Study of Personal Mobility Vehicle (PMV) with Active Inward Tilting Mechanism on Obstacle Avoidance and Energy Efficiency

Abstract

:Featured Application

Abstract

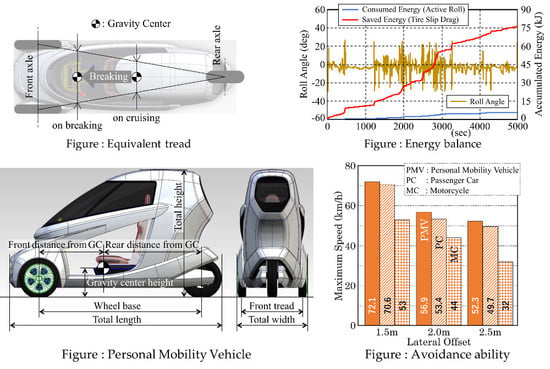

1. Introduction

- Self-standing ability from stop to very low speed

- Inner wheel lifting on sudden steering input

- Capability on obstacle avoidance

- Energy consumption on active tilting system

1.1. Self-Standing Ability from Stop to Very Low Speed

1.2. Study of PMVs with Active Tilting Mechanism

2. Multibody Dynamics Model

2.1. Vehicle Model

2.1.1. Suspension

2.1.2. Target Roll Angle

- TRA: target roll angle

- A: user amplification factor

- δ: tire steered angle

- v: vehicle speed

- l: wheel base

- P: proportional gain

- I: integral gain

- D: derivative gain

2.1.3. Tire

2.2. Driver Model

3. Inner Wheel Lifting Phenomena

3.1. Understanding Mechanism of Lifting Phenomena

- Inward roll response to steering input cannot occur in time due to roll moment of inertia.

- Transitional front wheel slip angle due to vehicle response delay caused by yaw moment of inertia causes outward roll moment. This roll moment further delays inward roll response.

- Too much rebound stroke of front outer wheel caused by inward roll response delay lifts up front body. Pitch moment of inertia delays recovery from front body lifting.

3.1.1. Influence of PID Factors on Roll Angle Tracking Control

3.1.2. Steering Input Condition

- LD: lateral displacement

- MA: steering wheel angle

- v: vehicle velocity

- f: steering input frequency

3.1.3. Relation between Steering Angle and Input Frequency

3.1.4. Vehicle Speed

3.2. Influences of Three Axis Moments of Inertia

3.2.1. Influence of Roll Moment of Inertia

3.2.2. Influence of Pitch and Yaw Moments of Inertia

3.2.3. Roll Resonance Frequency fφ and Influence of Roll Dynamics

- fφ: roll resonance frequency

- Kφ: roll stiffness

- Ixx: roll moment of inertia

3.3. Summary of This Section and Setting Specifications for Further Study

- Lateral displacement LD is proportional to steering angle MA and the square of vehicle speed v, and inversely proportional to the square of steering input frequency f.

- Increase of steering input frequency f itself is disadvantageous for front inner wheel lifting. Increase of input steering wheel angle MA to maintain lateral displacement LD on increase of steering input frequency f causes further severe conditions of front inner wheel lifting.

- Increase of vehicle speed v requires quicker steering input frequency f, which is disadvantageous for front inner wheel lifting.

- Inner wheel lifting phenomenon is only that vehicle roll is unavailable to follow target roll angle TRA due to roll moment of inertia of sprung mass Ixx* and is almost dominated by the roll dynamics of PMVs. Smaller Ixx* and larger Kφ, i.e., higher roll resonance frequency fφ improves front inner wheel lifting phenomena.

- Unstable roll phenomena without intentional steering input related to front inner wheel lifting phenomena is suppressed by decrease of I gain of PID tracking control to active roll angle. In order to study realistic roll moment of inertia Ixx* and roll stiffness Kφ, PID control parameters in further study are set as Equation (5).

4. Capability on Obstacle Avoidance

4.1. Comparison Front Wheel Steering (FWS) and Rear Wheel Steering (RWS)

4.1.1. Understanding of Vehicle Posture on Avoidance Behavior

- ρ: turning radius

- m: vehicle mass

- l: wheel base

- lf: front wheel base

- Kf: front cornering power

- lr: rear wheel base

- v: velocity

- δ: tire steer angle

4.1.2. Open Loop Simulation

4.1.3. Closed Loop Simulation

4.1.4. Judgment of FWS and RWS on Implementation

4.2. Comparison with Passenger Cars and Motorcycles

4.2.1. Vehicle Models of Passenger Cars and Motorcycles

4.2.2. Driving Course

4.2.3. Passing Speed Comparison and Understanding Social Acceptability

4.2.4. Mechanism of Superiority of PMV

- φe: equivariant roll angle

- dt: moment arm length on lateral transfer of load

- G.C.H.: gravity center height

- φa: actual roll angle

- da: moment arm length on actual roll

4.3. Summary of This Section

5. Energy Consumption on Active Tilting System

5.1. Mechanism of Energy Balance

5.1.1. Energy Consumption in Active Tilting Mechanism

- E: energy

5.1.2. Energy Consumption by Cornering Drag in Case of No Tilting

- E: energy

- Y: cornering force

- K: cornering power

- v: vehicle velocity

- t: time

5.2. Energy Consumption in Typical Driving Modes

5.2.1. Energy Consumption on Steady Circle

5.2.2. Energy Consumption in Slalom

5.3. Energy Consumption in Real World Condition

5.3.1. Typical European Evaluation Course (AMS)

5.3.2. Energy Consumption in AMS Magazine Evaluation Course

5.4. Social Acceptance from Viewpoint of Energy Consumption

6. Conclusions

- Front inner wheel lifting phenomenon is only that vehicle roll is unavailable to follow target roll angle TRA due to roll moment of inertia of sprung mass Ixx*. Smaller Ixx* and larger Kφ improve front inner wheel lifting phenomena.

- It is possible to suppress unstable roll phenomena without intentional steering input related to front inner wheel lifting phenomena by decreasing the I gain of roll tracking control (PID).

- PMVs with an active tilting mechanism have two advantages of vehicle dynamics. One is lateral transfer of vertical loads on front both wheels, in the same way as general cars, and the other is inward tilting on turning, the same as motorcycles.

- PMVs with an active tilting mechanism have an obstacle avoidance ability equal to or higher than that of passenger cars, because they have a much smaller roll moment of inertia than passenger cars and responsiveness equivalent to passenger cars.

- Energy consumption for an active tilting mechanism is much smaller than energy saving due to avoiding cornering drag by using the camber angle. This shows there is no need to worry about energy consumption with active tilting mechanisms.

- From a general energy efficiency point of view, smaller and lighter PMVs are significantly more efficient than general cars, because rolling resistance caused by vehicle mass and the tire rolling resistance coefficient is the major resistance in these vehicles.

Author Contributions

Funding

Conflicts of Interest

References

- Kaneko, T.; Kageyama, I.; Haraguchi, T.; Kuriyagawa, Y. A Study on the Harmonization of a Personal Mobility Vehicle with a Lean Mechanism in Road Traffic (First Report). In Proceedings of the JSAE Annual Congress (Spring), Yokohama, Japan, 25 May 2016; pp. 1350–1354. [Google Scholar]

- Haraguchi, T. Are PMVs with inward tilting mechanism like motorcycles accepted in future mobility society? In Proceedings of the Forum text of JSAE Annual Congress (Spring), Yokohama, Japan, 24 May 2019. [Google Scholar]

- CarMaker: Virtual Testing of Automobiles and Light-Duty Vehicles, IPG Automotive GmbH. Available online: https://ipg-automotive.com/products-services/simulation-software/carmaker/ (accessed on 20 October 2019).

- Haraguchi, T.; Kageyama, I.; Kaneko, T. Inner Wheel Lifting Characteristics of Tilting Type Personal Mobility Vehicle by Sudden Steering Input. Trans. Soc. Automot. Eng. Japan Inc. 2019, 50, 96–101. [Google Scholar]

- Kaneko, T.; Kageyama, I.; Haraguchi, T. A Study on Characteristics of the Vehicle Response by Abrupt Operation and an Improvement Method for Personal Mobility Vehicle with Leaning Mechanism. Trans. Soc. Automot. Eng. Japan Inc. 2019, 50, 796–801. [Google Scholar]

- Haraguchi, T.; Kaneko, T.; Kageyama, I.; Kobayashi, M.; Murayama, T. Obstacle Avoidance Maneuver of Personal Mobility Vehicles with Lean Mechanism-Comparison between Front and Rear Wheel Steering-. In Proceedings of the JSAE Annual Congress (Spring), Yokohama, Japan, 24 May 2017; pp. 494–499. [Google Scholar]

- Haraguchi, T.; Kaneko, T.; Kageyama, I. Study on Steering Response of Personal Mobility Vehicle (PMV) by Comparison of PMV with Passenger Cars and Motorcycles on the Obstacle Avoidance Performance. In Proceedings of the JSAE Annual Congress (Autumn), Nagoya, Japan, 17 October 2018. [Google Scholar]

- Haraguchi, T.; Kaneko, T.; Kageyama, I. Market Acceptability Study on Energy Balance of Personal Mobility Vehicle (PMV) with Active Tilting Mechanism. In Proceedings of the JSAE Annual Congress (Spring), Yokohama, Japan, 24 May 2019. [Google Scholar]

| Simple Construction | Slow Speed | Stability on Braking | Obstacle Avoidance | |||

|---|---|---|---|---|---|---|

| Single front wheel+Double rear wheels | ✔ | ▼Unstable | ▼ U.S. | |||

| Double front wheels + Single rear wheel | ✔ | |||||

| Front steering + Rear traction | ||||||

| Passive tilting mechanism Active tilting mechanism | ✔ ▼Active | ▼Falling ✔ | ▼Delay ✔ | |||

| Front traction + Rear steering | ▼Steer-by-wire | ▼Delay | ||||

| Double front wheels + Double rear wheels | ▼4 wheels | ✔ | ||||

| Front steering + Rear traction | ||||||

| Passive tilting mechanism Active tilting mechanism | ✔ ▼Active | ▼Falling ✔ | ▼Delay ✔ | |||

| Item | Unit | Value | Item | Unit | Value |

|---|---|---|---|---|---|

| Total length | m | 2.645 | Total mass | kg | 369.8 |

| Total width | m | 0.880 | Front mass distribution | kg | 222.1 |

| Total height | m | 1.445 | Rear mass distribution | kg | 147.7 |

| Wheel base | m | 2.020 | Roll moment of inertia | kgm2 | 58.8 |

| Front distance from gravity center | m | 0.807 | (Roll moment of inertia of sprung mass) | kgm2 | 43.0 |

| Rear distance from gravity center | m | 1.213 | Pitch moment of inertia | kgm2 | 197.3 |

| Front tread | m | 0.850 | (Pitch moment of inertia of sprung mass) | kgm2 | 118.0 |

| Gravity center height | m | 0.358 | Yaw moment of inertia | kgm2 | 187.3 |

| Steering gear ratio | - | 16.0 | (Yaw moment of inertia of sprung mass) | kgm2 | 102.3 |

| Passenger Car | Motorcycle | ||||

|---|---|---|---|---|---|

| Item | Unit | Value | Item | Unit | Value |

| Total length | m | 4.150 | Total length | m | 2.140 |

| Total width | m | 1.700 | Total width | m | 0.637 |

| Total height | m | 1.600 | Total height | m | 1.318 |

| Wheel base | m | 3.185 | Wheel base | m | 1.576 |

| Front tread | m | 1.508 | Front mass distribution | kg | 122.8 |

| Rear tread | m | 1.494 | Rear mass distribution | kg | 75.5 |

| Total mass | kg | 1463 | Total mass | kg | 198.3 |

| Gravity center height | m | 0.580 | Gravity center height | m | 0.350 |

| Driver | Maneuver | |||

|---|---|---|---|---|

| Item | Unit | Value | Item | Model |

| cornering cutting coefficient (ccc) | 0.1 | Longitudinal dynamics | IPGDriver | |

| Max. longitudinal acceleration | m/s2 | 3.0 | Lateral dynamics < 841.5 m | Follow course |

| Max. longitudinal deceleration | m/s2 | -4.0 | (Dl = 1.5 m) > 841.5 m | IPGDriver |

| Max. lateral acceleration | m/s2 | 20 | Lateral dynamics < 843.0 m | Follow course |

| PylonShiftFdCoef | 0.15 | (Dl = 2.0 m) > 843.0 m | IPGDriver | |

| Lateral dynamics < 844.0m | Follow course | |||

| (Dl = 2.5 m) > 844.0 m | IPGDriver | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haraguchi, T.; Kageyama, I.; Kaneko, T. Study of Personal Mobility Vehicle (PMV) with Active Inward Tilting Mechanism on Obstacle Avoidance and Energy Efficiency. Appl. Sci. 2019, 9, 4737. https://doi.org/10.3390/app9224737

Haraguchi T, Kageyama I, Kaneko T. Study of Personal Mobility Vehicle (PMV) with Active Inward Tilting Mechanism on Obstacle Avoidance and Energy Efficiency. Applied Sciences. 2019; 9(22):4737. https://doi.org/10.3390/app9224737

Chicago/Turabian StyleHaraguchi, Tetsunori, Ichiro Kageyama, and Tetsuya Kaneko. 2019. "Study of Personal Mobility Vehicle (PMV) with Active Inward Tilting Mechanism on Obstacle Avoidance and Energy Efficiency" Applied Sciences 9, no. 22: 4737. https://doi.org/10.3390/app9224737