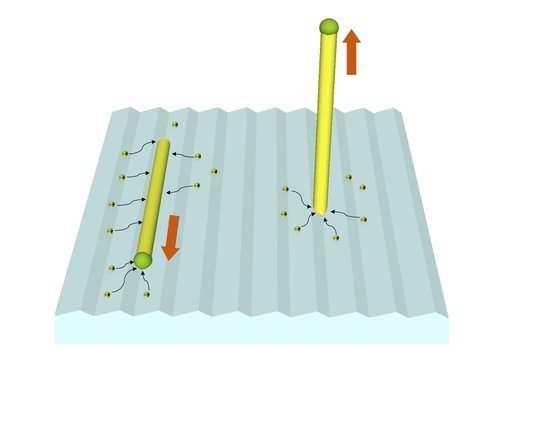

Kinetics of Guided Growth of Horizontal GaN Nanowires on Flat and Faceted Sapphire Surfaces

Abstract

:1. Introduction

2. Materials and Methods

2.1. NW Synthesis

2.2. NW Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brus, L.E. A simple model for the ionization potential, electron affinity, and aqueous redox potentials of small semiconductor crystallites. J. Chem. Phys. 1983, 79, 5566–5571. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, P.; Sun, Y.; Wu, Y.; Mayers, B.; Gates, B.; Yin, Y.; Kim, F.; Yan, H. One-Dimensional Nanostructures: Synthesis, Characterization, and Applications. Adv. Mater. 2003, 15, 353–389. [Google Scholar] [CrossRef]

- Samuelson, L. Self-forming nanoscale devices. Mater. Today 2003, 6, 22–31. [Google Scholar] [CrossRef]

- Duan, X.; Huang, Y.; Cui, Y.; Wang, J.; Lieber, C.M. Indium phosphide nanowires as building blocks for nanoscale electronic and optoelectronic devices. Nature 2001, 409, 66–69. [Google Scholar] [CrossRef]

- Huang, M.H.; Mao, S.; Feick, H.; Yan, H.; Wu, Y.; Kind, H.; Weber, E.; Russo, R.; Yang, P. Room-Temperature Ultraviolet Nanowire Nanolasers. Science 2001, 292, 1897–1899. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.R.; Lee, C.H.; Zheng, X. Direct Growth of Nanowire Logic Gates and Photovoltaic Devices. Nano Lett. 2010, 10, 1050–1054. [Google Scholar] [CrossRef]

- Schvartzman, M.; Tsivion, D.; Mahalu, D.; Raslin, O.; Joselevich, E. Self-integration of nanowires into circuits via guided growth. Proc. Natl. Acad. Sci. USA 2013, 110, 15195–15200. [Google Scholar] [CrossRef] [Green Version]

- Gazibegovic, S.; Car, D.; Zhang, H.; Balk, S.C.; Logan, J.A.; de Moor, M.W.A.; Cassidy, M.C.; Schmits, R.; Xu, D.; Wang, G.; et al. Epitaxy of advanced nanowire quantum devices. Nature 2017, 548, 434. [Google Scholar] [CrossRef] [Green Version]

- Gül, Ö.; Zhang, H.; Bommer, J.D.S.; de Moor, M.W.A.; Car, D.; Plissard, S.R.; Bakkers, E.P.A.M.; Geresdi, A.; Watanabe, K.; Taniguchi, T.; et al. Ballistic Majorana nanowire devices. Nat. Nanotechnol. 2018, 13, 192–197. [Google Scholar] [CrossRef]

- Wagner, R.S.; Ellis, W.C. Vapor-liquid-solid mechanism of single crystal growth. Appl. Phys. Lett. 1964, 4, 89–90. [Google Scholar] [CrossRef]

- Fan, Z.; Ho, J.C.; Jacobson, Z.A.; Yerushalmi, R.; Alley, R.L.; Razavi, H.; Javey, A. Wafer-Scale Assembly of Highly Ordered Semiconductor Nanowire Arrays by Contact Printing. Nano Lett. 2008, 8, 20–25. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Duan, X.; Wei, Q.; Lieber, C.M. Directed Assembly of One-Dimensional Nanostructures into Functional Networks. Science 2001, 291, 630–633. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smith, P.A.; Nordquist, C.D.; Jackson, T.N.; Mayer, T.S.; Martin, B.R.; Mbindyo, J.; Mallouk, T.E. Electric-field assisted assembly and alignment of metallic nanowires. Appl. Phys. Lett. 2000, 77, 1399–1401. [Google Scholar] [CrossRef] [Green Version]

- Jin, S.; Whang, D.; McAlpine, M.C.; Friedman, R.S.; Wu, Y.; Lieber, C.M. Scalable Interconnection and Integration of Nanowire Devices without Registration. Nano Lett. 2004, 4, 915–919. [Google Scholar] [CrossRef]

- Tsivion, D.; Schvartzman, M.; Popovitz-Biro, R.; von Huth, P.; Joselevich, E. Guided Growth of Millimeter-Long Horizontal Nanowires with Controlled Orientations. Science 2011, 333, 1003–1007. [Google Scholar] [CrossRef] [Green Version]

- Nikoobakht, B.; Michaels, C.A.; Stranick, S.J.; Vaudin, M.D. Horizontal growth and in situ assembly of oriented zinc oxide nanowires. Appl. Phys. Lett. 2004, 85, 3244–3246. [Google Scholar] [CrossRef]

- Fortuna, S.A.; Wen, J.; Chun, I.S.; Li, X. Planar GaAs Nanowires on GaAs (100) Substrates: Self-Aligned, Nearly Twin-Defect Free, and Transfer-Printable. Nano Lett. 2008, 8, 4421–4427. [Google Scholar] [CrossRef]

- Ben-Zvi, R.; Burrows, H.; Schvartzman, M.; Bitton, O.; Pinkas, I.; Kaplan-Ashiri, I.; Brontvein, O.; Joselevich, E. In-Plane Nanowires with Arbitrary Shapes on Amorphous Substrates by Artificial Epitaxy. ACS Nano 2019, 13, 5572–5582. [Google Scholar] [CrossRef]

- Morkoç, H. Handbook of Nitride Semiconductors and Devices, Materials Properties, Physics and Growth; John Wiley & Sons: Hoboken, NJ, USA, 2009; Volume 1. [Google Scholar]

- Guo, W.; Zhang, M.; Banerjee, A.; Bhattacharya, P. Catalyst-Free InGaN/GaN Nanowire Light Emitting Diodes Grown on (001) Silicon by Molecular Beam Epitaxy. Nano Lett. 2010, 10, 3355–3359. [Google Scholar] [CrossRef]

- Sarwar, A.T.M.G.; May, B.J.; Chisholm, M.F.; Duscher, G.J.; Myers, R.C. Ultrathin GaN quantum disk nanowire LEDs with sub-250 nm electroluminescence. Nanoscale 2016, 8, 8024–8032. [Google Scholar] [CrossRef]

- Gradečak, S.; Qian, F.; Li, Y.; Park, H.-G.; Lieber, C.M. GaN nanowire lasers with low lasing thresholds. Appl. Phys. Lett. 2005, 87, 173111. [Google Scholar] [CrossRef] [Green Version]

- Johnson, J.C.; Choi, H.-J.; Knutsen, K.P.; Schaller, R.D.; Yang, P.; Saykally, R.J. Single gallium nitride nanowire lasers. Nat. Mater. 2002, 1, 106–110. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Huang, Z.; Zhang, M.; Wu, M.; Mi, M.; Wang, C.; Yang, L.; Zhang, C.; Guo, L.; Ma, X.; et al. Temperature-Dependent Characteristics of AlGaN/GaN Nanowire Channel High Electron Mobility Transistors. Phys. Status Solidi A 2019, 216, 1900396. [Google Scholar] [CrossRef]

- He, Y.; Wang, C.; Mi, M.; Zhang, M.; Zhu, Q.; Zhang, P.; Wu, J.; Zhang, H.; Zheng, X.; Yang, L.J.A.P.E. Investigation of enhancement-mode AlGaN/GaN nanowire channel high-electron-mobility transistor with oxygen-containing plasma treatment. Appl. Phys. Express 2017, 10, 056502. [Google Scholar] [CrossRef]

- Tchernycheva, M.; Sartel, C.; Cirlin, G.; Travers, L.; Patriarche, G.; Largeau, L.; Mauguin, O.; Harmand, J.-C.; Dang, L.S.; Renard, J.; et al. GaN/AlN free-standing nanowires grown by molecular beam epitaxy. Phys. Status Solidi C 2008, 5, 1556–1558. [Google Scholar] [CrossRef]

- Qian, F.; Li, Y.; Gradečak, S.; Park, H.-G.; Dong, Y.; Ding, Y.; Wang, Z.L.; Lieber, C.M. Multi-quantum-well nanowire heterostructures for wavelength-controlled lasers. Nat. Mater. 2008, 7, 701–706. [Google Scholar] [CrossRef]

- Lim, S.K.; Brewster, M.; Qian, F.; Li, Y.; Lieber, C.M.; Gradečak, S. Direct Correlation between Structural and Optical Properties of III−V Nitride Nanowire Heterostructures with Nanoscale Resolution. Nano Lett. 2009, 9, 3940–3944. [Google Scholar] [CrossRef]

- Armitage, R.; Tsubaki, K. Multicolour luminescence from InGaN quantum wells grown over GaN nanowire arrays by molecular-beam epitaxy. Nanotechnology 2010, 21, 195202. [Google Scholar] [CrossRef]

- Tsivion, D.; Joselevich, E. Guided Growth of Epitaxially Coherent GaN Nanowires on SiC. Nano Lett. 2013, 13, 5491–5496. [Google Scholar] [CrossRef]

- Tsivion, D.; Joselevich, E. Guided Growth of Horizontal GaN Nanowires on Spinel with Orientation-Controlled Morphologies. J. Phys. Chem. C. 2014, 118, 19158–19164. [Google Scholar] [CrossRef]

- Maliakkal, C.B.; Hatui, N.; Bapat, R.D.; Chalke, B.A.; Rahman, A.A.; Bhattacharya, A. The Mechanism of Ni-Assisted GaN Nanowire Growth. Nano Lett. 2016, 16, 7632–7638. [Google Scholar] [CrossRef] [PubMed]

- Fröberg, L.E.; Seifert, W.; Johansson, J. Diameter-dependent growth rate of InAs nanowires. Phys. Rev. B 2007, 76, 153401. [Google Scholar] [CrossRef]

- Dubrovskii, V.G.; Sibirev, N.V.; Cirlin, G.E.; Soshnikov, I.P.; Chen, W.H.; Larde, R.; Cadel, E.; Pareige, P.; Xu, T.; Grandidier, B.; et al. Gibbs-Thomson and diffusion-induced contributions to the growth rate of Si, InP, and GaAs nanowires. Phys. Rev. B 2009, 79, 205316. [Google Scholar] [CrossRef]

- Lim, S.K.; Crawford, S.; Gradečak, S. Growth mechanism of GaN nanowires: Preferred nucleation site and effect of hydrogen. Nanotechnology 2010, 21, 345604. [Google Scholar] [CrossRef]

- Goren-Ruck, L.; Tsivion, D.; Schvartzman, M.; Popovitz-Biro, R.; Joselevich, E. Guided Growth of Horizontal GaN Nanowires on Quartz and Their Transfer to Other Substrates. ACS Nano 2014, 8, 2838–2847. [Google Scholar] [CrossRef]

- Oksenberg, E.; Martí-Sánchez, S.; Popovitz-Biro, R.; Arbiol, J.; Joselevich, E. Surface-Guided Core–Shell ZnSe@ZnTe Nanowires as Radial p–n Heterojunctions with Photovoltaic Behavior. ACS Nano 2017, 11, 6155–6166. [Google Scholar] [CrossRef] [Green Version]

- Oksenberg, E.; Popovitz-Biro, R.; Rechav, K.; Joselevich, E. Guided Growth of Horizontal ZnSe Nanowires and their Integration into High-Performance Blue–UV Photodetectors. Adv. Mater. 2015, 27, 3999–4005. [Google Scholar] [CrossRef]

- Reut, G.; Oksenberg, E.; Popovitz-Biro, R.; Rechav, K.; Joselevich, E. Guided Growth of Horizontal p-Type ZnTe Nanowires. J. Phys. Chem. C 2016, 120, 17087–17100. [Google Scholar] [CrossRef] [Green Version]

- Rothman, A.; Forsht, T.; Danieli, Y.; Popovitz-Biro, R.; Rechav, K.; Houben, L.; Joselevich, E. Guided Growth of Horizontal ZnS Nanowires on Flat and Faceted Sapphire Surfaces. J. Phys. Chem. C 2018, 122, 12413–12420. [Google Scholar] [CrossRef]

- Shalev, E.; Oksenberg, E.; Rechav, K.; Popovitz-Biro, R.; Joselevich, E. Guided CdSe Nanowires Parallelly Integrated into Fast Visible-Range Photodetectors. ACS Nano 2017, 11, 213–220. [Google Scholar] [CrossRef] [Green Version]

- Tsivion, D.; Schvartzman, M.; Popovitz-Biro, R.; Joselevich, E. Guided Growth of Horizontal ZnO Nanowires with Controlled Orientations on Flat and Faceted Sapphire Surfaces. ACS Nano 2012, 6, 6433–6445. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Oksenberg, E.; Popovitz-Biro, R.; Rechav, K.; Joselevich, E. Bottom-Up Tri-gate Transistors and Submicrosecond Photodetectors from Guided CdS Nanowalls. J. Am. Chem. Soc. 2017, 139, 15958–15967. [Google Scholar] [CrossRef]

- Xu, J.; Rechav, K.; Popovitz-Biro, R.; Nevo, I.; Feldman, Y.; Joselevich, E. High-Gain 200 ns Photodetectors from Self-Aligned CdS-CdSe Core-Shell Nanowalls. Adv. Mater. 2018, 30, e1800413. [Google Scholar] [CrossRef]

- Zi, Y.; Jung, K.; Zakharov, D.; Yang, C. Understanding Self-Aligned Planar Growth of InAs Nanowires. Nano Lett. 2013, 13, 2786–2791. [Google Scholar] [CrossRef]

- Shen, Y.; Chen, R.; Yu, X.; Wang, Q.; Jungjohann, K.L.; Dayeh, S.A.; Wu, T. Gibbs–Thomson Effect in Planar Nanowires: Orientation and Doping Modulated Growth. Nano Lett. 2016, 16, 4158–4165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rothman, A.; Dubrovskii, V.G.; Joselevich, E. Kinetics and mechanism of planar nanowire growth. Proc. Natl. Acad. Sci. USA 2020, 117, 152. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.-H.; Kim, D.-Y.; Hockey, B.J.; Wiederhorn, S.M.; Handwerker, C.A.; Blendell, J.E.; Carter, W.C.; Roosen, A.R. Equilibrium Shape of Internal Cavities in Sapphire. J. Am. Ceram. Soc. 1997, 80, 62–68. [Google Scholar] [CrossRef]

| NWs | Sapphire Substrate | Source Temp., °C | Fitting Parameters | |||||

|---|---|---|---|---|---|---|---|---|

| I, µm/min | θlv | θls | RGT, nm | λ, nm | m | |||

| GaN | AnnealedM-plane | 980 | 0.63 ± 0.12 | 1.00 ± 0.05 | 0.47 ± 0.03 | 6.02 ± 0.13 | 40.93 ± 2.71 | 2.03 ± 0.15 |

| GaN | R-plane | 1000 | 5.67 ± 0.78 | 1.00 ± 0.05 | 0.69 ± 0.02 | 5.34 ± 0.09 | 46.85 ± 0.55 | 1.93 ± 0.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rothman, A.; Maniš, J.; Dubrovskii, V.G.; Šikola, T.; Mach, J.; Joselevich, E. Kinetics of Guided Growth of Horizontal GaN Nanowires on Flat and Faceted Sapphire Surfaces. Nanomaterials 2021, 11, 624. https://doi.org/10.3390/nano11030624

Rothman A, Maniš J, Dubrovskii VG, Šikola T, Mach J, Joselevich E. Kinetics of Guided Growth of Horizontal GaN Nanowires on Flat and Faceted Sapphire Surfaces. Nanomaterials. 2021; 11(3):624. https://doi.org/10.3390/nano11030624

Chicago/Turabian StyleRothman, Amnon, Jaroslav Maniš, Vladimir G. Dubrovskii, Tomáš Šikola, Jindřich Mach, and Ernesto Joselevich. 2021. "Kinetics of Guided Growth of Horizontal GaN Nanowires on Flat and Faceted Sapphire Surfaces" Nanomaterials 11, no. 3: 624. https://doi.org/10.3390/nano11030624