Hybrid Photovoltaic Thermal Systems: Present and Future Feasibilities for Industrial and Building Applications

Abstract

:1. Introduction

2. PVT Systems and Their Performances

2.1. Air-Based PVT Systems

2.2. Water-Based PVT Systems

2.3. Bi-Fluid-Based PVT Systems

2.4. Heat-Pipe-Based PVT Systems

2.5. PCM-Based PVT Systems

2.6. Summary

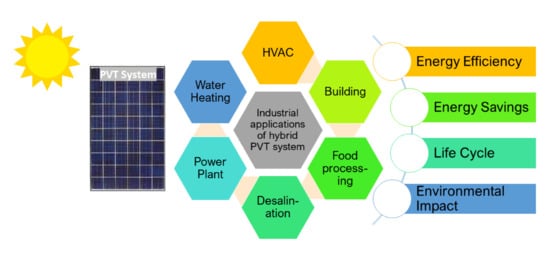

3. Industrial Applications of a Hybrid PVT System

3.1. Water Heating

3.2. Water Desalination

3.3. Thermal Management in Buildings

3.4. Agricultural Processes Solar Drier

3.5. Food Processing

3.6. Heating, Ventilation, and Air Conditioning

3.7. Thermal Powerplants

3.8. Summary of Hybrid PVT System Applications

3.9. Discussion and Inferences Abount Hybrid PVT Systems

4. Environmental Analysis of PVT Systems

5. Technical Challenges and Limitations

6. Conclusions and Recommendations

- Investigate the impact of dust and dirt on the efficiency of PVT systems under various weather conditions, as most previous research has focused on clean conditions with low occurrence and intensity of rain.

- Conduct experiments that simultaneously explore the use of nanofluid as the heat transfer fluid (HTF) and PCM/NEPCM as the cooling method, as this area has received limited attention compared to studies on nanofluid- and water-based PVT systems.

- Perform long-term tests to assess the performance of PVT devices over extended periods, including the examination of the effects of prolonged solar exposure on adhesives, glazes, selective coating materials, and other components.

- Explore alternative heat transfer techniques, such as PCMs and NEPCMs, as cooling media in PVT systems, as the majority of the existing literature primarily focuses on water and air as the cooling mediums. Investigate various PCM and NEPCM options for PVT systems.

- It is necessary to work on flame retardant and leakage-preventable PCMs to avoid leakage during the phase transition of the PCM-integrated PVT system.

- Consider studying nano-fluid-based jet impingement systems, as they have the potential to generate a greater amount of heat energy and electricity.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ALCC | Annualized life cycle cost |

| ALCS | Annualized life cycle savings |

| COP | Coefficient of performance |

| CPVT | Concentrated photovoltaic thermal |

| ECS | Electricity savings |

| EG | Ethylene glycol |

| Epv | Photovoltaic energy |

| Et | Thermal energy |

| HTF | Heat transfer fluid |

| LCC | Life cycle cost |

| LPM | Liters per minute |

| MC | Maintenance cost |

| N | Optimum number |

| NCOT | Nominal cell operating temperature |

| NEPCM | Nano-enhanced phase change material |

| PCM | Phase change materials |

| PMMA | Polymethyl methacrylate |

| PV | Photovoltaic |

| PVT | Photovoltaic thermal |

| PWF | Present worth factor |

| SAH | Solar air heater |

| STC | Standard temperature conditions |

| tCO2 | Tonne of carbon dioxide |

| Tmean | Mean temperature |

| V | Volt |

| VAR | Vapor absorption refrigeration |

| Voc | Open circuit voltage |

| W | Watts |

References

- Zhan, S.; Dong, B.; Chong, A. Improving energy flexibility and PV self-consumption for a tropical net zero energy office building. Energy Build. 2023, 278, 112606. [Google Scholar] [CrossRef]

- Laghari, I.A.; Samykano, M.; Pandey, A.K.; Kadirgama, K.; Tyagi, V.V. Advancements in PV-thermal systems with and without phase change materials as a sustainable energy solution: Energy, exergy and exergoeconomic (3E) analytic approach. Sustain. Energy Fuels 2020, 10, 4956–4987. [Google Scholar] [CrossRef]

- Hassan, A.; Wahab, A.; Qasim, M.A.; Janjua, M.M.; Ali, M.A.; Ali, H.M.; Javaid, N. Thermal management and uniform temperature regulation of photovoltaic modules using hybrid phase change materials-nanofluids system. Renew. Energy 2020, 145, 282–293. [Google Scholar] [CrossRef]

- Verma, S.; Verma, A.; Kumar, V.; Gangil, B. Materials Today: Proceedings Concentrated photovoltaic thermal systems using Fresnel lenses—A review. Mater. Today Proc. 2021, 44, 4256–4260. [Google Scholar] [CrossRef]

- Sadeghi, G.; Pisello, A.L.; Safarzadeh, H.; Poorhossein, M.; Jowzi, M. On the effect of storage tank type on the performance of evacuated tube solar collectors: Solar radiation prediction analysis and case study. Energy 2020, 198, 117331. [Google Scholar] [CrossRef]

- IEA. International Energy Agency (IEA) World Energy Outlook 2022. 2022. Available online: https://Www.Iea.Org/Reports/World-Energy-Outlook-2022/Executive-Summary (accessed on 20 June 2023).

- Jaganmohan, M. Global Cumulative Installed Solar PV Capacity 2000–2019. 2021. Available online: https://www.statista.com/statistics/280220/global-cumulative-installed-solar-pv-capacity/ (accessed on 20 June 2023).

- Diwania, S.; Agrawal, S.; Siddiqui, A.S.; Singh, S. Photovoltaic–thermal (PV/T) technology: A comprehensive review on applications and its advancement. Int. J. Energy Environ. Eng. 2020, 11, 33–54. [Google Scholar] [CrossRef] [Green Version]

- Raja, A.A.; Huang, Y. Novel parabolic trough solar collector and solar photovoltaic/thermal hybrid system for multi-generational systems. Energy Convers. Manag. 2020, 211, 112750. [Google Scholar] [CrossRef]

- Yang, L.; Huang, J.N.; Zhou, F. Thermophysical properties and applications of nano-enhanced PCMs: An update review. Energy Convers. Manag. 2020, 214, 112876. [Google Scholar] [CrossRef]

- Mandal, S.; Ghosh, S.K. Experimental investigation of the performance of a double pass solar water heater with reflector. Renew. Energy 2020, 149, 631–640. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.V.; Pandey, A.K.; Sharma, R.; Sari, A. PCM integrated glass in glass tube solar collector for low and medium temperature applications: Thermodynamic & techno-economic approach. Energy 2020, 198, 117238. [Google Scholar] [CrossRef]

- Khanmohammadi, S.; Baseri, M.M.; Ahmadi, P.; Al-Rashed, A.A.A.; Afrand, M. Proposal of a novel integrated ocean thermal energy conversion system with flat plate solar collectors and thermoelectric generators: Energy, exergy and environmental analyses. J. Clean. Prod. 2020, 256, 120600. [Google Scholar] [CrossRef]

- Ma, T.; Li, M.; Kazemian, A. Photovoltaic thermal module and solar thermal collector connected in series to produce electricity and high-grade heat simultaneously. Appl. Energy 2019, 261, 114380. [Google Scholar] [CrossRef]

- Liang, R.; Wang, C.; Wang, P.; Zhao, L. Performance modeling and analysis of a PVT-HP system with the roll-bond plate as the evaporator during winter conditions. Appl. Therm. Eng. 2023, 224, 120102. [Google Scholar] [CrossRef]

- Qiu, L.; Ouyang, Y.; Feng, Y.; Zhang, X. Review on micro/nano phase change materials for solar thermal applications. Renew. Energy 2019, 140, 513–538. [Google Scholar] [CrossRef]

- Pathak, S.K.; Tyagi, V.V.; Chopra, K.; Rejikumar, R.; Pandey, A.K. Integration of emerging PCMs and nano-enhanced PCMs with different solar water heating systems for sustainable energy future: A systematic review. Sol. Energy Mater. Sol. Cells 2023, 254, 112237. [Google Scholar] [CrossRef]

- Nejadhasan, S.; Zaheri, F.; Abiri, E.; Salehi, M.R. PVT-compensated low voltage LNA based on variable current source for low power applications. AEU Int. J. Electron. Commun. 2022, 143, 154042. [Google Scholar] [CrossRef]

- Liu, W.; Yao, J.; Jia, T.; Zhao, Y.; Dai, Y.; Zhu, J.; Novakovic, V. The performance optimization of DX-PVT heat pump system for residential heating. Renew. Energy 2023, 206, 1106–1119. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Al-Sulaiman, F.A.; Saidur, R.; Ben-Mansour, R. A review on recent development for the design and packaging of hybrid photovoltaic/thermal (PV/T) solar systems. Renew. Sustain. Energy Rev. 2018, 95, 110–129. [Google Scholar] [CrossRef]

- Kumar, R.R.; Samykano, M.; Pandey, A.K.; Kadirgama, K.; Tyagi, V.V. Phase change materials and nano-enhanced phase change materials for thermal energy storage in photovoltaic thermal systems: A futuristic approach and its technical challenges. Renew. Sustain. Energy Rev. 2020, 133, 110341. [Google Scholar] [CrossRef]

- Santosh, M.P.R.; Kumaresan, M.R.S.G. Study of effect of Al and Cu microparticles dispersed in D-Mannitol PCM for effective solar thermal energy storage. J. Therm. Anal. Calorim. 2020, 139, 895–904. [Google Scholar] [CrossRef]

- Kumar, R.; Pandey, A.K.; Samykano, M.; Aljafari, B.; Ma, Z.; Bhattacharyya, S.; Tyagi, V.V. Phase change materials integrated solar desalination system: An innovative approach for sustainable and clean water production and storage. Renew. Sustain. Energy Rev. 2022, 165, 112611. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 2, 318–345. [Google Scholar] [CrossRef]

- Kumar, R.; Pandey, A.K.; Samykano, M.; Mishra, Y.N.; Mohan, R.V.; Sharma, K.; Tyagi, V.V. Effect of surfactant on functionalized multi-walled carbon nano tubes enhanced salt hydrate phase change material. J. Energy Storage 2022, 55, 105654. [Google Scholar] [CrossRef]

- Alsaqoor, S.; Alqatamin, A.; Alahmer, A.; Nan, Z.; Al-Husban, Y.; Jouhara, H. The impact of phase change material on photovoltaic thermal (PVT) systems: A numerical stud. Int. J. Thermofluids 2023, 18, 100365. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Sathyamurthy, R.; Manokar, A.M.; Sharshir, S.W.; Essa, F.A.; Elshiekh, A.H. Experimental study on tubular solar still using Graphene Oxide Nano particles in Phase Change Material (NPCM’s) for fresh water production. J. Energy Storage 2020, 28, 101204. [Google Scholar] [CrossRef]

- Kumar, R.R. Experimental Investigations on Thermal Properties of Copper (II) Oxide Nanoparticles Enhanced Inorganic Phase Change Materials for Solar Thermal Energy Storage Applications. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Kumar, R.; Samykano, M.; Pandey, A.K.; Kadirgama, K.; Tyagi, V.V. A comparative study on thermophysical properties of functionalized and non-functionalized Multi-Walled Carbon Nano Tubes (MWCNTs) enhanced salt hydrate phase change material. Sol. Energy Mater. Sol. Cells 2022, 240, 111697. [Google Scholar] [CrossRef]

- Kumar, R.; Samykano, M.; Ngui, W.K.; Pandey, A.K.; Kalidasan, B.; Kadirgama, K.; Tyagi, V.V. Investigation of thermal performance and chemical stability of graphene enhanced phase change material for thermal energy storage. Phys. Chem. Earth 2022, 128, 103250. [Google Scholar] [CrossRef]

- Samykano, M. Role of phase change materials in thermal energy storage: Potential, recent progress and technical challenges. Sustain. Energy Technol. Assess. 2022, 52, 102234. [Google Scholar] [CrossRef]

- Dwivedi, P.; Sudhakar, K.; Soni, A.; Solomin, E.; Kirpichnikova, I. Advanced cooling techniques of P.V. modules: A state of art. Case Stud. Therm. Eng. 2020, 21, 100674. [Google Scholar] [CrossRef]

- Şirin, C.; Goggins, J.; Hajdukiewicz, M. A review on building-integrated photovoltaic/thermal systems for green buildings. Appl. Therm. Eng. 2023, 229, 120607. [Google Scholar] [CrossRef]

- Sathe, T.M.; Dhoble, A.S. A review on recent advancements in photovoltaic thermal techniques. Renew. Sustain. Energy Rev. 2017, 76, 645–672. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Morabito, A.; Bruno, R.; Ferraro, V.; Arcuri, N. Seasonal performances of photovoltaic cooling systems in different weather conditions. J. Clean. Prod. 2020, 272, 122459. [Google Scholar] [CrossRef]

- Jia, Y.; Alva, G.; Fang, G. Development and applications of photovoltaic–thermal systems: A review. Renew. Sustain. Energy Rev. 2019, 102, 249–265. [Google Scholar] [CrossRef]

- Pandey, A.; Laghari, I.A.; Kumar, R.R.; Chopra, K.; Samykano, M.; Abusorrah, A.M.; Sharma, K.; Tyagi, V. Energy, exergy, exergoeconomic and enviroeconomic (4-E) assessment of solar water heater with/without phase change material for building and other applications: A comprehensive review. Sustain. Energy Technol. Assess. 2021, 45, 101139. [Google Scholar] [CrossRef]

- Kalidasan, B.; Pandey, A.K.; Shahabuddin, S.; Samykano, M.; Thirugnanasambandam, M. Phase change materials integrated solar thermal energy systems: Global trends and current practices in experimental approaches. J. Energy Storage 2019, 27, 101118. [Google Scholar] [CrossRef]

- Ahmadi, A.; Ehyaei, M.; Doustgani, A.; Assad, M.E.H.; Hmida, A.; Jamali, D.; Kumar, R.; Li, Z.; Razmjoo, A. Recent residential applications of low-temperature solar collector. J. Clean. Prod. 2020, 279, 123549. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Kazem, H.A.; Chaichan, M.T.; Sopian, K. A review of photovoltaic thermal systems: Achievements and applications. Int. J. Energy Res. 2021, 45, 1269–1308. [Google Scholar] [CrossRef]

- Al-waeli, A.H.A.; Kazem, H.A. Advances in Nano-Materials Used in Photovoltaic/Thermal Systems. In Advances in Energy Materials, Advances in Material Research and Technology; Springer: Berlin/Heidelberg, Germany, 2020; pp. 105–133. [Google Scholar] [CrossRef]

- Alessandro, M.; Niccolao, A.; Claudio, D.P.; Fabrizio, L. Photovoltaic-thermal solar-assisted heat pump systems for building applications: Integration and design methods. Energy Built Environ. 2023, 4, 39–56. [Google Scholar] [CrossRef]

- Prasetyo, S.D.; Prabowo, A.R.; Arifin, Z. The use of a hybrid photovoltaic/thermal (PV/T) collector system as a sustainable energy-harvest instrument in urban technology. Heliyon 2023, 9, e13390. [Google Scholar] [CrossRef]

- You, T.; Wu, W.; Yang, H.; Liu, J.; Li, X. Hybrid photovoltaic/thermal and ground source heat pump: Review and perspective. Renew. Sustain. Energy Rev. 2021, 151, 111569. [Google Scholar] [CrossRef]

- Das, D.; Kalita, P.; Roy, O. Flat plate hybrid photovoltaic- thermal (PV/T) system: A review on design and development. Renew. Sustain. Energy Rev. 2018, 84, 111–130. [Google Scholar] [CrossRef]

- Good, C. Environmental impact assessments of hybrid photovoltaic-thermal (PV/T) systems—A review. Renew. Sustain. Energy Rev. 2016, 55, 234–239. [Google Scholar] [CrossRef]

- Chaibi, Y.; El Rhafiki, T.; Simón-Allué, R.; Guedea, I.; Luaces, S.C.; Gajate, O.C.; Kousksou, T.; Zeraouli, Y. Air-based hybrid photovoltaic/thermal systems: A review. J. Clean. Prod. 2021, 295, 126211. [Google Scholar] [CrossRef]

- Tirupati, V.; Sekhar, Y.R. Hybrid Photovoltaic/Thermal (PVT) Collector Systems With Different Absorber Configurations For Thermal Management—A Review. Energy Environ. 2023, 34, 690–735. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Shboul, B.; Elwardany, M.; Zohny, R.N.; Osama, A. The recent advancements in the building integrated photovoltaic/thermal (BIPV/T) systems: An updated review. Renew. Sustain. Energy Rev. 2022, 170, 112988. [Google Scholar] [CrossRef]

- Ekka, J.P.; Kumar, D. A review of industrial food processing using solar dryers with heat storage systems. J. Stored Prod. Res. 2023, 101, 102090. [Google Scholar] [CrossRef]

- Fikri, M.A.; Samykano, M.; Pandey, A.; Kadirgama, K.; Kumar, R.R.; Selvaraj, J.; Rahim, N.A.; Tyagi, V.; Sharma, K.; Saidur, R. Recent progresses and challenges in cooling techniques of concentrated photovoltaic thermal system: A review with special treatment on phase change materials (PCMs) based cooling. Sol. Energy Mater. Sol. Cells 2022, 241. [Google Scholar] [CrossRef]

- Anand, R.N.B.; Shankar, R.; Murugavelh, S.; Rivera, W.; Prasad, K.M. A review on solar photovoltaic thermal integrated desalination technologies. Renew. Sustain. Energy Rev. 2021, 141, 110787. [Google Scholar] [CrossRef]

- Özakin, A.N.; Kaya, F. Effect on the exergy of the PVT system of fins added to an air-cooled channel: A study on temperature and air velocity with ANSYS Fluent. Sol. Energy 2019, 184, 561–569. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Xie, L.; Li, Z.; Wu, X.; Zhao, O.; Zhong, J.; Zeng, X. A hybrid photovoltaic and water/air based thermal(PVT) solar energy collector with integrated PCM for building application. Renew. Energy 2022, 199, 662–671. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, G.N. Energy and exergy analysis of hybrid micro-channel photovoltaic thermal module. Sol. Energy 2011, 85, 356–370. [Google Scholar] [CrossRef]

- Touti, E.; Masmali, M.; Fterich, M.; Chouikhi, H. Experimental and numerical study of the PVT design impact on the electrical and thermal performances. Case Stud. Therm. Eng. 2023, 43, 102732. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N. Energy and exergy analysis of a mixed-mode greenhouse-type solar dryer, integrated with partially covered N-PVT air collector. Energy 2017, 128, 183–195. [Google Scholar] [CrossRef]

- Ali, H.M. Recent advancements in PV cooling and efficiency enhancement integrating phase change materials based systems—A comprehensive review. Sol. Energy 2019, 197, 163–198. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Perrella, S.; Cirone, D.; Bruno, R.; Arcuri, N. Efficiency improvement of photovoltaic modules via back surface cooling. Energies 2021, 14, 4. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F.; Manfren, M. Performance monitoring and modeling of an uncovered photovoltaic-thermal (PVT) water collector. Sol. Energy 2016, 135, 551–568. [Google Scholar] [CrossRef]

- Brottier, L.; Bennacer, R. Thermal performance analysis of 28 PVT solar domestic hot water installations in Western Europe. Renew. Energy 2020, 160, 196–210. [Google Scholar] [CrossRef]

- Misha, S.; Abdullah, A.L.; Tamaldin, N.; Rosli, M.A.M.; Sachit, F.A. Simulation CFD and experimental investigation of PVT water system under natural Malaysian weather conditions. Energy Rep. 2019, 6, 28–44. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Bruno, R.; Rollo, A.; Ferraro, V. A novel thermal model for PV panels with back surface spray cooling. Energy 2022, 255, 124401. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Perrella, S.; Bruno, R.; Arcuri, N. An accurate thermal model for the PV electric generation prediction: Long-term validation in different climatic conditions. Renew. Energy 2021, 163, 1092–1112. [Google Scholar] [CrossRef]

- Indartono, Y.S.; Suwono, A.; Pratama, F.Y. Improving photovoltaics performance by using yellow petroleum jelly as phase change material. Int. J. Low-Carbon Technol. 2016, 11, 333–337. [Google Scholar] [CrossRef] [Green Version]

- Bevilacqua, P.; Bruno, R.; Arcuri, N. Comparing the performances of different cooling strategies to increase photovoltaic electric performance in different meteorological conditions. Energy 2020, 195, 116950. [Google Scholar] [CrossRef]

- Jarimi, H.; Bakar, M.N.A.; Othman, M.; Din, M.H. Bi-fluid photovoltaic/thermal (PV/T) solar collector: Experimental validation of a 2-D theoretical model. Renew. Energy 2016, 85, 1052–1067. [Google Scholar] [CrossRef]

- Bakar, M.N.A.; Othman, M.; Din, M.H.; Manaf, N.A.; Jarimi, H. Design concept and mathematical model of a bi-fluid photovoltaic/thermal (PV/T) solar collector. Renew. Energy 2014, 67, 153–164. [Google Scholar] [CrossRef]

- Hissouf, M.; Feddaoui, M.; Najim, M.; Charef, A. Performance of a photovoltaic-thermal solar collector using two types of working fluids at different fluid channels geometry. Renew. Energy 2020, 162, 1723–1734. [Google Scholar] [CrossRef]

- Jouhara, H.; Chauhan, A.; Nannou, T.; Almahmoud, S.; Delpech, B.; Wrobel, L.C. Heat pipe based systems—Advances and applications. Energy 2017, 128, 729–754. [Google Scholar] [CrossRef]

- Diallo, T.M.; Yu, M.; Zhou, J.; Zhao, X.; Shittu, S.; Li, G.; Ji, J.; Hardy, D. Energy performance analysis of a novel solar PVT loop heat pipe employing a microchannel heat pipe evaporator and a PCM triple heat exchanger. Energy 2018, 167, 866–888. [Google Scholar] [CrossRef]

- Long, H.; Chow, T.T.; Ji, J. Building-integrated heat pipe photovoltaic/thermal system for use in Hong Kong. Sol. Energy 2017, 155, 1084–1091. [Google Scholar] [CrossRef]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Isaza-Ruiz, M.; Xu, X.; Vignarooban, K.; Phelan, P.; Inamuddin; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transf. 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Asefi, G.; Ma, T.; Wang, R. Techno-economic evaluation of photovoltaic thermal system integrated with porous phase change materials: Case studies in China. Energy Convers. Manag. 2022, 290, 117227. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Z.; Ma, T. Performance analysis of a photovoltaic panel integrated with phase change material. Energy Procedia 2019, 158, 1093–1098. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Ibrahim, N.I.; Mahbubul, I.M.; Ali, H.M.; Saidur, R.; Al-Sulaiman, F.A. Evaluation of solar collector designs with integrated latent heat thermal energy storage: A review. Sol. Energy 2018, 166, 334–350. [Google Scholar] [CrossRef]

- Hosouli, S.; Gomes, J.; Loris, A.; Pazmiño, I.-A.; Naidoo, A.; Lennermo, G.; Mohammadi, H. Evaluation of a solar photovoltaic thermal (PVT) system in a dairy farm in Germany. Sol. Energy Adv. 2023, 3. [Google Scholar] [CrossRef]

- Hossain, M.S.; Pandey, A.K.; Selvaraj, J.; Rahim, N.A.; Islam, M.M.; Tyagi, V.V. Two side serpentine flow based photovoltaic-thermal-phase change materials (PVT-PCM) system: Energy, exergy and economic analysis. Renew. Energy 2019, 136, 1320–1336. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Kazem, H.A.; Yousif, J.H.; Chaichan, M.T.; Sopian, K. Mathematical and neural network modeling for predicting and analyzing of nanofluid-nano PCM photovoltaic thermal systems performance. Renew. Energy 2020, 145, 963–980. [Google Scholar] [CrossRef]

- Bhakre, S.S.; Sawarkar, P.D.; Kalamkar, V.R. Numerical study on photovoltaic thermal phase change material system in hot climatic conditions. Appl. Therm. Eng. 2023, 227, 120423. [Google Scholar] [CrossRef]

- Naghdbishi, A.; Yazdi, M.E.; Akbari, G. Experimental investigation of the effect of multi-wall carbon nanotube—Water/glycol based nanofluids on a PVT system integrated with PCM-covered collector. Appl. Therm. Eng. 2020, 178, 115556. [Google Scholar] [CrossRef]

- Dhoke, A.; Sharma, R.; Saha, T.K. An approach for fault detection and location in solar PV systems. Sol. Energy 2019, 194, 197–208. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A.; Yang, Y. Optimization and dynamic techno-economic analysis of a novel PVT-based smart building energy system. Appl. Therm. Eng. 2020, 181, 115926. [Google Scholar] [CrossRef]

- Ma, Z.; Lin, W.; Sohel, M.I. Nano-enhanced phase change materials for improved building performance. Renew. Sustain. Energy Rev. 2016, 58, 1256–1268. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, S.R.; Saidani-Scott, H.; Abdellatif, O.E. Performance analysis for hybrid PV/T system using low concentration MWCNT (water-based) nanofluid. Sol. Energy 2019, 181, 108–115. [Google Scholar] [CrossRef]

- Mi, P.; Ma, L.; Zhang, J. Integrated optimization study of hot water supply system with multi-heat-source for the public bath based on PVT heat pump and water source heat pum. Appl. Therm. Eng. 2019, 176, 115146. [Google Scholar] [CrossRef]

- Jafari, M.; Armaghan, D.; Mahmoudi, S.M.S.; Chitsaz, A. Thermoeconomic analysis of a standalone solar hydrogen system with hybrid energy storage. Int. J. Hydrogen Energy 2019, 44, 19614–19627. [Google Scholar] [CrossRef]

- Kumar, L.; Hasanuzzaman, M.; Rahim, N.A.; Islam, M.M. Modeling, simulation and outdoor experimental performance analysis of a solar-assisted process heating system for industrial process heat. Renew. Energy 2021, 164, 656–673. [Google Scholar] [CrossRef]

- Somasundaram, S.; Tay, A.A.O. Performance study and economic analysis of photo-voltaic thermal system under real-life thermal loads in tropical climate. Sustain. Environ. Res. 2019, 1, s42834. [Google Scholar] [CrossRef] [Green Version]

- Maatallah, T.; Zachariah, R.; Al-Amri, F.G. Exergo-economic analysis of a serpentine flow type water based photovoltaic thermal system with phase change material (PVT-PCM/water). Sol. Energy 2019, 193, 195–204. [Google Scholar] [CrossRef]

- Rajoria, C.S.; Agrawal, S.; Tiwari, G.N. Exergetic and enviroeconomic analysis of novel hybrid PVT array. Sol. Energy 2013, 88, 110–119. [Google Scholar] [CrossRef]

- Yandri, E. The effect of Joule heating to thermal performance of hybrid PVT collector during electricity generation. Renew. Energy 2017, 111, 344–352. [Google Scholar] [CrossRef]

- Antony, A.; Wang, Y.D.; Roskilly, A.P. A detailed optimisation of solar photovoltaic/thermal systems and its application. Energy Procedia 2018, 158, 1141–1148. [Google Scholar] [CrossRef]

- Dannemand, M.; Perers, B.; Furbo, S. Performance of a demonstration solar PVT assisted heat pump system with cold buffer storage and domestic hot water storage tanks. Energy Build. 2019, 188–189, 46–57. [Google Scholar] [CrossRef]

- Mittelman, G.; Kribus, A.; Mouchtar, O.; Dayan, A. Water desalination with concentrating photovoltaic/thermal (CPVT) systems. Sol. Energy 2009, 83, 1322–1334. [Google Scholar] [CrossRef]

- Monjezi, A.A.; Chen, Y.; Vepa, R.; Kashyout, A.E.-H.B.; Hassan, G.; Fath, H.E.-B.; Kassem, A.E.-W.; Shaheed, M.H. Development of an off-grid solar energy powered reverse osmosis desalination system for continuous production of freshwater with integrated photovoltaic thermal (PVT) cooling. Desalination 2020, 495, 114679. [Google Scholar] [CrossRef]

- Ong, C.L.; Escher, W.; Paredes, S.; Khalil, A.S.G.; Michel, B. A novel concept of energy reuse from high concentration photovoltaic thermal (HCPVT) system for desalination. Desalination 2012, 295, 70–81. [Google Scholar] [CrossRef]

- Abdelgaied, M.; Abdullah, A.S.; Kabeel, A.E.; Abosheiasha, H.F. Assessment of an innovative hybrid system of PVT-driven RO desalination unit integrated with solar dish concentrator as preheating unit. Energy Convers. Manag. 2022, 258, 115558. [Google Scholar] [CrossRef]

- Calise, F.; Dentice, M.; Piacentino, A. A novel solar trigeneration system integrating PVT (photovoltaic/thermal collectors) and SW (seawater) desalination: Dynamic simulation and economic assessment. Energy 2014, 67, 129–148. [Google Scholar] [CrossRef]

- Xiao, L.; Shi, R.; Wu, S.; Chen, Z. Performance study on a photovoltaic thermal (PV/T) stepped solar still with a bottom channel. Desalination 2019, 471, 114129. [Google Scholar] [CrossRef]

- Alnaimat, F.; Klausner, J.F. Solar diffusion driven desalination for decentralized water production. DES 2012, 289, 35–44. [Google Scholar] [CrossRef]

- Xinxin, G.; Heng, Z.; Haiping, C.; Kai, L.; Jiguang, H.; Haowen, L. Experimental and theoretical investigation on a hybrid LCPV/T solar still system. Desalination 2019, 468, 114063. [Google Scholar] [CrossRef]

- Elaouzy, Y.; El Fadar, A. Investigation of building-integrated photovoltaic, photovoltaic thermal, ground source heat pump and green roof systems. Energy Convers. Manag. 2023, 283, 116926. [Google Scholar] [CrossRef]

- Zarei, A.; Liravi, M.; Rabiee, M.B.; Ghodrat, M. A Novel, eco-friendly combined solar cooling and heating system, powered by hybrid Photovoltaic thermal (PVT) collector for domestic application. Energy Convers. Manag. 2020, 222, 113198. [Google Scholar] [CrossRef]

- Braun, R.; Haag, M.; Stave, J.; Abdelnour, N.; Eicker, U. System design and feasibility of trigeneration systems with hybrid photovoltaic-thermal (PVT) collectors for zero energy office buildings in different climates. Sol. Energy 2020, 196, 39–48. [Google Scholar] [CrossRef]

- Chemisana, D.; Fernandez, E.F.; Riverola, A.; Moreno, A. Fluid-based spectrally selective filters for direct immersed PVT solar systems in building applications. Renew. Energy 2018, 123, 263–272. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.; Tahir, A.; Reddy, K.S.; Mallick, T.K. Performance enhancement of a Building-Integrated Concentrating Photovoltaic system using phase change material. Sol. Energy Mater. Sol. Cells 2016, 149, 29–39. [Google Scholar] [CrossRef] [Green Version]

- Baljit, S.S.S.; Chan, H.Y.; Sopian, K. Review of building integrated applications of photovoltaic and solar thermal systems. J. Clean. Prod. 2016, 137, 677–689. [Google Scholar] [CrossRef]

- Fterich, M.; Chouikhi, H.; Bentaher, H.; Maalej, A. Experimental parametric study of a mixed-mode forced convection solar dryer equipped with a PV/T air collector. Sol. Energy 2018, 171, 751–760. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Nayak, S.; Dubey, S.; Solanki, S.C.; Singh, R.D. Performance analysis of a conventional PV/T mixed mode dryer under no load condition. Int. J. Energy Res. 2009, 33, 919–930. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Abdelgaied, M. Performance of novel solar dryer. Process Saf. Environ. Prot. 2016, 102, 183–189. [Google Scholar] [CrossRef]

- Ziaforoughi, A.; Esfahani, J.A. A salient reduction of energy consumption and drying time in a novel PV-solar collector-assisted intermittent infrared dryer. Sol. Energy 2016, 136, 428–436. [Google Scholar] [CrossRef]

- Tiwari, S.; Agrawal, S.; Tiwari, G.N. PVT air collector integrated greenhouse dryers. Renew. Sustain. Energy Rev. 2018, 90, 142–159. [Google Scholar] [CrossRef]

- El, M.; Slimani, A.; Amirat, M.; Bahria, S.; Kurucz, I.; Aouli, M. Study and modeling of energy performance of a hybrid photovoltaic/thermal solar collector: Configuration suitable for an indirect solar dryer. Energy Convers. Manag. 2016, 125, 209–221. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N. Exergoeconomic analysis of photovoltaic-thermal (PVT) mixed mode greenhouse solar dryer. Energy 2016, 114, 155–164. [Google Scholar] [CrossRef]

- Herrando, M.; Simón, R.; Guedea, I.; Fueyo, N. The challenges of solar hybrid PVT systems in the food processing industry. Appl. Therm. Eng. 2021, 184, 116235. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, S.; Zhang, G. Study on the energy performance enhancement of a new PCMs integrated hybrid system with the active cooling and hybrid ventilations. Energy 2019, 179, 111–128. [Google Scholar] [CrossRef]

- Gaur, A.; Tiwari, G.N.; Ménézo, C.; Al-Helal, I.M. Numerical and experimental studies on a Building integrated Semi-transparent Photovoltaic Thermal (BiSPVT) system: Model validation with a prototype test setu. Energy Convers. Manag. 2016, 129, 329–343. [Google Scholar] [CrossRef]

- Gupta, N.; Tiwari, G.N. Effect of water flow on building integrated semitransparent photovoltaic thermal system with heat capacity. Sustain. Cities Soc. 2018, 39, 708–718. [Google Scholar] [CrossRef]

- Mateus, T.; Oliveira, A.C. Energy and economic analysis of an integrated solar absorption cooling and heating system in different building types and climates. Appl. Energy 2009, 86, 949–957. [Google Scholar] [CrossRef]

- Shah, R.; Srinivasan, P. Hybrid Photovoltaic and Solar Thermal Systems (PVT): Performance Simulation and Experimental Validation. Mater. Today Proc. 2018, 11, 22998–23006. [Google Scholar] [CrossRef]

- Wang, K.; Pantaleo, A.; Herrando, M.; Faccia, M.; Pesmazoglou, I.; Franchetti, B.M.; Markides, C. Spectral-splitting hybrid PV-thermal (PVT) systems for combined heat and power provision to dairy farms. Renew. Energy 2020, 159, 1047–1065. [Google Scholar] [CrossRef]

- Herrando, M.; Pantaleo, A.M.; Wang, K.; Markides, C.N. Solar combined cooling, heating and power systems based on hybrid PVT, PV or solar-thermal collectors for building applications. Renew. Energy 2019, 143, 637–647. [Google Scholar] [CrossRef]

- Yandri, E. Development and experiment on the performance of polymeric hybrid Photovoltaic Thermal (PVT) collector with halogen solar simulator. Sol. Energy Mater. Sol. Cells 2019, 201, 110066. [Google Scholar] [CrossRef]

- Pfahler, M.; Branner, S.; Refior, H. Die komplette Rotatorenmanschettenruptur—Differenzierte Op-Techniken und mittelfristige Ergebnisse. Z. Orthop. Und Ihre Grenzgeb. 2008, 137, 1037045. [Google Scholar] [CrossRef] [PubMed]

- Kazemian, A.; Taheri, A.; Sardarabadi, A.; Ma, T.; Passandideh-Fard, M.; Peng, J. Energy, exergy and environmental analysis of glazed and unglazed PVT system integrated with phase change material: An experimental approach. Sol. Energy 2020, 201, 178–189. [Google Scholar] [CrossRef]

- Lari, M.O.; Sahin, A.Z. Design, performance and economic analysis of a nanofluid-based photovoltaic/thermal system for residential applications. Energy Convers. Manag. 2017, 149, 467–484. [Google Scholar] [CrossRef]

- Arslan, E.; Aktaş, M. 4E analysis of infrared-convective dryer powered solar photovoltaic thermal collector. Sol. Energy 2020, 208, 46–57. [Google Scholar] [CrossRef]

- Gholamian, E.; Hanafizadeh, P.; Ahmadi, P.; Mazzarella, L. A transient optimization and techno-economic assessment of a building integrated combined cooling, heating and power system in Tehran. Energy Convers. Manag. 2020, 217, 112962. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Brinkley, J.; Hota, S.K.; Ferry, J.; Diaz, G.; Winston, R. Experimental performance of an ultra-low-cost solar photovoltaic-thermal (PVT) collector using aluminum minichannels and nonimaging optics. Appl. Energy 2020, 268. [Google Scholar] [CrossRef]

- Hassani, S.; Saidur, R.; Mekhilef, S.; Taylor, R.A. Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers. Manag. 2016, 123, 431–444. [Google Scholar] [CrossRef]

- Yousef, M.S.; Sharaf, M.; Huzayyin, A.S. Energy, exergy, economic, and enviroeconomic assessment of a photovoltaic module incorporated with a paraffin-metal foam composite: An experimental study. Energy 2022, 238, 121807. [Google Scholar] [CrossRef]

| Type of System | PCM | Thermal Efficiency | Electrical Efficiency | Overall Efficiency | Place of Study | Observations | Applications | References |

|---|---|---|---|---|---|---|---|---|

| Water-cooled PVT system | NA | NA | Increased by 7% | 75.8% | Iran | The COP of the system improved by 11%, and the water temperature increased by 9.17 °C. | Solar heating applications | [104] |

| Nanofluid-based PVT system | NA | NA | Increased by 33.95% | 83.26% | Egypt | The PV unit temperature reduced by 12 °C. Water heating applications. | Water heating | [85] |

| Water-based PVT system | NA | NA | 14% | 61% | Denmark | Exergy efficiency was increased by 4.03%, and total cost reduced by EUR 3.64/MWh. | Water heating | [83] |

| Solar combined heating cooling and power-based PVT system | NA | 55.1% | 8.62% | NA | Italy | Heating, cooling, and power systems for buildings. | Heating and cooling | [123] |

| Solar combined heating cooling and power-based PVT system | NA | 45.4% | 6.7–7.9% | - | Spain | Higher efficiency, lower fuel cost and higher reduction of CO2 emission. | Food processing, beer brewery, pig slaughterhouse, vegetable and fruit processing, and canning plant | [116] |

| Water-cooled PVT system | NA | NA | 9% | 41.8% | Iran | The developed system is convenient for all seasons because the produced power satisfies the demand at all times. | Water heating | [87] |

| Water-based PVT system | NA | 30% | 10.4% | NA | Singapore | Glazed PVT system had higher performance than unglazed PVT system. | Hot water for student hostel | [89] |

| Water-based hybrid PVT system | NA | 80% | 7.9% | NA | Japan | PVT system with PMMA absorber and copper plate provides 80% thermal efficiency, significant cooling effect, and 0.03%/°C reduction in electrical efficiency. | Water heating, swimming pool water heating | [124] |

| Water-based hybrid PVT system | NA | 13% enhanced | NA | NA | Japan | In a moderate wind speed (less than 1 m/s), negligible or no loss in thermal efficiency. | Swimming pool heating, floor heating | [92] |

| Water-based hybrid PVT system | NA | 450 kWh/m2–module/year | 275 kWh/m2–module/year | NA | Western Europe | The developed non-overglazed PVT system’s stagnation temperature is always lower than 74.5 °C, which is lower the chance of overheating the PV panel. | Water heating | [61] |

| Air-based PVT system | NA | 65% | 12.31% | NA | Tunisia | The developed prototype system reduces the moisture content from 91.2% to 22.32% for tray 1, 28.9% for tray 2 and 30.15% for using sunlight. | Drying tomatoes | [109] |

| Air-based PVT system | NA | NA | 13.11% | 42% | India | The electrical efficiency and temperature with and without air duct is 13.11%, 12% and 10.1 °C, 25 °C, respectively. | Space heating | [118] |

| Water-based PVT system | NA | NA | 15.5% | NA | Egypt | The developed system reduces electricity consumption by 0.12 kWh/m3. | Solar desalination | [96] |

| Nanofluid-based PVT system | RT-35HC (35 °C) | Enhanced by 20.8% | Enhanced by 14.5% | Enhanced by 14.1% | Pakistan | PCM-integrated nanofluid-based PVT system increases the thermal and overall energy by 17.50% and 12.0% compared to the water-based PCM-integrated PVT system. | Thermal management in buildings | [3] |

| Water-based PVT system | Paraffin wax (57 °C) | 26.8% | 17.33 | 40.59% | Kottayam, India | Heating water during night time, cooling PV cell during day time. | Water heating | [90] |

| Nanofluid-based PVT system | Paraffin wax (57–60 °C) | Enhanced by 23.52% | Enhanced by 4.22% | NA | Tehran, Iran | Heating water during night time. Reduces the PV panel temperature by 16–21%. | Water heating | [81] |

| Water-based hybrid PVT system | CaCl2.6H2O (22–26 °C) | 80% | 14.99% | NA | China | PCM and active water cooling systems are technically feasible in terms of thermal and electrical energy enhancement. | Heating and ventilation in buildings | [117] |

| Air-based PCM-integrated PVT system | RT42 (42 °C) | NA | Enhanced by 7.7% | NA | UK | The electrical efficiency improved by 7.7% and the reduction in cell temperature increased by 3.8 °C for PCM embedded PV system. | Building heating/cooling | [107] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samykano, M. Hybrid Photovoltaic Thermal Systems: Present and Future Feasibilities for Industrial and Building Applications. Buildings 2023, 13, 1950. https://doi.org/10.3390/buildings13081950

Samykano M. Hybrid Photovoltaic Thermal Systems: Present and Future Feasibilities for Industrial and Building Applications. Buildings. 2023; 13(8):1950. https://doi.org/10.3390/buildings13081950

Chicago/Turabian StyleSamykano, Mahendran. 2023. "Hybrid Photovoltaic Thermal Systems: Present and Future Feasibilities for Industrial and Building Applications" Buildings 13, no. 8: 1950. https://doi.org/10.3390/buildings13081950