1. Introduction

Algae show continuous growth at minimum environmental requirements and irrespective of seasons [

1]. Water, inorganic carbon, solar radiation and nutrients such as nitrogen(N), phosphorus (P) and potassium (K), temperature and pH are necessary for the growth of algae. Availability of nutrients is the most important factor for growing algae.

Chlorella spp. and

Scenedesmus spp. are the fastest-growing microalgae, and are rich in valuable constituents that can be used later for the production of many valuable products, e.g., food, pharmaceuticals, feed for animals, biofuels, bioplastics.

Chlorella vulgaris can be grown in autotrophic as well as heterotrophic conditions [

2].

C. vulgaris is known as one of the most useful microalgae with many potential applications, e.g., the high ability to remove pollutants [

3].

Algae can be cultivated in open ponds or closed systems in fresh or marine water. Algae could be cultivated in suspension in the solution or immobilized on alginate beads. Immobilization helps to achieve more density of algal cells as well, as it is easier to harvest immobilized algal biomass from wastewater. There are several chemical and organic substances that can be used for immobilization of algal cells, e.g., polyacrylamide gel, alginians, agar, carragens [

4].

The main challenge during cultivation of microalgae is utilization of fresh water and availability of nutrients. Wastewater—prior to being discharged to the sewage systems or recycled in industrial processes—has to be treated to reduce the load of contaminants. Microalgae can grow in N-rich wastewater and can assimilate ammonium nitrogen for biomass growth. The optimum concentration of nitrogen in the environment that can be assimilated by the most of the algal species is from 5 to 50 millimoles [

4]. Different microalgal species can utilize different quantities of nitrogen and phosphorus, e.g.,

Chlorella vulgaris has 8.5% of nitrogen in dry mass [

5,

6].

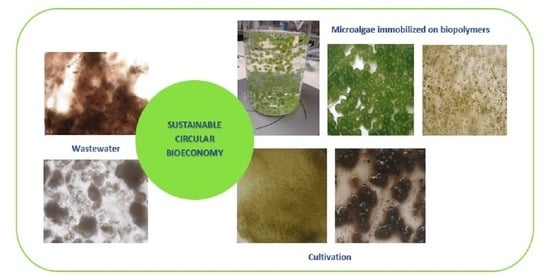

The Circular Economy addresses the benefits to the environment, economy and society. Nowadays, there is an urgent need for providing technological solutions that can adopt the principles of the circular economy—eliminate as much as possible of wastes and pollution, circulate products and materials and regenerate nature. Sustainable circular bioeconomy is an element of the circular economy that is connected to all processes, products and technologies that are “bio”, and aims at sustainability.

Sources of clean water are limited, industrial wastewaters are available, and utilization of biomass as a renewable energy source is increasing; therefore, wastewater could be used as a medium for production of biomass. Such an approach is directly connected to a sustainable circular bioeconomy, because biomass production in an environmentally friendly way in wastewater could be one of the solutions.

Industrial wastewater is usually characterized by many contaminants that are toxic to the environment and human health. Therefore, using industrial wastewater for cultivation of microalgae has not been previously investigated.

The main aim of the present study is highly innovative and was to assess the possibility of cultivating C. vulgaris and S. armatus when suspended and immobilized on carriers in industrial wastewater with high concentrations of inorganic and organic contaminants. Microalgae was immobilized on alginate beads that are biopolimers made of algal extracts.

There is no doubt that the results of these investigations are connected to sustainable development and can bring benefits to the environment, economy and society by fullfilling the sustainable circular bioeconomy principles.

3. Results

3.1. Batch Culture Cultivation Techniques of Microalgae

The oxygen concentration is an important factor for the indication of cell activity. Oxygen in water and wastewater comes mainly from the atmosphere and from the process of photosynthesis by aquatic plants.

Figure 1 presents the oxygen concentration changes with time during the cultivation of

C. vulgaris and

S. armatus in wastewater.

The oxygen concentration was rather low because the wastewater was heavily contaminated with several contaminants. In the initial period of research, the concentration of dissolved oxygen decreased in the control samples (C). These phenomena can be influenced by other reactions (e.g., nitrification) besides algal growth that took place in wastewater. From thirty days until eighty days dissolved oxygen concentration remained relatively constant, and on day one hundred the maximum value of 4.1 mg/L was reached.

Oxygen concentrations varied in the samples of wastewater with algae. In the wastewater with the addition of C. vulgaris microalgae, the oxygen concentrations reached the maximum values ranging from 4.2 to 4.4 mg/L. In the samples containing S. armatus, oxygen concentrations reached the maximum values ranging from 4.4 to 4.8 mg/L.

Figure 2 presents the chlorophyll-a concentration changes with time during the cultivation of

C. vulgaris and

S. armatus in wastewater.

The contaminants contained in the wastewater affected the duration of individual growth phases of the microalgae population. The analysis of the individual growth phases of microalgae (based on changes in chlorophyll-a) revealed that for the concentration of microalgae of 100 g/L, the logarithmic growth phase began after ten days and lasted for the next thirty days. The following phases of microalgae population growth were observed: lag, exponential (logarithmic) growth, stationary and death phase. However, in the samples containing S. armatus microalgae, the death phase began by the fiftieth day, which can be explained by the lower resistance of this species of algae, compared to C. vulgaris, and to the contaminants contained in the wastewater. Furthermore, in the case of microalgae C. vulgaris, after completion of the stationary phase (from 40 to 50 days) the phase of a very slow logarithmic growth started and lasted until the end of the research.

It can be concluded that industrial wastewater with high ammonium concentrations can be used to cultivate microalgal biomass of C. vulgaris and S. armatus species.

Figure 3 presents changes in pH values with time during cultivation of

C. vulgaris. and

S. armatus in wastewater.

Initially, a high pH above 9 was unfavourable for the growth of the population of microalgae and the assimilation of ammonium nitrogen. At high pH values, the form of NH3 has a higher proportion, which is less preferred by microalgae, and at a pH of ~7 the content of nitrogen in the form of N-NH4+, which is more easily assimilated by algae, is >95%.

Regardless of the type of sorbents and their concentration, there was a gradual decrease in the pH value during the tests, from the initial values in the range of pH = 9.1–9.3 to the final pH values of 7.3–8.0. In the control sample (C), pH was in the range of 8.1–9.2.

The analysis of the obtained test results shows that the use of algal biomass as a sorbent had a significant effect on the reduction in con N-NH4+ concentration in wastewater.

When microalgae were used at a dose of 100 g/L, the concentration of ammonium nitrogen in the wastewater decreased to 110 mgN-NH4+/L after sixty days, and to 20 mgN-NH4+/L after eighty days. Microalgae used in the dose of 50 g/L (sample 5Cv) on the sixtieth day lowered the concentration of ammoniacal nitrogen to the level of 187 mgN-NH4+/L, and on the eightieth day to the level of about 19 mgN-NH4+/L. Finally, it was reached 4 mgN-NH4+/L on the hundredth day for all samples.

3.2. Repeated Fed-Batch Culture Cultivation Techniques of Microalgae

Figure 4 presents changes in oxygen concentration during the cultivation of

C. vulgaris and

S. armatus in wastewater. The observed concentrations of dissolved oxygen reflected the photosynthesis process. During the first 18 days, there was a decrease in the dissolved oxygen content in wastewater, from the initial value ranging from 8.8 mg/L to 11.9 mg/L to the final values of 4.9–6.3 mg/L. This is related to the process of microalgae adaptation to the new wastewater environment. The increase in the dissolved oxygen concentration observed from day 24, indicated the beginning of the logarithmic growth phase.

From the thirtieth day after replacing the last portion of wastewater the dissolved oxygen concentration began to decrease in all samples, reaching the lowest values in the range of 3.3–6.3 mg/L observed in the last days. This was unfavourable for microalgae breeding.

In the control sample (C), changes in the concentration of oxygen dissolved in wastewater from the beginning to the 28th day were similar to those observed in other samples. The concentration changed from 8.8 mg/L on the first day to 3.0 mg/L on the last day.

Figure 5 presents changes in chlorophyll-a concentration during cultivation of

C. vulgaris and

S. armatus in wastewater. The initial concentration of chlorophyll-a in wastewater at the first day was ca. 5.0 mg/L (

Figure 5). In the following days, a decrease was observed in the concentration of chlorophyll-a that lasted, depending on the sample, to the eighth or twelfth day. This could be due to the adaptation of microalgae to new environmental conditions.

The fluctuations of chlorophyll-a concentration were observed in all samples (every ten days). In samples with microalgae suspended in solution, regardless of the dose of microalgae, chlorophyll-a production was higher than in wastewater with the addition of microalgae immobilized on alginate beads. This can be explained by the fact that the immobilized microalgae had a limited access to light, which is a key factor in the production of chlorophyll-a.

After replacing the wastewater, the highest concentration of chlorophyll-a reached 4.8 mg/L on the 24th day in the sample with C. vulgaris suspended in the solution. In the sample with S. armatus microalgae suspended in the solution, and the highest concentration of chlorophyll-a was 4.9 mg/L, also on the 24th day. In the wastewater contained immobilized microalgae, the highest concentration of chlorophyll-a was at the level of 2.6 mg/L after 28 days in samples with C. vulgaris and 1.3 mg/L in samples with S. armatus.

In the last days of the experiment, chlorophyll-a concentration in the samples with C. vulgaris immobilized ranged from 1.2 to 2.5 mg/L, whereas in the samples with S. armatus it ranged from 0.7 to 1.0 mg/L. In the samples of C. vulgaris microalgae in a suspended form, the concentration of chlorophyll-a was from 2.8 to 4.4 mg/L, whereas for S. armatus this was in the range from 3.5 to 4.2 mg/L.

The growth phases of microalgae from

C. vulgaris and

S. armatus showed similar trends throughout the range studied.

Figure 6 presents changes in pH values with time during cultivation of

C. vulgaris and

S. armatus.

The analysis of the data presented in

Figure 6 indicated that over time the pH value of wastewater decreased in all samples, from the initial values in the range of pH = 7.8–8.4 to the final values of pH ranging from 6.7 to 7.6. Similarly, to the tests carried out under static conditions, the fluctuation of the pH value was observed in dynamic conditions due to the ongoing metabolic processes in algal cells. The three-time exchange of wastewater portions for raw wastewater led to fluctuations in wastewater pH values, which is illustrated by the increases and decreases in the pH values.

In wastewater samples with the addition of immobilized microalgae N-NH4+, concentrations were lower over the entire time range from those determined in samples of wastewater with a suspension of microalgae. On day 10, ammonium nitrogen concentrations in wastewater were 59 and 95 mg N-NH4+/L in samples with microalgae in the immobilized form (B samples), and 76 and 97 mg N-NH4+/L with microalgae in the form of suspension (A samples). On day 40 ammonium nitrogen concentrations were 158 and 194 mg N-NH4+/L in samples with microalgae in the immobilized form, and 205 and 216 mg N-NH4+/L in samples with microalgae in the form of a suspension.

The microalgal cells were effectively immobilized on alginate beads (

Figure 7).

The natural polysaccharide was a good carrier medium for microalgae. Microscopic images confirmed a higher density of cells immobilized on alginate beads (

Figure 8).

Immobilized microalgae cells were less exposed to damage due to the turbulence caused by the mixing process compared to cells slowly suspended in the wastewater solution. Before the experiment, the number of microalgal cells immobilized on alginate beads was smaller than after the experiment.

Figure 9 shows numerical values of cells of

C. vulgaris and

S. armatus in wastewater.

Biomass concentration increased gradually. A higher increase in biomass concentration was observed at the lower initial concentration of S. armatus biomass in the sample with microalgae 5ScB, compared to the samples where the initial biomass concentration was higher.

The calculated results of the microalgal growth rate are shown in

Table 1. Suspended microalgae showed higher biomass growth than when immobilized on alginate beads.

4. Discussion

The changes in parameters such as dissolved oxygen, chlorophyll-a, pH, results of a microscopic analysis of cells, assessment of population growth and biomass growth rate have shown that industrial wastewater with high concentrations of N-NH4+ can be used as a growth medium for cultivation of C. vulgaris and S. armatus.

Oxygen is an important parameter for the growth of microalgae and can be used as an indicator of ongoing photosynthesis. Like other photosynthetic organisms,

C. vulgaris and

S. armatus release oxygen into the environment [

10,

11,

12]. Measures of the metabolic processes in microalgae cells include both the ability to produce oxygen and the level of its production. Low quantity of CO

2 supplied during 6 h/d influenced the low production of biomass, and as a result, low production of oxygen by algae. Oxygen which was generated during photosynthesis indicated the possibility of using wastewater with high concentrations of N-NH

4+ as a growth medium for

C. vulgaris and

S. armatus, and also promoted wastewater treatment processes.

The photosynthetic activity of microalgae, measured by the volume of released oxygen, increased when the pH value decreased. Alyabyev et al. [

13], showed a similar effect of pH on the photosynthetic activity of

Chlorella vulgaris and

Dunaliella maritima species.

Different forms of nitrogen may be present in wastewater, such as nitrates (V), nitrates (III) and ammonium nitrogen. Algae can assimilate ammonium nitrogen from the environment [

14]. The initial stage of assimilation of ammonium nitrogen is biosorption on the surface of microalgal cells [

7]. The effect of oxygen on the transformation of nitrogen forms has been broadly described in the literature. Zamorska and Papciak [

15] showed that at least 3.4 g of oxygen is needed to oxidize 1 g of ammonium nitrogen to nitrates (III), and 1.1 g of oxygen is used to oxidize 1 g of ammonium nitrogen to nitrates (V).

Nitrification, for which favourable pH values range from 7.2 to 9.0 [

16], is of little importance in processes leading to photosynthetic assimilation of nitrogen compounds by microalgae biomass [

17].

According to the literature, the minimum oxygen concentration necessary for the nitrification process should be 1.5–2.0 mg/L. Lower values of oxygen may cause incomplete oxidation of ammonium nitrogen to nitrates (V) [

16]. During the present research, oxygen concentrations below these values were found only on days 10 and 20 in wastewater, regardless of the microalgae concentration. In wastewater with the addition of microalgae, after the adaptation phase, the amount of oxygen produced by microalgae gradually increased to 4.2 mg/L and at the same time the ammonium nitrogen concentration decreased.

Pollutants in the environment (wastewater, effluents from fertilized areas) strongly affect the content of photosynthetic pigments in algae cells, and therefore, chlorophylls-a and b are the best markers of water quality [

18]. Janukowicz [

19] analyzed the concentration of chlorophyll-a of planktonic algae of the Szczecin Lagoon. According to his research, the average annual concentration of chlorophyll-a in Lake Nowowarpieńskie was 0.01625 mg/L [

19]. In the present study, the concentration values of photosynthetic pigments obtained were higher, which proves the stimulating effect of coke wastewater on chlorophyll-a concentration in microalgae species. This could be due to the high turbidity of the wastewater, which limited the access of solar radiation and microalgae were forced to increase the production of photosynthetic pigments to meet the energy demand.

The pH values obtained during the tests (6.7–7.8) were close to the optimal range for the growth of

C. vulgaris, which ranges from pH 6.0 to 9.0 [

20]. During the experiment, the gradual decrease in the pH value was consistent with the results obtained by Tam and Wong [

21], who found lower pH values during the logarithmic growth phase, when photosynthesis takes place most intensively, and higher pH values in the lag and stationary phases.

It should be emphasized that too high pH values may have unfavourable influence on algal cells at the biochemical level. Mayo [

22] showed that at pH> 9, the sugar metabolism in

C. vulgaris microalgae can be disturbed.

Algae can be cultured using phototrophic, mixotrophic or heterotrophic nutrition.

C. vulgaris can be grown using both auto- and heterotrophic nutrition. It has been shown that this species can grow in the presence of light and CO

2, or in the dark when an external source of organic carbon is supplied [

23]. This particular property allows the growth of this species of algae in wastewater with significant turbidity and limited access to light [

24]. The assimilation of organic compounds will take place in both mixed conditions, in light and in heterotrophic conditions, in the dark [

21].

The volatile fatty acids contained in wastewater could be a source of carbon for microalgae. C. vulgaris is a species extremely resistant to toxic substances present in the environment (e.g., phenols). Therefore, it can be used for treatment of wastewater with the content of toxic compounds. S. armatus is more sensitive than C. vulgaris to toxic substances present in the environment. This illustrates the observed changes in the growth phases of the microalgae population for both cultures.

The results are consistent with Tam and Wong [

21], who studied the effect of NH

3-N on the growth of microalgae

C. vulgaris in the range of concentrations from 10 to 1000 mg/L. The researchers observed that the higher the initial concentration of NH

3-N, the faster decrease in pH [

21].

Nitrogen transformation in wastewater influenced the growth of microalgae biomass. According to Li et al. [

25] the dynamics of growth of

Scenedesmus spp. LX1 depends on the form of nitrogen and decreases according to the formula of NH

4+-N> urea> NO

3-N. Researchers observed that when nitrate (V) or urea was in the environment, there was a steady increase in microalgae biomass whereas nitrogen was removed in 90% and phosphorus in 100%. When the source of nitrogen was ammonium ions, the growth of microalgae biomass was lower due to release of H

+ ions, which acidified the environment and then only 31.3% of nitrogen and 76.4% of phosphorus were removed [

25].

Kim et al. [

26] observed that when ammonia is the only source of nitrogen in the environment it causes a rapid decrease in pH, which in turn adversely affects the growth of microalgae. The authors observed that the concentration of ammonia of 330 mg/L caused inhibition of approx. 50% of

C. vulgaris cells. The growth of

C. vulgaris was inhibited at pH = 8–9, or at a concentration of ammonia of 700 mg/L. These studies proved that the concentration of ammonia and the pH of the environment are the most important factors affecting the growth of microalgae [

26].

Numerous authors have shown that different species of microalgae react differently to the nitrogen content in the environment. Velichkova et al. [

27] investigated the growth of

S. dimorphus in the presence of nitrogen compounds, where they obtained biomass concentration values ranging from 0.1116 g/L to 0.920 g/L, revealing a stimulating influence of nitrogen compounds on the growth of microalgae biomass. Kim et al. [

26] found that when ammonia concentration was 84 mg/L and the pH value was 4, the growth of

C. protothecodis was limited and the population did not show a logarithmic growth phase [

26]. Furthermore, Tam and Wong [

21] showed that at low nitrogen concentrations, chlorophyll-a synthesis by

C. vulgaris was limited, indicating that the factor limiting the synthesis was low nitrogen concentration.

In studies conducted under dynamic conditions, the initial cell number was 3.6 × 106 cells/L. The use of the carrier for immobilizing the cells was because immobilized microalgae cells were less exposed to damage due to turbulence caused by the mixing process than cells suspended in wastewater and the easier separation processes. The obtained microscopic images confirmed a higher density of microalgae immobilized on alginate beads compared to cells in the form of a suspension. Calculated growth rates of algal biomass (μ) indicated that the inverse relationship and growth rate in the form of suspended microalgae was higher than the growth of microalgae immobilized on alginate beads.

The growth rate of microalgae in the samples at a dose of 100 g/L of microalgae was: 2.3 ± 0.01 d

−1 (10CvA sample); 3.8 ± 0.03 d

−1 (10CvB); 2.2 ± 0.02 d

−1 (sample 10ScA) and 4.0 ± 0.06 d

−1 (sample 10ScB). In the samples with dose of 50 g/L of microalgae the growth rate (μ) was in the order of: 1.2 ± 0.01 d

−1 (sample 5CvA); 2.2 ± 0.02 d

−1 (sample 5CvB); 1.3 ± 0.02 d

−1 (sample 5SCA) and 2.4 ± 0.05 d

−1 (sample 5ScB). This can be explained by the fact that when microorganisms are immobilized on alginate beads, then there is a limitation of diffusion associated with the rate of penetration of the substrate into the flocks or the carrier. This is described by the Monod constant

Km characterizing the affinity of the substrate for microorganisms, with its value depending on the growth of microorganisms and the susceptibility of compounds to decomposition. The constant

Km is higher when microorganisms grow in aggregates, and lower when they occur in a dispersed form in solution [

28].

Silva-Benavides and Torzillo [

7] conducted research on the cultivation of

C. vulgaris in municipal wastewater. The authors found that the growth rate of biomass cultivated in the form of a suspension was 30.5 mg/Ld with PAR 20 μmol/m

2s light and biomass growth rate of 42.1 mg/Ld, with a lighting of 60 μmol/m

2s. The author of the present work used monoculture and industrial wastewater with high ammonium nitrogen concentrations, which led to the differences in the rate of biomass growth due to different physico–chemical composition of wastewater.

The experiments were carried out during the day at 29 °C, which was beneficial for the growth of microalgae. According to the literature, the range of optimal temperatures for the growth of

S. armatus microalgae is 20–40 °C, whereas for

C. vulgaris it is 25–30 °C, with the best biomass growth at 30 °C [

27]. Higher temperatures accelerate the diffusion of substrates into microbial cells [

29]. Cassidy [

29] showed that higher temperatures increase the phosphorus content in the microalgae biomass. Moreover, with the temperature rising the rate of nitrification increases [

16].

The present research proved that it is possible to use industrial wastewater for cultivation of microalgae C. vulgaris and S. armatus, in batch and repeated fed-batch culture technique, suspended in the solution or immobilized on alginate biopolymers. The present investigations fulfill the principles of the sustainable circular bioeconomy by helping to reduce resource consumption and contaminants emissions to the environment.

The microalgae could be used for wastewater remediation, biomass production, and water quality control [

30]. They could utilize wastewater as an inorganic nutrient source or production of biofuel [

31]. Mixed bacteria–microalgae cultures are found in high-rate algal ponds (HRAPs) to treat wastewaters (e.g., municipal, industrial, agricultural) [

32]. The microalgae–bacteria consortium could be used for industrial wastewater treatment. The removal of organic matter and nutrients could be achieved as well as the utilization of algal biomass for producing several products [

33]. Microalgae-bacteria consortium can utilise both organic nitrogen (such as urea) and inorganic nitrogen (in the form of ammonium/ammonia) as well as nitrite and nitrates. The microalgae–bacteria consortium into wastewater treatment helps the generation of O

2 through photosynthesis, necessary for heterotrophic bacteria to biodegrade carbonaceous materials. During the microalgae–bacteria consortium treatment processes a greenhouse gas emission rate is lowering, because the majority of N is assimilated by the microalgae–bacteria consortium instead of being converted to oxides of nitrogen [

34]. The algae could be used for water and wastewater treatment, as feedstock for producing biofuels, food, cosmetics, pharmaceuticals, fertilizers and also could be used as feed for animals [

35].