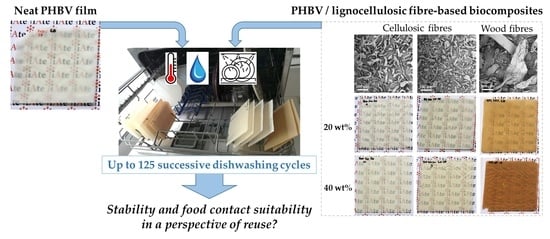

Physical-Chemical and Structural Stability of Poly(3HB-co-3HV)/(ligno-)cellulosic Fibre-Based Biocomposites over Successive Dishwashing Cycles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of PHBV-Based Films

2.3. Dishwashing Procedure

2.4. Laser Granulometry

2.5. Colorimetry

2.6. Differential Scanning Calorimetry (DSC)

2.7. Tensile Properties

2.8. Overall Migration

3. Results and Discussion

3.1. Stability of PHBV

3.1.1. Visual Aspect and Colour

3.1.2. Tensile Properties

3.1.3. Overall Migration in Liquid Food Simulants

3.2. Stability of PHBV/(Ligno-)Cellulosic Fibre-Based Biocomposites

3.2.1. Description of (Ligno-)Cellulosic Fibres

3.2.2. Visual Aspect and Colour

3.2.3. Microstructure of PHBV-Based Biocomposites

3.2.4. Weight Uptake and Swelling of PHBV-Based Biocomposites

3.2.5. Tensile Properties

3.2.6. Overall Migration

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dey, A.; Dhumal, C.V.; Sengupta, P.; Kumar, A.; Pramanik, N.K.; Alam, T. Challenges and Possible Solutions to Mitigate the Problems of Single-Use Plastics Used for Packaging Food Items: A Review. J. Food Sci. Technol. 2020, 58, 3251–3269. [Google Scholar] [CrossRef] [PubMed]

- Mulder, K.F. Sustainable Consumption and Production of Plastics? Technol. Forecast. Soc. Chang. 1998, 58, 105–124. [Google Scholar] [CrossRef]

- Ertz, M.; Huang, R.; Jo, M.-S.; Karakas, F.; Sarigöllü, E. From Single-Use to Multi-Use: Study of Consumers’ Behavior toward Consumption of Reusable Containers. J. Environ. Manag. 2017, 193, 334–344. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M. Accumulation and Fragmentation of Plastic Debris in Global Environments. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1985–1998. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Galgani, F.; Jaunet, S.; Campillo, A.; Guenegen, X.; His, E. Distribution and Abundance of Debris on the Continental Shelf of the North-Western Mediterranean Sea. Mar. Pollut. Bull. 1995, 30, 713–717. [Google Scholar] [CrossRef]

- Avery-Gomm, S.; O’Hara, P.D.; Kleine, L.; Bowes, V.; Wilson, L.K.; Barry, K.L. Northern Fulmars as Biological Monitors of Trends of Plastic Pollution in the Eastern North Pacific. Mar. Pollut. Bull. 2012, 64, 1776–1781. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [Green Version]

- Accorsi, R.; Baruffaldi, G.; Manzini, R. A Closed-Loop Packaging Network Design Model to Foster Infinitely Reusable and Recyclable Containers in Food Industry. Sustain. Prod. Consum. 2020, 24, 48–61. [Google Scholar] [CrossRef]

- Coelho, P.M.; Corona, B.; ten Klooster, R.; Worrell, E. Sustainability of Reusable Packaging–Current Situation and Trends. Resour. Conserv. Recycl. X 2020, 6, 100037. [Google Scholar] [CrossRef]

- Ministère de la Transition Écologique Décret N°2021-517 2021; Official Journal of the French Republic: Paris, France, 2021.

- Keskin, G.; Kızıl, G.; Bechelany, M.; Pochat-Bohatier, C.; Öner, M. Potential of Polyhydroxyalkanoate (PHA) Polymers Family as Substitutes of Petroleum Based Polymers for Packaging Applications and Solutions Brought by Their Composites to Form Barrier Materials. Pure Appl. Chem. 2017, 89, 1841–1848. [Google Scholar] [CrossRef]

- Koller, M. Poly(Hydroxyalkanoates) for Food Packaging: Application and Attempts towards Implementation. Appl. Food Biotechnol. 2014, 1, 3–15. [Google Scholar] [CrossRef]

- Koller, M.; Braunegg, G. Biomediated Production of Structurally Diverse Poly(Hydroxyalkanoates) from Surplus Streams of the Animal Processing Industry. Polimery 2015, 60, 298–308. [Google Scholar] [CrossRef] [Green Version]

- Barham, P.J. Physical Properties of Poly(Hydroxybutyrate) and Poly(Hydroxybutyrate-Co-Hydroxyvalerate). In Novel Biodegradable Microbial Polymers; Dawes, E.A., Ed.; NATO ASI Series; Springer: Dordrecht, The Netherland, 1990; pp. 81–96. ISBN 978-94-009-2129-0. [Google Scholar]

- David, G.; Michel, J.; Gastaldi, E.; Gontard, N.; Angellier-Coussy, H. How Vine Shoots as Fillers Impact the Biodegradation of PHBV-Based Composites. Int. J. Mol. Sci. 2020, 21, 228. [Google Scholar] [CrossRef] [Green Version]

- Deroiné, M.; Le Duigou, A.; Corre, Y.-M.; Le Gac, P.-Y.; Davies, P.; César, G.; Bruzaud, S. Accelerated Ageing and Lifetime Prediction of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) in Distilled Water. Polym. Test. 2014, 39, 70–78. [Google Scholar] [CrossRef] [Green Version]

- Deroiné, M.; Le Duigou, A.; Corre, Y.-M.; Le Gac, P.-Y.; Davies, P.; César, G.; Bruzaud, S. Seawater Accelerated Ageing of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate). Polym. Degrad. Stab. 2014, 105, 237–247. [Google Scholar] [CrossRef] [Green Version]

- Deroiné, M.; César, G.; Le Duigou, A.; Davies, P.; Bruzaud, S. Natural Degradation and Biodegradation of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) in Liquid and Solid Marine Environments. J. Polym. Environ. 2015, 23, 493–505. [Google Scholar] [CrossRef] [Green Version]

- Chan, C.M.; Vandi, L.-J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Mechanical Performance and Long-Term Indoor Stability of Polyhydroxyalkanoate (PHA)-Based Wood Plastic Composites (WPCs) Modified by Non-Reactive Additives. Eur. Polym. J. 2018, 98, 337–346. [Google Scholar] [CrossRef] [Green Version]

- Chea, V.; Angellier-Coussy, H.; Peyron, S.; Kemmer, D.; Gontard, N. Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Films for Food Packaging: Physical-Chemical and Structural Stability under Food Contact Conditions. J. Appl. Polym. Sci. 2016, 133, 41850. [Google Scholar] [CrossRef]

- Zembouai, I.; Bruzaud, S.; Kaci, M.; Benhamida, A.; Corre, Y.-M.; Grohens, Y. Mechanical Recycling of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)/Polylactide Based Blends. J. Polym. Environ. 2014, 22, 449–459. [Google Scholar] [CrossRef] [Green Version]

- Zaverl, M.; Seydibeyoğlu, M.Ö.; Misra, M.; Mohanty, A. Studies on Recyclability of Polyhydroxybutyrate-Co-Valerate Bioplastic: Multiple Melt Processing and Performance Evaluations. J. Appl. Polym. Sci. 2012, 125, E324–E331. [Google Scholar] [CrossRef]

- Soroudi, A.; Jakubowicz, I. Recycling of Bioplastics, Their Blends and Biocomposites: A Review. Eur. Polym. J. 2013, 49, 2839–2858. [Google Scholar] [CrossRef]

- Battegazzore, D.; Frache, A.; Abt, T.; Maspoch, M.L. Epoxy Coupling Agent for PLA and PHB Copolymer-Based Cotton Fabric Bio-Composites. Compos. Part B Eng. 2018, 148, 188–197. [Google Scholar] [CrossRef]

- European Commission Règlement (UE). n°10/2011 de la Commission du 14 janvier 2011 concernant les matériaux et objets en matière plastique destinés à entrer en contact avec des denrées alimentaires. Off. J. Eur. Union 2011, 10, 89. [Google Scholar]

- Haque, A.N.M.A.; Zhang, Y.; Naebe, M. A Review on Lignocellulose/Poly (Vinyl Alcohol) Composites: Cleaner Approaches for Greener Materials. Cellulose 2021, 28, 10741–10764. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from Renewable and Sustainable Resources: Challenges and Innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, Y.; Yang, B.; Liu, J.; Sun, B.; Cao, C.; Zou, X.; Lutes, R.; He, Z. Prospects for Replacement of Some Plastics in Packaging with Lignocellulose Materials: A Brief Review. BioResources 2018, 13, 4550–4576. [Google Scholar] [CrossRef] [Green Version]

- Angellier-Coussy, H.; Kemmer, D.; Gontard, N.; Peyron, S. Physical–Chemical and Structural Stability of PHBV/Wheat Straw Fibers Based Biocomposites under Food Contact Conditions. J. Appl. Polym. Sci. 2020, 137, 49231. [Google Scholar] [CrossRef]

- David, G.; Croxatto Vega, G.; Sohn, J.; Nilsson, A.E.; Hélias, A.; Gontard, N.; Angellier-Coussy, H. Using Life Cycle Assessment to Quantify the Environmental Benefit of Upcycling Vine Shoots as Fillers in Biocomposite Packaging Materials. Int. J. Life Cycle Assess. 2021, 26, 738–752. [Google Scholar] [CrossRef]

- Sanchez-Safont, E.L.; Cabedo, L.; Gamez-Perez, J. Cellulose-Reinforced Biocomposites Based on PHB and PHBV for Food Packaging Applications. In Sustainable Food Packaging Technology; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2021; pp. 225–261. ISBN 978-3-527-82007-8. [Google Scholar]

- Lammi, S.; Gastaldi, E.; Gaubiac, F.; Angellier-Coussy, H. How Olive Pomace Can Be Valorized as Fillers to Tune the Biodegradation of PHBV Based Composites. Polym. Degrad. Stab. 2019, 166, 325–333. [Google Scholar] [CrossRef]

- Chan, C.M.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B.; Vandi, L.-J. Mechanical and Physical Stability of Polyhydroxyalkanoate (PHA)-Based Wood Plastic Composites (WPCs) under Natural Weathering. Polym. Test. 2019, 73, 214–221. [Google Scholar] [CrossRef]

- Meereboer, K.W.; Pal, A.K.; Cisneros-López, E.O.; Misra, M.; Mohanty, A.K. The Effect of Natural Fillers on the Marine Biodegradation Behaviour of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV). Sci. Rep. 2021, 11, 911. [Google Scholar] [CrossRef] [PubMed]

- Lemos Junior, W.J.F.; do Amaral dos Reis, L.P.; de Oliveira, V.S.; Lopes, L.O.; Pereira, K.S. Reuse of Refillable PET Packaging: Approaches to Safety and Quality in Soft Drink Processing. Food Control. 2019, 100, 329–334. [Google Scholar] [CrossRef]

- Arfat, Y.A.; Ahmed, J.; Hiremath, N.; Auras, R.; Joseph, A. Thermo-Mechanical, Rheological, Structural and Antimicrobial Properties of Bionanocomposite Films Based on Fish Skin Gelatin and Silver-Copper Nanoparticles. Food Hydrocoll. 2017, C, 191–202. [Google Scholar] [CrossRef]

- Mokrzycki, W.S.; Tatol, M. Color Difference ΔE: A Survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Barham, P.J.; Keller, A.; Otun, E.L.; Holmes, P.A. Crystallization and Morphology of a Bacterial Thermoplastic: Poly-3-Hydroxybutyrate. J. Mater. Sci. 1984, 19, 2781–2794. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Gontard, N.; Angellier-Coussy, H. Impact of Fibre Moisture Content on the Structure/Mechanical Properties Relationships of PHBV/Wheat Straw Fibres Biocomposites. Compos. Sci. Technol. 2015, 117, 386–391. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Angellier-Coussy, H.; Machado, D.; Hilliou, L.; Staebler, A.; Vicente, A.; Gontard, N. Exploring the Potentialities of Using Lignocellulosic Fibres Derived from Three Food By-Products as Constituents of Biocomposites for Food Packaging. Ind. Crops Prod. 2015, 69, 110–122. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Angellier-Coussy, H.; Guillard, V.; Gontard, N. Vegetal Fiber-Based Biocomposites: Which Stakes for Food Packaging Applications? J. Appl. Polym. Sci. 2016, 133, 42528. [Google Scholar] [CrossRef]

- Mihranyan, A.; Llagostera, A.P.; Karmhag, R.; Strømme, M.; Ek, R. Moisture Sorption by Cellulose Powders of Varying Crystallinity. Int. J. Pharm. 2004, 269, 433–442. [Google Scholar] [CrossRef]

- Thoury-Monbrun, V. Formalisation des Relations Structure/Propriétés de Transfert de Matière Dans un Biocomposite Modèle. Ph.D. Thesis, Université Montpellier, Montpellier, France, 2018. [Google Scholar]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A.; Riedl, B. Analysis of Among-Species Variability in Wood Fiber Surface Using DRIFTS and XPS: Effects on Esterification Efficiency. J. Wood Chem. Technol. 2008, 28, 296–315. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Perré, P.; Riedl, B. Effects of Wood Fiber Surface Chemistry on Strength of Wood–Plastic Composites. Appl. Surf. Sci. 2015, 343, 11–18. [Google Scholar] [CrossRef]

- Shebani, A.N.; Van Reenen, A.J.; Meincken, M. The Effect of Wood Species on the Mechanical and Thermal Properties of Wood—LLDPE Composites. J. Compos. Mater. 2009, 43, 1305–1318. [Google Scholar] [CrossRef]

- Stark, N.M.; Rowlands, R.E. Effects of Wood Fiber Characteristics on Mechanical Properties of Wood/Polypropylene Composites. Wood Fiber. Sci. 2003, 35, 167–174. [Google Scholar]

- Zhu, Y.; Wu, F.; Trmcic, A.; Wang, S.; Warriner, K. Microbiological Status of Reusable Plastic Containers in Commercial Grower/Packer Operations and Risk of Salmonella Cross-Contamination between Containers and Cucumbers. Food Control 2020, 110, 107021. [Google Scholar] [CrossRef]

| Melting Temperature Tm (°C) | Composite’s Melting Enthalpy ΔHm (J.g−1) | PHBV’s Degree of Crystallinity χc (%) | Crystallisation Temperature Tc (°C) | ||

|---|---|---|---|---|---|

| PHBV | Cycle 0 | 175.9 ± 0.1 | 82.3 ± 1.0 | 56.4 ± 0.7 | 127.2 ± 0.3 |

| Cycle 5 | 176.6 ± 0.8 | 84.6 ± 0.3 | 57.9 ± 0.3 | 127.2 ± 0.1 | |

| Cycle 10 | 175.2 ± 0.1 | 82.8 ± 0.4 | 56.7 ± 0.3 | 127.5 ± 0.1 | |

| Cycle 50 | 177.6 ± 1.1 | 82.5 ± 0.6 | 56.5 ± 0.4 | 127.2 ± 0.0 | |

| Cycle 70 | 176.6 ± 0.1 | 83.9 ± 0.5 | 57.5 ± 0.3 | 127.1 ± 0.2 | |

| Cycle 125 | 175.9 ± 0.8 | 81.9 ± 0.3 | 56.1 ± 0.2 | 127.3 ± 0.1 | |

| Filler grade | Code | Type | L/d (Supplier) | d10 (µm) | d50 (µm) | d90 (µm) | Span | L* | a* | b* |

|---|---|---|---|---|---|---|---|---|---|---|

| Arbocel B00 | B00 | Short cellulose fibres/ 99.5% cellulose content | 4.8 | 15.5 ± 0.1 | 57.1 ± 0.5 | 161 ± 1.7 | 2.55 ± 0.03 | 97.0 | −0.33 | 3.86 |

| Arbocel BE 600 30 PU | BE 600 | Bleached cellulose microfibres/ 98% cellulose content | 2.0 | 10.3 ± 0.1 | 31.0 ± 0.2 | 78.1 ± 1.1 | 2.19 ± 0.04 | 96.8 | −0.51 | 4.62 |

| Filtracel EFC 950 | EFC 950 | Purified chemithermo-mechanical (CTMP) wood pulp | 2.1 | 17.3 ± 0.2 | 94.8 ± 1.9 | 394 ± 20 | 3.97 ± 0.22 | 76.8 | 4.40 | 22.8 |

| Difference of Colour ΔE | ||||

|---|---|---|---|---|

| Cycle 1 | Cycle 5 | Cycle 10 | ||

| PHBV | 0.5 | 0.8 | 0.5 | |

| 20 wt% | PHBV/B00 | 0.5 | 4.9 | 6.8 |

| PHBV/BE 600 | 2.6 | 15.6 | 3.1 | |

| PHBV/EFC 950 | 0.6 | 1.5 | 3.4 | |

| 40 wt% | PHBV/B00 | 2.7 | 12.4 | 14.5 |

| PHBV/BE 600 | 5.7 | 10.2 | 11.7 | |

| PHBV/EFC 950 | 8.0 | 12.2 | 13.4 | |

| Melting Temperature Tm (°C) | Composite’s Melting Enthalpy ΔHm (J/g) | PHBV’s Degree of Crystallinity χc (%) | Crystallisation Temperature Tc (°C) | |||

|---|---|---|---|---|---|---|

| PHBV | Cycle 0 | 175.9 ± 0.1 | 82.3 ± 1.0 | 56.4 ± 0.7 | 127.2 ± 0.3 | |

| Cycle 5 | 176.6 ± 0.8 | 84.6 ± 0.3 | 57.9 ± 0.3 | 127.2 ± 0.1 | ||

| Cycle 10 | 175.2 ± 0.1 | 82.8 ± 0.4 | 56.7 ± 0.3 | 127.5 ± 0.1 | ||

| Cycle 50 | 177.6 ± 1.1 | 82.5 ± 0.6 | 56.5 ± 0.4 | 127.2 ± 0.0 | ||

| Cycle 70 | 176.6 ± 0.1 | 83.9 ± 0.5 | 57.5 ± 0.3 | 127.1 ± 0.2 | ||

| Cycle 125 | 175.9 ± 0.8 | 81.9 ± 0.3 | 56.1 ± 0.2 | 127.3 ± 0.1 | ||

| 20 wt% | PHBV/ B00 | Cycle 0 | 174.1 ± 0.5 | 65.8 ± 2.0 | 56.3 ± 1.7 | 126.6 ± 0.2 |

| Cycle 5 | 174.3 ± 0.5 | 72.9 ± 0.7 | 62.4 ± 0.7 | 126.9 ± 0.0 | ||

| Cycle 10 | 172.5 ± 0.7 | 67.1 ± 0.3 | 57.4 ± 0.3 | 124.8 ± 1.2 | ||

| PHBV/ BE 600 | Cycle 0 | 174.7 ± 0.8 | 68.0 ± 0.2 | 58.2 ± 0.2 | 126.4 ± 0.2 | |

| Cycle 5 | 174.2 ± 0.6 | 67.3 ± 1.7 | 57.6 ± 1.5 | 126.1 ± 0.1 | ||

| Cycle 10 | 174.4 ± 0.5 | 62.4 ± 1.1 | 53.4 ± 0.9 | 125.9 ± 0.1 | ||

| PHBV/ EFC 950 | Cycle 0 | 173.7 ± 0.3 | 64.0 ± 7.1 | 54.8 ± 6.0 | 124.4 ± 0.4 | |

| Cycle 5 | 176.5 ± 0.5 | 71.4 ± 0.7 | 61.1 ± 0.6 | 125.8 ± 0.0 | ||

| Cycle 10 | 170.5 ± 1.4 | 61.0 ± 6.8 | 52.2 ± 5.9 | 120.0 ± 2.8 | ||

| 40 wt% | PHBV/ B00 | Cycle 0 | 175.6 ± 0.4 | 71.7 ± 3.1 | 81.8 ± 3.6 | 126.7 ± 0.2 |

| Cycle 5 | 173.1 ± 0.3 | 60.9 ± 0.1 | 69.5 ± 0.1 | 125.1 ± 0.7 | ||

| Cycle 10 | 169.1 ± 0.4 | 45.4 ± 0.9 | 51.8 ± 1.1 | 121.1 ± 0.3 | ||

| PHBV/ BE 600 | Cycle 0 | 171.9 ± 0.4 | 47.0 ± 0.6 | 53.7 ± 0.6 | 125.7 ± 0.1 | |

| Cycle 5 | 171.6 ± 0.2 | 53.9 ± 0.1 | 61.5 ± 0.1 | 124.4 ± 0.0 | ||

| Cycle 10 | 168.8 ± 0.3 | 42.8 ± 0.7 | 48.9 ± 0.8 | 120.4 ± 0.4 | ||

| PHBV/ EFC 950 | Cycle 0 | 169.8 ± 0.9 | 47.3 ± 0.7 | 54.0 ± 0.8 | 123.9 ± 0.4 | |

| Cycle 5 | 171.6 ± 0.5 | 52.4 ± 0.3 | 59.8 ± 0.4 | 123.2 ± 0.5 | ||

| Cycle 10 | 168.1 ± 1.6 | 45.0 ± 2.6 | 51.4 ± 2.9 | 115.5 ± 2.2 | ||

| EtOH 50% (vol/vol) | EtOH 95% (vol/vol) | |||

|---|---|---|---|---|

| PHBV |  Up to 125 cycles Up to 125 cycles | 50 cycles | ||

| PHBV Biocomposites | 20 wt% | 40 wt% | 20 wt% | 40 wt% |

| Arbocel B00 | Up to 10 cycles | 1 cycle | 1 cycle | 1 cycle |

| Arbocel BE 600 30 PU | Up to 10 cycles | NOT REUSABLE | 3 cycles | 1 cycle |

| Filtracel EFC 950 | NOT REUSABLE | NOT REUSABLE | 1 cycle | NOT REUSABLE |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doineau, E.; Rol, F.; Gontard, N.; Angellier-Coussy, H. Physical-Chemical and Structural Stability of Poly(3HB-co-3HV)/(ligno-)cellulosic Fibre-Based Biocomposites over Successive Dishwashing Cycles. Membranes 2022, 12, 127. https://doi.org/10.3390/membranes12020127

Doineau E, Rol F, Gontard N, Angellier-Coussy H. Physical-Chemical and Structural Stability of Poly(3HB-co-3HV)/(ligno-)cellulosic Fibre-Based Biocomposites over Successive Dishwashing Cycles. Membranes. 2022; 12(2):127. https://doi.org/10.3390/membranes12020127

Chicago/Turabian StyleDoineau, Estelle, Fleur Rol, Nathalie Gontard, and Hélène Angellier-Coussy. 2022. "Physical-Chemical and Structural Stability of Poly(3HB-co-3HV)/(ligno-)cellulosic Fibre-Based Biocomposites over Successive Dishwashing Cycles" Membranes 12, no. 2: 127. https://doi.org/10.3390/membranes12020127