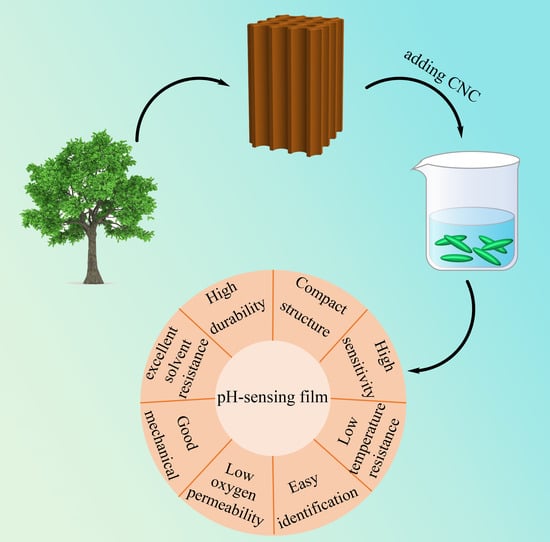

Effect of Cellulose Nanocrystal Addition on the Physicochemical Properties of Hydroxypropyl Guar-Based Intelligent Films

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of pH-Sensing Films

2.3. Characterization

2.3.1. Thickness Measurement

2.3.2. FTIR

2.3.3. SEM

2.3.4. Stress–Strain Measurements

2.3.5. Oxygen Permeability (OP)

2.3.6. Water Vapor Permeability (WVP)

2.4. Measurements of the Color Responses of the pH-Sensing Films in Buffers at Different pH Values

2.5. Measurements of the Solvent Resistances and Weight Losses of the pH-Sensing Films

2.6. Measurements of High- and Low-Temperature Resistances

2.7. Light Resistance Measurements

2.8. Durability Measurements

2.9. Measurement of Meat Freshness

2.10. Detection of the Total Volatile Basic Nitrogen (TVBN) Levels

3. Results and Discussion

3.1. Mechanical Properties and Morphologies of the pH-Sensing Films

3.2. Barrier Properties of the pH-Sensing Films

3.3. Color Response Analysis of the pH-Sensing Films to Buffers at different pH values

3.4. Solvent Resistances and Weight Losses of the pH-Sensing Films

3.5. Temperature Resistance, Light Resistance, and Durability of the pH-Sensing Films

3.6. Application of the pH-Sensing Films for Monitoring Chicken Breast Freshness

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Silva-Pereira, M.C.; Teixeira, J.A.; Pereira-Júnior, V.A.; Stefani, R. Chitosan/corn starch blend films with extract from Brassica oleraceae (red cabbage) as a visual indicator of fish deterioration. LWT-Food Sci. Technol. 2015, 61, 258–262. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Lu, S.; Chen, X. A visual pH sensing film using natural dyes from Bauhinia blakeana Dunn. Sens. Actuators B-Chem. 2014, 198, 268–273. [Google Scholar] [CrossRef]

- Choi, I.; Lee, J.Y.; Lacroix, M.; Han, J. Intelligent pH indicator film composed of agar/potato starch and anthocyanin extracts from purple sweet potato. Food Chem. 2017, 218, 122–128. [Google Scholar] [CrossRef] [PubMed]

- Prietto, L.; Mirapalhete, T.C.; Pinto, V.Z.; Hoffmann, J.F.; Vanier, N.L.; Lim, L.T.; Dias, A.R.G.; Zavareze, E.D. pH-sensitive films containing anthocyanins extracted from black bean seed coat and red cabbage. LWT-Food Sci. Technol. 2017, 80, 492–500. [Google Scholar] [CrossRef]

- Zhang, K.; Huang, T.; Yan, H.; Hu, X.; Ren, T. Novel pH-sensitive films based on starch/polyvinyl alcohol and food anthocyanins as a visual indicator of shrimp deterioration. Int. J. Biol. Macromol. 2020, 145, 768–776. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.Y.; Wang, L.J. Preparation of a visual pH-sensing film based on tara gum incorporating cellulose and extracts from grape skins. Sens. Actuators B-Chem. 2016, 235, 401–407. [Google Scholar] [CrossRef]

- Shukla, V.; Kandeepan, G.; Vishnuraj, M.R.; Soni, A. Anthocyanins Based Indicator Sensor for Intelligent Packaging Application. Agric. Res. 2016, 5, 205–209. [Google Scholar] [CrossRef]

- Ma, Q.; Liang, T.; Cao, L.; Wang, L. Intelligent poly (vinyl alcohol)-chitosan nanoparticles-mulberry extracts films capable of monitoring pH variations. Int. J. Biol. Macromol. 2018, 108, 576–584. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, Y.; Cha, R.; Yang, J.; Jiang, X. Water-soluble nanocrystalline cellulose films with highly transparent and oxygen barrier properties. Nanoscale 2016, 8, 973–978. [Google Scholar] [CrossRef]

- Silva, H.M.D.; Mageste, A.B.; Silva, S.; Dias Ferreira, G.M.; Ferreira, G.M.D. Anthocyanin immobilization in carboxymethylcellulose/starch films: A sustainable sensor for the detection of Al (III) ions in aqueous matrices. Carbohydr. Polym. 2020, 230, 115679. [Google Scholar] [CrossRef]

- Saurabh, C.; Gupta, S.; Variyar, P.S.; Sharma, A. Effect of addition of nanoclay, beeswax, tween-80 and glycerol on physicochemical properties of guar gum films. Ind. Crop. Prod. 2016, 89, 109–118. [Google Scholar] [CrossRef]

- Dai, L.; Wang, B.; Long, Z.; Chen, L.; Zhang, D.; Guo, S. Properties of hydroxypropyl guar/TEMPO-oxidized cellulose nanofibrils composite films. Cellulose 2015, 22, 3117–3126. [Google Scholar] [CrossRef]

- Nayak, B.R.; Singh, R.P. Synthesis and characterization of grafted hydroxypropyl guar gum by ceric ion induced initiation. Eur. Polym. J. 2001, 37, 1655–1666. [Google Scholar] [CrossRef]

- Qing, Y.; Sabo, R.; Zhu, J.Y.; Agarwal, U.; Cai, Z.Y.; Wu, Y.Q. A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohyd. Polym. 2013, 97, 226–234. [Google Scholar] [CrossRef]

- Sacui, I.A.; Nieuwendaal, R.C.; Burnett, D.J.; Stranick, S.J.; Jorfi, M.; Weder, C.; Foster, E.J.; Olsson, R.T.; Gilman, J.W. Comparison of the properties of cellulose nanocrystals and cellulose nanofibrils isolated from bacteria, tunicate, and wood processed using acid, enzymatic, mechanical, and oxidative methods. ACS Appl. Mater. Interfaces 2014, 6, 6127–6138. [Google Scholar] [CrossRef]

- Hu, Y.; Tang, L.; Lu, Q.; Wang, S.; Chen, X.; Huang, B. Preparation of cellulose nanocrystals and carboxylated cellulose nanocrystals from borer powder of bamboo. Cellulose 2014, 21, 1611–1618. [Google Scholar] [CrossRef]

- Kang, H.; Liu, R.; Huang, Y. Cellulose-based gels. Macromol. Chem. Phys. 2016, 217, 1322–1334. [Google Scholar] [CrossRef]

- Xu, K.M.; Liu, C.; Kang, K.; Zheng, Z.; Wang, S.; Tang, Z.; Yang, W. Isolation of nanocrystalline cellulose from rice straw and preparation of its biocomposites with chitosan: Physicochemical characterization and evaluation of interfacial compatibility. Compos. Sci. Technol. 2018, 154, 8–17. [Google Scholar] [CrossRef]

- Wu, C.; Saito, T.; Fujisawa, S.; Fukuzumi, H.; Isogai, A. Ultrastrong and high gas-barrier nanocellulose/clay-layered composites. Biomacromolecule 2012, 13, 1927–1932. [Google Scholar] [CrossRef] [PubMed]

- Long, K.; Cha, R.; Zhang, Y.; Li, J.; Ren, F.; Jiang, X. Cellulose nanocrystals as reinforcements for collagen-based casings with low gas transmission. Cellulose 2017, 25, 463–471. [Google Scholar] [CrossRef]

- Dai, L.; Long, Z.; Chen, J.; An, X.Y.; Cheng, D.; Khan, A.; Ni, Y. Robust guar gum/cellulose nanofibrils multilayer films with good barrier properties. ACS Appl. Mater. Interfaces 2017, 9, 5477–5485. [Google Scholar] [CrossRef] [PubMed]

- Poinot, T.; Govin, A.; Grosseau, P. Importance of coil-overlapping for the effectiveness of hydroxypropylguars as water retention agent in cement-based mortars. Cem. Concr. Res. 2014, 56, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Keating, B.A.; Hill, C.A.S.; Sun, D.; English, R.; Davies, P.; McCue, C. The water vapor sorption behavior of a galactomannan cellulose nanocomposite film analyzed using parallel exponential kinetics and the Kelvin-Voigt viscoelastic model. J. Appl. Polym. Sci. 2013, 129, 2352–2359. [Google Scholar] [CrossRef] [Green Version]

- Thombare, N.; Jha, U.; Mishra, S.; Siddiqui, M.Z. Guar gum as a promising starting material for diverse applications: A review. Int. J. Biol. Macromol. 2016, 88, 361–372. [Google Scholar] [CrossRef] [PubMed]

- Sharma, M.; Mondal, D.; Mukesh, C.; Prasad, K. Solvent responsive healing of guar gum and guar gum–multiwalled carbon nanotube nanocomposite gels prepared in an ionic liquid. RSC Adv. 2013, 3, 16509–16515. [Google Scholar] [CrossRef]

- Osterberg, M.; Vartiainen, J.; Lucenius, J.; Hippi, U.; Seppala, J.; Serimaa, R.; Laine, J. A fast method to produce strong NFC films as a platform for barrier and functional materials. ACS Appl. Mater. Interfaces 2013, 5, 4640–4647. [Google Scholar] [CrossRef]

- Jiménez, N.; Bohuon, P.; Lima, J.; Dornier, M.; Vaillant, F.; Pérez, A.M. Kinetics of anthocyanin degradation and browning in reconstituted blackberry juice treated at high temperatures (100–180 °C). J. Agric. Food Chem. 2010, 58, 2314–2322. [Google Scholar] [CrossRef]

- Cavalcanti, R.N.; Santos, D.T.; Meireles, M.A.A. Non-thermal stabilization mechanisms of anthocyanins in model and food systems—An overview. Food Res. Int. 2011, 44, 499–509. [Google Scholar] [CrossRef]

- Kang, S.; Wang, H.; Guo, M.; Zhang, L.; Chen, M.; Jiang, S.; Li, X.; Jiang, S. Ethylene-vinyl Alcohol Copolymer/montmorillonite Multilayer Barrier Film Coated with Mulberry Anthocyanin for Freshness Monitoring. J. Agric. Food Chem. 2018, 66, 13268–13276. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Y.; Cao, Y.; Xiong, K.; Ma, L.; Zhu, W.; Long, Z.; Dong, C. Effect of Cellulose Nanocrystal Addition on the Physicochemical Properties of Hydroxypropyl Guar-Based Intelligent Films. Membranes 2021, 11, 242. https://doi.org/10.3390/membranes11040242

Meng Y, Cao Y, Xiong K, Ma L, Zhu W, Long Z, Dong C. Effect of Cellulose Nanocrystal Addition on the Physicochemical Properties of Hydroxypropyl Guar-Based Intelligent Films. Membranes. 2021; 11(4):242. https://doi.org/10.3390/membranes11040242

Chicago/Turabian StyleMeng, Yahui, Yunfeng Cao, Kaifeng Xiong, Li Ma, Wenyuan Zhu, Zhu Long, and Cuihua Dong. 2021. "Effect of Cellulose Nanocrystal Addition on the Physicochemical Properties of Hydroxypropyl Guar-Based Intelligent Films" Membranes 11, no. 4: 242. https://doi.org/10.3390/membranes11040242