System Development for Diffusion Bonding of Multiple Unit Tubes to Produce Long Tubular Tungsten Heavy Alloys

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Fabrication of Unit Tubes

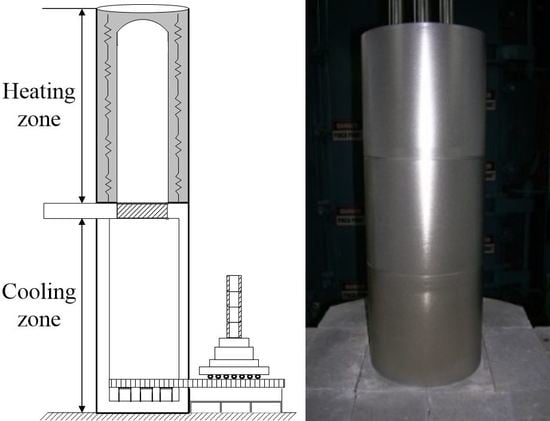

2.2. System Design to Fabricate Long Tubular Products

3. Results and Discussion

3.1. System Development to Fabricate Long Tubular Products

3.2. Fabrication of Long Tubular Products

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pathak, A.; Panchal, A.; Nandy, T.K.; Singh, A.K. Ternary W-Ni-Fe tungsten heavy alloys: A first principles and experimental investigations. Int. J. Refract. Met. Hard Mater. 2018, 75, 43–49. [Google Scholar] [CrossRef]

- Panchal, A.; Nandy, T.K. Effect of composition, heat treatment and deformation on mechanical properties of tungsten heavy alloys. Mater. Sci. Eng. A 2018, 733, 374–384. [Google Scholar] [CrossRef]

- Tehrani, M.S.; Naeini, H.M.; Hartley, P.; Khademizadeh, H. Localized edge buckling in cold roll-forming of circular tube section. J. Mater. Process. Technol. 2006, 177, 617–620. [Google Scholar] [CrossRef]

- Moon, Y.H.; Kim, D.W.; Van Tyne, C.J. Analytical model for prediction of sidewall curl during stretch-bend sheet metal forming. Int. J. Mech. Sci. 2008, 50, 666–675. [Google Scholar] [CrossRef]

- Yi, H.K.; Kim, D.W.; Van Tyne, C.J.; Moon, Y.H. Analytical prediction of springback based on residual differential strain during sheet metal bending. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 117–129. [Google Scholar] [CrossRef]

- Chen, W.; Jiang, J.; Li, D.; Zou, T.; Peng, Y. Flower pattern and roll positioning design for the cage roll forming process of ERW pipes. J. Mater. Process. Technol. 2019, 264, 295–312. [Google Scholar] [CrossRef]

- Wang, F.J.; Shuang, Y.H.; Hu, J.H.; Wang, Q.H.; Sun, J.C. Explorative study of tandem skew rolling process for producing seamless steel tubes. J. Mater. Process. Technol. 2014, 214, 1597–1604. [Google Scholar] [CrossRef]

- Kim, S.Y.; Joo, B.D.; Shin, S.; Van Tyne, C.J.; Moon, Y.H. Discrete layer hydroforming of three-layered tubes. Int. J. Mach. Tools Manuf. 2013, 68, 56–62. [Google Scholar] [CrossRef]

- Han, S.; Woo, Y.; Hwang, T.; Oh, I.; Moon, Y.H. Tailor layered tube hydroforming for fabricating tubular parts with dissimilar thickness. Int. J. Mach. Tools Manuf. 2019, 138, 51–65. [Google Scholar] [CrossRef]

- Yi, H.K.; Pavlina, E.J.; Van Tyne, C.J.; Moon, Y.H. Application of a combined heating system for the warm hydroforming of lightweight alloy tubes. J. Mater. Process. Technol. 2008, 203, 532–536. [Google Scholar] [CrossRef]

- Park, J.Y.; Han, S.W.; Jeong, H.S.; Cho, J.R.; Moon, Y.H. Advanced sealing system to prevent leakage in hydroforming. J. Mater. Process. Technol. 2017, 247, 103–110. [Google Scholar] [CrossRef]

- Rajiv, S.; Sundaram, K.S.; Narendran, C. Finite element analysis of electromagnetic compression forming of steel tubes. Procedia Eng. 2012, 38, 2520–2524. [Google Scholar] [CrossRef] [Green Version]

- Park, H.; Kim, D.; Lee, J.; Kim, S.J.; Lee, Y.; Moon, Y.H. Effect of an aluminum driver sheet on the electromagnetic forming of DP780 steel sheet. J. Mater. Process. Technol. 2016, 235, 158–170. [Google Scholar] [CrossRef]

- Nandam, S.R.; Ravikiran, U.; Rao, A.A. Machining of tungsten heavy alloy under cryogenic environment. Procedia Mater. Sci. 2014, 6, 296–303. [Google Scholar] [CrossRef] [Green Version]

- Alvarado-Contreras, J.A.; Olevsky, E.A.; Maximenko, A.L.; German, R.M. A continuum approach for modeling gravitational effects on grain settling and shape distortion during liquid phase sintering of tungsten heavy alloys. Acta Mater. 2014, 65, 176–184. [Google Scholar] [CrossRef]

- Dinçer, O.; Pehlivanoğlu, M.K.; Çalişkan, N.K.; Karakaya, İ.; Kalkanli, A. Processing and microstructural characterization of liquid phase sintered tungsten–nickel–cobalt heavy alloys. Int. J. Refract. Met. Hard Mater. 2015, 50, 106–112. [Google Scholar] [CrossRef]

- Heaney, D.F.; German, R.M.; Ahn, I.S. The gravitational effects on low solid-volume fraction liquid-phase sintering. J. Mech. Sci. 1995, 30, 5808–5812. [Google Scholar] [CrossRef]

- Wu, Y.; German, R.M.; Marx, B.; Bollina, R.; Bell, M. Characteristics of densification and distortion of Ni–Cu liquid-phase sintered tungsten heavy alloy. Mater. Sci. Eng. A 2003, 344, 158–167. [Google Scholar] [CrossRef]

- Park, Z.S.; Lee, S.; Lee, T.; Kim, J.H.; Moon, Y.H. Fabrication of long tubular parts made of tungsten-heavy alloys by inductive bonding of multiple tubes. Int. J. Refract. Met. Hard Mater. 2019, 85, 105058. [Google Scholar] [CrossRef]

- Song, M.C.; Moon, Y.H. Coupled electromagnetic and thermal analysis of induction heating for the forging of marine crankshafts. Appl. Therm. Eng. 2016, 98, 98–109. [Google Scholar] [CrossRef]

- Kim, D.K.; Woo, Y.Y.; Park, K.S.; Sim, W.J.; Moon, Y.H. Advanced induction heating system for hot stamping. Int. J. Adv. Manuf. Technol. Int. 2018, 99, 583–593. [Google Scholar] [CrossRef]

- Jung, H.K.; Kang, C.G.; Moon, Y.H. Induction Heating of Semisolid Billet and Control of Globular Microstructure to Prevent Coarsening Phenomena. J. Mater. Eng. Perform. 2000, 9, 12–23. [Google Scholar] [CrossRef]

- Seo, D.M.; Hwang, T.W.; Moon, Y.H. Carbonitriding of Ti-6Al-4V alloy via laser irradiation of pure graphite powder in nitrogen environment. Surf. Coat. Technol. 2019, 363, 244–254. [Google Scholar] [CrossRef]

- Jang, J.H.; Joo, B.D.; Van Tyne, C.J.; Moon, Y.H. Characterization of deposited layer fabricated by direct laser melting process. Met. Mater. Int. 2013, 19, 497–506. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, G.H.; Chou, K.C. Densification behavior of ultrafine W-Ni-Fe composite powders produced by a two-stage reduction process. Powder Technol. 2020, 360, 430–443. [Google Scholar] [CrossRef]

- Joo, B.D.; Jang, J.H.; Lee, J.H.; Son, Y.M.; Moon, Y.H. Selective laser melting of Fe-Ni-Cr layer on AISI H13 tool steel. Trans. Nonferrous Met. Soc. China 2009, 19, 921–924. [Google Scholar] [CrossRef]

- Park, Z.S.; Han, S.W.; Kim, J.H.; Kim, S.; Moon, Y.H. Manufacture of Tungsten Heavy Alloy Tube by Diffusion Bonding of Semicircular Tubes. J. Mater. Eng. Perform. 2020, 29, 699–711. [Google Scholar] [CrossRef]

- Gurwell, W.E. Solid-State Sintering of Tungsten Heavy Alloys. Mater. Manuf. Process. 1994, 9, 1115–1126. [Google Scholar] [CrossRef]

- Kim, E.S.; Lee, K.H.; Moon, Y.H. A feasibility study of the partial squeeze and vacuum die casting process. J. Mater. Process. Technol. 2000, 105, 42–48. [Google Scholar] [CrossRef]

- Hwang, T.W.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Functionally graded properties in directed-energy-deposition titanium parts. Opt. Laser Technol. 2018, 105, 80–88. [Google Scholar] [CrossRef]

- Jang, J.H.; Lee, J.H.; Joo, B.D.; Moon, Y.H. Flow characteristics of aluminum coated boron steel in hot press forming. Trans. Nonferrous Met. Soc. China 2009, 19, 913–916. [Google Scholar] [CrossRef]

- Hafızoğlu, H.; Durlu, N. Effect of sintering temperature on the high strain rate-deformation of tungsten heavy alloys. Int. J. Impact Eng. 2018, 121, 44–54. [Google Scholar] [CrossRef]

- Park, Z.S.; VanTyne, C.J.; Kim, J.; Hwang, T.W.; Kim, Y.; Moon, Y.H. Die-less manufacturing of tube by diffusion bonding of unit rods made of tungsten heavy alloy. Int. J. Adv. Manuf. Technol. 2020, 106, 1213–1221. [Google Scholar] [CrossRef]

- Li, M.; Ruprecht, D.; Kracker, G.; Höschen, T.; Neu, R. Impact of heat treatment on tensile properties of 97W2Ni1Fe heavy alloy. J. Nucl. Mater. 2018, 512, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Park, Z.S.; Kim, J.; Woo, Y.Y.; Lee, H.; Kim, J.H.; Moon, Y.H. Forced circulation of nitrogen gas for accelerated and eco-friendly cooling of metallic parts. Appl. Sci. 2019, 9, 3679. [Google Scholar] [CrossRef] [Green Version]

| Case | Temp (°C) | Microstructure | Bonding Quality |

|---|---|---|---|

| A | 1427 | Figure 12a,b,c | Bad |

| B | 1438 | Figure 12d,e | Bad |

| C | 1441 | Figure 12f | Acceptable |

| D | 1443 | Figure 12g | Good |

| E | 1454 | Figure 12h,i | Overheat (distortion) |

| Position | Hardness (HRC) | Tensile Properties (ASTM E8M) | |

|---|---|---|---|

| Tensile Strength (kg/mm2) | Elongation (%) | ||

| Bonded Zone | 29.75 | 95.2 | 29.1 |

| Non-bonded base | 29.69 | 95.9 | 28.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, Z.S.; Woo, Y.Y.; Han, S.W.; Oh, I.Y.; Hwang, T.W.; Kim, Y.; Moon, Y.H. System Development for Diffusion Bonding of Multiple Unit Tubes to Produce Long Tubular Tungsten Heavy Alloys. Appl. Sci. 2020, 10, 2988. https://doi.org/10.3390/app10082988

Park ZS, Woo YY, Han SW, Oh IY, Hwang TW, Kim Y, Moon YH. System Development for Diffusion Bonding of Multiple Unit Tubes to Produce Long Tubular Tungsten Heavy Alloys. Applied Sciences. 2020; 10(8):2988. https://doi.org/10.3390/app10082988

Chicago/Turabian StylePark, Zu Seong, Young Yun Woo, Sang Wook Han, Il Yeong Oh, Tae Woo Hwang, Yangjin Kim, and Young Hoon Moon. 2020. "System Development for Diffusion Bonding of Multiple Unit Tubes to Produce Long Tubular Tungsten Heavy Alloys" Applied Sciences 10, no. 8: 2988. https://doi.org/10.3390/app10082988