The Effect of Microbiologically Induced Concrete Corrosion in Sewer on the Bearing Capacity of Reinforced Concrete Pipes: Full-Scale Experimental Investigation

Abstract

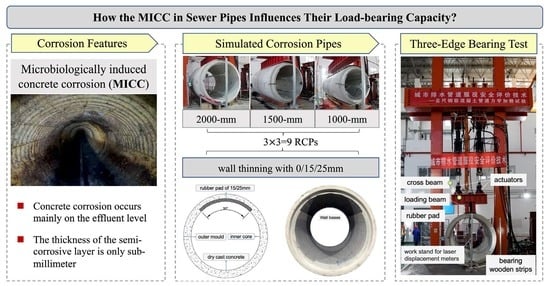

:1. Introduction

1.1. Microbiologically Induced Concrete Corrosion in Sewer Pipes

- Stage 1: It is an abiotic process dominantly, in which the pH of the concrete surface is reduced by acidic gases such as carbon dioxide and sulfide.

- Stage 2: After pH < 9, the concrete surface gradually becomes a habitable place for neutrophilic sulfur oxidizing bacteria (NSOB) and some fungi. Their metabolites will continue to lower the surface pH.

- Stage 3: After pH < 4, the dominant colony succeeded in acidophilic sulfur oxidizing bacteria (ASOB). In this phase, H2S spilled from effluent is converted to sulfuric acid. Steady concrete corrosion is thus initiated.

1.2. Literature Review on the Effect of MICC on Sewer Pipe Structure

1.3. Characterization Approach of the Bearing Capacity of Sewer Pipes

1.4. The Present Study’s Contribution and Organization

2. Specimens, Equipment, and Methods

2.1. Fabrication of Simulated Corrosion Pipes

2.2. Three Edge Bearing Test System

2.3. Loading and Monitoring

2.3.1. Loading Procedures

2.3.2. Displacement Monitoring Method

2.4. Bearing Capacity Characterization

2.4.1. D-Load, Peak Load and Ultimate Load

2.4.2. The Failure Energy

2.4.3. Ring Deflection and Ring Stiffness

3. Results and Discussions

3.1. Loading Behavior

3.2. Bearing Capacity

3.2.1. Comparison of the D-Load, Peak Load and Ultimate Load

3.2.2. Ring Stiffness

3.2.3. Failure Energy

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Parande, A.K.; Ramsamy, P.L.; Ethirajan, S.; Rao, C.R.K.; Palanisamy, N. Deterioration of reinforced concrete in sewer environments. In Proceedings of the Institution of Civil Engineers-Municipal Engineer; Thomas Telford Ltd.: London, UK, 2006. [Google Scholar] [CrossRef]

- Wang, Y.; Li, P.; Li, J. The monitoring approaches and non-destructive testing technologies for sewer pipelines. Water Sci. Technol. 2022, 85, 3107–3121. [Google Scholar] [CrossRef]

- Wu, M.; Wang, T.; Wu, K.; Kan, L. Microbiologically induced corrosion of concrete in sewer structures: A review of the mechanisms and phenomena. Constr. Build. Mater. 2020, 239, 117813. [Google Scholar] [CrossRef]

- Olmstead, W.; Hamlin, H. Converting portions of the Los Angeles outfall sewer into a septic tank. Eng. News 1900, 44, 317–318. [Google Scholar]

- Parker, C. The Corrosion of Concrete: 1. The Isolation of A Species of Bacterium Associated with The Corrosion of Concrete Exposed to Atmospheres Containing Hydrogen Sulphide. Aust. J. Exp. Biol. Med. Sci. 1945, 23, 81–90. [Google Scholar] [CrossRef]

- Parker, C. The function of Thiobacillus concretivorus (nov. spec.) in the corrosion of concrete exposed to atmospheres containing hydrogen sulphide. Aust. J. Exp. Biol. Med. Sci. 1945, 23, 91–98. [Google Scholar] [CrossRef]

- De Belie, N.; Monteny, J.; Beeldens, A.; Vincke, E.; Van Gemert, D.; Verstraete, W. Experimental research and prediction of the effect of chemical and biogenic sulfuric acid on different types of commercially produced concrete sewer pipes. Cem. Concr. Res. 2004, 34, 2223–2236. [Google Scholar] [CrossRef]

- Ehrich, S.; Helard, L.; Letourneux, R.; Willocq, J.; Bock, E. Biogenic and Chemical Sulfuric Acid Corrosion of Mortars. J. Mater. Civ. Eng. 1999, 11, 340–344. [Google Scholar] [CrossRef]

- Sand, W. Importance of Hydrogen Sulfide, Thiosulfate, and Methylmercaptan for Growth of Thiobacilli during Simulation of Concrete Corrosion. Appl. Environ. Microbiol. 1987, 53, 1645–1648. [Google Scholar] [CrossRef] [Green Version]

- Mori, T.; Nonaka, T.; Tazaki, K.; Koga, M.; Hikosaka, Y.; Noda, S. Interactions of nutrients, moisture and pH on microbial corrosion of concrete sewer pipes. Water Res. 1992, 26, 29–37. [Google Scholar] [CrossRef]

- Wells, T.; Melchers, R. An observation-based model for corrosion of concrete sewers under aggressive conditions. Cem. Concr. Res. 2014, 61, 1–10. [Google Scholar] [CrossRef]

- O’Connell, M.; McNally, C.; Richardson, M.G. Biochemical attack on concrete in wastewater applications: A state of the art review. Cem. Concr. Compos. 2010, 32, 479–485. [Google Scholar] [CrossRef]

- Mori, T.; Koga, M.; Hikosaka, Y.; Nonaka, T.; Mishina, F.; Sakai, Y.; Koizumi, J.-I. Microbial Corrosion of Concrete Sewer Pipes, H2S Production from Sediments and Determination of Corrosion Rate. Water Sci. Technol. 1991, 23, 1275–1282. [Google Scholar] [CrossRef]

- Zuo, Z.; Ren, D.; Qiao, L.; Li, H.; Huang, X.; Liu, Y. Rapid dynamic quantification of sulfide generation flux in spatially heterogeneous sediments of gravity sewers. Water Res. 2021, 203, 117494. [Google Scholar] [CrossRef] [PubMed]

- Grengg, C.; Mittermayr, F.; Ukrainczyk, N.; Koraimann, G.; Kienesberger, S.; Dietzel, M. Advances in concrete materials for sewer systems affected by microbial induced concrete corrosion: A review. Water Res. 2018, 134, 341–352. [Google Scholar] [CrossRef]

- Islander, R.L.; Devinny, J.S.; Mansfeld, F.; Postyn, A.; Shih, H. Microbial Ecology of Crown Corrosion in Sewers. J. Environ. Eng. 1991, 117, 751–770. [Google Scholar] [CrossRef]

- Wang, Y.; Li, P.; Wang, L. The Testing Methods and Prediction Models for Concrete Corrosion in Sewer Pipelines: A State-of-the-Art Review. J. Test. Eval. 2022, 50, 20210702. [Google Scholar] [CrossRef]

- Kiliswa, M.W.; Scrivener, K.L.; Alexander, M.G. The corrosion rate and microstructure of Portland cement and calcium aluminate cement-based concrete mixtures in outfall sewers: A comparative study. Cem. Concr. Res. 2019, 124, 105818. [Google Scholar] [CrossRef]

- Kong, L.; Lu, H.; Fu, S.; Zhang, G. Effect of corrosion layer on the deterioration of concrete in gravity sewers. Constr. Build. Mater. 2021, 272, 121663. [Google Scholar] [CrossRef]

- Fang, H.; Yang, K.; Du, X.; Li, B.; Zhang, X.; Tan, P. Experimental and numerical study on mechanical analysis of buried corroded concrete pipes under static traffic loads. Appl. Sci. 2019, 9, 5002. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Fang, H.; He, H.; Yang, K.; Chen, C.; Wang, F. Numerical simulation and full-scale test on dynamic response of corroded concrete pipelines under Multi-field coupling. Constr. Build. Mater. 2019, 200, 368–386. [Google Scholar] [CrossRef]

- Fang, H.; Yang, K.; Du, X.; Li, B.; Zhang, X.; Tan, P. Experimental study on the mechanical properties of corroded concrete pipes subjected to diametral compression. Constr. Build. Mater. 2020, 261, 120576. [Google Scholar] [CrossRef]

- Zamanian, S.; Hur, J.; Shafieezadeh, A. A high-fidelity computational investigation of buried concrete sewer pipes exposed to truckloads and corrosion deterioration. Eng. Struct. 2020, 221, 111043. [Google Scholar] [CrossRef]

- Scheperboer, I.C.; Luimes, R.A.; Suiker, A.S.J.; Bosco, E.; Clemens, F.H.L.R. Experimental-numerical study on the structural failure of concrete sewer pipes. Tunn. Undergr. Space Technol. 2021, 116, 104075. [Google Scholar] [CrossRef]

- Luimes, R.A.; Scheperboer, I.C.; Suiker, A.S.J.; Bosco, E.; Clemens, F.H.L.R. Effect of biochemical attack on the mechanical performance of used concrete sewer pipes. Constr. Build. Mater. 2022, 346, 128390. [Google Scholar] [CrossRef]

- Lay, G.R.; Brachman, R.W.I. Full-scale physical testing of a buried reinforced concrete pipe under axle load. Can. Geotech. J. 2014, 51, 394–408. [Google Scholar] [CrossRef]

- Xu, M.; Shen, D.; Rakitin, B. The longitudinal response of buried large-diameter reinforced concrete pipeline with gasketed bell-and-spigot joints subjected to traffic loading. Tunn. Undergr. Space Technol. 2017, 64, 117–132. [Google Scholar] [CrossRef]

- ASTM C497-20e1; Standard Test Methods for Concrete Pipe, Concrete Box Sections, Manhole Sections, or Tile. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Wong, L.S.; Nehdi, M.L. Critical Analysis of International Precast Concrete Pipe Standards. Infrastructures 2018, 3, 18. [Google Scholar] [CrossRef] [Green Version]

- Ablin, R.L.; Kinshella, P. Dude, Where’s My Pipe-Accelerated Corrosion Rate Threatens Phoenix Sewers. In Proceedings of the Pipeline Division Specialty Congress 2004, San Diego, CA, USA, 1–4 August 2004. [Google Scholar] [CrossRef]

- GB/T-16752; Test Methods of Concrete and Reinforced Concrete Sewer Pipes. General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2017.

- Younis, A.-A.; Ramadan, A.S.; Wong, L.S.; Nehdi, M.L. New rational test for reinforced-concrete pipe eliminating subjective crack-width criteria. Structures 2020, 28, 2507–2522. [Google Scholar] [CrossRef]

- Watkins, R.K. Structural Mechanics of Buried Pipes; CRC Press: Boca, Raton, FL, USA, 1999. [Google Scholar] [CrossRef]

- O’Brien, S.F.; Yi, Q.L. How do I interpret a confidence interval? Transfusion 2016, 56, 1680–1683. [Google Scholar] [CrossRef]

- Rooyackers, F.A.M.; Bosco, E.; Suiker, A.S.J.; Clemens, F.H.L.R. A chemo-mechanical model for biogenic sulphide corrosion of concrete. Cem. Concr. Res. 2022, 160, 106809. [Google Scholar] [CrossRef]

- Jiang, G.; Keller, J.; Bond, P.L.; Yuan, Z. Predicting concrete corrosion of sewers using artificial neural network. Water Res. 2016, 92, 52–60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Li, P.; Guo, Y.; Yang, H.; Ye, Z.; Wang, L. Predicting the Microbiologically Induced Concrete Corrosion in Sewer Based on XGBoost Algorithm. Case Stud. Constr. Mat. 2022, 17, e01649. [Google Scholar] [CrossRef]

| Inner Diameter (mm) | Wall Loss (mm) | Wall Thickness (mm) | Effective Length (mm) | Concrete Cover (mm) | Steel Cage (mm) | |||

|---|---|---|---|---|---|---|---|---|

| Diameter of Longitudinal Bars | Diameter of Circumferential Bars | Numbers of Longitudinal Bars | Space of Circumferential Bars | |||||

| 1000 | 0/15/25 | 140 | 3000 | 30 | 8 | 7 | 9 | 66.2 |

| 1500 | 165 | 8 | 6 | 18 | 41.6 | |||

| 2000 | 210 | 8 | 6 | 18 | 49.5 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, P.; Liu, H.; Wang, W.; Guo, Y.; Wang, L. The Effect of Microbiologically Induced Concrete Corrosion in Sewer on the Bearing Capacity of Reinforced Concrete Pipes: Full-Scale Experimental Investigation. Buildings 2022, 12, 1996. https://doi.org/10.3390/buildings12111996

Wang Y, Li P, Liu H, Wang W, Guo Y, Wang L. The Effect of Microbiologically Induced Concrete Corrosion in Sewer on the Bearing Capacity of Reinforced Concrete Pipes: Full-Scale Experimental Investigation. Buildings. 2022; 12(11):1996. https://doi.org/10.3390/buildings12111996

Chicago/Turabian StyleWang, Yajian, Pengpeng Li, Huifang Liu, Wentao Wang, Yang Guo, and Linbing Wang. 2022. "The Effect of Microbiologically Induced Concrete Corrosion in Sewer on the Bearing Capacity of Reinforced Concrete Pipes: Full-Scale Experimental Investigation" Buildings 12, no. 11: 1996. https://doi.org/10.3390/buildings12111996