Evaluation of Sensitivity and Calibration of the Chaboche Kinematic Hardening Model Parameters for Numerical Ratcheting Simulation

Abstract

:1. Introduction

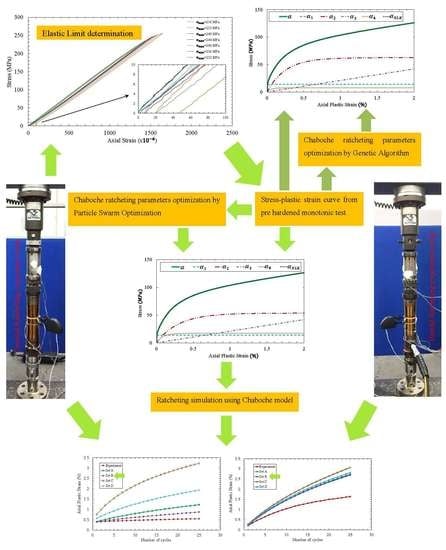

2. Determination of Chaboche Material Parameters

2.1. Material and Specification

2.2. Specimen Preparation

2.3. Experimental Setup

2.4. Experiment Results and Discussion

3. Automated Calibration of Chaboche Parameter

3.1. Chaboche Model of Ratcheting

3.2. Extraction of Stress-Plastic Strain Data

3.3. Parameter Generation Based on Physical Meaning

3.4. Determination of Ratcheting Parameters Using Intelligent Optimization Methods

3.4.1. Genetic Algorithm

Selection Activity

Crossover Activity

Mutation Activity

3.4.2. Particle Swarm Optimization

PSO Formulation

3.5. Results and Discussions—Automated Parameter Calibration of Chaboche Model

4. Finite Element Model

5. Finite Element Results and Discussion

6. Conclusions

- Tests on 316L austenitic steels show the presence of transient Bauschinger effect in upper hysteresis curve with of ±0.75% symmetric strain hardening range in comparison with post-stabilized monotonic curve.

- The efficiency of generating ratcheting parameters, in terms of MSE and optimization time, is better in the PSO method compared to GA.

- The elastic limit obtained from the incremental uniaxial test after pre-hardening offers an improved uniaxial ratcheting prediction.

- Compared to the hysteresis curve, the ratcheting parameters obtained from post-stabilized monotonic curve present more accurate ratcheting prediction.

Author Contributions

Funding

Conflicts of Interest

References

- Varvani-Farahani, A. Fatigue–ratcheting damage assessment of steel samples under asymmetric multiaxial stress cycles. Theor. Appl. Fract. Mech. 2014, 73, 152–160. [Google Scholar] [CrossRef]

- Hamidinejad, S.; Varvani-Farahani, A. Ratcheting assessment of steel samples under various non-proportional loading paths by means of kinematic hardening rules. Mater. Des. 2015, 85, 367–376. [Google Scholar] [CrossRef]

- Mozafari, F. Stress Concentration in Compressor Blades with Pits. Ph.D. Thesis, Universiti Teknologi Malaysia, Skudai, Malaysia, 2014. [Google Scholar]

- Foroutan, M.; Ahmadzadeh, G.; Varvani-Farahani, A. Axial and hoop ratcheting assessment in pressurized steel elbow pipes subjected to bending cycles. Thin-Walled Struct. 2018, 123, 317–323. [Google Scholar] [CrossRef]

- Dalla Palma, M. Modelling of cyclic plasticity for austenitic stainless steels 304L, 316L, 316L (N)-IG. Fusion Eng. Des. 2016, 109, 20–25. [Google Scholar] [CrossRef]

- Ahmadzadeh, G.; Varvani-Farahani, A. Ratcheting assessment of steel alloys under step-loading conditions. Mater. Des. 2013, 51, 231–241. [Google Scholar] [CrossRef]

- Lee, C.-H.; Chang, K.-H.; Van Do, V.N. Numerical investigation on the ratcheting behavior of pressurized stainless steel pipes under cyclic in-plane bending. Mar. Struct. 2016, 49, 224–238. [Google Scholar] [CrossRef]

- Mohanty, S.; Soppet, W.K.; Majumdar, S.; Natesan, K. Chaboche-based cyclic material hardening models for 316 SS–316 SS weld under in-air and pressurized water reactor water conditions. Nucl. Eng. Des. 2016, 305, 524–530. [Google Scholar] [CrossRef]

- Ravikiran, A.; Dubey, P.; Agrawal, M.; Reddy, G.; Singh, R.; Vaze, K. Experimental and numerical studies of ratcheting in a pressurized piping system under seismic load. J. Press. Vessel Technol. 2015, 137, 031011. [Google Scholar] [CrossRef]

- Shen, J.; Chen, H.; Liu, Y. A new four-dimensional ratcheting boundary: Derivation and numerical validation. Eur. J. Mech.-A/Solids 2018, 71, 101–112. [Google Scholar] [CrossRef] [Green Version]

- Bari, S.; Hassan, T. Anatomy of coupled constitutive models for ratcheting simulation. Int. J. Plast. 2000, 16, 381–409. [Google Scholar] [CrossRef]

- Chaboche, J.-L. On some modifications of kinematic hardening to improve the description of ratchetting effects. Int. J. Plast. 1991, 7, 661–678. [Google Scholar] [CrossRef]

- Chen, X.; Chen, X.; Yu, D.; Gao, B. Recent progresses in experimental investigation and finite element analysis of ratcheting in pressurized piping. Int. J. Press. Vessels Pip. 2013, 101, 113–142. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Pezeshki-Najafabadi, S.; Badnava, H. Parameter determination of Chaboche kinematic hardening model using a multi objective Genetic Algorithm. Comput. Mater. Sci. 2011, 50, 1114–1122. [Google Scholar] [CrossRef]

- Rojíček, J.; Halama, R. Numerical simulations of pipeline bending tests. Appl. Comput. Mech. 2008, 2, 347–356. [Google Scholar]

- Shojaei, A.; Eslami, M.; Mahbadi, H. Cyclic loading of beams based on the Chaboche model. Int. J. Mech. Mater. Des. 2010, 6, 217–228. [Google Scholar] [CrossRef]

- Ramezansefat, H.; Shahbeyk, S. The Chaboche hardening rule: A re-evaluation of calibration procedures and a modified rule with an evolving material parameter. Mech. Res. Commun. 2015, 69, 150–158. [Google Scholar] [CrossRef]

- Rojicek, J. Identification of material parameters by FEM. Mod. Mach. Sci. J. 2010, 2, 185–188. [Google Scholar]

- Abdel-Karim, M.; Ohno, N. Kinematic hardening model suitable for ratchetting with steady-state. Int. J. Plast. 2000, 16, 225–240. [Google Scholar] [CrossRef]

- Ohno, N.; Wang, J.-D. Kinematic hardening rules with critical state of dynamic recovery, part I: Formulation and basic features for ratchetting behavior. Int. J. Plast. 1993, 9, 375–390. [Google Scholar] [CrossRef]

- Halama, R.; Poruba, Z. Tangent modulus in numerical integration of constitutive relations and its influence on convergence of NR method. Appl. Comput. Mech. 2009, 3, 27–38. [Google Scholar]

- Kalnins, A.; Rudolph, J.; Willuweit, A. Using the nonlinear kinematic hardening material model of Chaboche for elastic–plastic ratcheting analysis. J. Press. Vessel Technol. 2015, 137, 031006. [Google Scholar] [CrossRef]

- Bari, S.; Hassan, T. Kinematic hardening rules in uncoupled modeling for multiaxial ratcheting simulation. Int. J. Plast. 2001, 17, 885–905. [Google Scholar] [CrossRef]

- Bari, S.; Hassan, T. An advancement in cyclic plasticity modeling for multiaxial ratcheting simulation. Int. J. Plast. 2002, 18, 873–894. [Google Scholar] [CrossRef]

- Rahman, S.M. Finite Element Analysis and Related Numerical Schemes for Ratcheting Simulation. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2006. [Google Scholar]

- Rahman, S.M.; Hassan, T.; Corona, E. Evaluation of cyclic plasticity models in ratcheting simulation of straight pipes under cyclic bending and steady internal pressure. Int. J. Plast. 2008, 24, 1756–1791. [Google Scholar] [CrossRef]

- Mozafari, F.; Thamburaja, P.; Srinivasa, A.; Moslemi, N. A rate independent inelasticity model with smooth transition for unifying low-cycle to high-cycle fatigue life prediction. Int. J. Mech. Sci. 2019, 159, 325–335. [Google Scholar] [CrossRef]

- Abdel-Karim, M. Effect of elastic modulus variation during plastic deformation on uniaxial and multiaxial ratchetting simulations. Eur. J. Mech.-A/Solids 2011, 30, 11–21. [Google Scholar] [CrossRef]

- Code, P.V. Section VIII Division 1. In UG-126 Pressure Relief Valves to UG-129 Marking; American Society of Mechanical Engineers (ASME) International: New York, NY, USA, 2010; Division 1-Subsection NB, 3228.4(b). [Google Scholar]

- Zhou, J.; Sun, Z.; Kanouté, P.; Retraint, D. Experimental analysis and constitutive modelling of cyclic behaviour of 316L steels including hardening/softening and strain range memory effect in LCF regime. Int. J. Plast. 2018, 107, 54–78. [Google Scholar] [CrossRef]

- Jiao, R.; Kyriakides, S. Ratcheting, wrinkling and collapse of tubes under axial cycling. Int. J. Solids Struct. 2009, 46, 2856–2870. [Google Scholar] [CrossRef] [Green Version]

- Jiao, R.; Kyriakides, S. Ratcheting and wrinkling of tubes due to axial cycling under internal pressure: Part I experiments. Int. J. Solids Struct. 2011, 48, 2814–2826. [Google Scholar] [CrossRef]

- Paquette, J.; Kyriakides, S. Plastic buckling of tubes under axial compression and internal pressure. Int. J. Mech. Sci. 2006, 48, 855–867. [Google Scholar] [CrossRef]

- Portier, L.; Calloch, S.; Marquis, D.; Geyer, P. Ratchetting under tension–torsion loadings: Experiments and modelling. Int. J. Plast. 2000, 16, 303–335. [Google Scholar] [CrossRef]

- Taleb, L. About the cyclic accumulation of the inelastic strain observed in metals subjected to cyclic stress control. Int. J. Plast. 2013, 43, 1–19. [Google Scholar] [CrossRef]

- Yoshida, F.; Uemori, T.; Fujiwara, K. Elastic–plastic behavior of steel sheets under in-plane cyclic tension–compression at large strain. Int. J. Plast. 2002, 18, 633–659. [Google Scholar] [CrossRef]

- Kang, G.; Ohno, N.; Nebu, A. Constitutive modeling of strain range dependent cyclic hardening. Int. J. Plast. 2003, 19, 1801–1819. [Google Scholar] [CrossRef]

- Dong, Y.; Kang, G.; Yu, C. A dislocation-based cyclic polycrystalline visco-plastic constitutive model for ratchetting of metals with face-centered cubic crystal structure. Comput. Mater. Sci. 2014, 91, 75–82. [Google Scholar] [CrossRef]

- Zhu, Y.; Kang, G.; Yu, C. A finite cyclic elasto-plastic constitutive model to improve the description of cyclic stress-strain hysteresis loops. Int. J. Plast. 2017, 95, 191–215. [Google Scholar] [CrossRef]

- Chaboche, J.-L. Time-independent constitutive theories for cyclic plasticity. Int. J. Plast. 1986, 2, 149–188. [Google Scholar] [CrossRef]

- Agius, D.; Kajtaz, M.; Kourousis, K.I.; Wallbrink, C.; Wang, C.H.; Hu, W.; Silva, J. Sensitivity and optimisation of the Chaboche plasticity model parameters in strain-life fatigue predictions. Mater. Des. 2017, 118, 107–121. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, J. Particle swarm optimization. In Encyclopedia of Machine Learning; Springer: Berlin/Heidelberg, Germany, 2011; pp. 760–766. [Google Scholar]

| C | Mn | P | Co | Si | Cr | Ni | Mo | Ti | Al | V | Zr | N | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0314 | 1.53 | 0.0378 | 0.373 | 0.365 | 16.4 | 11.4 | 2.14 | 0.007 | 0.004 | 0.074 | 0.018 | 0.104 | 0.01 |

| E (GPa) | ||

|---|---|---|

| 264 | 601 | 172 |

| Type | PSO Method | GA Method |

|---|---|---|

| 296870, 17958, 2118, 20508 | 300871, 25155, 2118, 14182 | |

| 21179, 335, 0, 1196 | 21803, 402, 0, 1903 | |

| Optimization Time (s) | 617 | 721 |

| MSE | 0.325 | 0.691 |

| Type | Set A | Set B | Set C | Set D |

|---|---|---|---|---|

| 2446600, 12207, 2118, 24246 | 296870, 17958, 2118, 20508 | 140520, 29589, 2118, 31040 | 140220, 16725, 2118, 15818 | |

| 27439, 291, 0, 796 | 21179, 335, 0, 1196 | 4471, 899, 0, 325 | 47864, 282, 0, 732 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moslemi, N.; Gol Zardian, M.; Ayob, A.; Redzuan, N.; Rhee, S. Evaluation of Sensitivity and Calibration of the Chaboche Kinematic Hardening Model Parameters for Numerical Ratcheting Simulation. Appl. Sci. 2019, 9, 2578. https://doi.org/10.3390/app9122578

Moslemi N, Gol Zardian M, Ayob A, Redzuan N, Rhee S. Evaluation of Sensitivity and Calibration of the Chaboche Kinematic Hardening Model Parameters for Numerical Ratcheting Simulation. Applied Sciences. 2019; 9(12):2578. https://doi.org/10.3390/app9122578

Chicago/Turabian StyleMoslemi, Navid, Mohsen Gol Zardian, Amran Ayob, Norizah Redzuan, and Sehun Rhee. 2019. "Evaluation of Sensitivity and Calibration of the Chaboche Kinematic Hardening Model Parameters for Numerical Ratcheting Simulation" Applied Sciences 9, no. 12: 2578. https://doi.org/10.3390/app9122578