Efficiency Analysis of Manufacturing Line with Industrial Robots and Human Operators

Abstract

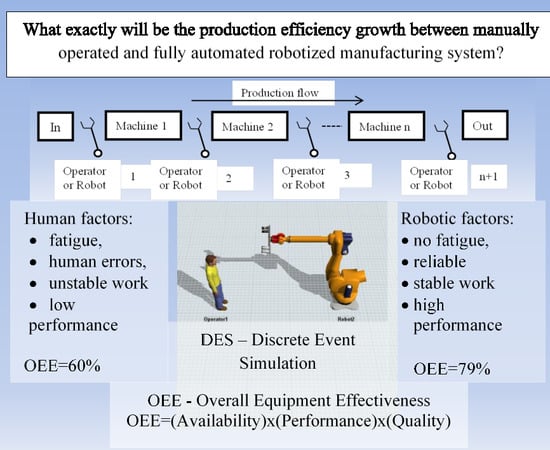

:1. Introduction

2. Problem Definition—Manufacturing Process of Engine Heads

3. Human and Robot Factors Influencing the Production Process

- Over 50% of companies keep records of the robot reliability and safety data;

- In robotic systems, major sources of failure are software failure, human error and circuit board troubles from the users’ point of view;

- The most common range of the experienced MTBF is 500–1000 h;

- Most of the companies need about 1–8 h for the repair of their robots.

4. Work Efficiency and Productivity Evaluation

- Production throughput;

- Manufacturing lead-time (MLT);

- Work in progress (WIP);

- Queue length;

- Mean tardiness and the rate of tardy parts (relative to the number of parts produced on-time);

- Quality of the products;

- Utilization of equipment, which can be described with different metrics including:

- ⚬

- OEE—overall equipment effectiveness;

- ⚬

- OFE—overall factory effectiveness.

Availability and Failures

5. Example—Simulation Models

- Milling process mean time = 450 s;

- Milling machine setup per part = 30 s;

- Drilling = 30 s;

- Automatic deburring = 30 s;

- Hand deburring = 40–50 s;

- Washing = 180 s (capacity 10 parts);

- Flow test = 60 s;

- Leak test = 60 s;

- Inspection = 50 s;

- Load/unload time of human operator = 20–30 s;

- Load/unload time of robot = 5 s;

- Conveyor speed = 1 m/s;

- Quality level: 99% for human operated line, 99.9 % for robot-operated line.

6. Simulation Experiments

7. Industrial Implementation of Robotic Line—Case Study

- Industrial implementation of robotic line had required the following steps:

- Detailed design of manufacturing line and required equipment;

- Purchase of machines and robots;

- Installation of machines and robots;

- Personnel training;

- Machine and robot programming and testing;

- Material delivery and product distribution contracting.

- Material delivery delays;

- Equipment failures (mainly milling machines, the drilling machine and washing station);

- Power supply disturbances;

- Lower working speed;

- Insufficient quality.

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Glaser, A. Industrial Robots; Industrial Press: New York, NY, USA, 2009. [Google Scholar]

- Hägele, M.; Nilsson, K.; Pires, J.N. Industrial Robotics. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Barosz, P.; Gołda, G.; Kampa, A. The Conceptual Design of Flexible Manufacturing System with the Use of Computer Simulation in Enterprise Dynamics. J. Res. Adm. Sci. 2018, 7, 1–6. Available online: http://www.jraspublications.org/index.php/JRAS/article/view/22 (accessed on 20 April 2019).

- Kampa, A.; Gołda, G.; Paprocka, I. Discrete event simulation method as a tool for improvement of manufacturing systems. Computers 2017, 6, 10. [Google Scholar] [CrossRef]

- Gołda, G.; Kampa, A.; Krenczyk, D. The methodology of modeling and simulation of human resources and industrial robots in FlexSim. In FlexSim in Academe: Teaching and Research; Pawlewski, P., Hoffa-Dabrowska, P., Golinska-Dawson, P., Werner-Lewandowska, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 87–99. [Google Scholar] [CrossRef]

- Tulio, T. Design of Flexible Production Systems: Methodologies and Tools; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Banks, J.; Carson, J.S.; Nelson, B.L.; Nicol, D. Discrete-Event System Simulation, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA; New York, NY, USA, 2010. [Google Scholar]

- Renna, P.; Mancusi, V. Controllable processing time policy in job shop manufacturing systems: Design and evaluation by simulation modelling. Int. J. Serv. Oper. Manag. 2017, 27, 366. [Google Scholar] [CrossRef]

- Renna, P.; Ambrico, M. Evaluation of cellular manufacturing configurations in dynamic conditions using simulation. International J. Adv. Manuf. Technol. 2011, 56, 1235–1251. [Google Scholar] [CrossRef]

- Ingemansson, A.; Bolmsjo, G.S. Improved efficiency with production disturbance reduction in manufacturing systems based on discrete-event simulation. J. Manuf. Technol. Manag. 2004, 15, 267–279. [Google Scholar] [CrossRef]

- Burduk, A. Stability Analysis of the Production System Using Simulation Models. In Process Simulation and Optimization in Sustainable Logistics and Manufacturing; Springer: Berlin/Heidelberg, Germany, 2014; pp. 69–83. [Google Scholar]

- Robinson, S. Conceptual modelling for simulation part I: Definition and requirements. J. Oper. Res. Soc. 2008, 59, 278–290. [Google Scholar] [CrossRef] [Green Version]

- Jia, Y.; Tian, H.; Chen, C.; Wang, L. Predicting the availability of production lines by combining simulation and surrogate model. Adv. Prod. Eng. Manag. 2017, 12, 285–295. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Arndt, T.; Lanza, G. A Flexible Simulation Support for Production Planning and Control in Small and Medium Enterprises. Procedia CIRP 2016, 56, 389–394. [Google Scholar] [CrossRef] [Green Version]

- Kasemset, C.; Kachitvichyanukul, V. Simulation-Based Procedure for Bottleneck Identification. In AsiaSim 2007. Communications in Computer and Information Science; Park, J.W., Kim, T.G., Kim, Y.B., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; Volume 5. [Google Scholar]

- Plaia, A.; Lombardo, A.; Lo Nigro, G. Robust Design of Automated Guided Vehicles System in an FMS. In Advanced Manufacturing Systems and Technology; Kuljanic, E., Ed.; Springer: Vienna, Austria, 1996; pp. 259–266. [Google Scholar]

- Azadivar, F.; Wang, J. Facility layout optimization using simulation and genetic algorithms. Int. J. Prod. Res. 2000, 38, 4369–4383. [Google Scholar] [CrossRef]

- Kampa, A. Planning and scheduling of work in robotic manufacturing systems with flexible production. J. Mach. Eng. 2012, 12, 34–44. [Google Scholar]

- Krenczyk, D.; Davidrajuh, R.; Skolud, B. Comparing Two Methodologies for Modeling and Simulation of Discrete-Event Based Automated Warehouses Systems. In Advances in Manufacturing II. Lecture Notes in Mechanical Engineering; Hamrol, A., Kujawińska, A., Barraza, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Zamora-Antuñano, M.A.; Cruz-Salinas, J.; Rodríguez-Reséndiz, J.; González-Gutiérrez, C.A.; Méndez-Lozano, N.; Paredes-García, W.J.; Altamirano-Corro, J.A.; Gaytán-Díaz, J.A. Statistical Analysis and Data Envelopment Analysis to Improve the Efficiency of Manufacturing Process of Electrical Conductors. Appl. Sci. 2019, 9, 3965. [Google Scholar] [CrossRef] [Green Version]

- Beaverstock, M.; Greenwood, A.; Lavery, E.; Nordgren, W. Applied Simulation: Modeling and Analysis Using FlexSim; FlexSim Software Products Inc.: Orem, UT, USA, 2012. [Google Scholar]

- Gola, A.; Wiechetek, Ł. Modelling and simulation of production flow in job-shop production system with enterprise dynamics software. Appl. Comput. Sci. 2017, 13, 87–97. [Google Scholar]

- Sharma, P. Discrete-Event Simulation. Int. J. Sci. Technol. Res. 2015, 4, 136–140. [Google Scholar]

- Chryssolouris, G. Manufacturing Systems—Theory and Practice; Springer: New York, NY, USA, 2005. [Google Scholar]

- Kamble, P.G.; Hebbal, S.S. An Overview of Manufacturing Enterprise Modeling and Applications for CIM Environment. Contemp. Eng. Sci. 2010, 3, 201–214. [Google Scholar]

- Greenwood, A.; Pawlewski, P.; Bocewicz, G. A conceptual design tool to facilitate simulation model development: Object flow diagram. In Proceedings of the 2013 Winter Simulation Conference, Washington, DC, USA, 8–11 December 2013; pp. 1292–1303. [Google Scholar]

- Veisi, B.; Farughi, H.; Raissi, S. Two-Machine Robotic Cell Sequencing under Different Uncertainties. Int. J. Simul. Model. 2018, 17, 284–294. [Google Scholar] [CrossRef]

- Ormon, S.W.; Cassady, C.R.; Greenwood, A.G. Reliability prediction models to support conceptual design. Reliab. IEEE Trans. 2002, 51, 151–157. [Google Scholar] [CrossRef]

- Tran, N.-H.; Park, H.-S.; Nguyen, Q.-V.; Hoang, T.-D. Development of a Smart Cyber-Physical Manufacturing System in the Industry 4.0 Context. Appl. Sci. 2019, 9, 3325. [Google Scholar] [CrossRef] [Green Version]

- Matheson, E.; Minto, R.; Zampieri, E.G.G.; Faccio, M.; Rosati, G. Human-robot collaboration in manufacturing applications: A review. Robotics 2019, 8, 100. [Google Scholar] [CrossRef] [Green Version]

- Bogue, R. Robots that interact with humans: A review of safety technologies and standards. Ind. Robot 2017, 44, 395–400. [Google Scholar] [CrossRef]

- Hietanen, A.; Latokartano, J.; Pieters, R.; Lanz, M.; Kamarainen, J.-K. AR-based interaction for human-robot collaborative manufacturing. Robot. Comput. -Integr. Manuf. 2020, 63, 101891. [Google Scholar] [CrossRef]

- Long, P.; Chevallereauo, C.; Chablat, D.; Girin, A. An industrial security system for human-robot coexistence. Ind. Robot 2018, 45, 220–226. [Google Scholar] [CrossRef] [Green Version]

- Harriott, C.E.; Adams, J.A. Modeling Human Performance for Human–Robot Systems. Rev. Hum. Factors Ergon. 2013, 9, 94–130. Available online: http://rev.sagepub.com/content/9/1/94 (accessed on 20 November 2019). [CrossRef]

- Baines, T.; Mason, S.; Siebers, P.O.; Ladbrook, J. Humans: The missing link in manufacturing simulation? Simul. Model. Pract. Theory 2004, 12, 515–526. [Google Scholar] [CrossRef] [Green Version]

- Gołda, G.; Kampa, A.; Paprocka, I. Analysis of Human Operators and Industrial Robots Performance and Reliability. MPER 2018, 9, 24–33. [Google Scholar]

- Davidrajuh, R. Modeling Humanoid Robot as a Discrete Event System A Modular Approach based on Petri Nets. In Proceedings of the 2015 3rd International Conference on Artificial Intelligence, Modelling and Simulation (AIMS), Kota Kinabalu, Malaysia, 2–4 December 2015; pp. 277–282. [Google Scholar] [CrossRef]

- Huang, X.-Q.; Tang, X.-T.; Chen, L. Simulation for trajectory tracking of multi-flexible-link space robot with deadzone. Int. J. Simul. Model. 2018, 17, 677–689. [Google Scholar] [CrossRef]

- Genaidy, A.M.; Gupta, T. Robot and human performance evaluation. In Human—Robot Interaction; Rahimi, M., Karwowski, W., Eds.; Taylor & Francis: London, UK, 1992; pp. 4–15. [Google Scholar]

- Nof, S.Y. Handbook of Industrial Robotics; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Groover, M.P. Work Systems: The Methods, Measurement and Management of Work; Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Kampa, A. The review of reliability factors related to industrial robots. Robot. & Autom. Eng. J. (RAEJ) 2018, 3, 1–5. Available online: https://juniperpublishers.com/raej/RAEJ.MS.ID.555624.php (accessed on 20 February 2020).

- Sakai, H.; Amasaka, K. The robot reliability design and improvement method and the advanced Toyota production system. Ind. Robot 2007, 34, 310–316. [Google Scholar] [CrossRef]

- Dhillon, B.S.; Aleem, M.A. A report on robot reliability and safety in Canada: A survey of robot users. J. Qual. Maint. Eng. 2000, 6, 61–74. [Google Scholar] [CrossRef]

- Hansen, R.C. Overall Equipment Effectiveness; Industrial Press: New York, NY, USA, 2005. [Google Scholar]

- Muthiah, K.M.N.; Huang, S.H. A review of literature on manufacturing systems productivity measurement and improvement. Int. J. Ind. Syst. Eng. 2006, 1, 461–484. [Google Scholar] [CrossRef] [Green Version]

- Ghafoorpoor Yazdi, P.; Azizi, A.; Hashemipour, M. An Empirical Investigation of the Relationship between Overall Equipment Efficiency (OEE) and Manufacturing Sustainability in Industry 4.0 with Time Study Approach. Sustainability 2018, 10, 3031. [Google Scholar] [CrossRef] [Green Version]

- Gołda, G.; Kampa, A.; Foit, K. Study of inter-operational breaks impact on materials flow in flexible manufacturing system. IOP Conf. Ser. Mater. Sci. Eng. 2018, 1–6. [Google Scholar] [CrossRef]

- Smith, D.J. Reliability, Maintainability and Risk. Practical Methods for Engineers; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Woods, D.D. Modeling and predicting human error. In Human Performance Models for Computer-Aided Engineering; Elkind, J., Card, S., Hochberg, J., Huey, B., Eds.; Academic Press: Cambridge, MA, USA, 1990; pp. 248–274. [Google Scholar]

- Sage Clarity. 2018 OEE Benchmark Study. Available online: https://sageclarity.com/articles-oee-benchmark-study/ (accessed on 26 May 2019).

| Human Factor | Robot Factor | |

|---|---|---|

| Work parameters | Unstable, slow work, fatigue | Stable, fast work |

| Adaptation for new task | Fast adaptation | Slow programming |

| Flexibility, working area | Large flexibility, large operating range | Lower flexibility, limited range |

| Errors and failures | High human errors rate | Low failures rate |

| Replacement and repair | Can be replaced | Require repairing |

| Labour cost | High | Low |

| Investment cost for human/robot workstation | Low | High |

| Simulation Time [h] | Prod. Limit PL [Pcs.] | Human Operated Line | Robotic Line | ||||

|---|---|---|---|---|---|---|---|

| Average Production Pavg [Pcs.] | Std. dev. | OFE | Average Production Pavg [Pcs.] | Std. dev. | OFE | ||

| 24 | 1536 | 664.6 | 8.4 | 0.432682 | 867.1 | 1.05 | 0.56451 |

| 48 | 3072 | 1656.2 | 10.1 | 0.539128 | 2165.1 | 1.29 | 0.70478 |

| 120 | 7680 | 4624.1 | 14.9 | 0.602096 | 6062.7 | 2.23 | 0.78941 |

| 480 | 30,720 | 18,517 | 18.3 | 0.602767 | 24,243 | 3.7 | 0.78916 |

| 2880 | 184,320 | 110,739 | 89.0 | 0.600798 | 145,437 | 6.8 | 0.78904 |

| 5760 | 368,640 | 222,146 | 115 | 0.60261 | 290,856 | 21.2 | 0.78899 |

| Simulation Time [h] | Production Limit PL [Pcs.] | Human Operated Line | Robotic Line | ||||

|---|---|---|---|---|---|---|---|

| Average Production Pavg [Pcs.] | Std. dev. | OFE | Average Production Pavg [Pcs.] | Std. dev. | OFE | ||

| 24 | 1536 | 660.3 | 4.9 | 0.429883 | 855 | 34 | 0.556641 |

| 48 | 3072 | 1647.8 | 10.4 | 0.536393 | 2145 | 56 | 0.698242 |

| 120 | 7680 | 4605.3 | 14.6 | 0.599648 | 5974 | 211 | 0.777865 |

| 480 | 30,720 | 18,453 | 36 | 0.600684 | 24,045 | 311 | 0.782715 |

| 2880 | 184,320 | 110,537 | 84 | 0.599702 | 144,116 | 748 | 0.781879 |

| 5760 | 368,640 | 221,156 | 134 | 0.599924 | 287,852 | 1001 | 0.780849 |

| Simulation | 24 | 48 | 120 | 480 | 2880 | 5760 | Δavg |

|---|---|---|---|---|---|---|---|

| ΔOFEh | 0.002799 | 0.002735 | 0.002448 | 0.002083 | 0.001096 | 0.002686 | 0.002308 |

| ΔOFEr | 0.007869 | 0.006538 | 0.011545 | 0.006445 | 0.007161 | 0.008141 | 0.00795 |

| Model–Robotic Line (without Failures) | Real Line (Planned–without Failures) | Real Line (12 Months Average–with Failures) | |

|---|---|---|---|

| Availability | 0.9042 | 0.9042 | 0.8824 |

| Performance | 0.8739 | 0.8856 | 0.8856 |

| Quality | 0.9990 | 0.9990 | 0.9962 |

| OFE | 0.7894 | 0.8000 | 0.7785 |

| 2018 | I | II | III | IV | V | VI | |

|---|---|---|---|---|---|---|---|

| Planned OFE | 80% | 80% | 80% | 80% | 80% | 80% | |

| Obtained OFE | 77.30% | 81.70% | 77.30% | 82.72% | 78.82% | 80.00% | |

| 2018 | VII | VIII | IX | X | XI | XII | Avg. |

| Planned OFE | 80% | 80% | 80% | 80% | 80% | 80% | 80% |

| Obtained OFE | 76.05% | 73.29% | 78.00% | 77.01% | 75.68% | 76.35% | 77.85% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barosz, P.; Gołda, G.; Kampa, A. Efficiency Analysis of Manufacturing Line with Industrial Robots and Human Operators. Appl. Sci. 2020, 10, 2862. https://doi.org/10.3390/app10082862

Barosz P, Gołda G, Kampa A. Efficiency Analysis of Manufacturing Line with Industrial Robots and Human Operators. Applied Sciences. 2020; 10(8):2862. https://doi.org/10.3390/app10082862

Chicago/Turabian StyleBarosz, Piotr, Grzegorz Gołda, and Adrian Kampa. 2020. "Efficiency Analysis of Manufacturing Line with Industrial Robots and Human Operators" Applied Sciences 10, no. 8: 2862. https://doi.org/10.3390/app10082862