Green Extracts from Coffee Pulp and Their Application in the Development of Innovative Brews

Abstract

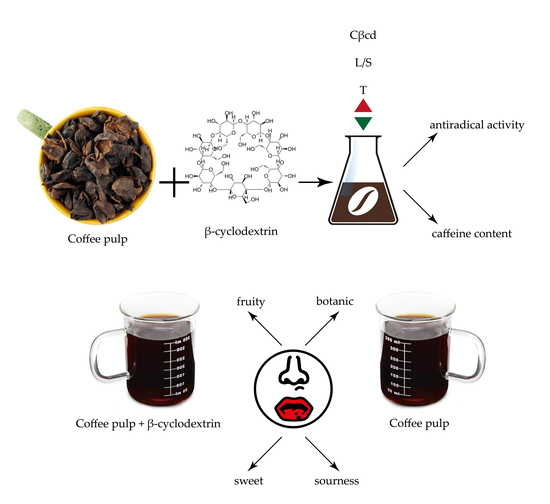

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Plant Material

2.3. Experimental Design and Response Surface Methodology

2.4. Extraction Process

2.5. Determination of Antiradical Activity (AAR)

2.6. Determination of Caffeine Extraction Yield

2.7. Determination of Total Polyphenol Yield (YTP)

2.8. Determination of Caffeine and Chlorogenic Acid Content

2.9. Sensory Analysis

2.9.1. Preparation of Brews

2.9.2. Quantitative Descriptive Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Extraction Yield

3.2. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Coffee Organization. Total Production. Available online: http://www.ico.org/historical/1990onwards/PDF/1a-total-production.pdf (accessed on 12 May 2020).

- Alves, R.C.; Rodrigues, F.; Antónia Nunes, M.; Vinha, A.F.; Oliveira, M.B.P.P. State of the Art in Coffee Processing By-Products. In Handbook of Coffee Processing By-Products; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 1–26. [Google Scholar] [CrossRef]

- Esquivel, P.; Jiménez, V.M. Functional Properties of Coffee and Coffee By-Products. Food Res. Int. 2012, 46, 488–495. [Google Scholar] [CrossRef]

- Heeger, A.; Kosińska-Cagnazzo, A.; Cantergiani, E.; Andlauer, W. Bioactives of Coffee Cherry Pulp and Its Utilisation for Production of Cascara Beverage. Food Chem. 2017, 221, 969–975. [Google Scholar] [CrossRef]

- de Souza Gois Barbosa, M.; dos Santos Scholz, M.B.; Kitzberger, C.S.G.; de Toledo Benassi, M. Correlation between the Composition of Green Arabica Coffee Beans and the Sensory Quality of Coffee Brews. Food Chem. 2019, 292, 275–280. [Google Scholar] [CrossRef]

- Farah, A.; De Paulis, T.; Trugo, L.C.; Martin, P.R. Effect of Roasting on the Formation of Chlorogenic Acid Lactones in Coffee. J. Agric. Food Chem. 2005, 53, 1505–1513. [Google Scholar] [CrossRef]

- Seninde, D.R.; Chambers, E. Coffee Flavor: A Review. Beverages 2020, 6, 44. [Google Scholar] [CrossRef]

- Frank, O.; Blumberg, S.; Kunert, C.; Zehentbauer, G.; Hofmann, T. Structure Determination and Sensory Analysis of Bitter-Tasting 4-Vinylcatechol Oligomers and Their Identification in Roasted Coffee by Means of LC-MS/MS. J. Agric. Food Chem. 2007, 55, 1945–1954. [Google Scholar] [CrossRef]

- Cai, R.; Yuan, Y.; Cui, L.; Wang, Z.; Yue, T. Cyclodextrin-Assisted Extraction of Phenolic Compounds: Current Research and Future Prospects. Trends Food Sci. Technol. 2018, 79, 19–27. [Google Scholar] [CrossRef]

- Goula, A.M. Ultrasound-Assisted Extraction of Pomegranate Seed Oil–Kinetic Modeling. J. Food Eng. 2013, 117, 492–498. [Google Scholar] [CrossRef]

- Kurkov, S.V.; Loftsson, T. Cyclodextrins. Int. J. Pharm. 2013, 453, 167–180. [Google Scholar] [CrossRef]

- Mourtzinos, I.; Menexis, N.; Iakovidis, D.; Makris, D.; Goula, A. A Green Extraction Process to Recover Polyphenols from Byproducts of Hemp Oil Processing. Recycling 2018, 3, 15. [Google Scholar] [CrossRef] [Green Version]

- Diamanti, A.C.; Igoumenidis, P.E.; Mourtzinos, I.; Yannakopoulou, K.; Karathanos, V.T. Green Extraction of Polyphenols from Whole Pomegranate Fruit Using Cyclodextrins. Food Chem. 2017, 214, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Rajha, H.N.; Chacar, S.; Afif, C.; Vorobiev, E.; Louka, N.; Maroun, R.G. β-Cyclodextrin-Assisted Extraction of Polyphenols from Vine Shoot Cultivars. J. Agric. Food Chem. 2015, 63, 3387–3393. [Google Scholar] [CrossRef] [PubMed]

- Astray, G.; Gonzalez-Barreiro, C.; Mejuto, J.C.; Rial-Otero, R.; Simal-Gándara, J. A Review on the Use of Cyclodextrins in Foods. Food Hydrocoll. 2009, 23, 1631–1640. [Google Scholar] [CrossRef]

- Prabu, S.; Swaminathan, M.; Sivakumar, K.; Rajamohan, R. Preparation, Characterization and Molecular Modeling Studies of the Inclusion Complex of Caffeine with Beta-Cyclodextrin. J. Mol. Struct. 2015, 1099, 616–624. [Google Scholar] [CrossRef]

- Górnas, P.; Neunert, G.; Baczyński, K.; Polewski, K. Beta-Cyclodextrin Complexes with Chlorogenic and Caffeic Acids from Coffee Brew: Spectroscopic, Thermodynamic and Molecular Modelling Study. Food Chem. 2009, 114, 190–196. [Google Scholar] [CrossRef]

- Aree, T. Understanding Structures and Thermodynamics of β-Cyclodextrin Encapsulation of Chlorogenic, Caffeic and Quinic Acids: Implications for Enriching Antioxidant Capacity and Masking Bitterness in Coffee. Food Chem. 2019, 293, 550–560. [Google Scholar] [CrossRef] [PubMed]

- Cordoba, N.; Fernandez-Alduenda, M.; Moreno, F.L.; Ruiz, Y. Coffee Extraction: A Review of Parameters and Their Influence on the Physicochemical Characteristics and Flavour of Coffee Brews. Trends Food Sci. Technol. 2020, 96, 45–60. [Google Scholar] [CrossRef]

- Sato, Y.; Itagaki, S.; Kurokawa, T.; Ogura, J.; Kobayashi, M.; Hirano, T.; Sugawara, M.; Iseki, K. In Vitro and in Vivo Antioxidant Properties of Chlorogenic Acid and Caffeic Acid. Int. J. Pharm. 2011, 403, 136–138. [Google Scholar] [CrossRef]

- Arnous, A.; Makris, D.P.; Kefalas, P. Correlation of Pigment and Flavanol Content with Antioxidant Properties in Selected Aged Regional Wines from Greece. J. Food Compos. Anal. 2002, 15, 655–665. [Google Scholar] [CrossRef]

- Belay, A.; Ture, K.; Redi, M.; Asfaw, A. Measurement of Caffeine in Coffee Beans with UV/Vis Spectrometer. Food Chem. 2008, 108, 310–315. [Google Scholar] [CrossRef]

- Korompokis, K.; Igoumenidis, P.E.; Mourtzinos, I.; Karathanos, V.T. Green Extraction and Simultaneous Inclusion Complex Formation of Sideritis Scardica Polyphenols. Int. Food Res. J. 2017, 24, 1233–1238. [Google Scholar]

- Tutunchi, P.; Roufegarinejad, L.; Hamishehkar, H.; Alizadeh, A. Extraction of Red Beet Extract with β-Cyclodextrin-Enhanced Ultrasound Assisted Extraction: A Strategy for Enhancing the Extraction Efficacy of Bioactive Compounds and Their Stability in Food Models. Food Chem. 2019, 297, 124994. [Google Scholar] [CrossRef] [PubMed]

- Santos, C.I.A.V.; Teijeiro, C.; Ribeiro, A.C.F.; Rodrigues, D.F.S.L.; Romero, C.M.; Esteso, M.A. Drug Delivery Systems: Study of Inclusion Complex Formation for Ternary Caffeine–β-Cyclodextrin–Water Mixtures from Apparent Molar Volume Values at 298.15 K and 310.15 K. J. Mol. Liq. 2016, 223, 209–216. [Google Scholar] [CrossRef]

- Yu, E.C. Novel Decaffeination Process Using Cyclodextrins. Appl. Microbiol. Biotechnol. 1988, 28, 546–552. [Google Scholar] [CrossRef]

- Rescifina, A.; Chiacchio, U.; Iannazzo, D.; Piperno, A.; Romeo, G. β-Cyclodextrin and Caffeine Complexes with Natural Polyphenols from Olive and Olive Oils: NMR, Thermodynamic, and Molecular Modeling Studies. J. Agric. Food Chem. 2010, 58, 11876–11882. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, Y.; Wang, Y.; Qin, Y.; Liu, B.; Bai, M. Two Green Approaches for Extraction of Dihydromyricetin from Chinese Vine Tea Using β-Cyclodextrin-Based and Ionic Liquid-Based Ultrasonic-Assisted Extraction Methods. Food Bioprod. Process. 2019, 116, 1–9. [Google Scholar] [CrossRef]

- Radojković, M.; Zeković, Z.; Sudar, R.; Jokić, S.; Cvetanović, A. Optimization of Solid-Liquid Extraction of Antioxidants and Saccharides from Black Mulberry Fruit by Response Surface Methodology. J. Food Nutr. Res. 2012, 50, 167–176. [Google Scholar]

- Drevelegka, I.; Goula, A.M. Recovery of Grape Pomace Phenolic Compounds through Optimized Extraction and Adsorption Processes. Chem. Eng. Process. Process Intensif. 2020, 149, 107845. [Google Scholar] [CrossRef]

- Goula, A.M.; Thymiatis, K.; Kaderides, K. Valorization of Grape Pomace: Drying Behavior and Ultrasound Extraction of Phenolics. Food Bioprod. Process. 2016, 100, 132–144. [Google Scholar] [CrossRef]

- Favre, L.C.; dos Santos, C.; López-Fernández, M.P.; Mazzobre, M.F.; del Pilar Buera, M. Optimization of β-Cyclodextrin-Based Extraction of Antioxidant and Anti-Browning Activities from Thyme Leaves by Response Surface Methodology. Food Chem. 2018, 265, 86–95. [Google Scholar] [CrossRef]

- Chapko, M.J.; Seo, H.-S. Characterizing Product Temperature-Dependent Sensory Perception of Brewed Coffee Beverages: Descriptive Sensory Analysis. Food Res. Int. 2019, 121, 612–621. [Google Scholar] [CrossRef] [PubMed]

- Dai, Q.; Liu, S.; Jin, H.; Jiang, Y.; Xia, T. Effects of Additive β-Cyclodextrin on the Performances of Green Tea Infusion. J. Chem. 2019, 2019, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Deshaware, S.; Gupta, S.; Singhal, R.S.; Joshi, M.; Variyar, P.S. Debittering of Bitter Gourd Juice Using β-Cyclodextrin: Mechanism and Effect on Antidiabetic Potential. Food Chem. 2018, 262, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Szejtli, J.; Szente, L. Elimination of Bitter, Disgusting Tastes of Drugs and Foods by Cyclodextrins. Eur. J. Pharm. Biopharm. 2005, 61, 115–125. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Saez, N.; García, A.T.; Pérez, I.D.; Rebollo-Hernanz, M.; Mesías, M.; Morales, F.J.; Martín-Cabrejas, M.A.; del Castillo, M.D. Use of Spent Coffee Grounds as Food Ingredient in Bakery Products. Food Chem. 2017, 216, 114–122. [Google Scholar] [CrossRef] [PubMed]

- Severini, C.; Caporizzi, R.; Fiore, A.G.; Ricci, I.; Onur, O.M.; Derossi, A. Reuse of Spent Espresso Coffee as Sustainable Source of Fibre and Antioxidants. A Map on Functional, Microstructure and Sensory Effects of Novel Enriched Muffins. LWT-Food Sci. Technol. 2020, 119, 108877. [Google Scholar] [CrossRef]

- Martinez-Saez, N.; Ullate, M.; Martin-Cabrejas, M.A.; Martorell, P.; Genovés, S.; Ramon, D.; del Castillo, M.D. A Novel Antioxidant Beverage for Body Weight Control Based on Coffee Silverskin. Food Chem. 2014, 150, 227–234. [Google Scholar] [CrossRef]

| Independent Variable | Coded Variable Levels | ||||

|---|---|---|---|---|---|

| −1.68 | −1.00 | 0 | +1.00 | +1.68 | |

| Cβcd (% w/v) | 0 | 3.75 | 9.25 | 14.75 | 18.5 |

| L/S (mL/g) | 13 | 20 | 30 | 40 | 47 |

| T (°C) | 30 | 40 | 55 | 70 | 80 |

| Independent Variables | Responses | ||||||

|---|---|---|---|---|---|---|---|

| Design Point | Cβcd (mg/mL) | L/S (mL/g) | T (°C) | AAR (μmol TRE/g) | CCaf (mg/g) | ||

| Measured | Predicted | Measured | Predicted | ||||

| 1 | 3.75 | 20 | 40 | 20.013 | 19.254 | 4.186 | 4.181 |

| 2 | 14.75 | 20 | 40 | 19.862 | 18.615 | 4.016 | 4.047 |

| 3 | 3.75 | 40 | 40 | 22.164 | 21.276 | 4.447 | 4.494 |

| 4 | 14.75 | 40 | 40 | 24.202 | 28.323 | 4.438 | 4.364 |

| 5 | 3.75 | 20 | 70 | 32.347 | 28.486 | 4.357 | 4.445 |

| 6 | 14.75 | 20 | 70 | 21.019 | 22.167 | 4.496 | 4.463 |

| 7 | 3.75 | 40 | 70 | 25.261 | 26.769 | 4.878 | 4.861 |

| 8 | 14.75 | 40 | 70 | 27.117 | 28.136 | 4.863 | 4.883 |

| 9 | 0 | 30 | 55 | 21.949 | 24.453 | 4.698 | 4.638 |

| 10 | 18.5 | 30 | 55 | 27.938 | 25.065 | 4.505 | 4.544 |

| 11 | 9.25 | 13 | 55 | 14.201 | 17.102 | 4.151 | 4.110 |

| 12 | 9.25 | 47 | 55 | 27.157 | 23.894 | 4.712 | 4.733 |

| 13 | 9.25 | 30 | 30 | 23.634 | 23.023 | 4.073 | 4.080 |

| 14 | 9.25 | 30 | 80 | 30.324 | 30.56 | 4.761 | 4.733 |

| 15 | 9.25 | 30 | 55 | 22.425 | 22.882 | 4.579 | 4.567 |

| 16 | 9.25 | 30 | 55 | 21.472 | 22.882 | 4.490 | 4.567 |

| 17 | 9.25 | 30 | 55 | 25.615 | 22.882 | 4.611 | 4.567 |

| 18 | 9.25 | 30 | 55 | 22.637 | 22.882 | 4.588 | 4.567 |

| 19 | 9.25 | 30 | 55 | 22.679 | 22.882 | 4.568 | 4.567 |

| 20 | 9.25 | 30 | 55 | 22.401 | 22.882 | 4.566 | 4.567 |

| Sample Name | Raw Materials | Cβcd (mg/mL) | L/S (mL/g) | T (°C) | t (h) |

|---|---|---|---|---|---|

| AQC | Arabica coffee beans | 0 | 30 | 30 | 2 |

| AQC/CD | Arabica coffee beans | 9.25 | |||

| AQCW | Arabica coffee pulp | 0 | |||

| AQCW/CD | Arabica coffee pulp | 9.25 |

| Modality | Descriptor | Definition |

|---|---|---|

| Odor | Botanic | Characteristic odor associated with typical dried black tea notes |

| Fruity | Overall odor associated with floral, sweet, ripe fruits and characteristic odor of coffee pulp | |

| Earthy | Odor associated with bread and wet soil | |

| Roasted | Characteristic odor of over-roasted hazelnuts (220 °C/10 minutes) | |

| Taste | Bitter | The fundamental sensation associated with caffeic acid |

| Sweet | The fundamental sensation associated with sucrose | |

| Sourness | Taste associated with sour/fermented-like aromatics | |

| Sour-roasted like | Characteristic acidic, sharp and pungent taste associated with excessively roasted coffee beans | |

| Botanic | Characteristic taste of black tea infusion | |

| Earthy | Characteristic taste associated with bread crust | |

| Tactile sensation | Astringent | A dry penetrating sensation in the nasal cavity |

| Characteristics ** | Attributes | Samples | |||

|---|---|---|---|---|---|

| AQC *** | AQC/CD | AQCW | AQCW/CD | ||

| O | Botanic | 7.8 b | 6.4 b | 54.6 a | 52.1 a |

| O | Fruity | 5.8 b | 1.8 b | 49.5 a | 33.2 a |

| O | Earthy | 30.7 a | 31.9 a | 11.9 b | 13.8 b |

| O | Roasted | 61.6 a | 60.5 a | 1.1 b | 1.6 b |

| T | Bitter | 56.4 a | 35.9 b | 3.1 c | 2.3 c |

| T | Sweet | 6.2 c | 5.9 c | 23.5 b | 38.5 a |

| T | Sourness | 1.1 b | 2.1 b | 49.4 a | 43.6 a |

| T | Sour-roasted | 26.3 a | 37.5 a | 2.0 b | 1.4 b |

| T | Botanic | 4.9 b | 4.5 b | 42.5 a | 38.6 a |

| T | Earthy | 33.1 a | 31.1 a | 8.7 b | 9.5 b |

| MF | Astrigency | 21.9 ab | 24.6 a | 17.7 ab | 10.1 b |

| AQC * | AQC/CD | AQCW | AQCW/CD | |

|---|---|---|---|---|

| Total phenolics (mg GAE/mL) | 558.96 ± 4.18 | 684.45 ± 9.02 | 278.99 ± 4.51 | 198.30 ± 2.95 |

| Caffeine (mg/mL) | 0.4211 | 0.4257 | 0.1357 | 0.1388 |

| Chlorogenic acid (mg/mL) | 0.1065 | 0.1086 | 0.152 | 0.151 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loukri, A.; Tsitlakidou, P.; Goula, A.; Assimopoulou, A.N.; Kontogiannopoulos, K.N.; Mourtzinos, I. Green Extracts from Coffee Pulp and Their Application in the Development of Innovative Brews. Appl. Sci. 2020, 10, 6982. https://doi.org/10.3390/app10196982

Loukri A, Tsitlakidou P, Goula A, Assimopoulou AN, Kontogiannopoulos KN, Mourtzinos I. Green Extracts from Coffee Pulp and Their Application in the Development of Innovative Brews. Applied Sciences. 2020; 10(19):6982. https://doi.org/10.3390/app10196982

Chicago/Turabian StyleLoukri, Anastasia, Petroula Tsitlakidou, Athanasia Goula, Andreana N. Assimopoulou, Konstantinos N. Kontogiannopoulos, and Ioannis Mourtzinos. 2020. "Green Extracts from Coffee Pulp and Their Application in the Development of Innovative Brews" Applied Sciences 10, no. 19: 6982. https://doi.org/10.3390/app10196982