Light Extraction Enhancement of InGaN Based Micro Light-Emitting Diodes with Concave-Convex Circular Composite Structure Sidewall

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tan, G.; Huang, Y.; Li, M.-C.; Lee, S.-L.; Wu, S.-T. High dynamic range liquid crystal displays with a mini-LED backlight. Opt. Express 2018, 26, 16572–16584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alhassan, A.I.; Young, E.C.; Alyamani, A.Y.; Albadri, A.; Nakamura, S.; DenBaars, S.P.; Speck, J.S. Reduced-droop green III-nitride light-emitting diodes utilizing GaN tunnel junction. Appl. Phys. Express 2018, 11, 042101. [Google Scholar] [CrossRef]

- Ferreira, R.X.G.; Xie, E.; Mckendry, J.J.D.; Rajbhandari, S.; Chun, H.; Faulkner, G.; Watson, S.; Kelly, A.E.; Gu, E.; Penty, R.V.; et al. High bandwidth GaN-based Micro-LEDs for Multi-Gb/s visible light communications. IEEE Photon. Technol. Lett. 2016, 28, 2023–2026. [Google Scholar] [CrossRef]

- Tsai, S.-C.; Li, M.J.; Fang, H.-C.; Tu, C.-H.; Liu, C.-P. Efficiency enhancement of blue light emitting diodes by eliminating V-defects from InGaN/GaN multiple quantum well structures through GaN capping layer control. Appl. Surf. Sci. 2018, 439, 1127–1132. [Google Scholar] [CrossRef]

- Park, N.-M.; Oh, M.; Na, Y.-B.; Cheong, W.-S.; Kim, H. Sputter deposition of Sn-doped ZnO/Ag/Sn-doped ZnO transparent contact layer for GaN LED applications. Mater. Lett. 2016, 180, 72–76. [Google Scholar] [CrossRef] [Green Version]

- Cai, Y.; Zou, X.; Liu, C.; Lau, K.M. Voltage-Controlled GaN HEMT-LED Devices as Fast-Switching and Dimmable Light Emitters. IEEE Electron Device Lett. 2018, 39, 224–227. [Google Scholar] [CrossRef]

- Haitz, R.; Tsao, J.Y. Solid-state light: ‘The Case’ 10 years after and future prospects. Phys. Status Solidi A 2011, 208, 17–29. [Google Scholar] [CrossRef]

- Son, K.R.; Lee, T.H.; Lee, B.R.; Im, H.S.; Kim, T.G. Nitride-Based Microlight-Emitting Diodes Using AlN Thin-Film Electrodes with Nanoscale Indium/Tin Conducting Filaments. Small 2018, 14, 1801032. [Google Scholar] [CrossRef]

- Chang, C.-H.; Lee, Y.-L.; Wang, Z.-F.; Liu, R.-C.; Tsai, J.-H.; Liu, W.-C. Performance Improvement of GaN-Based Light-Emitting Diodes with a Microhole Array, 45° Sidewalls, and a SiO2 Nanoparticle/Microsphere Passivation Layer. IEEE Trans. Electron Devices 2019, 66, 505–511. [Google Scholar] [CrossRef]

- Wu, T.; Sher, C.-W.; Lin, Y.; Lee, C.-F.; Liang, S.; Lu, Y.; Chen, S.-W.H.; Guo, W.; Kuo, H.-C.; Chen, Z. Mini-LED and Micro-LED: Promising Candidates for the Next Generation Display Technology. Appl. Sci. 2018, 8, 1557. [Google Scholar] [CrossRef]

- Daly, S.; Kunkel, T.; Sun, X.; Farrell, S.; Crum, P. 41.1: Distinguished Paper: Viewer Preferences for Shadow, Diffuse, Specular, and Emissive Luminance Limits of High Dynamic Range Displays. SID Symp. Dig. Tech. Pap. 2013, 44, 563–566. [Google Scholar] [CrossRef]

- Mao, P.; Sun, F.; Yao, H.; Chen, J.; Zhao, B.; Xie, B.; Han, M.; Wang, G. Extraction of light trapped due to total internal reflection using porous high refractive index nanoparticle films. Nanoscale 2014, 6, 8177–8184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kolbe, T.; Knauer, A.; Chua, C.; Yang, Z.; Einfeldt, S.; Vogt, P.; Johnson, N.M.; Weyers, M.; Kneissl, M. Optical polarization characteristics of ultraviolet (In)(Al)GaN multiple quantum well light emitting diodes. Appl. Phys. Lett. 2010, 97, 171105. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, W.; Peng, M.; Dai, J.; Chen, C. Light-extraction enhancement of GaN-based 395 nm flip-chip light-emitting diodes by an Al-doped ITO transparent conductive electrode. Opt. Lett. 2018, 43, 2684–2687. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.H.; Kim, H.G.; Chandramohan, S.; Kim, H.K.; Kim, H.Y.; Ryu, J.H.; Park, Y.J.; Beak, Y.S.; Lee, J.-S.; Park, J.S.; et al. Improving the optical performance of InGaN light-emitting diodes by altering light reflection and refraction with triangular air prism arrays. Opt. Lett. 2012, 37, 88–90. [Google Scholar] [CrossRef] [PubMed]

- Jewell, J.; Simeonov, D.; Huang, S.-C.; Speck, J.; Hu, Y.-L.; Nakamura, S.; Weisbuch, C. Double embedded photonic crystals for extraction of guided light in light-emitting diodes. Appl. Phys. Lett. 2012, 100, 171105. [Google Scholar] [CrossRef]

- Kuo, C.-T.; Hsu, L.-H.; Huang, B.-H.; Kuo, H.-C.; Lin, C.-C.; Cheng, Y.-J. Influence of the microstructure geometry of patterned sapphire substrates on the light extraction efficiency of GaN LEDs. Appl. Opt. 2016, 55, 7387–7391. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, S.; Chang, C.; Lin, H.; Li, X.; Lin, Y.; Liu, C. Fabrication of nano-cavity patterned sapphire substrate using self-assembly meshed Pt thin film on c-plane sapphire substrate. Thin Solid Films 2017, 628, 127–131. [Google Scholar] [CrossRef]

- Liou, J.-K.; Chen, C.-C.; Chou, P.-C.; Tsai, Z.-J.; Chang, Y.-C.; Liu, W.-C. Implementation of a High-Performance GaN-Based Light-Emitting Diode Grown on a Nanocomb-Shaped Patterned Sapphire Substrate. IEEE J. Quantum Electron. 2014, 50, 973–980. [Google Scholar] [CrossRef]

- Yao, Y.-C.; Hwang, J.-M.; Yang, Z.-P.; Haung, J.-Y.; Lin, C.-C.; Shen, W.-C.; Chou, C.-Y.; Wang, M.-T.; Huang, C.-Y.; Chen, C.-Y.; et al. Enhanced external quantum efficiency in GaN-based vertical-type light-emitting diodes by localized surface plasmons. Sci. Rep. 2016, 6, 22659. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, C.; Shen, Y.W.Y.; Yang, H.; Gu, C.; Li, J.; Liu, B.; Xu, X. Light emitting enhancement and angle-resolved property of surface textured GaN-based vertical LED. J. Opt. 2016, 45, 81–86. [Google Scholar] [CrossRef]

- Wang, M.-S.; Yang, L.; Huang, X.-J. Strong Enhancement in Light Output of GaN-Based LEDs with Graded-Refractive-Index ITO Deposited on Textured V-Shaped Pits. IEEE Electron Device Lett. 2014, 35, 464–466. [Google Scholar] [CrossRef]

- Hsu, C.; Chan, Y.; Chen, W.; Chang, C.; Liou, J.; Cheng, S.; Guo, D.; Liu, W. Study of GaN-based LEDs with hybrid SiO2 microsphere/nanosphere antireflection coating as a passivation layer by a rapid convection deposition. IEEE Trans. Electron Devices 2017, 64, 1134–1139. [Google Scholar] [CrossRef]

- Liou, J.-K.; Chan, Y.-C.; Chen, W.-C.; Chang, C.-H.; Chen, C.-Y.; Tsai, J.-H.; Liu, W.-C. Characteristics of GaN-Based LEDs with Hybrid Microhole Arrays and SiO2 Microspheres/Nanoparticles Structures. IEEE Trans. Electron Devices 2017, 64, 2854–2858. [Google Scholar] [CrossRef]

- Lee, B.R.; Lee, T.H.; Son, K.-R.; Kim, T.G. ITO/Ag/AlN/Al2O3 multilayer electrodes with conductive channels: Application in ultraviolet light-emitting diodes. J. Alloy. Compd. 2018, 741, 21–27. [Google Scholar] [CrossRef]

- Huang, J.-K.; Liu, C.-Y.; Chen, T.-P.; Huang, H.-W.; Lai, F.-I.; Lee, P.-T.; Lin, C.-H.; Chang, C.-Y.; Kao, T.S.; Kuo, H.-C. Enhanced Light Extraction Efficiency of GaN-Based Hybrid Nanorods Light-Emitting Diodes. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 354–360. [Google Scholar] [CrossRef]

- Zhu, P.; Liu, G.; Zhang, J.; Tansu, N. FDTD Analysis on Extraction Efficiency of GaN Light-Emitting Diodes with Microsphere Arrays. J. Disp. Technol. 2013, 9, 317–323. [Google Scholar] [CrossRef]

- Monavarian, M.; Rashidi, A.; Aragon, A.A.; Oh, S.H.; Rishinaramangalam, A.K.; DenBaars, S.P.; Feezell, D. Impact of crystal orientation on the modulation bandwidth of InGaN/GaN light-emitting diodes. Appl. Phys. Lett. 2018, 112, 041104. [Google Scholar] [CrossRef]

- Pynn, C.D.; Chan, L.; Gonzalez, F.L.; Berry, A.; Hwang, D.; Wu, H.; Margalith, T.; Morse, D.E.; DenBaars, S.P.; Gordon, M.J. Enhanced light extraction from free-standing InGaN/GaN light emitters using bio-inspired backside surface structuring. Opt. Express 2017, 25, 15778–15785. [Google Scholar] [CrossRef]

- Wu, P.-C.; Ou, S.-L.; Horng, R.-H.; Wuu, D.-S. Enhanced Light Extraction of High-Voltage Light Emitting Diodes Using a Sidewall Chamfer Structure. IEEE Photon. J. 2017, 9, 8201409. [Google Scholar] [CrossRef]

- Lee, Y.-L.; Liu, W.-C. Enhanced Light Extraction of GaN-Based Light-Emitting Diodes With a Hybrid Structure Incorporating Microhole Arrays and Textured Sidewalls. IEEE Trans. Electron Devices 2018, 65, 3305–3310. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Liu, W.-C. Light Extraction Enhancement of GaN-Based Light-Emitting Diodes with Textured Sidewalls and ICP-Transferred Nanohemispherical Backside Reflector. IEEE Trans. Electron Devices 2017, 64, 3672–3677. [Google Scholar] [CrossRef]

- Lv, J.J.; Zheng, C.J.; Zhou, S.J.; Fang, F.; Yuan, S. Highly efficient and reliable high power InGaN/GaN LEDs with 3D patterned step-like ITO and wavy sidewalls. Phys. Status Solidi A 2016, 213, 1181–1186. [Google Scholar] [CrossRef]

- Kim, B.-J.; Mastro, M.A.; Jung, H.; Kim, H.-Y.; Kim, S.H.; Holm, R.T.; Hite, J.; Eddy, C.R.; Bang, J.; Kim, J. Inductively coupled plasma etching of nano-patterned sapphire for flip-chip GaN light emitting diode applications. Thin Solid Films 2008, 516, 7744–7747. [Google Scholar] [CrossRef] [Green Version]

- Samwel, E.O.; Bissell, P.R.; Lodder, J.C. Remanent magnetic measurements on perpendicular recording materials with compensation for demagnetizing fields. J. Appl. Phys. 1993, 73, 1353–1359. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.-J.; Huang, C.-C.; Chen, T.-Y.; Hsu, C.-S.; Liou, J.-K.; Liu, W.-C. Improved Performance of an InGaN-Based Light-Emitting Diode with a p-GaN/n-GaN Barrier Junction. IEEE J. Quantum Electron. 2011, 47, 755–761. [Google Scholar] [CrossRef]

- Tang, B.; Miao, J.; Liu, Y.; Wan, H.; Li, N.; Zhou, S.; Gui, C. Enhanced Light Extraction of Flip-Chip Mini-LEDs with Prism-Structured Sidewall. Nanomaterials 2019, 9, 319. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, H.; Dai, J.; Zhang, S.; Wang, S.; He, J.; Liang, R.; Zhang, Z.-H.; Chen, C. Enhanced the Optical Power of AlGaN-Based Deep Ultraviolet Light-Emitting Diode by Optimizing Mesa Sidewall Angle. IEEE Photon. J. 2018, 10, 6100807. [Google Scholar] [CrossRef]

- Shakya, J.; Knabe, K.; Li, J.; Kim, K.H.; Lin, J.Y.; Jiang, H.X. Polarization of III-nitride blue and ultraviolet light-emitting diodes. Appl. Phys. Lett. 2005, 86, 91107. [Google Scholar] [CrossRef]

- Zhou, Q.; Xu, M.; Li, Q.; Wang, H. Improved Efficiency of GaN-based Green LED by a Nano-micro Complex Patterned Sapphire Substrate. IEEE Photon. Technol. Lett. 2017, 29, 983–986. [Google Scholar] [CrossRef]

- Mandy, M.M.L.; Aleksandra, B.D.; Li, E.H. Refractive index of InGaN of InGaN/GaN quantum well. J. Appl. Phys. 1998, 84, 6312–7317. [Google Scholar]

- Guo, Y.; Zhang, Y.; Yan, J.; Xie, H.; Liu, L.; Chen, X.; Hou, M.; Qin, Z.; Wang, J.; Li, J. Light extraction enhancement of AlGaN-based ultraviolet light-emitting diodes by substrate sidewall roughening. Appl. Phys. Lett. 2017, 111, 011102. [Google Scholar] [CrossRef]

- Ryu, H.Y. Investigation of the purcell effect in GaN-based vertical LED structures using FDTD simulation. Opt. Quant. Electron. 2016, 48, 6. [Google Scholar] [CrossRef]

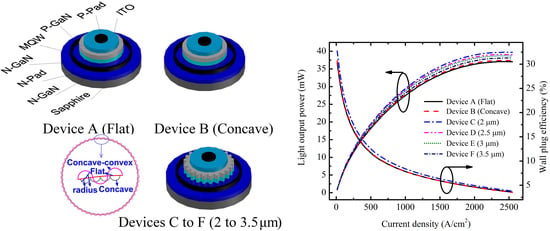

| Device | Saturation Current Density (A/cm2) | Saturation Light Output Power (mW) | Enhancement of Light Output Power |

|---|---|---|---|

| Device A (Flat) | 2420.3 | 37.08 | 0% |

| Device B (Concave) | 2433.1 | 37.46 | 1% |

| Device C (2 μm) | 2458.5 | 39.75 | 7.2% |

| Device D (2.5 μm) | 2458.5 | 39.09 | 5.4% |

| Device E (3 μm) | 2458.5 | 38.67 | 4.3% |

| Device F (3.5 μm) | 2458.5 | 38.11 | 2.8% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, L.; Zhou, Q.; Hu, W.; Wang, H.; Yao, R. Light Extraction Enhancement of InGaN Based Micro Light-Emitting Diodes with Concave-Convex Circular Composite Structure Sidewall. Appl. Sci. 2019, 9, 3458. https://doi.org/10.3390/app9173458

Tan L, Zhou Q, Hu W, Wang H, Yao R. Light Extraction Enhancement of InGaN Based Micro Light-Emitting Diodes with Concave-Convex Circular Composite Structure Sidewall. Applied Sciences. 2019; 9(17):3458. https://doi.org/10.3390/app9173458

Chicago/Turabian StyleTan, Lijun, Quanbin Zhou, Wenlong Hu, Hong Wang, and Ruohe Yao. 2019. "Light Extraction Enhancement of InGaN Based Micro Light-Emitting Diodes with Concave-Convex Circular Composite Structure Sidewall" Applied Sciences 9, no. 17: 3458. https://doi.org/10.3390/app9173458