Magneto-Transport Properties of Co–Cu Thin Films Obtained by Co-Sputtering and Sputter Gas Aggregation

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

3.1. X-ray Diffraction

3.2. Magnetic Properties

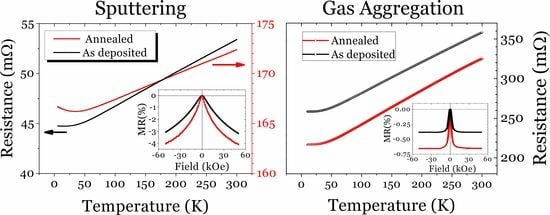

3.3. Magnetotransport Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baibich, M.N.; Broto, J.M.; Fert, A.; Van Dau, F.N.; Petroff, F.; Eitenne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant magnetoresistance of (001)Fe/(001)Cr magnetic superlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef] [Green Version]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828–4830. [Google Scholar] [CrossRef] [Green Version]

- Berkowitz, A.E.; Mitchell, J.R.; Carey, M.J.; Young, A.P.; Zhang, S.; Spada, F.E.; Parker, F.T.; Hutten, A.; Thomas, G. Giant Magnetoresistance in heterogeneous Cu-Co Alloys. Phys. Rev. Lett. 1992, 68, 3745–3748. [Google Scholar] [CrossRef]

- Xiao, J.Q.; Jiang, J.S.; Chien, C.L. Giant magnetoresistance in nonmultilayer magnetic systems. Phys. Rev. Lett. 1992, 68, 3749–3752. [Google Scholar] [CrossRef]

- Allia, P.; Knobel, M.; Tiberto, P.; Vinai, F. Magnetic properties and giant magnetoresistance of melt-spun granular Cu100 -Co alloys. Phys. Rev. B 1995, 52, 15398–15411. [Google Scholar] [CrossRef] [Green Version]

- Peng, D.; Wang, J.; Wang, L.; Liu, X.; Wang, Z.; Chen, Y. Electron transport properties of magnetic granular films. Sci. China Physics, Mech. Astron. 2013, 56, 15–28. [Google Scholar] [CrossRef]

- Lopez Anton, R.; Fdez-gubieda, M.; Garcia-arribas, A.; Herreros, J.; Insausti, M. Preparation and characterisation of Cu–Co heterogeneous alloys by potentiostatic electrodeposition. Mater. Sci. Eng. A 2002, 335, 94–100. [Google Scholar] [CrossRef]

- Lopezanton, R.; Fernandezgubiedaruiz, M. The effect of the deposition parameters on the magnetic and magnetotransport properties of laser ablated Cu–Co thin films. Sens. Actuators A Phys. 2003, 106, 203–207. [Google Scholar] [CrossRef]

- Wurster, S.; Weissitsch, L.; Stückler, M.; Knoll, P.; Krenn, H.; Pippan, R.; Bachmaier, A. Tuneable magneto-resistance by severe plastic deformation. Metals (Basel) 2019, 9, 1188. [Google Scholar] [CrossRef] [Green Version]

- Berkowitz, A.E.; Mitchell, J.R.; Carey, M.J.; Young, A.P.; Rao, D.; Starr, A.; Zhang, S.; Spada, F.E.; Parker, F.T.; Hutten, A.; et al. Giant magnetoresistance in heterogeneous Cu-Co and Ag-Co alloy films (invited). J. Appl. Phys. 1993, 73, 5320–5325. [Google Scholar] [CrossRef]

- Dupuis, V.; Tuaillon, J.; Prevel, B.; Perez, A.; Melinon, P.; Guiraud, G.; Parent, F.; Steren, L.B.; Morel, R.; Barthelemy, A.; et al. From the superparamagnetic to the magnetically ordered state in systems of transition metal clusters embedded in matrices. J. Magn. Magn. Mater. 1997, 165, 42–45. [Google Scholar] [CrossRef]

- Rubin, S.; Micklitz, H. Giant magnetoresistance in granular Co/Ag films prepared by the deposition of well-defined Co clusters. Mater. Sci. Forum 1997, 235–238, 711–716. [Google Scholar] [CrossRef]

- Rubin, S.; Holdenried, M.; Micklitz, H. Well-defined Co clusters embedded in an Ag matrix: A model system for the giant magnetoresistance in granular films. Eur. Phys. J. B 1998, 5, 23–28. [Google Scholar] [CrossRef]

- De Toro, J.A.; Gonzalez, J.A.; Normile, P.S.; Muñiz, P.; Andrés, J.P.; López Antón, R.; Canales-Vázquez, J.; Riveiro, J.M. Energy barrier enhancement by weak magnetic interactions in Co/Nb granular films assembled by inert gas condensation. Phys. Rev. B 2012, 85, 1–7. [Google Scholar] [CrossRef]

- Miranda, M.; Estévez-Rams, E.; Martínez, G.; Baibich, N. Phase separation in Cu90Co10 high-magnetoresistance materials. Phys. Rev. B—Condens. Matter Mater. Phys. 2003, 68, 1–8. [Google Scholar] [CrossRef]

- Ilyn, M.; Zhukova, V.; Garcia, C.; Del Val, J.J.; Ipatov, M.; Granovsky, A.; Zhukov, A. Kondo effect and magnetotransport properties in Co-Cu microwires. IEEE Trans. Magn. 2012, 48, 3532–3535. [Google Scholar] [CrossRef]

- Zhukova, V.; Mino, J.; Del Val, J.J.; Ipatov, M.; Martinez-Amesti, A.; Varga, R.; Churyukanova, M.; Zhukov, A. Magnetoresistance and Kondo-like behaviour in Co5Cu95 microwires. J. Alloys Compd. 2016, 674, 266–271. [Google Scholar] [CrossRef]

- Zhukov, A.; Mino, J.; del Val, J.J.; Varga, R.; Martinez, G.; Baibich, M.N.; Ipatov, M.; Churyukanova, M.; Zhukova, V. GMR effect and Kondo-like behaviour in Co-Cu microwires. J. Alloys Compd. 2017, 695, 976–980. [Google Scholar] [CrossRef]

- Zhukova, V.; Mino, J.; Del Val, J.J.; Ipatov, M.; Varga, R.; Baibich, M.N.; Martinez, G.; Granovsky, A.; Zhukov, A. GMR and Kondo Effects in Cu-Co Microwires. J. Supercond. Nov. Magn. 2017, 30, 1109–1114. [Google Scholar] [CrossRef]

- Zhukova, V.; Mino, J.; Del Val, J.J.; Varga, R.; Martinez, G.; Baibich, M.; Ipatov, M.; Zhukov, A. Kondo-like behavior and GMR effect in granular Cu90Co10 microwires. AIP Adv. 2017, 7. [Google Scholar] [CrossRef] [Green Version]

- Kondo, J. Resistance Minimum in Dilute Magnetic Alloys. Prog. Theor. Phys. 1964, 32, 37–49. [Google Scholar] [CrossRef] [Green Version]

- Lobov, I.D.; Kirillova, M.M.; Makhnev, A.A.; Romashev, L.N.; Korolev, A.V.; Milyaev, M.A.; Proglyado, V.V.; Bannikova, N.S.; Ustinov, V.V. Magnetooptical, optical, and magnetotransport properties of Co/Cu superlattices with ultrathin cobalt layers. Phys. Solid State 2017, 59, 53–62. [Google Scholar] [CrossRef]

- Ustinov, V.V.; Romashev, L.N.; Milayev, M.A.; Korolev, A.V.; Krinitsina, T.P.; Burkhanov, A.M. Kondo-like effect in the resistivity of superparamagnetic cluster-layered Fe/Cr nanostructures. J. Magn. Magn. Mater. 2006, 300, 148–152. [Google Scholar] [CrossRef]

- Schrieffer, J.R.; Wolff, P.A. Relation between the Anderson and Kondo Hamiltonians. Phys. Rev. 1966, 149, 491–492. [Google Scholar] [CrossRef]

- Hewson, A.C. The Kondo Problem to Heavy Fermions; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- González, J.A.; Andrés, J.P.; López Antón, R.; De Toro, J.A.; Normile, P.S.; Muniz, P.; Riveiro, J.M.; Nogués, J. Maximizing Exchange Bias in Co/CoO Core/Shell Nanoparticles by Lattice Matching between the Shell and the Embedding Matrix. Chem. Mater. 2017, 29, 5200–5206. [Google Scholar] [CrossRef] [Green Version]

- Maeda, A.; Kume, M.; Oikawa, S.; Shimizu, Y.; Doi, M. Annealing effects on the magnetoresistance characteristics of grain-type alloy thin films. J. Phys. Condens. Matter 1993, 5, 4641–4646. [Google Scholar] [CrossRef]

- López Antón, R.; Fdez-Gubieda, M.L.; Insausti, M.; García-Arribas, A.; Herreros, J. Influence of the preparation method on the properties of Cu–Co heterogeneous alloys. J. Non. Cryst. Solids 2001, 287, 26–30. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 386–387. ISBN 978-0-471-47741-9. [Google Scholar]

- Antón, R.L.; González, J.A.; Andrés, J.P.; Svalov, A.V.; Kurlyandskaya, G.V. Structural and Magnetic Properties of Ni 0. 8 Fe 0. 2/Ti Nanoscale Multilayers. Nanomaterials 2018, 8, 780. [Google Scholar] [CrossRef] [Green Version]

- Stearns, M.B.; Cheng, Y. Determination of para- and ferromagnetic components of magnetization and magnetoresistance of granular Co/Ag films (invited). J. Appl. Phys. 1994, 75, 6894–6899. [Google Scholar] [CrossRef]

- García Prieto, A.; Fdez-Gubieda, M.L.; Meneghini, C.; García-Arribas, A.; Mobilio, S. Microstructural and magnetic evolution upon annealing of giant magnetoresistance melt-spun Co-Cu granular alloys. Phys. Rev. B—Condens. Matter Mater. Phys. 2003, 67, 1–11. [Google Scholar] [CrossRef]

- Ennen, I.; Kappe, D.; Rempel, T.; Glenske, C.; Hütten, A. Giant Magnetoresistance: Basic concepts, microstructure, magnetic interactions and applications. Sensors (Switzerland) 2016, 16, 904. [Google Scholar] [CrossRef]

- Cichorek, T.; Bochenek, L.; Schmidt, M.; Czulucki, A.; Auffermann, G.; Kniep, R.; Niewa, R.; Steglich, F.; Kirchner, S. Two-Channel Kondo Physics due to As Vacancies in the Layered Compound ZrAs1.58Se0.39. Phys. Rev. Lett. 2016, 117, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Sato, H.; Kobayashi, Y.; Aoki, Y.; Yamamoto, H. Transport properties in granular Co-Ag alloys. J. Phys. Condens. Matter 1995, 7, 7053–7062. [Google Scholar] [CrossRef]

- Granovsky, A.B.; Ilyn, M.; Zhukov, A.; Zhukova, V.; Gonzalez, J. Giant magnetoresistance of granular microwires: Spin-dependent scattering in integranular spacers. Phys. Solid State 2011, 53, 320–322. [Google Scholar] [CrossRef]

- Ananya, P.; Maity, K.P.; Kamble, R.B.; Prasad, V. Tuning spin one channel to exotic orbital two-channel Kondo effect in ferrimagnetic composites of LaNiO3 and COFe2O4. J. Phys. Condens. Matter 2018, 30, 375701. [Google Scholar] [CrossRef]

- Grüner, G.; Zawadowski, A. Magnetic impurities in metals. Rep. Prog. Phys. 1974, 37, 1497–1583. [Google Scholar] [CrossRef]

- Gerber, A.; Milner, A.; Korenblit, I.Y.; Karpovsky, M.; Gladkikh, A.; Sulpice, A. Temperature dependence of resistance and magnetoresistance of nanogranular Co-Ag films. Phys. Rev. B—Condens. Matter Mater. Phys. 1998, 57, 13667–13673. [Google Scholar] [CrossRef]

- Saito, Y.; Inomata, K.; Uji, S.; Terashima, T.; Aoki, H. Temperature dependence of Giant Magnetoresistance in Co/Cu superlattices. J. Phys. Soc. Japan 1994, 63, 1263–1267. [Google Scholar] [CrossRef]

| Sample | µ (µB) | D (nm) | % SPM | % FM |

|---|---|---|---|---|

| Co3 sp a-d | 30 | 0.7 | 28.2 | 0.9 |

| Co 3 sp ann | 680 | 2.0 | 27.7 | 14.6 |

| Co9 sp a-d | 120 | 0.9 | 19.3 | 0.7 |

| Co9 sp ann | 1700 | 2.2 | 18.8 | 40.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López Antón, R.; Andrés, J.P.; Ipatov, M.; González, J.A.; González, J.; Zhukova, V.; Zhukov, A. Magneto-Transport Properties of Co–Cu Thin Films Obtained by Co-Sputtering and Sputter Gas Aggregation. Nanomaterials 2021, 11, 134. https://doi.org/10.3390/nano11010134

López Antón R, Andrés JP, Ipatov M, González JA, González J, Zhukova V, Zhukov A. Magneto-Transport Properties of Co–Cu Thin Films Obtained by Co-Sputtering and Sputter Gas Aggregation. Nanomaterials. 2021; 11(1):134. https://doi.org/10.3390/nano11010134

Chicago/Turabian StyleLópez Antón, Ricardo, Juan Pedro Andrés, Mihail Ipatov, Juan Antonio González, Julián González, Valentina Zhukova, and Arcady Zhukov. 2021. "Magneto-Transport Properties of Co–Cu Thin Films Obtained by Co-Sputtering and Sputter Gas Aggregation" Nanomaterials 11, no. 1: 134. https://doi.org/10.3390/nano11010134