Developments and Prospects of Farmland Application of Biogas Slurry in China—A Review

Abstract

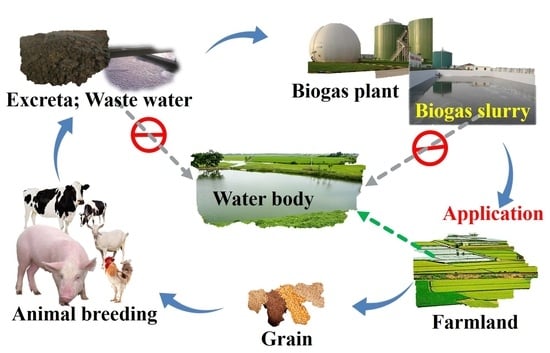

:1. Introduction

2. Composition of Biogas Slurry

3. Advance in Farmland Consumption of Biogas Slurry

3.1. Advantages of Using Biogas Slurry in Farmland

3.1.1. Soil Fertilization

3.1.2. Improvement in Crop Production

3.1.3. Quality Improvement

3.1.4. Bacteriostatic

3.1.5. Prevention and Control of Soil Acidification

3.1.6. Improved Microbial Structure and Soil Enzyme Activity

3.2. Approaches of Using Biogas Slurry in Farmland

3.2.1. Seed Soaking

3.2.2. Foliar Fertilizer Using Biogas Slurry

3.2.3. Base Fertilizer Using Biogas Slurry

3.2.4. Top Dressing Fertilizer Using Biogas Slurry

3.2.5. Hydroponics

3.2.6. Animal Feed

3.3. Application Methods of Using Biogas Slurry in Farmland

3.3.1. Drip Irrigation

3.3.2. Ditch Irrigation and Flood Irrigation

3.3.3. Spraying Application

3.3.4. Combine Application

3.4. Challenges of Using Biogas Slurry in Farmland

3.4.1. Water Environment

3.4.2. Soil Environment

3.4.3. Nitrogen in BS and the Atmospheric Environment

3.4.4. BS Application and Crop Safety

4. Conclusions and Prospects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jain, S.; Jain, S.; Wolf, I.T.; Lee, J.; Tong, Y.W. A comprehensive review on operating parameters and different pretreatment methodologies for anaerobic digestion of municipal solid waste. Renew. Sustain. Energy Rev. 2015, 52, 142–154. [Google Scholar] [CrossRef]

- Lou, M.; Jin, H.; Liang, D.; Zhu, Y.; Zhu, N.; Li, D. Fluorescence spectra characteristics of dissolved organic matter in mesophilic anaerobic digestion of pig and dairy manure slurries. Spectrosc. Spectr. Anal. 2022, 42, 141–146. [Google Scholar] [CrossRef]

- Lu, G.; Yang, F.; Chen, H.; Du, T. Research progress on application of biogas slurry. Soil Fertil. Sci. China 2021, 1, 339–345. [Google Scholar] [CrossRef]

- Deng, L.; Liu, Y.; Zheng, D.; Wang, L.; Pu, X.; Song, L.; Wang, Z.; Lei, Y.; Chen, Z.; Long, Y. Application and development of biogas technology for the treatment of waste in China. Renew. Sustain. Energy Rev. 2017, 70, 845–851. [Google Scholar] [CrossRef]

- Han, M.; Liu, K.; Wang, S.; Qin, L.; Gao, C. Definition, ingredient, approaches and risks for reuse in biogas slurry. J. Agric. 2014, 4, 54–57. Available online: http://ww-w.cqvip.com/qk/97993a/201410/662779509.html (accessed on 12 February 2014).

- Hu, Y.; Cheng, H.; Tao, S. Environmental and human health challenges of industrial livestock and poultry farming in China and their mitigation. Environ. Int. 2017, 107, 111–130. [Google Scholar] [CrossRef] [PubMed]

- Zou, M.; Dong, H.; Zhu, Z.; Zhan, Y.; Zhang, Y.; Yue, C. Progress and prospect of treatments and resource utilization of biogas slurry on livestock and poultry farms. China Poult. 2020, 42, 103–109. [Google Scholar] [CrossRef]

- Rodriguez-Navas, C.; Björklund, E.; Halling-Sørensen, B.; Hansen, M. Biogas final digestive byproduct applied to croplands as fertilizer contains high levels of steroid hormones. Environ. Pollut. 2013, 180, 368–371. [Google Scholar] [CrossRef]

- Shen, Q.; Shan, S.; Zhou, J.; Wang, Z. Determination and analysis of compositions in biogas alurry produced by swine manure digestion. China Biogas 2014, 32, 83–86. Available online: http://www.cqvip.com/qk/90336x/201403/50110248.html (accessed on 24 March 2013).

- Wang, X.; Yan, X.; Li, X. Environmental safety risk for application of anaerobic fermentation biogas slurry from livestock manure in agricultural land in China. Sci. Agric. Sin. 2021, 54, 110–139. [Google Scholar] [CrossRef]

- Qin, W.; Egolfopoulos, F.N.; Tsotsis, T.T. Fundamental and environmental aspects of landfill gas utilization for power generation. Chem. Eng. J. 2001, 82, 157–172. [Google Scholar] [CrossRef]

- Huo, C.; Wu, S.; Guo, J.; Cheng, H.; Ren, H.; Dong, R.; Pang, C. Analysis of phytohormone and qunolin-ketone components in anaerobic digestion effluent. China Biogas 2011, 29, 7–10. Available online: https://www.cnki.com.cn/Article/CJFDTOTAL-ZGZQ201105003.htm (accessed on 23 May 2011).

- Yin, F.; Zhan, Y.; Yue, C.; Hu, X.; Zhu, Z.; Dong, H. Research progress on membrane technology for treatment of husbandry biogas slurry and wastewater. J. Agro-Environ. Sci. 2021, 40, 2335–2341. [Google Scholar] [CrossRef]

- Song, C.; Shan, S.; Zhang, M.; Wen, X. Concentration and determination of composition of biogas slurry. Trans. Chin. Soc. Agric. Eng. 2011, 27, 256–259. [Google Scholar] [CrossRef]

- Huang, H.; Wu, Y.; Li, X.; Wu, R.; Wu, L.; Jiang, Q. Measurement of nutrient content, heavy metal and antibiotic residue in livestock and poultry manure of Ningxia farm and safety evaluation analysis. J. Agric. Sci. 2018, 39, 1–8. [Google Scholar] [CrossRef]

- Ma, Y.; Ding, J.; Zhao, L.; Meng, H.; Shen, Y.; Cheng, H.; Wang, J. Advances in recycling and reuse of nitrogen from biogas slurry. Environ. Pollut. Control 2018, 40, 339–344. [Google Scholar] [CrossRef]

- Ke, L.; Liu, X.; Du, B.; Wang, Y.; Zheng, Y.; Li, Q. Component analysis and risk assessment of biogas slurry from biogas plants. Chin. J. Chem. Eng. 2022, 44, 182–191. [Google Scholar] [CrossRef]

- Zu, B.; Liu, L.; Zu, J.; Wei, S. Design of fecal sewage treatment project from large-scale duck farm. China Water Wastewater 2009, 25, 34–37. Available online: http://ww-w.cqvip.com/qk/95430x/200902/29130510.html (accessed on 30 July 2008).

- Jin, H.; Chang, Z.; Ye, X.; Ma, Y.; Zhu, J. Physical and chemical characteristics of anaerobically digested slurry from large-scale biogas project in Jiangsu Province. Trans. Chin. Soc. Agric. Eng. 2011, 27, 291–296. [Google Scholar] [CrossRef]

- Wan, J.; Fu, Y.; Deng, M.; Yu, X.; Wang, J. Treatment of hogpen biogas slurry by A/O-SBBR-oxidation pond constructed wetlands. Ind. Water Treat. 2017, 37, 101–104. Available online: http://www.cqvip.com/qk/95815x/20178/673012906.html (accessed on 7 June 2017).

- Zhu, G.; Zhao, J.; Zhao, X.; Lu, X. Characteristics of nutrients removal from stored algae anaerobic biogas slurry in artificial aquatic vegetable wetlands. Appl. Mech. Mater. 2012, 178–181, 777–782. [Google Scholar] [CrossRef]

- Lang, L. Study on the Effect of Ecological Filter–Constructed Wetland Combined Process on Waste Biogas Slurry. Master’s Dissertation, Anhui Agricultural University, Hefei, China, 2017. Available online: https://cdmd.cnki.com.cn/Article/CDMD-10364-1017256026.htm (accessed on 30 May 2017).

- Yetilmezsoy, K.; Sertyesilisik, B.; Kocak, E.; Sapci-Zengin, Z. Ameliorative effect of different doses of MgNH4PO4·6H2O precipitate recovered from the effluent of UASB treating poultry manure wastewater: Growth of Lolium perenne. Int. J. Food Agric. Environ. 2009, 7, 823–831. Available online: https://pubag.nal.usda.gov/catalog/774748 (accessed on 30 May 2017).

- Wang, Z.; Wu, H.; Guan, Y.; Liang, Y.; Liu, Y. Integrated technology of “Three Separations and One Purification” treatment on livestock and poultry farm fecal sewage. J. Agric. Resour. Environ. 2013, 30, 63–67. Available online: http://cqvip.jskjwx.org/article/detail.aspx?id=47427008 (accessed on 13 May 2013).

- Bai, X.; Li, Z.; Yin, F.; Cheng, S.; Bai, X.; Zhang, Y. Evaporation treatment on biogas slurry from anaerobic fermentation. Trans. Chin. Soc. Agric. Mach. 2015, 46, 164–170. [Google Scholar] [CrossRef]

- Zhan, Y.; Dong, H.; Yin, F.; Yue, C. The combined process of paper filtration and ultrafiltration for the pretreatment of the biogas slurry from swine manure. Int. J. Environ. Res. Public Health 2018, 15, 1894. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Chi, X.; Zhou, W.; Du, D.; Peng, J.; Xiao, N. Experimental study on piggery biogas slurry concentration process by reverse osmosis membrane. Environ. Eng. 2019, 37, 87–90. [Google Scholar] [CrossRef]

- He, Q.; Shi, M.; Feng, L.; Ai, P.; Yuan, Q.; Yan, S. Research progress of biogas slurry resourceful treatment by membrane distillation. Trans. Chin. Soc. Agric. Eng. 2021, 37, 259–268. [Google Scholar] [CrossRef]

- Luján-Facundo, M.J.; Iborra-Clar, M.I.; Mendoza-Roca, J.A.; Also-Jesús, M. Alternatives for the management of pig slurry: Phosphorous recovery and biogas generation. J. Water Process Eng. 2019, 30, 100473. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, D. Ozonation and flocculation combination treatment biogas slurry of cow dung. China Biogas 2020, 38, 37–44. Available online: http://www.cqvip.com/qk/9033-6x/202001/7101184388.html (accessed on 21 March 2019).

- Song, Y.; Wang, G.; Li, R.; Chen, G. Research progress of biogas slurry treatment and resource utilization. Trans. Chin. Soc. Agric. Eng. 2021, 37, 237–250. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, Z.; Li, Y.; Zhang, Y.; Lin, H.; Wang, J. Comprehensive evaluation of several typical pollution control engineerings of livestock and poultry breeding. Chin. J. Environ. Eng. 2014, 8, 4555–4560. Available online: http://www.cqvip.com/qk/90325c/201410/72747490504849524948485653.html (accessed on 20 September 2013).

- Nicholson, F.; Bhogal, A.; Cardenas, L.; Chadwick, D.; Misselbrook, T.; Rollett, A.; Taylor, M.; Thorman, R.; Williams, J. Nitrogen losses to the environment following food-based digestate and compost applications to agricultural land. Environ. Pollut. 2017, 228, 504–516. [Google Scholar] [CrossRef] [PubMed]

- Haraldsen, T.K.; Andersen, U.; Krogstad, T.; Sørheim, R. Liquid digestate from anaerobic treatment of source-separated household waste as fertilizer to barley. Waste Manag. 2011, 29, 1271–1276. [Google Scholar] [CrossRef] [PubMed]

- Robles, Á.; Aguado, D.; Barat, R.; Borrás, L.; Bouzas, A.; Giménez, J.B.; Martí, N.; Ribes, J.; Ruano, M.V.; Serralta, J.; et al. New frontiers from removal to recycling of nitrogen and phosphorus from wastewater in the circular economy. Bioresour. Technol. 2020, 300, 122673. [Google Scholar] [CrossRef] [PubMed]

- Shahbaz, M.; Akhtar, M.J.; Ahmed, W.; Wakeel, A. Integrated effect of different N-fertilizer rates and bioslurry application on growth and N-use efficiency of okra (Hibiscus esculentus L.). Turk. J. Agric. For. 2014, 38, 311–319. [Google Scholar] [CrossRef]

- Nzila, A. Biodegradation of high-molecular-weight polycyclic aromatic hydrocarbons under anaerobic conditions: Overview of studies, proposed pathways and future perspectives. Environ. Pollut. 2018, 239, 788–802. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Luo, L.; Carswell, A.; Misselbrook, T.; Shen, J.; Han, J. Changes in soil organic carbon status and microbial community structure following biogas slurry application in a wheat-rice rotation. Sci. Total Environ. 2021, 757, 143786. [Google Scholar] [CrossRef]

- Wang, L.; Wang, G.; Wang, H.; Zhou, G.; Zhao, C.; Wang, P.; Jiang, S. Effects of applying biogas slurry instead of chemical fertilizer on the growth of melon and soil microorganism. J. South Agric. 2021, 52, 2498–2506. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, Y.; Sheng, J.; Guan, Y.; Wu, H.; Chen, L.; Zheng, J. Analysis of water environment risk on biogas slurry disposal in paddy field. Trans. Chin. Soc. Agric. Eng. 2016, 32, 213–220. [Google Scholar] [CrossRef]

- Liu, C.; Zheng, Y.; Liu, S.; Liu, Q.; Yan, L. Effects of biogas slurry application on nitrogen loss soil in black soil area during the autumn fallow period. J. Agro-Environ. Sci. 2021, 40, 2528–2536. [Google Scholar] [CrossRef]

- Li, H.; Tan, F.; Ke, L.; Xia, D.; Wang, Y.; He, N.; Zheng, Y.; Li, Q. Mass balances and distributions of C, N, and P in the anaerobic digestion of different substrates and relationships between products and substrates. Chem. Eng. J. 2016, 287, 329–336. [Google Scholar] [CrossRef]

- Dong, Y.; Liang, D.; Li, D.; Jin, H. Characteristic analysis of main nutrient content in biogas slurry. Jiangsu J. Agric. Sci. 2021, 37, 1206–1214. [Google Scholar] [CrossRef]

- Jing, D.; Chen, Y.; Dai, C.; Li, P. Research situation and prospect of biogas slurry utilization in fish culture. Hubei Agric. Sci. 2016, 55, 5886–5890. [Google Scholar] [CrossRef]

- Sheets, J.P.; Yang, L.; Ge, X.; Wang, Z.; Li, Y. Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. Waste Manag. 2015, 44, 94–115. [Google Scholar] [CrossRef] [PubMed]

- Möller, K. Effects of anaerobic digestion on soil carbon and nitrogen turnover, N emissions, and soil biological activity. A review. Agron. Sustain. Dev. 2015, 35, 1021–1041. [Google Scholar] [CrossRef]

- Niyungeko, C.; Liang, X.; Liu, C.; Zhou, J.; Chen, L.; Lu, Y.; Tiimub, B.M.; Li, F. Effect of biogas slurry application on soil nutrients, phosphomonoesterase activities, and phosphorus species distribution. J. Soils Sediments 2020, 20, 900–910. [Google Scholar] [CrossRef]

- Chen, S.; Yu, W.; Zhang, Z.; Luo, S. Soil properties and enzyme activities as affected by biogas slurry irrigation in the Three Gorges Reservoir areas of China. J. Environ. Biol. 2015, 36, 513–520. Available online: http://jeb.co.in/journal_issues/201503_mar15/paper_26.pdf (accessed on 29 September 2014).

- Xu, C.; Tian, Y.; Sun, Y.; Dong, L. Effects of biogas slurry irrigation on growth, photosynthesis, and nutrient status of Perilla frutescens seedlings. Commun. Soil Sci. Plant Anal. 2013, 44, 3381–3390. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Wu, D.; Luo, X.; Dong, R.; Shao, L. Effects of long-term application of biogas surry on sil and products. China Biogas 2018, 36, 87–91. [Google Scholar] [CrossRef]

- Yu, D.; Wen, Z.; Li, X.; Song, X.; Wu, H.; Yang, P. Effects of straw return on bacterial communities in a wheat-maize rotation system in the North China Plain. PLoS ONE 2018, 13, e0198087. [Google Scholar] [CrossRef]

- Yılmaz, E.; Çanakcı, M.; Topakcı, M.; Sönmez, S.; Ağsaran, B.; Alagöz, Z.; Çıtak, S.; Uras, D.S. Effect of vineyard pruning residue application on soil aggregate formation, aggregate stability and carbon content in different aggregate sizes. Catena 2019, 183, 104219. [Google Scholar] [CrossRef]

- Song, Z.; Song, Z.; Shan, S. Particle fractionation and organic carbon content in coastal saline soils with natural fallow and pig slurry amendments. J. Zhejiang AF Univ. 2011, 28, 214–218. [Google Scholar] [CrossRef]

- Yan, L.; Liu, Q.; Liu, C.; Liu, Y.; Zhang, M.; Zhang, Y.; Zhang, Y.; Gu, W. Effect of swine biogas slurry application on soil dissolved organic matter (DOM) content and fluorescence characteristics. Ecotoxicol. Environ. Saf. 2019, 184, 109616. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Zhuang, H.; Zhang, C.; Dang, H.; Ping, L.; Zhang, C.; Fan, Z.; Shan, S. Effects of biogas slurry substituting for chemical fertilizer on soil fertility and quality of citrus Changshan-huyou. J. Zhejiang Agric. Sci. 2021, 62, 324–329. [Google Scholar] [CrossRef]

- Chen, Y.; Dong, H.; Tao, X.; Shang, B. Effect of irrigating winter wheat with anaerobic digested swine farm wastewater (ADSFW) on soil quality. Chin. Agric. Sci. Bull. 2011, 27, 154–158. Available online: http://www.cqvip.com/Main/Detail.aspx?id=-37292128 (accessed on 7 September 2010).

- Yang, L.; Wang, K.; Pang, W.; Zhang, F. Effect of biogas slurry on soil quality of intensive plantation field in Xinjiang oasis for 5 years. Soil Fertil. Sci. China 2012, 5, 17–21. Available online: https://d.wanfangdata.com.cn/periodical/trfl2012-05004 (accessed on 3 March 2012).

- Li, Y.; Xu, J.; Liu, B.; Sun, Q.; Li, J.; Liu, J.; Lang, Q.; Sun, R.; Jin, H. Effects of different biogas slurries on soil microbial carbon metabolism. Chin. J. Eco-Agric. 2021, 29, 1921–1930. [Google Scholar] [CrossRef]

- Wang, W.; Wei, J.; Ma, W.; Yang, Y.; Guo, C. Effect of nitrogen amendment and straw-stubble input on accumulation of soil organic matter in typical farmlands of Huang-Huai-Hai Plain. Acta Ecol. Sin. 2010, 30, 3591–3598. Available online: http://www.cnki.com.cn/Article/CJFDTotal-STXB201013026.htm (accessed on 15 November 2009).

- Huang, J.; Xu, P.; Peng, Z.; Yu, J.; Tu, Y.; Yang, L.; Wu, X.; Lin, Z. Biogas slurry use amount for suitable soil nutrition and biodiversity in paddy soil. J. Plant Nutr. Fertil. 2016, 22, 362–371. [Google Scholar] [CrossRef]

- Huang, J.; Peng, Z.; Xu, P.; Tu, Y.; Yang, L.; Wu, X.; Lin, Z. Effects of paddy field disposal of biogas slurry on rice production, soil fertility and environmental safety. Guangdong Agric. Sci. 2016, 43, 69–76. [Google Scholar] [CrossRef]

- Huang, J.; Wu, Z.; Gao, L.; Tang, X.; Ma, Y.; Zheng, B. Effects of biogas slurry on soil quality and yield quality of Chinese cabbage. J. Anhui Agric. Univ. 2013, 40, 849–854. [Google Scholar] [CrossRef]

- Cui, Y.; Azeem, M.; Sun, J.; Zhang, Z.; Yang, S. Effects of biogas slurry combined with chemical fertilizer on soil chemical properties and corn yield and quality. Shandong Agric. Sci. 2020, 52, 77–81. [Google Scholar] [CrossRef]

- Li, J.; Sun, J.; Yang, L.; Azeem, M.; Zhang, Z.; Yang, S. Effects of excessive biogas slurry returning on soil environmental capacity and maize growth. J. Henan Agric. Sci. 2021, 50, 49–56. [Google Scholar] [CrossRef]

- Xu, M.; Xian, Y.; Wu, J.; Gu, Y.; Yang, G.; Zhang, X.; Peng, H.; Yu, X.; Xiao, Y.; Li, L. Effect of biogas slurry addition on soil properties, yields, and bacterial composition in the rice-rape rotation ecosystem over 3 years. J. Soils Sediments 2019, 19, 2534–2542. [Google Scholar] [CrossRef]

- Ruan, R.; Tu, R.; Li, Y.; Hu, H.; Wu, J. Study on the response of the stability of red soil aggregates to chemical fertilizer mixture with biogas slurry in dryland farming. Soil Fertil. Sci. China 2021, 4, 26–32. [Google Scholar] [CrossRef]

- Gao, L.; Yu, X.; Li, R.; Yang, Q.; Cui, X.; Li, S.; Wang, P. Effects of biogas formulated manure on yield and quality of banana and soil quality. J. Trop. Biol. 2017, 8, 209–215. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Li, J.; Sun, Q.; Li, J.; Xu, J.; Liu, B.; Lang, Q.; Qiao, Y. Organic management practices enhance soil food web biomass and complexity under greenhouse conditions. Appl. Soil Ecol. 2021, 167, 104010. [Google Scholar] [CrossRef]

- Lai, X.; Wu, J.; Wang, J.; Xu, M.; Mao, X.; Li, Y. The long-term effects of biogas slurry on soil properties and potential risks of heavy metals in soils. J. Soil Water Conserv. 2018, 32, 359–364. [Google Scholar] [CrossRef]

- Qiao, F.; Xiao, Y.; Zhao, S. Consecutive application of biogas manure affects maize production and soil chemical properties in Hailin farm. Chin. Agric. Sci. Bull. 2018, 34, 93–98. Available online: http://www.cqvip.com/QK/91831X/201836/6100080027.html (accessed on 1 September 2018).

- Dong, Y.; Zhou, X.; Ye, B.; Liu, Y. Effect of long-term biogas slurry application in rice field on soil chemical properties and C-N-P stoichiometry. J. Zhejiang Agric. Sci. 2021, 62, 2398–2401. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, Y.; Ye, B.; Jin, J.; Nie, X.; Fan, Z. Effect of continuous application of biogas slurry on soil properties in tea garden. J. Zhejiang Agric. Sci. 2022, 63, 52–55,59. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=7106295710 (accessed on 30 May 2017).

- Zheng, J.; Yan, F.; Pan, Z.; Feng, Z.; Li, X. Meta analysis on the effect of biogas slurry on crop yield in China. China Biogas 2019, 37, 78–84. [Google Scholar] [CrossRef]

- Huang, H.; Cao, J.; Chang, Z.; Cao, Y. Effects of digested pig slurry application on yields, nitrogen and phosphorous uptakes by rice and wheat. Soils 2013, 45, 412–418. [Google Scholar] [CrossRef]

- Shao, W.; Ji, L.; Sun, C.; Jiang, X.; Wen, T.; Tang, J.; Zhang, A. Effects of application rate of biogas slurry on growth, grain yield and heavy metals contents of rice. Acta Agric. Zhejiangensis 2017, 29, 1963–1969. [Google Scholar] [CrossRef]

- Song, S. Effects of Biogas Manure on Crop Growth and Soil Microbial Properties under Rice-Wheat Rotation System in Chengdu Plain. Ph.D. Dissertation, Sichuan Agricultural University, Chengdu, China, 2017. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10626-1018071320.htm (accessed on 16 November 2018).

- Wang, G.; Kou, X.; Zhang, J.; Wang, S.; Xu, R.; Han, G.; Tang, H.; Zhu, L.; Bi, J.; Wu, L. Effect of chemical fertilizer nitrogen substitution by biogas slurry on the growth and quality of rice. Chin. J. Ecol. 2018, 37, 2672–2679. [Google Scholar] [CrossRef]

- Hou, F.; Chen, Y.; Yang, Z.; Jin, C.; Shi, K.; Chen, C.; Feng, G.; Li, H. Effects of digested pig slurry application on agronomic trait, yield and forage quality of indica rice. J. Zhejiang Univ. (Agric. Life Sci.) 2019, 45, 325–331. [Google Scholar] [CrossRef]

- Xu, K.; Li, C.; Wu, C.; Jiang, Z.; Li, Y. Application of biogas slurry in rice production. Shanghai Agric. Sci. Technol. 2020, 1, 115–116. [Google Scholar] [CrossRef]

- Sun, G.; Wang, X.; Sheng, J.; Zhang, L.; Wang, Z.; Zhou, W. Rice quality and nitrogen use efficiency under long-term application of pig manure or biogas slurry. J. Agro-Environ. Sci. 2021, 40, 2521–2527. [Google Scholar] [CrossRef]

- Chen, B. Effect of the Agricultural Usage of Biogas Slurry on Maize Yield, Quality and Environmental Quality of Soil. Master’s Dissertation, Sichuan Agricultural University, Chengdu, China, 2010. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10626-2010244613.htm (accessed on 16 April 2011).

- Wu, J.; Wang, J.; Zhang, L.; Liu, Y.; Chen, B.; Meng, X. Effects of biogas slurry on yield and quality of maize. J. Nucl. Agric. Sci. 2014, 28, 905–911. Available online: https://d.wanfangdata.com.cn/periodical/hnxb201405022 (accessed on 1 August 2013).

- Yang, Z.; Ding, H.; Chen, Y.; Jin, C.; Shi, K.; Hou, F.; Feng, G.; Huang, Q. Effects of different application amount of biogas-slurry on barley agronomic traits & feeding quality. Acta Ecol. Anim. Domastici 2019, 40, 59–65. [Google Scholar] [CrossRef]

- Zhou, G.; Xue, X.; Su, S.; Gu, G. Effects of drip irrigation with biogas slurry on yield and quality of watermelon. J. Changjiang Veg. 2014, 12, 59–60. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, H.; Guo, D.; Wang, Q.; Yan, S.; Wang, G.; Ma, Y. Effect of biogas slurry application on incidence of fusarium wilt, fruit yield and quality of watermelon. Soils 2015, 47, 904–910. [Google Scholar] [CrossRef]

- Cheng, W.; Zhang, A.; Cai, X.; Zhu, J.; Wang, P.; Li, Y.; Yang, Y. Effects of soaking seed with biogas slurry and foliar spraying it on germination, agronomic traits and quality of watermelon. J. Hebei Agric. Sci. 2018, 22, 34–36. [Google Scholar] [CrossRef]

- Hao, S.; Yin, S.; Huang, Y.; Du, X.; Zhang, L.; Li, S. Effects of foliar spraying of biogas slurry on the quality and yield of Huangguan pear. China Fruits 2012, 1, 24–26. [Google Scholar] [CrossRef]

- Wang, L.; Ye, X.; Du, J.; Zhang, Y.; Lin, J.; Xi, Y.; Kong, X. Effects of different application methods of biogas slurry on pear orchard soil and pear fruit yield and quality. Jiangsu Agric. Sci. 2021, 49, 138–143. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, D. Effect of indirect underground drip irrigation with biogas slurry on yield and quality of red grape. Anhui Agric. Sci. Bull. 2018, 24, 46–47. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Sun, G.; Li, T. Study on the correlation between fertilization and quality and yield of flat peach. Shihezi Sci. Technol. 2019, 2, 1–7. [Google Scholar] [CrossRef]

- Lin, S.; Ling, W.; Sun, Q.; Han, J.; Li, P. Effects of biogas slurry application on purple cabbage growth and the soil properties in coast saline-alkali land. China Biogas 2019, 37, 80–87. [Google Scholar] [CrossRef]

- Hu, Z.; Wan, Q.; Li, H.; Li, Y.; Li, R.; Yang, Y. Effects of sprinkler irrigation with biogas slurry on tea garden soil and tea yield. J. South Agric. 2020, 51, 2757–2763. [Google Scholar] [CrossRef]

- Song, B.; Cao, X.; Ma, H.; Mu, X.; Wu, L.; Zhang, C.; Shi, H.; Ma, C. Effect of spraying biogas slurry on fruit quality of hami melon. Tianjing Agric. Sci. 2016, 22, 11–14. [Google Scholar] [CrossRef]

- He, M.; Jiang, Z.; Xu, J.; Song, B.; Chen, Y. Effect of biogas slurry spraying on yield and plant physiology of greenhouse melon. Chin. Agric. Sci. Bull. 2018, 34, 24–28. Available online: http://www.cqvip.com/QK/91831X/201811/675205700.html (accessed on 21 December 2017).

- Chen, N.; Mao, H.; Chen, S.; Wei, Y.; Fang, S. Effect of biogas slurry foliar spraying on leaf photosynthesis characteristics, fruit yield and quality of pepino in greenhouse. China Cucurbits Veg. 2021, 34, 88–93. [Google Scholar] [CrossRef]

- Hao, Y. Effect of Biogas Slurry Applying on Soil Quality in Vineyard and Grape Yield and Quality. Master’s Dissertation, Gansu Agricultural University, Lanzhou, China, 2019. [Google Scholar] [CrossRef]

- Gao, W.; Azeem, M.; Sun, J.; Zhang, Z.; Li, J.; Yang, S. Influences of combined application of biogas slurry and chemical fertilizers on apple growth and soil physic-chemical properties–Taking Yantai Red Fuji apple as an example. Jiangsu Agric. Sci. 2020, 48, 160–165. [Google Scholar] [CrossRef]

- Zhao, F.; Sun, Q.; Li, J.; Liu, C.; Wei, Z.; Zhang, J.; Liu, B. Effects of different biogas fertilizers on yield, quality and nitrogen use efficiency of the rape. J. Soil Water Conserv. 2010, 24, 127–130. Available online: http://www.cnki.com.cn/article/cjfdtotal-trqs201003028.htm (accessed on 1 January 2010).

- Wang, H.; Xu, Y.; Zhou, S.; Qu, Y. Effect of different concentration of biogas slurry on growth and quality of Ipomoea aquatic floating cultured in solar greenhouse. J. Shenyang Agric. Univ. 2013, 44, 650–655. [Google Scholar] [CrossRef]

- Li, S.; Liu, J.; Xia, Y.; Sun, Z. Effects of biogas slurry application patterns on the nutrient absorption of pakchoi and substrate environment. Acta Agric. Shanghai 2014, 30, 68–72. [Google Scholar] [CrossRef]

- Huang, L.; Lou, R.; Xu, Y.; Li, J.; Zhu, Y. Preliminary study on insect repellent and disease control effect of biogas fertilizer on rice. China Biogas 2014, 32, 79–82. [Google Scholar] [CrossRef]

- Zhang, Y. Comparative experiment on the effect of biogas fertilizer and conventional fertilizer on rice yield. Agric. Jilin 2018, 1, 63. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Yin, J.; Zhang, J.; Zhang, Y.; Tang, J.; Wu, D. Effects of short-term biogas slurry returning on wheat yield and soil physiochemical properties. J. Henan Inst. Sci. Technol. (Nat. Sci. Ed.) 2019, 47, 5–9. Available online: https://d.wanfangdata.com.cn/periodical/hnzjsyxb201904002 (accessed on 30 May 2019).

- Sui, H.; Chen, X.; Qin, N.; Wang, G.; Xu, K.; Ai, P. Effects of drip irrigation with biogas slurry on yield and quality of tomato and physical and chemical properties of soil. Shandong Agric. Sci. 2016, 48, 80–84. [Google Scholar] [CrossRef]

- Jia, L.; Zhao, J.; Yang, C.; Liu, L.; Chen, J.; Yang, G.; Ren, G. Effect of topdressing biogas fertilizer on growth, yield and quality of tomato. Acta Agric. Boreali-Occident. Sin. 2017, 26, 897–905. [Google Scholar] [CrossRef]

- Ma, X.; Tao, Z. Effects of biogas slurry spraying on the pest and yield of cabbage. China Biogas 2019, 37, 90–92. [Google Scholar] [CrossRef]

- Xi, H.; Li, G.; Tao, A.; Gu, P.; Han, D.; Li, N.; Chen, X. Effect of drip fertigation with organic liquid fertilizer on soil environment, fruit yield, quality, and economic benefits of citrus cv. beni madonna. Acta Agric. Zhejiangensis 2021, 33, 670–677. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, G.; Ye, Z.; Wu, J.; Ye, B. Effect of biogas slurry application on Hongmeiren fruit quality and soil fertility. J. Zhejiang Agric. Sci. 2022, 63, 86–89,93. [Google Scholar] [CrossRef]

- Odlare, M.; Arthurson, V.; Pell, M.; Svensson, K.; Nehrenheim, E.; Abubaker, J. Land application of organic waste-Effects on the soil ecosystem. Appl. Energy 2011, 88, 2210–2218. [Google Scholar] [CrossRef]

- Wu, H.; Guo, D.; Ma, Y.; Chang, Z. Effects of pig manure-biogas slurry application on soil ammonia volatilization and maize output and quality. Chin. J. Eco-Agric. 2012, 20, 163–168. [Google Scholar] [CrossRef]

- Tang, W.; Wu, J.; Sun, B.; Yang, G.; Yang, Q. Effects of application amounts of biogas slurry on yield and quality of rice. J. Agro-Environ. Sci. 2010, 29, 2268–2273. Available online: http://www.cqvip.com/QK/71135X/201107/36464981.html (accessed on 19 May 2010).

- Wang, W.; Chen, C.; Qiu, Z.; Wu, J.; Wang, W.; Cao, W.; Du, L.; Bian, X. Effects of application amounts of biogas slurry on rice growth and the balance of nitrogen, phosphorus in soil system. Crops 2014, 3, 85–91. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Q.; Yang, G.; Shen, F.; Zhang, X.; Zhang, Y. Effects of biogas slurry on yield and quality of oil-seed rape. J. Plant Nutr. 2013, 36, 2084–2098. [Google Scholar] [CrossRef]

- Moreno-García, B.; Guillén, M.; Quílez, D. Response of paddy rice to fertilization with pig slurry in northeast Spain: Strategies to optimize nitrogen use efficiency. Field Crops Res. 2017, 208, 44–54. [Google Scholar] [CrossRef]

- Yang, X.; Jia, Q.; Wang, C.; Zhang, Z. Effect of pig manure and urine returning to the field on fertilizer reduction and efficiency improvement in rice planting. Mod. Agric. Sci. Technol. 2021, 12, 9–11. [Google Scholar] [CrossRef]

- Zhou, Q. Effects of Applying Biogas Liquid Manure and Two Kinds of Microbiological Fertilizer on the Growth and Quality of Lycium barbarum L. Master’s Dissertation, Gansu Agricultural University, Lanzhou, China, 2012. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10733-1012034349.htm (accessed on 16 June 2012).

- Xu, P.; Huang, J.; Peng, Z.; Yu, J.; Lin, Z.; Yang, L.; Wu, X. Effects of slurry on yield, quality and nutrition absorption of Chinese cabbage. Guangdong Agric. Sci. 2014, 41, 71–73. [Google Scholar] [CrossRef]

- Cui, Y.; Ma, D.; Zhao, Y.; Lei, Q.; Ding, S. Impacts of biogas slurry application on growth and quality of pepper. Jiangsu Agric. Sci. 2019, 47, 131–134. [Google Scholar] [CrossRef]

- Gao, X.; Kong, X.; Guo, Y.; Li, J.; Raza, S.; Chen, Z. Effects of chemical fertilizers replacement by biogas slurry on yield, quality and nutrient uptake of muskmelon. North Hortic. 2019, 14, 25–31. Available online: https://d.wanfangdata.com.cn/periodical/bfyany201914005 (accessed on 6 March 2019).

- Cao, Y.; Chang, Z.; Ma, Y.; Yang, H.; Fu, G. Control mechanism of phytophthora blight of chilli pepper by anaerobically digested pig slurry–The roles of ammonium and humic acid in biogas slurry. Chin. J. Eco-Agric. 2013, 21, 1119–1126. [Google Scholar] [CrossRef]

- Cao, Y.; Chang, Z.; Ma, Y.; Yang, H.; Fu, G. Effects of application of anaerobically digested slurry on suppression of pepper (Capsicum frutescens L.) blight and soil biological characteristics. Sci. Agric. Sin. 2013, 46, 507–516. [Google Scholar] [CrossRef]

- Shang, B.; Tao, X.; Chen, Y.; Dong, H.; Huang, H. Inhibitory effect of biogas slurry of cattle manure on vegetable pathogens. J. Agro-Environ. Sci. 2011, 30, 753–760. Available online: http://www.cqvip.com/QK/71135X/201107/37546934.html (accessed on 25 August 2010).

- Feng, Z.; Dong, T.; Zhao, L.; Fu, C.; Li, Y.; Shi, Y.; Feng, H.; Wei, F.; Zhang, D.; Zhu, H. The control effect and mechanism of concentrated biogas slurry on verticillium wilt of upland cotton. Cotton Sci. 2018, 30, 375–385. [Google Scholar] [CrossRef]

- Min, Y.Y.; Toyota, K.; Sato, E.; Takada, A. Effects of anaerobically digested slurry on Meloidogyne incognita and Pratylenchus penetrans in tomato and radish production. Appl. Environ. Soil Sci. 2011, 2011, 528712. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, J.; Wu, H.; Yan, S.; Guo, D.; Wang, G.; Ma, Y. Soil chemical and microbial responses to biogas slurry amendment and its effect on Fusarium wilt suppression. Appl. Soil Ecol. 2016, 107, 116–123. [Google Scholar] [CrossRef]

- Cao, Y.; Ma, Y.; Wu, H.; Wang, G.; Guo, D.; Wang, Q.; Yan, S. Suppression of fusarium wilt of watermelon by biogas slurry application and its effect on soil microbiological characteristics. Soil Fertil. Sci. China 2016, 1, 34–41. [Google Scholar] [CrossRef]

- Li, Y.; Liu, B.; Xu, J.; Li, J.; Lang, Q.; Qiao, Y.; Sun, Q. Effects of soil flooding of biogas slurry on root-knot nematode (Meloidogyne spp.) and soil nematode community. Chin. J. Eco-Agric. 2020, 28, 1249–1257. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, W.; Wang, W.; Li, W.; He, X.; Yang, X. Effects of biogas slurry on soil microbial characteristics of broccoli. Chin. Agric. Sci. Bull. 2017, 29, 112–115. Available online: http://www.cqvip.com/QK/91831X/201729/673598109.html (accessed on 21 March 2017).

- Sang, D.; Yong, S. Field test report on controlling root rot of Astragalus membranaceus with biogas slurry and biogas residue. China Biogas 2011, 29, 55–56. [Google Scholar] [CrossRef]

- Wang, A.; Zhao, X.; Sun, L.; Li, H.; Luo, X. Effect of soil conditioner of biogas slurry on acid soil improvement in Jiaodong area. China Biogas 2019, 37, 98–102. Available online: http://www.cnki.com.cn/Article/CJFDTotal-ZGZQ201904016.html (accessed on 20 November 2018).

- Zheng, X.; Fan, J.; Zhou, J.; He, Y. Effects of combined application of biogas slurry and chemical fertilizer on soil nutrients and peanut yield in upland red soil. Acta Pedol. Sin. 2016, 53, 675–684. [Google Scholar] [CrossRef]

- Zheng, X.; Fan, J.; Cui, J.; Xu, L.; Zhu, Z.; Zhou, J.; He, Y. Analysis on metabolic characteristics and functional diversity of soil edaphon communities in upland red soil under biogas slurry application. Acta Ecol. Sin. 2016, 36, 5865–5875. [Google Scholar] [CrossRef]

- Wang, K.; Xu, Y.; Dai, H.; Lian, M.; Xiang, X.; Zong, D.; Ju, J.; Shu, J. Application of biogas slurry in soil improvement. Jiangsu Agric. Sci. 2019, 47, 299–303. [Google Scholar] [CrossRef]

- Tang, Y.; Wen, G.; Li, P.; Cheng, D.; Han, J. Effects of biogas slurry application on crop production and soil properties in a rice-wheat rotation on coastal reclaimed farmland. Water Air Soil Pollut. 2019, 230, 51. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, L.; Wu, D.; Dai, C.; Han, J. Assessment of heavy metal pollution and bearing capacity estimation of continuous biogas slurry application on cropland: A case study of the coastal rice-wheat rotated farmland in Jiangsu, China. China Environ. Sci. 2019, 39, 1687–1695. [Google Scholar] [CrossRef]

- Zhu, R. Effects of Biogas Slurry and Biochar on Soil Aggregate Organic Carbon and Microbial Community Diversity. Master’s Dissertation, Nanjing Forestry University, Nanjing, China, 2019. Available online: http://cdmd.cnki.com.cn/article/cdmd-10298-1020802002.htm (accessed on 18 June 2019).

- Li, W.; Hu, C.; Yang, L.; Wang, H.; Liu, X.; Li, S. Effects of biogas slurry on tea plantation soil nutrients and tea quality. J. Hubei Polytech. Univ. 2021, 37, 17–22. [Google Scholar] [CrossRef]

- Cao, Z. Future orientation of ecological agriculture. Chin. J. Eco-Agric. 2013, 21, 29–38. Available online: http://cqvip.com/QK/97771A/201301/44558809.Html (accessed on 6 October 2012).

- Li, Y.; Li, J.; Li, J.; Yang, H. Effects of different management practices on microbial biomass carbon and protozoa abundance under greenhouse conditions. Soils 2018, 50, 696–704. [Google Scholar] [CrossRef]

- Feng, D.; Wu, J.; Yang, G.; Zhang, L.; Zhang, Y.; Wang, J. Influence of long-term applications of biogas slurry on microbial community composition and enzymatic activities in surface soil under rice-rape rotation. J. Agro-Environ. Sci. 2014, 33, 1644–1651. [Google Scholar] [CrossRef]

- Yu, F.; Luo, X.; Song, C.; Zhang, M.; Shan, S. Concentrated biogas slurry enhanced soil fertility and tomato quality. Acta Agric. Scand. Sect. B-Soil Plant Sci. 2010, 60, 262–268. [Google Scholar] [CrossRef]

- Chai, Y.; Huang, L.; Dong, Y.; Li, Y.; Wang, Z.; Shan, S.; Ping, L.; Zhang, W. Effects of biogas slurry application rates on soil physical and chemical properties and carbon storage of bamboo forest. Trans. Chin. Soc. Agric. Eng. 2019, 35, 214–220. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, S.; Qiu, X.; Wang, J. Progress of biogas slurry drip irrigation technology. China Biogas 2021, 39, 68–73. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=7106483997 (accessed on 16 March 2021).

- Zheng, X.; Fan, J.; He, Y.; Cui, J.; Xu, L.; Zhu, Z.; Zhou, J. Effect of total nitrogen ratio of biogas slurry/chemical fertilizer on microflora and enzyme activities of soil. Trans. Chin. Soc. Agric. Eng. 2015, 31, 142–150. [Google Scholar] [CrossRef]

- Lv, W.; Wu, J.; Gou, S.; Yang, G.; Wang, L.; Chen, J. The research of biogas slurry on yield and safety. Appl. Mech. Mater. 2011, 71–78, 3142–3146. [Google Scholar] [CrossRef]

- Abubaker, J.; Cederlund, H.; Arthurson, V.; Pell, M. Bacterial community structure and microbial activity in different soils amended with biogas residues and cattle slurry. Appl. Soil Ecol. 2013, 72, 171–180. [Google Scholar] [CrossRef]

- Wentzel, S.; Joergensen, R.G. Effects of biogas and raw slurries on grass growth and soil microbial indices. J. Plant Nutr. Soil Sci. 2016, 179, 215–222. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Q.; Ma, J.; Chapman, S.; Zou, P.; Ye, J.; Yu, Q.; Sun, W.; Lin, H.; Jiang, L. Soil microbial activity and community composition as influenced by application of pig biogas slurry in paddy field in southeast China. Paddy Water Environ. 2020, 18, 15–25. [Google Scholar] [CrossRef]

- Guan, T.; Feng, W.; Wang, H.; Wang, Y.; Zhu, Y.; Guo, T. Effect of topdressing amount of biogas slurry on soil microorganisms and enzyme activities in winter wheat. J. Triticeae Crops 2010, 30, 721–726. Available online: http://www.cqvip.com/QK/96016B/201004/1001412009.html (accessed on 10 January 2010).

- Zhang, H.; Wang, G. Effects of biogas slurry combinated with nitrogen fertilizer on soil microbial biomass and enzyme activities. J. Anhui Agric. Sci. 2011, 39, 16601–16603. [Google Scholar] [CrossRef]

- Hao, X.; Hong, J.; Qiao, Z. Effect of biogas slurry on biological properties of cabbage continuous cropping soil. Chin. J. Appl. Environ. Biol. 2011, 17, 384–387. [Google Scholar] [CrossRef]

- Yuan, D.; Liu, C.; Pu, G.; Wu, D. Effects of seed soaking with biogas slurry on seed germination and seedling growth of tageteserecta. China J. Chin. Mater. Medica 2011, 36, 817–822. Available online: https://pubmed.ncbi.nlm.nih.gov/21761715 (accessed on 23 October 2010).

- Lu, G.; Yang, F.; Wang, H.; Du, T.; Zheng, J.; Xing, H. Effects of biogas slurry soaking seeds on seed germination and physiological characteristics of Astragalus membranaceus var. mongholicus seedling. Soil Fertil. Sci. China 2019, 5, 155–162. [Google Scholar] [CrossRef]

- Shi, L.; Liu, J.; Wei, Y.; Li, B.; Xue, Y.; Bi, Z. Current status of resource utilization of biogas slurry in agriculture. Chin. Agric. Sci. Bull. 2019, 35, 109–117. Available online: https://www.cnki.com.cn/Article/CJFDTotal-ZNTB201935018.htm (accessed on 13 August 2018).

- Yang, W.; Shao, D.; Zhou, Z.; Xia, Q.; Chen, J.; Cao, X.; Zheng, T.; Sun, S. Carbon quantum dots (CQDs) nanofiltration membranes towards efficient biogas slurry valorization. Chem. Eng. J. 2020, 385, 123993. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, C.; Li, K.; Chen, B.; Wang, F. Effect of biogas slurry spraying on leaf photosynthetic characteristics of nectarine (Prunus persica var. nectarina) in solar greenhouse. J. Fruit Sci. 2011, 28, 680–684. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=38527477 (accessed on 10 November 2010).

- Bi, T.; Hu, H.; Liu, L.; Guo, D.; Wang, C.; Zhao, X.; Wu, K.; Yang, B.; Yin, F.; Zhang, W. Effect of biogas slurry application on high efficient production of walnut. J. Northeast Agric. Sci. 2020, 45, 119–121,128. [Google Scholar] [CrossRef]

- Xue, S.; Zhang, C.; Liu, X.; Wang, L. Experimental report on the effect of spraying pure biogas concentrate on cucumber and tomato. Jilin Agric. 2013, 2, 72. Available online: http://www.cqvip.com/qk/86121x/201304/45702718.html (accessed on 1 April 2013).

- Fan, B.; Ni, L.; Shi, W. Effects of concentrated slurry fertilizers on pakchoi growth and soil quality. Soils 2015, 47, 868–873. [Google Scholar] [CrossRef]

- Cui, W.; Li, S.; Li, G.; Chen, Q.; Li, Y.; Zhang, B.; Luo, W. Current research status and perspectives on liquid organic fertilizer utilization based on concentrating biogas slurry. J. Agro-Environ. Sci. 2021, 40, 2482–2493. [Google Scholar] [CrossRef]

- Fu, Y. Study on the Selection of Biogas Slurry Concentration-Separation Process and Effect of Biogas Slurry. Master’s Dissertation, Inner Mongolia University of Technology, Hohhot, China, 2018. Available online: https://cdmd.cnki.com.cn/Article/CDMD-10128-1018795510.htm (accessed on 16 December 2018).

- Wu, Z.; Jin, L.; Wang, G. Effect of biogas slurry fertilizer on yield and quality of muskmelon in greenhouse. Chin. Hortic. Abstr. 2015, 10, 38–39. Available online: http://www.cqvip.com/qk/60020x/201510/666329359.html (accessed on 22 June 2015).

- Li, J.; Jiang, H. The effect of biogas manure on the growth of the seedling of Dendrobium officinale KimuraetMigo. Ningxia J. Agric. For. Sci. Technol. 2016, 57, 48–49. [Google Scholar] [CrossRef]

- Zhou, J. Study on the effect of biogas slurry root irrigation on the yield and stress resistance of Angelica sinensis. China Biogas 2015, 33, 84–86. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=666413994 (accessed on 11 March 2015).

- Gao, X. Effects of Integrated Application of Biogas Slurry Water and Fertilizer Instead of Chemical Fertilizer on Greenhouse Crops and Soil Properties. Master’s Dissertation, Northwest A&F University, Yangling, China, 2019. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10712-1019845671.htm (accessed on 6 August 2019).

- Zhang, L.; Li, Z.; Liu, H.; Liu, S.; Wang, Y.; He, Y.; Zhang, H. Water purification of aquatic cultivated celery in the diluted slurry with different concentrations. Resour. Environ. Yangtze Basin 2011, 20, 154–158. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=1002326304 (accessed on 30 November 2010).

- Yu, C.; Wang, C.; Sheng, M.; Pan, L. Application effect of piggery biogas slurry on the soilless culture of swamp cabbage. J. Nucl. Agric. Sci. 2015, 29, 178–182. Available online: https://d.wanfangdata.com.cn/periodical/hnxb201501023 (accessed on 10 January 2014).

- Yang, X.; Wang, W.; Hu, X.; Li, X.; Fan, Y. Effect of biogas slurry on photosynthesis, yield and quality of lettuce grown in hydroponic culture. J. Irrig. Drain. 2017, 36, 55–59,85. [Google Scholar] [CrossRef]

- Liang, F.; Cui, Q.; Tu, T.; Yu, G.; Wang, W.; Yan, S. Benign treatment of biogas slurry and improvement in lettuce quality using hydroponics. J. Agro-Environ. Sci. 2018, 37, 788–795. [Google Scholar] [CrossRef]

- Odlare, M.; Nehrenheim, E.; Ribé, V.; Thorin, E.; Gavare, M.; Grube, M. Cultivation of algae with indigenous species-Potentials for regional biofuel production. Appl. Energy 2011, 88, 3280–3285. [Google Scholar] [CrossRef]

- Tan, F.; Wang, Z.; Zhouyang, S.; Li, H.; Xie, Y.; Wang, Y.; Zheng, Y.; Li, Q. Nitrogen and phosphorus removal coupled with carbohydrate production by five microalgae cultures cultivated in biogas slurry. Bioresour. Technol. 2016, 221, 385–393. [Google Scholar] [CrossRef] [PubMed]

- Das, M.; Ayyappan, S.; Dash, B.; Muduli, H.K. Heterotrophic bacterial populations and dehydrogenase activity in fish ponds under different fertilisation practices. Indian J. Fish. 2013, 60, 87–90. Available online: http://eprints.cmfri.org.in/id/eprint/9599 (accessed on 30 October 2013).

- Chu, C.; Li, S.; Ma, D.; Pan, Z.; Cao, Y. Effect of subsurface drip irrigation with aerated biogas slurry on yield and quality of Chinese chives. China Biogas 2013, 31, 41–47. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, Y.; Yao, L.; Zhang, H.; Guo, H.; Liu, Y. Effect of biogas slurry application on strawberry planting. China Biogas 2013, 31, 36–39. [Google Scholar] [CrossRef]

- Wang, Z. Effect of underground drip irrigation with biogas slurry on yield and quality of cucumber. Agric. Eng. Technol. 2018, 38, 15–16. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Shi, Q.; Liu, D. Effect of drip irrigation with biogas slurry on yield and quality of processing tomato. China Biogas 2013, 31, 59–62. [Google Scholar] [CrossRef]

- Ma, D.; Chu, C.; Li, S.; Bi, Y.; Zhang, L. Effects of underground drip irrigation with biogas slurry and aeration after irrigation on tomato yield and quality. Agric. Eng. Technol. 2017, 37, 18–19. [Google Scholar] [CrossRef]

- Wang, X.; Sun, Z.; He, J.; Jiao, B. Research on the effect of drip irrigation of biogas slurry improved alkaline-saline soil in Gansu. China Rural Water Hydropower 2018, 3, 55–58,61. Available online: http://www.cqvip.com/QK/91883A/201803/674842076.html (accessed on 26 September 2017).

- Wang, Y. Research on the Use of Farmland Disposal Technology by Biogas Slurry And Soil Environmental Effects. Master’s Dissertation, Zhejiang Normal University, Hangzhou, China, 2010. [Google Scholar] [CrossRef]

- An, J.; Song, Z. A preliminary study of effect of application biogas residue and biogas slurry on codonopsis pilosula. China Biogas 2011, 29, 51–52. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=40354989 (accessed on 15 August 2011).

- Zhang, F.; Hu, S.; Kang, K.; Huang, H.; Yang, H.; Li, C.; Li, T. Effect of highly efficient biogas slurry fertilizer on greenhouse tomatoes. J. Northwest AF Univ. (Nat. Sci. Ed.) 2013, 41, 75–78. [Google Scholar] [CrossRef]

- Yuan, Y.; Gao, Z.; Jia, S.; Gao, X.; Zhang, W.; Liu, C.; Wang, D. Effects of digestate application on N2O and NH3 emissions of apple orchard soil. J. Hebei Agric. Univ. 2019, 42, 57–64. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, Z.; Li, Z.; Li, B. Effects of firedamp liquid on yield and quality of tomato, radish, celery and China bean. Guizhou Agric. Sci. 2007, 35, 99–100. [Google Scholar] [CrossRef]

- Wang, C. Effect of Spraying Biogas and KH2PO4 on the Leaves Photosynthetic Characteristics and Fruit Quality of Nectarine (Prunes per sick var. Nectarina Maxim). Master’s Dissertation, Gansu Agricultural University, Lanzhou, China, 2010. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10733-1011026398.html (accessed on 16 May 2011).

- Chen, J.; Jia, L.; Zhao, J.; Wang, Y.; Ren, G.; Yang, G. Effect of spraying biogas slurry on apple yield, quality and sucrose metabolism enzyme activity. North Hortic. 2017, 18, 35–41. Available online: http://www.cqvip.com/QK/97019X/201718/673249310.html (accessed on 5 April 2017).

- Zhou, W.; Sun, G.; Wang, X.; Tong, H.; Sheng, J. Risk of nitrogen loss under the combined application of biogas slurry and organic fertilizer. J. Agro-Environ. Sci. 2019, 38, 1743–1750. [Google Scholar] [CrossRef]

- Yuan, J.; Qi, X.; Zhao, J.; Li, P.; Du, Z.; Li, K.; Wang, P. The effect of biochar amendment and slurry application on soil aggregation and organic carbon distribution. J. Irrig. Drain. 2022, 41, 80–86. [Google Scholar] [CrossRef]

- Song, D.; He, Z.; Dong, Y.; Dai, W.; Yang, X.; Cao, L.; Sha, Z. Nitrogen losses and Cu, Pb changes of paddy field affected by adding duckweed under biogas slurry application. Chin. J. Eco-Agric. 2020, 28, 608–618. [Google Scholar] [CrossRef]

- Cheng, H.; Zhang, Y.; Meng, H.; Shen, Y.; Ding, J.; Zhan, S. Parameter optimization of preparation for biogas slurry based water-soluble liquid fertilizer containing humic acid. Trans. Chin. Soc. Agric. Eng. 2018, 34, 227–233. [Google Scholar] [CrossRef]

- Ran, Y.; Wu, Y.; Xu, L.; Liang, F.; Yan, S. Growth performance of rice at the tillering stage after applying CO2-rich biogas slurry. J. Agric. Resour. Environ. 2020, 37, 202–208. [Google Scholar] [CrossRef]

- Qi, B.; Wang, H.; Li, J.; Jiang, X.; Li, R.; Wang, W. Fertilizer efficiency and safety of liquid digestate membrane concentrate based fertilizer on pakchoi (Brassica chinensis L.). Southwest China J. Agric. Sci. 2021, 34, 89–93. [Google Scholar] [CrossRef]

- Kang, X.; Zheng, Y.; Li, Q. Effects of combined use of biogas slurry and nitrogen fertilizer on yield and quality of Taraxacum mongolicum. J. Changjiang Veg. 2019, 16, 74–77. Available online: https://d.wanfangdata.com.cn/periodical/cjsc201916026 (accessed on 29 March 2019).

- Li, C.; Qu, Z.; Gou, M.; Su, Y.; Huo, X. Effects of biochar amendment on soil water and nutrient utilization efficiencies and tomato growth. J. Agro-Environ. Sci. 2014, 33, 2187–2193. [Google Scholar] [CrossRef]

- Zheng, J.; Li, X.; Ma, J.; Xiang, P.; Wang, J. Effects of combined application of biochar and biogas slurry on percolate electrical conductivity, total nitrogen and soil physical and chemical properties. Agric. Res. Arid Areas 2020, 38, 134–144. Available online: https://d.wanfangdata.com.cn/periodical/ghdqnyyj202003018 (accessed on 17 September 2019).

- Zheng, J.; Li, X.; Ma, J.; Ma, B.; Wang, Y.; Wang, L. Effect of biogas slurry combined with straw biochar on soil organic matter and total nitrogen content. J. Agro-Environ. Sci. 2020, 39, 1111–1121. [Google Scholar] [CrossRef]

- Jiang, T.; Wang, L.; Sun, F.; Cheng, J.; He, T.; Qin, S.; Fan, C.; Yin, W. Effects of solid-digestate biochar application on soil nitrogen leaching and cabbage yield with liquid-digestate irrigation in karst-mountainous region of southwest China. Acta Agric. Zhejiangensis 2021, 33, 2104–2115. [Google Scholar] [CrossRef]

- Luo, L. Effects of Concentrated Biogas Slurry Application Combined with Chemical Fertilizers on Rice and Rape Yield and Quality. Master’s Dissertation, Zhejiang A&F University, Hangzhou, China, 2010. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10341-1011026892.htm (accessed on 9 June 2010).

- Liu, J. Biogas Slurry Coupled with Other Source of Manure Application Reseach in Culthure of Organic Ground Substance. Master’s Dissertation, Henan Agricultural University, Zhengzhou, China, 2013. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Tian, P.; Li, K.; Ge, X. Preparation and function of medicine and fertilizer integrated aqua based on berberine and biogas slurry. Sci. Technol. Food Ind. 2018, 39, 309–313. [Google Scholar] [CrossRef]

- Liu, M.; Wang, H.; Wang, Y.; Luan, B.; Chen, M. Field control effects of mixed application of pesticides fertilizer. Agrochemicals 2019, 58, 929–931. [Google Scholar] [CrossRef]

- Wang, H.; Wang, E.; Wang, Y.; Luan, B.; Wang, P.; Chen, M. The field control effects of the mixture of chicken manure and fluridamide on Aphis citricola. China Fruits 2019, 6, 83–86. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, Y.; Sheng, J.; Liang, Y.; Wu, H.; Chen, L.; Zheng, J. Effects of biogas slurry application on paddy field water nitrogen content at tillering stage. Chin. J. Eco-Agric. 2015, 23, 1544–1551. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, Y.; Sheng, J.; Guan, Y.; Wu, H.; Chen, L.; Zheng, J. Effects of biogas slurry degradation on nitrogen content in paddy field water of panicle fertilizer stage. J. Soil Water Conserv. 2015, 29, 246–251. [Google Scholar] [CrossRef]

- Yang, R.; Sun, Q.; Zhao, H.; Zou, G.; Liu, B.; Li, L. Precision application of biogas slurry and its environmental effects in paddy fields. J. Agro-Environ. Sci. 2017, 36, 1566–1572. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, Q.; Chen, D.; Li, A.; Qian, S.; Fu, J.; Wang, J. Effects of paddy field disposal of biogas slurry on the rice production, soil quality and environmental safety. J. Agro-Environ. Sci. 2011, 30, 1328–1336. Available online: https://d.wanfangdata.com.cn/periodical/nyhjbh201107011 (accessed on 6 January 2011).

- Li, S. Nitrogen Dynamics in Paddy Field after Irrigation of Biogas Slurry and Its Impact on the Environment. Master’s Dissertation, Zhejiang University, Hangzhou, China, 2011. Available online: http://cdmd.cnki.com.cn/article/cdmd-10335-1011052437.htm (accessed on 19 January 2011).

- Kang, L.; Zhao, Z.; Qu, M.; Chen, Q. Effects of biogas waste on solanaceae vegetable growth and soil nutrient accumulation in greenhouse. China Veg. 2011, 22/24, 57–62. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=90718367504849499049484955 (accessed on 10 October 2010).

- Du, H.; Gao, W.; Li, J.; Shen, S.; Wang, F.; Fu, L.; Zhang, K. Effects of digested biogas slurry application mixed with irrigation water on nitrate leaching during wheat-maize rotation in the North China Plain. Agric. Water Manag. 2019, 213, 882–893. [Google Scholar] [CrossRef]

- Ma, H. Antibiotic residue and human health-Be on guard against the abuse of antibiotics in poultry farming. Cap. Med. 2014, 23, 23–24. Available online: http://med.wanfangdata.com.cn/Paper/Detail/PeriodicalPaper_sdyy201423008 (accessed on 21 January 2015).

- Qian, M.; Wu, H.; Wang, J.; Zhang, H.; Zhang, Z.; Zhang, Y.; Lin, H.; Ma, J. Occurrence of trace elements and antibiotics in manure-based fertilizers from the Zhejiang Province of China. Sci. Total Environ. 2016, 559, 174–181. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Wan, M.; Liu, R.; Wang, G.; Zhang, X.; Wen, X.; Zhao, Y.; Chen, L. Study on the quality of digested piggery wastewater in large-scale farms in Jiaxing. Environ. Sci. 2014, 35, 2650–2657. [Google Scholar] [CrossRef]

- Shen, A.; Xi, H.; Jiang, M.; An, W.; Wang, Y.; Chen, X. Establishment and operation effect of ecological recycling model of biogas slurry from livestock. J. Zhejiang Agric. Sci. 2019, 60, 1271–1274. [Google Scholar] [CrossRef]

- Zhou, Y.; Feng, R.; Zhu, P.; Li, Z.; Kang, Q. Review of pretreatment technology before biogas slurry used as resource in China. Adv. Environ. Prot. 2020, 10, 249–258. [Google Scholar] [CrossRef]

- Bian, B.; Zhou, L.; Li, L.; Lv, L.; Fan, Y. Risk assessment of heavy metals in air, water, vegetables, grains, and related soils irrigated with biogas slurry in Taihu Basin, China. Environ. Sci. Pollut. Res. 2015, 22, 7794–7807. [Google Scholar] [CrossRef]

- Zhou, L.; Lv, L. Characteristics of heavy metal in biogas slurry, soil and vegetable system. J. Nanjing Tech Univ. (Nat. Sci. Ed.) 2017, 39, 63–69. [Google Scholar] [CrossRef]

- Wang, Y. Effects of Irrigation Intensity of Biogas Slurry on Soil and Plant Nutrient and Heavy Metal Content. Master’s Dissertation, Guangxi University, Nanning, China, 2018. [Google Scholar] [CrossRef]

- Han, J.; Fan, D.; Guo, Y.; Shen, J.; Han, J. Effect of pig slurry on the availability of heavy metals in soils with different pH. Res. Agric. Mod. 2021, 42, 2–9. [Google Scholar] [CrossRef]

- Wu, G.; Liao, X.; He, D.; Li, J. Current situation and countermeasures of livestock industry pollution control in China. J. Agro-Environ. Sci. 2014, 33, 1261–1264. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=663951755 (accessed on 16 May 2014).

- Cui, B.; Gao, F.; Hu, C.; Li, Z.; Fan, X.; Cui, E. The use of brackish and reclaimed waste water in agriculture: A review. J. Irrig. Drain. 2019, 38, 60–68. [Google Scholar] [CrossRef]

- Guo, Q.; Gong, X.; Liu, H. Study on effect of long-term application of biogas manure on soil nutrients and salt in protected-land vegetable field. Acta Agric. Boreali-Occident. Sin. 2020, 29, 127–134. [Google Scholar] [CrossRef]

- Sun, T.; Wang, P.; Chen, X.; Cai, Y.; Ren, L.; Lv, Z. Effects of liquid bacterial fertilizer prepared by biogas slurry from food waste digesting on physical and chemical properties of farmland Soil. Environ. Eng. 2020, 38, 201–206. [Google Scholar] [CrossRef]

- Fan, J.; Li, Y.; Hu, C.; Li, J.; Zhang, Z.; Li, D.; Li, W. Response of sunflower to salt and alkali stress induced by biogas slurry irrigation. J. Agric. Resour. Environ. 2022, 39, 193–200. [Google Scholar] [CrossRef]

- Jin, H.; Fu, G.; Chang, Z.; Ye, X.; Chen, G.; Du, J. Distribution of nitrogen in liquid and solid fraction of pig and dairy manure in anaerobic digestion reactor. Trans. Chin. Soc. Agric. Eng. 2012, 28, 208–214. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=43900673 (accessed on 30 May 2012).

- Jin, H.; Chang, Z.; Guo, D.; Wu, H. Effect of topdressing with digested pig slurry on ammonia volatilization in vegetable fields. Acta Pedol. Sin. 2012, 49, 86–95. Available online: https://www.doc88.com/p-1844633373974.html (accessed on 22 August 2012).

- Jin, H.; Chang, Z.; Wu, H.; Guo, D.; Huang, H.; Ma, Y.; Xu, Y.; Zhang, J. NH3 and N2O emission and nitrogen loss rate from biogas liquid produced by pig slurry after topdressing on vegetable fields. J. Plant Nutr. Fertil. 2013, 19, 1155–1165. [Google Scholar] [CrossRef]

- Deng, O.; Jiang, L.; Chen, D.; Yang, S.; Lv, J. Ammonia volatilization from the biogas slurry irrigation paddy field. J. Soil Water Conserv. 2011, 25, 233–236. [Google Scholar] [CrossRef]

- Li, H.; Luo, N.; Ma, J.; Li, N.; Chen, X.; Shen, A.; Guo, B.; Fu, Q. Effect of biogas slurry irrigation on farmland soils and environment. J. Zhejiang Agric. Sci. 2019, 60, 1317–1321. [Google Scholar] [CrossRef]

- Martines, A.M.; Nogueria, M.A.; Santos, C.A.; Nakatani, A.S.; Andrade, C.A.; Coscione, A.R.; Cantarella, H.; Sousa, J.P.; Cardoso, E.J.B.N. Ammonia volatilization in soil treated with tannery sludge. Bioresour. Technol. 2010, 101, 4690–4696. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Chen, Y.; He, T.; Liu, R.; Yi, M.; Yang, Z. Nitrogen leaching losses following biogas slurry irrigation to purple soil of the Three Gorges Reservoir Area. Environ. Sci. Pollut. Res. 2018, 25, 29096–29103. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Wang, K.; Li, H.; Sun, X.; Ma, J.; Zhang, J.; Yang, Z. Effects of surface application of biogas slurry and urea in different proportions on ammonia volatilization in paddy field. J. Anhui Agric. Sci. 2022, 50, 154–157. [Google Scholar] [CrossRef]

- Tian, Y.; He, F.; Yin, B.; Zhu, Z. Ammonia volatilization from paddy fields in the Taihu lake region as affected by N and P combination in fertilization. Acta Pedol. Sin. 2007, 44, 893–900. Available online: http://cqvip.jskjwx.org/article/detail.aspx?id=25442262 (accessed on 10 May 2006).

- Yang, S.; Peng, S.; Xu, J.; Yao, J.; Jin, X.; Song, J. Characteristics and simulation of ammonia volatilization from paddy fields under different water and nitrogen management. Trans. Chin. Soc. Agric. Eng. 2012, 28, 99–104. [Google Scholar] [CrossRef]

- Li, X.; Yang, J.; Wang, C.; Bai, G.; You, L.; Yi, Y.; Huang, F.; Li, B.; Zeng, P. Effects of pig manure applications on ammonia volatilization in soil during rice season in Chengdu Plain. J. Agro-Environ. Sci. 2015, 34, 2236–2244. [Google Scholar] [CrossRef]

- Sommer, S.G.; Génermont, S.; Cellier, P.; Hutchings, N.J.; Olesen, J.E.; Morvan, T. Processes controlling ammonia emission from livestock slurry in the field. Eur. J. Agron. 2003, 19, 465–486. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, H.; Zhu, Z.; Li, L.; Zhou, T.; Jiang, B.; Xin, H. CH4, NH3, N2O and NO emissions from stored biogas digester effluent of pig manure at different temperatures. Agric. Ecosyst. Environ. 2016, 217, 1–12. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, H.; Zhu, Z.; Gerber, P.J.; Xin, H.; Smith, P.; Opio, C.; Steinfeld, H.; Chadwick, D. Mitigating greenhouse gas and ammonia emissions from swine manure management: A system analysis. Environ. Sci. Technol. 2017, 51, 4503–4511. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Wang, D.; Wang, Y.; Wang, X.; Feng, Y. Opportunities and challenges for biogas development: A review in 2013–2018. Curr. Pollut. Rep. 2019, 5, 25–35. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Zhang, Y.; Guo, Z.; Sheng, J.; Zheng, J. COD in biogas slurry: Effects on cucumber seedling growth and soil environmental factors. Chin. Agric. Sci. Bull. 2019, 35, 15–22. Available online: http://www.cqvip.com/qk/91831x/20194/90788466504849574852484851.html (accessed on 4 June 2018).

- Zhang, Y.; Li, Z.; Zhang, L.; Li, S.; Zhang, Q.; Zhan, X. Effect of physicochemical properties of liquid digestate of pig manure on seed germination of maize. China Biogas 2021, 39, 13–21. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, G.; Wang, Z.; Zong, J.; Zhou, W.; Sheng, J. Analysis of rice seedling growth restriction factors under biogas slurry application. J. Agro-Environ. Sci. 2021, 40, 2537–2543. [Google Scholar] [CrossRef]

- Ye, J.; Miao, J.; Huang, Y.; Li, Y.; Li, Z. Effects of biogas slurry irrigation on heavy metal content and yield of lettuce. Acta Agric. Jiangxi 2014, 26, 96–99. [Google Scholar] [CrossRef]

- Yang, J.; Feng, W.; Jia, L.; Han, B.; Yang, Z.; Chang, Y.; Dou, F.; Liu, M.; Xing, S.; Wang, P. Effects of topdressing biogas slurry on the content of heavy metals in Chinese cabbage and soil. J. Hebei Agric. Sci. 2015, 19, 68–73. [Google Scholar] [CrossRef]

- Mainardis, M.; Buttazzoni, M.; Gievers, F.; Vance, C.; Magnolo, F.; Murphy, F.; Goi, D. Life cycle assessment of sewage sludge pretreatment for biogas production: From laboratory tests to full-scale applicability. J. Clean. Prod. 2021, 322, 129056. [Google Scholar] [CrossRef]

- van den Berg, P.; Huerta-Lwanga, E.; Corradini, F.; Geissen, V. Sewage sludge application as a vehicle for microplastics in eastern Spanish agricultural soils. Environ. Pollut. 2020, 261, 114198. [Google Scholar] [CrossRef]

- Urra, J.; Alkorta, I.; Mijangos, I.; Epelde, L.; Garbisu, C. Application of sewage sludge to agricultural soil increases the abundance of antibiotic resistance genes without altering the composition of prokaryotic communities. Sci. Total Environ. 2019, 647, 1410–1420. [Google Scholar] [CrossRef]

| Element in Biogas Slurry | PM | DM | CM | MM | ||||

|---|---|---|---|---|---|---|---|---|

| Range | Average | Range | Average | Range | Average | Range | Average | |

| pH | 4.23–9.20 | 7.52 | 6.10–9.20 | 7.75 | 6.77–8.50 | 7.80 | 6.15–8.20 | 7.37 |

| TN (mg/L) | 0.80–7280.00 | 1166.71 | 32.00–6500.00 | 1488.59 | 400.00–5700.00 | 3226.13 | 0.04–5900.00 | 1369.31 |

| TP (mg/L) | 0.54–2220.50 | 291.60 | 10.00–3700.00 | 561.67 | 49.00–4650.00 | 959.71 | 0.03–3900.00 | 665.90 |

| TK (mg/L) | 0.33–8880.00 | 1144.26 | 11.00–9650.00 | 1679.10 | 390.00–4400.00 | 2858.31 | 0.12–3200.00 | 1240.21 |

| NH4+-N (mg/L) | 66.53–1800.00 | 597.53 | 80.35–1098.00 | 493.47 | ND | ND | 250.50–787.80 | 519.15 |

| NO3−-N (mg/L) | 0.19–472.16 | 67.84 | 0.70–223.70 | 71.53 | ND | ND | ND | ND |

| DP (mg/L) | 0.16–1730.00 | 261.40 | 80.00–1860.00 | 416.88 | ND | ND | 0.16–201.10 | 76.68 |

| DK (mg/L) | 0.86–5010.00 | 986.47 | 263.20–2500.00 | 1418.33 | ND | ND | 0.84–2316.70 | 764.73 |

| Hg (mg/L) | 0–0.167 | 0.028 | 0–0.119 | 0.024 | 0–0.054 | 0.014 | ||

| Cd (mg/L) | 0–7.51 | 0.126 | 0–0.190 | 0.039 | 0–4.3 | 0.367 | ||

| As (mg/L) | 0–13 | 0.868 | 0.001–4.576 | 0.235 | 0.01–5.21 | 0.548 | ||

| Pb (mg/L) | 0–36.07 | 0.710 | 0.008–1.056 | 0.199 | 0–2.430 | 0.345 | ||

| Cr (mg/L) | 0–24.18 | 0.657 | 0–3.146 | 0.301 | 0.001–10.18 | 1.085 | ||

| Ni (mg/L) | 0–5.85 | 0.317 | 0.027–0.063 | 0.045 | 0.088–0.55 | 0.281 | ||

| Cu (mg/L) | 0–99 | 4.50 | 0.02–30.03 | 2.63 | 0–2.12 | 0.78 | ||

| Zn (mg/L) | 0–205.43 | 9.11 | 0.1–68.15 | 8.31 | 0–13.94 | 4.06 | ||

| Cl (mg/L) | 150–3647.5 | 917.1 | 850.5–963 | 906.8 | 540–1087 | 813.5 | ||

| Na (mg/L) | 88.5–559 | 287.1 | 994.45 | 994.45 | 172.29 | 172.29 | ||

| Se (mg/L) | 0–0.232 | 0.049 | 0.002–0.022 | 0.012 | 0.011 | 0.011 | ||

| Mn (mg/L) | 0–50.8 | 6.815 | 0.231–124.6 | 61.092 | 0–50.8 | 7.534 | ||

| Fe (mg/L) | 0.0014–6.05 | 2.505 | 0.0084–48.3 | 18.56 | 0.0054–13.3 | 4.962 | ||

| Mg (mg/L) | 0.0057–253.34 | 109.6 | 0.352–553 | 225.06 | 0.0109–89.46 | 32.82 | ||

| Ca (mg/L) | 0.0042–264 | 81.65 | 0.785–769 | 280.8 | 0.0426–96.1 | 61.14 | ||

| Oxytetracycline (mg/L) | 0.0001–0.994 | 0.1456 | 0.5748 | 0.5748 | 0.0759–0.4007 | 0.2383 | ||

| Tetracycline (mg/L) | 0–0.9821 | 0.0296 | 0.0208–0.5608 | 0.2908 | 0.0289–12.862 | 4.3106 | ||

| Chloromycin (mg/L) | 0.0002–0.642 | 0.0415 | ND | ND | ND | ND | ||

| Norfloxacin (mg/L) | 0–0.204 | 0.0191 | 0.0054–0.1189 | 0.0641 | 0.056–0.2048 | 0.1065 | ||

| Ciprofloxacin (mg/L) | 0.0002–0.0513 | 0.0052 | 0.016–0.0227 | 0.0183 | 0.005–0.0071 | 0.0058 | ||

| Enrofloxacin (mg/L) | 0–0.1513 | 0.0108 | 0.0058–0.089 | 0.0520 | 0.0073–0.0676 | 0.0519 | ||

| Amino Acids | Contents (mg/L) | Amino Acids | Contents (mg/L) | Plant Hormones | Contents (μg/L) | B Vitamins | Contents (mg/L) |

|---|---|---|---|---|---|---|---|

| Cysteine | 2.92 | Arginine | 0.63 | Indole acetic acid (IAA) | 332 | B1 | 0.089 |

| Serine | 2.07 | Proline | 0.58 | Gibberellin (GA4) | 0.857 | B2 | 0.022 |

| Threonine | 1.41 | Valine | 0.56 | Gibberellin (GA19) | 1.47 | B6 | 0.530 |

| Lysine | 1.05 | Leucine | 0.45 | Gibberellin (GA53) | 0.271 | B11 | 0.078 |

| Glycine | 1.01 | Methionine | 0.36 | Cytokinin (iPR) | 0.00194 | B12 | 0.009 |

| Tyrosine | 0.88 | Alanine | 0.36 | 8-hydroxy-3,4-dihydroquinoline-2-ketone | 737.5 | ||

| Aspartic acid | 0.76 | Phenylalanine | 0.33 | 3,4-dihydroquinoline-2-ketone | 177.5 | ||

| Isoleucine | 0.75 | Glutamate | 0.31 | ||||

| Histidine | 0.63 |

| Slurry Type | Crops | Production Increase Range | References | |

|---|---|---|---|---|

| Comparison with Conventional Chemical Fertilizer | Comparison with No Fertilization | |||

| PM | Rice | 0.2–20.4% | 1.0–102.5% | [61,74,75,76,77,78,79,80] |

| Wheat | 2.9–22.4% | 97.1–217.5% | [74,76] | |

| Corn | 0.6% | 5.6–13.2% | [81,82] | |

| Barley | 1.1–2.0% | 31.9–111.9% | [83] | |

| Watermelon | 0.2–24.9% | ND | [84,85,86] | |

| Pear | 12.0% | 3.1–7.4% | [87,88] | |

| Grape | ND | 10.7–18.3% | [89] | |

| Peach | ND | 9.7–43.7% | [90] | |

| Cabbage | ND | 75.4–133.9% | [91] | |

| Tea | ND | 9.3–93.4% | [92] | |

| DM | Corn | ND | 59.2–81.7% | [70] |

| Melon | 8.8–32.2% | 8.6–33.0% | [93,94,95] | |

| Grape | 30.0–170.0% | ND | [96] | |

| CM | Corn | 9.0–26.2% | 12.9–107.7% | [63,64] |

| Apple | 2.0–3.5% | 42.8–67.0% | [97] | |

| Leafy vegetables | 9.1–45.1% | 45.1% | [98,99,100] | |

| MM | Rice | 4.6–7.7% | 4.1% | [101,102] |

| Wheat | ND | 28.2–71.1% | [103] | |

| Tomato | 0.49–21.59% | 15.6–39.8% | [104,105] | |

| Cabbage | 8.5–41.2% | ND | [106] | |

| Tangerine | 11.8–24.8% | 32.4–56.4% | [107,108] | |

| Soil Type | Crops | Slurry Type | Total Nitrogen Consumption of Slurry (kg/hm2) | Years | Improvement Range of Soil Enzyme Activity | References | |

|---|---|---|---|---|---|---|---|

| Comparison with No Fertilization | Comparison with Conventional Chemical Fertilizer | ||||||

| Yellow loamy paddy soil | Rice–rape | PM | 157.5–694.9 | 3 | Urease 31.8–74.6%, catalase 4.4–85.1%, sucrase 30.4–228.6% | Urease 21.7–61.1%, catalase 19–111%, sucrase 45.4–266.4% | [140] |

| Retention paddy soil | Rice–wheat | PM | 210.3–540.9 | 3 | Urease 30.5–79.5%, protease 19.1–41.4%, phosphatase 11.3–29.7%, catalase 6.4–40.1%, sucrase 0.2–39.3%, amylase 53.1–161.4%, cellulase 15.8–104.8%, lactase 30.1–65.2% | Urease 26.7–74.8%, protease 9.1–43.3%, phosphatase 7.3–8.8%, catalase 14.9–30.2%, sucrase 3–49.4%, amylase 28–145.7%, cellulase 38.5–48.3%, lactase 13.3–37.1% | [76] |

| Medium loam | Wheat | PM | 60–180 | 1 | Urease 57.5–72.5%, protease 31.7–62.6% | Urease 10.5–21.1%, protease 6–30.1% | [149] |

| Red soil | Peanut | PM | 36–240 | 2 | Urease 16.2–62.3%, dehydrogenase 48.6–133.1% | Urease 11.3–24.1%, dehydrogenase 33.8–120.5% | [144] |

| Aeolian sandy soil | Grape | DM | 190–1160 | 2 | ND | Urease 41–113.8%, phosphatase 32.4–106.4%, sucrase 62.7–98% | [96] |

| ND | Cucumber | (P+C)M | 37.5–150 | 1 | Polyphenol oxidase 13.49–14.75%, cellulase 68.7–71.9%, chitinase 41.0–57.5%, | ND | [150] |

| ND | Cabbage | (P+S)M | 504–675 | 3 | ND | Urease 2.4%, protease 95.4–139.7%, phosphatase 50.5–137.6%, invertase 55.7–64.0% | [151] |

| Paddy soil | Citrus | (P+D)M | 450 | 4 | ND | Urease 53.8–100.0%, protease 23.1–100.0%, phosphatase 20.2–42.3%, catalase 107.0–127.5%, dehydrogenase 36.6–96.0%, sucrase 47.4–111.8% | [108] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Sanusi, I.A.; Wang, J.; Ye, X.; Kana, E.B.G.; Olaniran, A.O.; Shao, H. Developments and Prospects of Farmland Application of Biogas Slurry in China—A Review. Microorganisms 2023, 11, 2675. https://doi.org/10.3390/microorganisms11112675

Wang Z, Sanusi IA, Wang J, Ye X, Kana EBG, Olaniran AO, Shao H. Developments and Prospects of Farmland Application of Biogas Slurry in China—A Review. Microorganisms. 2023; 11(11):2675. https://doi.org/10.3390/microorganisms11112675

Chicago/Turabian StyleWang, Zichen, Isaac A. Sanusi, Jidong Wang, Xiaomei Ye, Evariste B. Gueguim Kana, Ademola O. Olaniran, and Hongbo Shao. 2023. "Developments and Prospects of Farmland Application of Biogas Slurry in China—A Review" Microorganisms 11, no. 11: 2675. https://doi.org/10.3390/microorganisms11112675