Circularly Polarized Light Detection by Chiral Photonic Cellulose Nanocrystal with ZnO Photoconductive Layer in Ultraviolet Region

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Cellulose Nanocrystal Suspension

2.3. Preparation of the ZnO Layer

2.4. Device Fabrication

2.5. Characterization

2.6. Circularly Polarization State Detection Test

3. Results and Discussion

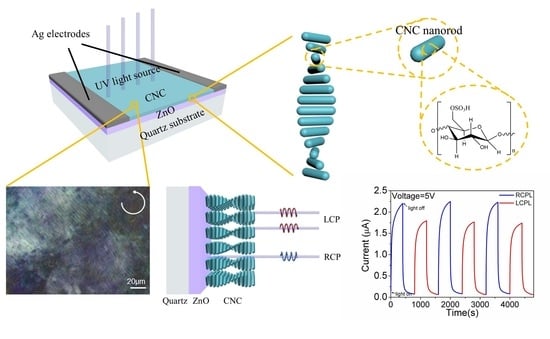

3.1. Fabrication and Structure of CNC/ZnO Photodetector

3.2. Morphological and Chiroptical Study

3.3. Ultraviolet Photoconductivity of ZnO Layer

3.4. CPL Detection of CNC/ZnO Photodetector

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Okano, K.; Taguchi, M.; Fujiki, M.; Yamashita, T. Circularly polarized luminescence of Rhodamine B in a supramolecular chiral medium formed by a vortex flow. Angew. Chem. Int. Ed. 2011, 50, 12474–12477. [Google Scholar] [CrossRef] [PubMed]

- Fujita, T.; Morimoto, K.; Kiyama, H.; Allison, G.; Larsson, M.; Ludwig, A.; Valentin, S.R.; Wieck, A.D.; Oiwa, A.; Tarucha, S. Angular momentum transfer from photon polarization to an electron spin in a gate-defined quantum dot. Nat. Commun. 2019, 10, 2991. [Google Scholar] [CrossRef]

- 3Sherson, J.F.; Krauter, H.; Olsson, R.K.; Julsgaard, B.; Hammerer, K.; Cirac, I.; Polzik, E.S. Quantum teleportation between light and matter. Nature 2006, 443, 557–560. [Google Scholar] [CrossRef]

- Togan, E.; Chu, Y.; Trifonov, A.S.; Jiang, L.; Maze, J.; Childress, L.; Dutt, M.V.; Sorensen, A.S.; Hemmer, P.R.; Zibrov, A.S.; et al. Quantum entanglement between an optical photon and a solid-state spin qubit. Nature 2010, 466, 730–734. [Google Scholar] [CrossRef] [Green Version]

- Shuvaev, S.; Suturina, E.A.; Mason, K.; Parker, D. Chiral probes for alpha1-AGP reporting by species-specific induced circularly polarised luminescence. Chem. Sci. 2018, 9, 2996–3003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kunnen, B.; Macdonald, C.; Doronin, A.; Jacques, S.; Eccles, M.; Meglinski, I. Application of circularly polarized light for non-invasive diagnosis of cancerous tissues and turbid tissue-like scattering media. J. Biophotonics 2015, 8, 317–323. [Google Scholar] [CrossRef]

- Yu, N.; Aieta, F.; Genevet, P.; Kats, M.A.; Gaburro, Z.; Capasso, F. A broadband, background-free quarter-wave plate based on plasmonic metasurfaces. Nano Lett. 2012, 12, 6328–6333. [Google Scholar] [CrossRef]

- Gansel Justyna, K.; Thiel, M.; Rill Michael, S.; Decker, M.; Bade, K.; Saile, V.; von Freymann, G.; Linden, S.; Wegener, M. Gold helix photonic metamaterial as broadband circular polarizer. Science 2009, 325, 1513–1515. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Gao, L.; Gao, W.; Ge, C.; Du, X.; Li, Z.; Yang, Y.; Niu, G.; Tang, J. Circularly polarized light detection using chiral hybrid perovskite. Nat. Commun. 2019, 10, 1927. [Google Scholar] [CrossRef]

- Schulz, M.; Balzer, F.; Scheunemann, D.; Arteaga, O.; Lützen, A.; Meskers, S.C.J.; Schiek, M. Chiral excitonic organic photodiodes for direct detection of circular polarized light. Adv. Funct. Mater. 2019, 29, 1900684. [Google Scholar] [CrossRef]

- Zhang, X.; Weng, W.; Li, L.; Wu, H.; Yao, Y.; Wang, Z.; Liu, X.; Lin, W.; Luo, J. Heterogeneous integration of chiral lead-chloride perovskite crystals with Si wafer for boosted circularly polarized light detection in solar-blind ultraviolet region. Small 2021, 17, e2102884. [Google Scholar] [CrossRef] [PubMed]

- Ishii, A.; Miyasaka, T. Direct detection of circular polarized light in helical 1D perovskite-based photodiode. Sci. Adv. 2020, 6, eabd3274. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Coppens, Z.J.; Besteiro, L.V.; Wang, W.; Govorov, A.O.; Valentine, J. Circularly polarized light detection with hot electrons in chiral plasmonic metamaterials. Nat. Commun. 2015, 6, 8379. [Google Scholar] [CrossRef]

- Yang, Y.; da Costa, R.C.; Smilgies, D.M.; Campbell, A.J.; Fuchter, M.J. Induction of circularly polarized electroluminescence from an achiral light-emitting polymer via a chiral small-molecule dopant. Adv. Mater. 2013, 25, 2624–2628. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.; Ota, F.; San Jose, B.A.; Akagi, K. Chiroptical resolution and thermal switching of chirality in conjugated polymer luminescence via selective reflection using a double-layered cell of chiral nematic liquid crystal. Adv. Funct. Mater. 2017, 27, 1604529. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Ahmad, I.; Abdullah, I.; Dufresne, A.; Zainudin, S.Y.; Sheltami, R.M. Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 2012, 19, 855–866. [Google Scholar] [CrossRef]

- Revol, J.-F.; Godbout, L.; Dong, X.-M.; Gray, D.G.; Chanzy, H.; Maret, G. Chiral nematic suspensions of cellulose crystallites; phase separation and magnetic field orientation. Liq. Cryst. 1994, 16, 127–134. [Google Scholar] [CrossRef]

- Marchessault, R.H.; Morehead, F.F.; Walter, N.M. Liquid crystal systems from fibrillar polysaccharides. Nature 1959, 184, 632–633. [Google Scholar] [CrossRef]

- Pan, J.; Hamad, W.; Straus, S.K. Parameters affecting the chiral nematic phase of nanocrystalline cellulose films. Macromolecules 2010, 43, 3851–3858. [Google Scholar] [CrossRef]

- De La Cruz, J.A.; Liu, Q.; Senyuk, B.; Frazier, A.W.; Peddireddy, K.; Smalyukh, I.I. Cellulose-based reflective liquid crystal films as optical filters and solar gain regulators. ACS Photonics 2018, 5, 2468–2477. [Google Scholar] [CrossRef]

- Tao, J.; Zou, C.; Jiang, H.; Li, M.; Lu, D.; Mann, S.; Xu, Y. Optically ambidextrous reflection and luminescence in self-organized left-handed chiral nematic cellulose nanocrystal films. CCS Chem. 2021, 3, 932–945. [Google Scholar] [CrossRef]

- Von Freymann, G.; Kitaev, V.; Lotsch, B.V.; Ozin, G.A. Bottom-up assembly of photonic crystals. Chem. Soc. Rev. 2013, 42, 2528–2554. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dumanli, A.G.; Kamita, G.; Landman, J.; van der Kooij, H.; Glover, B.J.; Baumberg, J.J.; Steiner, U.; Vignolini, S. Controlled, bio-inspired self-assembly of cellulose-based chiral reflectors. Adv. Opt. Mater. 2014, 2, 646–650. [Google Scholar] [CrossRef] [PubMed]

- Araki, J.; Kuga, S. Effect of trace electrolyte on liquid crystal type of cellulose microcrystals. Langmuir 2001, 17, 4493–4496. [Google Scholar] [CrossRef]

- Dong, X.M.; Kimura, T.; Revol, J.-F.; Gray, D.G. Effects of ionic strength on the isotropic–chiral nematic phase transition of suspensions of cellulose crystallites. Langmuir 1996, 12, 2076–2082. [Google Scholar] [CrossRef]

- Azizi Samir, M.A.S.; Alloin, F.; Dufresne, A. Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 2005, 6, 612–626. [Google Scholar] [CrossRef]

- Kamble, A.S.; Sinha, B.B.; Chung, K.; Gil, M.G.; Burungale, V.; Park, C.-J.; Kim, J.H.; Patil, P.S. Effect of hydroxide anion generating agents on growth and properties of ZnO nanorod arrays. Electrochim. Acta 2014, 149, 386–393. [Google Scholar] [CrossRef]

- Tarwal, N.L.; Shinde, V.V.; Kamble, A.S.; Jadhav, P.R.; Patil, D.S.; Patil, V.B.; Patil, P.S. Photoluminescence and photoelectrochemical properties of nanocrystalline ZnO thin films synthesized by spray pyrolysis technique. Appl. Surf. Sci. 2011, 257, 10789–10794. [Google Scholar] [CrossRef]

- Inamdar, S.I.; Ganbavle, V.V.; Rajpure, K.Y. ZnO based visible–blind UV photodetector by spray pyrolysis. Superlattices Microstruct. 2014, 76, 253–263. [Google Scholar] [CrossRef]

- Liu, Y.; Gorla, C.R.; Liang, S.; Emanetoglu, N.; Lu, Y.; Shen, H.; Wraback, M. Ultraviolet detectors based on epitaxial ZnO films grown by MOCVD. J. Electron. Mater. 2000, 29, 69–74. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, H.; Zhang, L.; Yuan, J.; Yan, S.; Wang, C. Low-temperature synthesis of ZnO nanoparticles by solid-state pyrolytic reaction. Nanotechnology 2002, 14, 11–15. [Google Scholar] [CrossRef]

- Shaikh, S.K.; Inamdar, S.I.; Ganbavle, V.V.; Rajpure, K.Y. Chemical bath deposited ZnO thin film based UV photoconductive detector. J. Alloys Compd. 2016, 664, 242–249. [Google Scholar] [CrossRef]

- Gao, J.; Liu, W.-J.; Ding, S.-J.; Lu, H.-L.; Zhang, D.W. High performance ultraviolet photodetectors with atomic-layer-deposited ZnO films via low-temperature post-annealing in air. AIP Adv. 2018, 8, 015015. [Google Scholar] [CrossRef]

- Portesi, C.; Lolli, L.; Taralli, E.; Rajteri, M.; Monticone, E. E-beam evaporated ZnO thin films: Fabrication and characterization as UV detector. Eur. Phys. J. Plus 2015, 130, 45. [Google Scholar] [CrossRef]

- Malek, M.F.; Mamat, M.H.; Musa, M.Z.; Khusaimi, Z.; Sahdan, M.Z.; Suriani, A.B.; Ishak, A.; Saurdi, I.; Rahman, S.A.; Rusop, M. Thermal annealing-induced formation of ZnO nanoparticles: Minimum strain and stress ameliorate preferred c-axis orientation and crystal-growth properties. J. Alloy. Compd. 2014, 610, 575–588. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Alsaad, A.M.; Albiss, B.A.; Al-Akhras, M.A.; El-Nasser, H.M.; Qattan, I.A. Optical and structural properties of sputter deposited ZnO thin films in relevance to post-annealing and substrate temperatures. Thin Solid Film 2016, 606, 133–142. [Google Scholar] [CrossRef]

- Bedia, A.; Bedia, F.Z.; Aillerie, M.; Maloufi, N.; Ould Saad Hamady, S.; Perroud, O.; Benyoucef, B. Optical, electrical and structural properties of nano-pyramidal ZnO films grown on glass substrate by spray pyrolysis technique. Opt. Mater. 2014, 36, 1123–1130. [Google Scholar] [CrossRef]

- Mu, X.; Gray, D.G. Formation of chiral nematic films from cellulose nanocrystal suspensions is a two-stage process. Langmuir 2014, 30, 9256–9260. [Google Scholar] [CrossRef]

- Mu, X.; Gray, D.G. Droplets of cellulose nanocrystal suspensions on drying give iridescent 3-D “coffee-stain” rings. Cellulose 2015, 22, 1103–1107. [Google Scholar] [CrossRef]

- Majoinen, J.; Kontturi, E.; Ikkala, O.; Gray, D.G. SEM imaging of chiral nematic films cast from cellulose nanocrystal suspensions. Cellulose 2012, 19, 1599–1605. [Google Scholar] [CrossRef]

- Beck, S.; Bouchard, J.; Berry, R. Controlling the reflection wavelength of iridescent solid films of nanocrystalline cellulose. Biomacromolecules 2011, 12, 167–172. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Vyas, S.; Periasamy, C.; Chakrabarti, P. Structural and optical characterization of ZnO thin films for optoelectronic device applications by RF sputtering technique. Superlattices Microstruct. 2014, 75, 378–389. [Google Scholar] [CrossRef]

- Raoufi, D. Synthesis and photoluminescence characterization of ZnO nanoparticles. J. Lumin. 2013, 134, 213–219. [Google Scholar] [CrossRef]

- Dumanli, A.G.; van der Kooij, H.M.; Kamita, G.; Reisner, E.; Baumberg, J.J.; Steiner, U.; Vignolini, S. Digital color in cellulose nanocrystal films. ACS Appl. Mater. Interfaces 2014, 6, 12302–12306. [Google Scholar] [CrossRef]

- Gu, P.; Zhu, X.; Yang, D. Effect of annealing temperature on the performance of photoconductive ultraviolet detectors based on ZnO thin films. Appl. Phys. A 2019, 125, 50. [Google Scholar] [CrossRef]

- Shopsowitz, K.E.; Hamad, W.Y.; MacLachlan, M.J. Chiral nematic mesoporous carbon derived from nanocrystalline cellulose. Angew. Chem. Int. Ed. Engl. 2011, 50, 10991–10995. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Zhao, S.; Yu, Y.; Li, M.; Zhao, L.; Gao, L. Circularly Polarized Light Detection by Chiral Photonic Cellulose Nanocrystal with ZnO Photoconductive Layer in Ultraviolet Region. Nanomaterials 2021, 11, 3098. https://doi.org/10.3390/nano11113098

Zhang B, Zhao S, Yu Y, Li M, Zhao L, Gao L. Circularly Polarized Light Detection by Chiral Photonic Cellulose Nanocrystal with ZnO Photoconductive Layer in Ultraviolet Region. Nanomaterials. 2021; 11(11):3098. https://doi.org/10.3390/nano11113098

Chicago/Turabian StyleZhang, Boyu, Sixiang Zhao, Yingying Yu, Ming Li, Liancheng Zhao, and Liming Gao. 2021. "Circularly Polarized Light Detection by Chiral Photonic Cellulose Nanocrystal with ZnO Photoconductive Layer in Ultraviolet Region" Nanomaterials 11, no. 11: 3098. https://doi.org/10.3390/nano11113098