Investigation of Heater Structures for Thermal Conductivity Measurements of SiO2 and Al2O3 Thin Films Using the 3-Omega Method

Abstract

:1. Introduction

- Even if all requirements are fulfilled, choosing different heater geometries within the boundaries still leads to differing results.

2. Materials and Methods

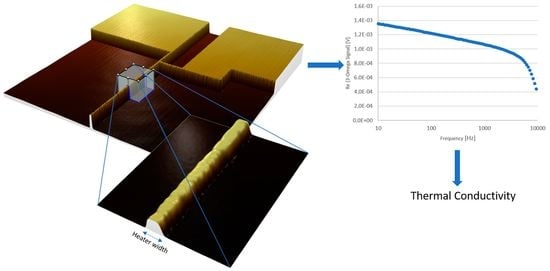

2.1. Three-Omega Method

2.2. Prerequisites for the 3-Omega Method

2.3. Investigations on Heater Dimensions Using Laser Scanning Microscopy

2.4. Materials

2.4.1. Silicon Dioxide

2.4.2. Aluminum Oxide

2.5. Sample Structure

3. Results and Discussion

3.1. Measurement of Temperature Coefficient of Resistance

3.2. Investigation of Possible Measurement Influences

- Bridge balancing frequency: The Wheatstone bridge was balanced before the measurement at one specific frequency, while the measurement itself took place at frequencies between 10 Hz and 10 kHz. Frequencies of interest were between 100 Hz and 1 kHz, as calculated from equations in Table 1. Therefore, the bridge balancing frequency was set within this range. Three measurements with different bridge balancing frequencies were taken.

- Contact position on the contact pads: The heater structures were connected to the measurement setup using contact needles. The contact positions were chosen in such a way that the distance to the heater itself was as large or as small as possible. A depiction thereof is shown in Figure 7.

- Contact force: It is possible to apply different contact forces to the needles. Unfortunately, there was no way to measure exact forces in this setup. Consequently, undefined small and high contact forces were specified through the penetration depth into the gold contact pad. This penetration depth was obtained using the LSM. The measurement results are illustrated in Figure 8. Contact force 1 corresponded to a penetration depth of 100 nm, and contact force 2 corresponded to a penetration depth of 380 nm.

- Measurement delay: This parameter defined how long the LIA stayed at one frequency to ensure a stable signal before executing the measurement. This was important because after approaching a new measurement frequency, the sample needs some time to adjust, as the thermal wave is dependent on the frequency and therefore changes after each frequency step. Two measurements were carried out; the delay time was set to 5 s for the first and to 20 s for the second measurement.

- Damaged pad structure: It should be obvious that damaged structures influence the measurement. However, already, minor damages, as shown in Figure 7 on the left side of the second contact point, did significantly influence the measurement and therefore could not be ignored.

- Native oxide layer: A native oxide layer forms on top of the substrate before any film can be deposited. To obtain the exact thickness of this layer, a pure substrate wafer was examined using a special ellipsometer, indicating a native oxide thickness of 1.03 nm. This finding was supported by Morita et al. [48]. Even if assuming a very low thermal conductivity of 0.15 Wm−1 K−1 for this oxide layer, the thermal resistance was 6.9 × 10−9 m2 KW−1, which was around two magnitudes lower than the total interface resistance of the samples (Ri = 2.6 × 10−7 m2 KW−1) and could therefore be neglected. It should be noted that the ellipsometer measurement result included airborne molecular contamination (AMC). AMC contributes typically to half of the measured thickness and is removed prior to thin film deposition by heating. Thus, the real native oxide thermal resistance was even lower. SiO2 and Al2O3 are both inert against oxidation in air or water, and therefore, no oxide could form on top of the deposited thin film.

- Influence of heater temperature on thin films: According to FEM simulations carried out in COMSOL Multiphysics® (version 6, 2021, Comsol Multiphysics GmbH, Göttingen, Germany) the maximum DC temperature rise was 1.69 K, and the temperature amplitude was 1.78 K. Thus, the heater temperature rise was much lower than the deposition temperatures of 400 °C and 350 °C for SiO2 and Al2O3, respectively. Therefore, no change in thin film properties was expected.

3.3. Silicon Dioxide

3.4. Aluminum Oxide

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nolas, G.S.; Goldsmid, H.J. Thermal Conductivity of semiconductors. In Thermal Conductivity; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef]

- Delan, A.; Rennau, M.; Schulz, S.; Gessner, T. Thermal conductivity of ultra low-k dielectrics. Microelectron. Eng. 2003, 70, 280–284. [Google Scholar] [CrossRef]

- Zhao, D.; Qian, X.; Gu, X.; Jajja, S.A.; Yang, R. Measurement Techniques for Thermal Conductivity and Interfacial Thermal Conductance of Bulk and Thin Film Materials. J. Electron. Packag. 2016, 138, 040802. [Google Scholar] [CrossRef] [Green Version]

- Chien, H.-C.; Yao, D.-J.; Huang, M.-J.; Chang, T.-Y. Thermal conductivity measurement and interface thermal resistance estimation using SiO2 thin film. Rev. Sci. Instrum. 2008, 79, 54902. [Google Scholar] [CrossRef]

- Maize, K.; Ezzahri, Y.; Singer, S.; Majumdar, A.; Shakouri, A. Measurement of Thin Film Isotropic and Anisotropic Thermal Conductivity Using 3 Omega and Thermoreflectance Imaging. In Proceedings of the 2008 Twenty-fourth Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 16–20 March 2008; IEEE Service Center: Piscataway, NJ, USA, 2008. ISBN 9781424421244. [Google Scholar]

- Mayer, P.M.; Lüerssen, D.; Ram, R.J.; Hudgings, J.A. Theoretical and experimental investigation of the thermal resolution and dynamic range of CCD-based thermoreflectance imaging. JOSA A 2007, 24, 1156–1163. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.; Qian, X.; Yang, R. Tutorial: Time-domain thermoreflectance (TDTR) for thermal property characterization of bulk and thin film materials. J. Appl. Phys. 2018, 124, 161103. [Google Scholar] [CrossRef] [Green Version]

- Koh, Y.K.; Singer, S.L.; Kim, W.; Zide, J.M.O.; Lu, H.; Cahill, D.G.; Majumdar, A.; Gossard, A.C. Comparison of the 3ω method and time-domain thermoreflectance for measurements of the cross-plane thermal conductivity of epitaxial semiconductors. J. Appl. Phys. 2009, 105, 54303. [Google Scholar] [CrossRef]

- Gembarovic, J.; Wang, H.; Apostolescu, S.; Paganelli, D.; Scotto, P. In-plane thermal diffusivity measurement of highly thermal conductive thin films by the flash method. In Proceedings of the 2018 34th Thermal Measurement, Modeling & Management Symposium (SEMI-THERM), San Jose, CA, USA, 19–23 March 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 197–199, ISBN 978-1-5386-4402-7. [Google Scholar]

- Baba, T.; Ono, A. Improvement of the laser flash method to reduce uncertainty in thermal diffusivity measurements. Meas. Sci. Technol. 2001, 12, 2046–2057. [Google Scholar] [CrossRef]

- Huang, S.; Ruan, X.; Zou, J.; Fu, X.; Yang, H. Thermal conductivity measurement of submicrometer-scale silicon dioxide films by an extended micro-Raman method. Microsyst. Technol. 2009, 15, 837–842. [Google Scholar] [CrossRef]

- Soini, M.; Zardo, I.; Uccelli, E.; Funk, S.; Koblmüller, G.; Fontcuberta i Morral, A.; Abstreiter, G. Thermal conductivity of GaAs nanowires studied by micro-Raman spectroscopy combined with laser heating. Appl. Phys. Lett. 2010, 97, 263107. [Google Scholar] [CrossRef]

- Metzke, C.; Kühnel, F.; Weber, J.; Benstetter, G. Scanning Thermal Microscopy of Ultrathin Films: Numerical Studies Regarding Cantilever Displacement, Thermal Contact Areas, Heat Fluxes, and Heat Distribution. Nanomaterials 2021, 11, 491. [Google Scholar] [CrossRef]

- Metzke, C.; Frammelsberger, W.; Weber, J.; Kühnel, F.; Zhu, K.; Lanza, M.; Benstetter, A.G. On the Limits of Scanning Thermal Microscopy of Ultrathin Films. Materials 2020, 13, 518. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Corbino, O. Thermal ocillations in lamps of thin fibres with alternating current flowing through them and the resulting effect on the rectifier as a result of the presence of even-numbered harmonics. Phys. Z. 1910, 413–417. [Google Scholar]

- Corbino, O. Periodic resistance changes of fine metal threads which are brought together by alternating streams as well as deduction of their thermo characteristics at high temperatures. Phys. Z. 1911, 292–295. [Google Scholar]

- Birge, N.O.; Nagel, S.R. Wide-frequency specific heat spectrometer. Rev. Sci. Instrum. 1987, 58, 1464–1470. [Google Scholar] [CrossRef]

- Cahill, D.G.; Fischer, H.E.; Klitsner, T.; Swartz, E.T.; Pohl, R.O. Thermal conductivity of thin films: Measurements and understanding. J. Vac. Sci. Technol. A Vac. Surf. Films 1989, 7, 1259–1266. [Google Scholar] [CrossRef]

- Lee, S.-M.; Cahill, D.G. Heat transport in thin dielectric films. J. Appl. Phys. 1997, 81, 2590–2595. [Google Scholar] [CrossRef]

- Kim, J.H.; Feldman, A.; Novotny, D. Application of the three omega thermal conductivity measurement method to a film on a substrate of finite thickness. J. Appl. Phys. 1999, 86, 3959–3963. [Google Scholar] [CrossRef]

- Jin, J.; Manoharan, M.P.; Wang, Q.; Haque, M.A. In-plane thermal conductivity of nanoscale polyaniline thin films. Appl. Phys. Lett. 2009, 95, 33113. [Google Scholar] [CrossRef]

- Hu, X.J.; Padilla, A.A.; Xu, J.; Fisher, T.S.; Goodson, K.E. 3-Omega Measurements of Vertically Oriented Carbon Nanotubes on Silicon. J. Heat Transf. 2006, 2006, 1109–1113. [Google Scholar] [CrossRef] [Green Version]

- Schiffres, S.N.; Malen, J.A. Improved 3-omega measurement of thermal conductivity in liquid, gases, and powders using a metal-coated optical fiber. Rev. Sci. Instrum. 2011, 82, 64903. [Google Scholar] [CrossRef] [Green Version]

- Jain, A.; Goodson, K.E. Measurement of the thermal conductivity and heat capacity of freestanding shape memory thin films using the 3 omega method. J. Heat Transf. 2008, 2008, 102402. [Google Scholar] [CrossRef] [Green Version]

- Yamane, T.; Nagai, N.; Katayama, S.; Todoki, M. Measurement of thermal conductivity of silicon dioxide thin films using a 3ω method. J. Appl. Phys. 2002, 91, 9772. [Google Scholar] [CrossRef]

- Shenoy, S.; Barrera, E.V.; Bayazitoglu, Y. Non-Fourier 3-Omega Method for Thermal Conductivity Measurement. Nanoscale Microscale Thermophys. Eng. 2010, 14, 123–136. [Google Scholar] [CrossRef]

- Borca-Tasciuc, T.; Kumar, A.R.; Chen, G. Data Reduction in 3 Omega Method for THin-Film Thermal Conductivity Determination. Rev. Sci. Instrum. 2001, 2001, 2139–2147. [Google Scholar] [CrossRef]

- Cahill, D.G. Thermal conductivity measurement from 30 to 750 K: The 3ω method. Rev. Sci. Instrum. 1990, 61, 802–808. [Google Scholar] [CrossRef]

- Ramu, A.T.; Bowers, J.E. Analysis of the “3-Omega” method for substrates and thick films of anisotropic thermal conductivity. J. Appl. Phys. 2012, 112, 43516. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Zhou, S.G.; Yao, D.-Y.; Kim, C.J.; Zheng, X.Y.; Liu, Z.L.; Wang, K.L. Heat Conduction in Alloy-Based Superlattices. In Proceedings of the 17th International Conference on Thermoelectrics, Nagoya, Japan, 28 May 1998; pp. 202–205. [Google Scholar]

- Katz, J.S.; Barako, M.T.; Park, W.; Sood, A.; Asheghi, M.; Goodson, K.E. Highly Anisotropic Thermal Conductivity in Spin-Cast Polystyrene Nano-Films. In Proceedings of the 2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 477–481, ISBN 978-1-5386-1272-9. [Google Scholar]

- Dames, C. Measuring the Thermal Conductivity of Thin Films: 3 Omega and Related Electrothermal Methods. Annu. Rev. Heat Transf. 2013, 16, 7–49. [Google Scholar] [CrossRef]

- Tanaka, S.; Takiishi, M.; Miyazaki, K.; Tsukamoto, H. Measurements of Thermal Conductivity of Thin Films by 3-omega Method. In Proceedings of the Micro/Nanoscale Heat Transfer International Conference, Tainan, Taiwan, 6–9 June 2008. [Google Scholar]

- Raudzis, C.E. Anwendung und Erweiterung der 3 Omega Methode zur Charakterisierung Komplexer Mehrschichtsysteme in der Mikrosystemtechnik. Ph.D. Thesis, Eberhard-Karls-Universität zu Tübingen, Tübingen, Germany, 2007. [Google Scholar]

- Raudzis, C.E.; Schatz, F.; Wharam, D. Extending the 3ω method for thin-film analysis to high frequencies. J. Appl. Phys. 2003, 93, 6050–6055. [Google Scholar] [CrossRef]

- Feldman, A. Algorithm for solutions of the thermal diffusion equation in a stratified medium with a modulated heating source. High Temp.-High Press. 1999, 31, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Ju, Y.S.; Goodson, K.E. process-dependent thermal transport properties of silicon-dioxide films deposited using low-pressure chemical vapor deposition. J. Appl. Phys. 1999, 1999, 7130–7134. [Google Scholar] [CrossRef] [Green Version]

- Jaber, W.; Chapuis, P.-O. Non-idealities in the 3 ω method for thermal characterization in the low- and high-frequency regimes. AIP Adv. 2018, 8, 45111. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Jiang, H.C.; Liu, C.; Dong, J.W.; Chow, P. Annealing of Al2O3 thin films prepared by atomic layer deposition. J. Phys. D Appl. Phys. 2007, 40, 3707–3713. [Google Scholar] [CrossRef]

- Huff, H.R.; Gilmer, D.C. High Dielectric Constant Materials: VLSI MOSFET Applications; Springer: Berlin/Heidelberg, Germany, 2005; ISBN 3540210814. [Google Scholar]

- Griffin, A.J.; Brotzen, F.R.; Loos, P.J. Effect of thickness on the transverse thermal conductivity of thin dielectric films. J. Appl. Phys. 1994, 75, 3761–3764. [Google Scholar] [CrossRef]

- Goodson, K.E.; Flik, M.I.; Su, L.T.; Antoniadis, D.A. Annealing-temperature dependence of the thermal conductivity of LPCVD silicon-dioxide layers. IEEE Electron Device Lett. 1993, 14, 490–492. [Google Scholar] [CrossRef]

- Govorkov, S.; Ruderman, W.; Horn, M.W.; Goodman, R.B.; Rothschild, M. A new method for measuring thermal conductivity of thin films. Rev. Sci. Instrum. 1997, 68, 3828–3834. [Google Scholar] [CrossRef]

- Cahill, D.G.; Allen, T.H. Thermal conductivity of sputtered and evaporated SiO2 and TiO2 optical coatings. Appl. Phys. Lett. 1994, 65, 309–311. [Google Scholar] [CrossRef]

- Aarik, J.; Kasikov, A.; Kirm, M.; Lange, S.; Uustare, T.; Mändar, H. Optical properties of crystalline Al2O3 thin films grown by atomic layer deposition. In Proceedings of the Society of Photo-Optical Instrumentation Engineers (SPIE): 4th International Conference on Advanced Optical Materials and Devices, Tartu, Estonia, 6–9 July 2004; pp. 1–10. [Google Scholar]

- Wang, Z.-Y.; Zhang, R.-J.; Lu, H.-L.; Chen, X.; Sun, Y.; Zhang, Y.; Wei, Y.-F.; Xu, J.-P.; Wang, S.-Y.; Zheng, Y.-X.; et al. The impact of thickness and thermal annealing on refractive index for aluminum oxide thin films deposited by atomic layer deposition. Nanoscale Res. Lett. 2015, 10, 46. [Google Scholar] [CrossRef] [Green Version]

- Jakschik, S.; Schroeder, U.; Hecht, T.; Gutsche, M.; Seidl, H.; Bartha, J.W. Crystallization behavior of thin ALD-Al2O3 films. Thin Solid Films 2002, 425, 216–220. [Google Scholar] [CrossRef]

- Morita, M.; Ohmi, T.; Hasegawa, E.; Kawakami, M.; Ohwada, M. Growth of native oxide on a silicon surface. J. Appl. Phys. 1990, 68, 1272–1281. [Google Scholar] [CrossRef]

- Foley, B.M.; Brown-Shaklee, H.J.; Duda, J.C.; Cheaito, R.; Gibbons, B.J.; Medlin, D.; Ihlefeld, J.F.; Hopkins, P.E. Thermal conductivity of nano-grained SrTiO3 thin films. Appl. Phys. Lett. 2012, 101, 231908. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.-J.; Park, Y.-H.; Hinoki, T. Influence of Grain Size on Thermal Conductivity of SiC Ceramics. IOP Conf. Ser. Mater. Sci. Eng. 2011, 18, 162014. [Google Scholar] [CrossRef]

- Liu, W.L.; Shamsa, M.; Calizo, I.; Balandin, A.A.; Ralchenko, V.; Popovich, A.; Saveliev, A. Thermal conduction in nanocrystalline diamond films: Effects of the grain boundary scattering and nitrogen doping. Appl. Phys. Lett. 2006, 89, 171915. [Google Scholar] [CrossRef] [Green Version]

- Mishra, V.; Garay, J.E.; Dames, C. Leveraging Anisotropy for Coupled Optimization of Thermal Transport and Light Transmission in Micro-Structured Materials for High-Power Laser Applications. Adv. Theory Simul. 2020, 3, 2000036. [Google Scholar] [CrossRef]

- Makris, A.; Haeger, T.; Heiderhoff, R.; Riedl, T. From diffusive to ballistic Stefan–Boltzmann heat transport in thin non-crystalline films. RSC Adv. 2016, 6, 94193–94199. [Google Scholar] [CrossRef] [Green Version]

| Desired Approximation | Equation |

|---|---|

| Film heat flow is quasistatic, indicating that the material does not store energy and heat spreads equally [32,37] | |

| Substrate is semi-infinite [27,32] | |

| Heater counts as a line source [27,32] | |

| Heater counts as infinitely long [32] | |

| Heater is considered massless to neglect the volumetric heat capacity of the heater [27,32,37] | |

| Convection and radiation losses are negligible [28,32] | |

| Substrate is isothermal [27,32] | |

| Heat flow through thin film is one dimensional [27,32] | |

| Heater thickness does not influence measurement [38] | |

| Influence of native oxide layer is neglectable [38,39] | |

| Influence of contact pads is neglectable [38] | |

| Heater counts as uniform heat source [32] |

| Film Thickness (nm) | Thermal Conductivity (Wm−1 K−1) | Reference |

|---|---|---|

| 100 | 0.05–0.08 | Griffin, 1994 [41] |

| 100 | 0.73–0.9 | Lee, 1997 [19] |

| 200 | 0.85–1.15 | Goodson, 1993 [42] |

| 500 | 0.2–0.3 | Griffin, 1994 [41] |

| 500 | 0.59–0.77 | Govorkov, 1997 [43] |

| 500 | 1.15–1.4 | Goodson, 1993 [42] |

| 1000 | 0.35–0.6 | Griffin, 1994 [41] |

| 1000 | 0.59–0.61 | Govorkov, 1997 [43] |

| 1000 | 0.1–1.3 | Cahill, 1994 [44] |

| 100 | 0.05–0.9 | - |

| 500 | 0.2–1.4 | - |

| 1000 | 0.35–1.3 | - |

| Bulk Material | Film Material | Deposition Method | Film Thickness (nm) | Annealing Temperature (°C) |

|---|---|---|---|---|

| Si | SiO2 | PECVD | 107 | — |

| Si | SiO2 | PECVD | 510 | — |

| Si | SiO2 | PECVD | 1018 | — |

| Si | Al2O3 | LP ALD | 115 | — |

| Si | Al2O3 | LP ALD | 102.7 | 1000 |

| Heater Length (mm) | Heater Width (µm) | Balancing Frequency (Hz) | Thermal Conductivity (Wm−1 K−1) |

|---|---|---|---|

| 11.086 | 3.10 | 100 | 0.84 |

| 11.086 | 3.10 | 500 | 0.83 |

| 11.086 | 3.10 | 1000 | 0.83 |

| Contact position | |||

| 13.096 | 3.47 | 1 | 0.72 |

| 13.096 | 3.47 | 2 | 0.72 |

| Contact force | |||

| 13.098 | 4.88 | 1 | 0.73 |

| 13.098 | 4.88 | 2 | 0.73 |

| Measurement delay | |||

| 11.092 | 6.38 | 5 s | 0.77 |

| 11.092 | 6.38 | 20 s | 0.77 |

| Pad condition | |||

| 13.096 | 3.47 | intact | 0.72 |

| 13.096 | 3.47 | damaged | 0.68 |

| Film Thickness (nm) | Thermal Conductivity (Wm−1 K−1) | Reference Values (Wm−1 K−1) |

|---|---|---|

| 107 | 0.28 | 0.05–0.9 [19,41] |

| 510 | 0.62 | 0.2–1.4 [41,42,43] |

| 1018 | 0.77 | 0.35–1.3 [41,43,44] |

| Annealing Temperature (°C) | Film Thickness (nm) | Thermal Conductivity (Wm−1 K−1) | Reference Value (Wm−1 K−1) |

|---|---|---|---|

| - | 115 | 0.81 | 0.8 [53] |

| 1000 | 102.7 | 0.93 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kühnel, F.; Metzke, C.; Weber, J.; Schätz, J.; Duesberg, G.S.; Benstetter, G. Investigation of Heater Structures for Thermal Conductivity Measurements of SiO2 and Al2O3 Thin Films Using the 3-Omega Method. Nanomaterials 2022, 12, 1928. https://doi.org/10.3390/nano12111928

Kühnel F, Metzke C, Weber J, Schätz J, Duesberg GS, Benstetter G. Investigation of Heater Structures for Thermal Conductivity Measurements of SiO2 and Al2O3 Thin Films Using the 3-Omega Method. Nanomaterials. 2022; 12(11):1928. https://doi.org/10.3390/nano12111928

Chicago/Turabian StyleKühnel, Fabian, Christoph Metzke, Jonas Weber, Josef Schätz, Georg S. Duesberg, and Günther Benstetter. 2022. "Investigation of Heater Structures for Thermal Conductivity Measurements of SiO2 and Al2O3 Thin Films Using the 3-Omega Method" Nanomaterials 12, no. 11: 1928. https://doi.org/10.3390/nano12111928