Nanowire Arrays Obtained by a Multiparameter Optimization of Chemical Bath Deposition Growth. Cryst. Growth Des. 2016, 16, 2140–2150. [Google Scholar] [CrossRef]

- Ding, J.N.; Liu, Y.B.; Tan, C.B.; Yuan, N.Y. Investigations into the impact of various substrates and ZnO ultra-thin seed layers prepared by atomic layer deposition on growth of ZnO nanowire array. Nanoscale Res. Lett. 2012, 7, 368. [Google Scholar] [CrossRef] [Green Version]

- Basinova, N.; Cernohorsky, O.; Grym, J.; Kucerova, S.; Faitova, H.; Yatskiv, R.; Vanis, J.; Vesely, J.; Maixner, J. Highly Textured Seed Layers for the Growth of Vertically Oriented ZnO Nanorods. Crystals 2019, 9, 566. [Google Scholar] [CrossRef] [Green Version]

- Demes, T.; Ternon, C.; Morisot, F.; Riassetto, D.; Legallais, M.; Roussel, H.; Langlet, M. Mechanisms involved in the hydrothermal growth of ultra-thin and high aspect ratio ZnO nanowires. Appl. Surf. Sci. 2017, 410, 423–431. [Google Scholar] [CrossRef]

- Blasse, G.; Grabmaier, B.C. Luminescent Materials; Springer: Berlin/Heidelberg, Germany, 1994; p. 232. [Google Scholar]

- Aspnes, D.E. Local-field effects and effective-medium theory: A microscopic perspective. Am. J. Phys. 1982, 50, 704–709. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amara, N.; Martin, A.; Potdevin, A.; Réveret, F.; Riassetto, D.; Chadeyron, G.; Langlet, M. Nanostructuration of YAG:Ce Coatings by ZnO Nanowires: A Smart Way to Enhance Light Extraction Efficiency. Nanomaterials 2022, 12, 2568. https://doi.org/10.3390/nano12152568

Amara N, Martin A, Potdevin A, Réveret F, Riassetto D, Chadeyron G, Langlet M. Nanostructuration of YAG:Ce Coatings by ZnO Nanowires: A Smart Way to Enhance Light Extraction Efficiency. Nanomaterials. 2022; 12(15):2568. https://doi.org/10.3390/nano12152568

Chicago/Turabian StyleAmara, Nehed, Aubry Martin, Audrey Potdevin, François Réveret, David Riassetto, Geneviève Chadeyron, and Michel Langlet. 2022. "Nanostructuration of YAG:Ce Coatings by ZnO Nanowires: A Smart Way to Enhance Light Extraction Efficiency" Nanomaterials 12, no. 15: 2568. https://doi.org/10.3390/nano12152568