Failure-Analysis Based Redesign of Furnace Conveyor System Components: A Case Study

Abstract

:1. Introduction

- -

- It can partially melt and adhere to the roll, generating a build-up that leads to format trajectory deviation inside the furnace. Therefore, the formats do not exit the furnace in a proper position for robotic transferring to the stamping press.

- -

- The molten AlSi can infiltrate in the pores and micro-cracks in the roll surfaces. When the furnace is cooled down for a stop or an energy saving condition, such as a weekend stand-by, the infiltrated metal solidifies and acts as a wedge, which leads to roller fracture.

- -

- Blanks can be loaded widthwise, leading to shorter production lines.

- -

- Transport system-to-blank contact is reduced, minimizing conveying system contamination problems due to AlSi coating melting.

- -

- Blank location accuracy at the exit point of the blanks from the furnace is improved as a result of the fixed stroke of the rolling beams.

- -

- Overall equipment efficiency is increased owing to lower maintenance needs and less stops are needed for correcting blank positioning at the furnace exit.

2. Materials and Methods

- Metallurgical analysis of the fractured component and proposal of the failure mechanism.

- Chemical analysis to verify that the material was correctly supplied.

- Tensile testing of a specimen from the area of the journal that works the coldest in service, to ensure there was not an initial mechanical property problem from the beginning.

- Microstructural inspection in the neighborhood of the fracture and in a position far from the fracture (cold area), to check the phase evolution of the material during service in the cracked area compared with a section thermally unaltered in service.

- Fractographic inspection of the fracture surface to determine the nature of the damage that the roll suffered and its trajectory.

- Verification of the concordance of the observations against the expected failure mode by design of the roller.

- Investigation of the deviations between the expected working conditions and the actual working conditions of the rolls that would fit with the failure mechanism.

- In situ measurement of the temperature in the failure site with the furnace running.

- Verification of the stress in the failure site by studying the load profile during the movement sequence in the running furnace.

- Proposal of the failure mechanism taking into account the deviations of the actual working condition from the loads and temperatures expected from design.

- Redesign of the roll to avoid future failures.

3. Results and Discussion

3.1. Metallurgical Analyses

3.2. Investigation of the Deviations

3.3. Roller Redesign

- The insulation of the area was improved and a temperature reduction of 50 °C was achieved in the affected area, slowing down the carbide precipitation kinetics and arresting sigma phase embrittlement.

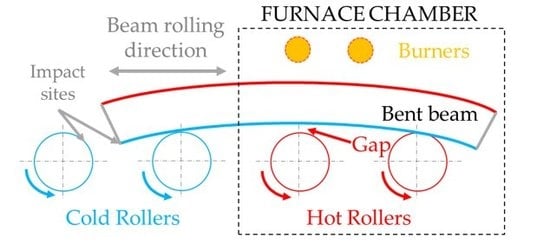

- The thermal differences leading to beam bending were evened with radiation deflectors and a proper sitting of the beam on three or four rollers, depending on the stroke’s position, was achieved. Working loads were corrected this way, reducing the stress in the fillet radius.

- The design of the roll was made more robust by increasing the journal diameter from Ø54 mm to Ø64 mm and by reducing the stress concentration factor thanks to a fillet of R20 mm and tangent to the cone instead of a truncated R7 mm fillet (Figure 10).

- -

- The service loads were reduced by between 33% and 50% depending on the beam’s position (33% if the beam passed from sitting in two rollers to sitting on three rollers and 50% in the case in which the beams passed from sitting on four rollers to sitting on four rollers).

- -

- The generation of over temperatures in the fillet was avoided, so that the reduction of the hot strength was avoided.

- -

- The stress in the failure area was reduced by 40%. The main factor contributing to this improvement is an increased inertia when changing from Ø54 mm to Ø64 mm, as both the bending and torsion stresses in the failure area are inversely proportional to Ø3: 543/643 = 0.60.

- -

- The stress concentration factor was reduced to 1.25 (r/d = 0.31 and D/d = 1.12 from the bending stepped round bar with a fillet chart in the work of [22]). Also introducing the scale (1.25) and roughness (1.1) leaves a peak stress of 1.25 × 1.25 × 1.1 × 21 = 39 MPa.

4. Conclusions

- -

- The supply condition of the broken steel was correct and clearly different from its metallurgical condition on the fracture site.

- -

- The roller was designed against creep, but the failure was caused by mechanical fatigue crack growth combined with ductile collapse when the resistant section was severely reduced.

- -

- The actual metallurgical condition of the steel did not fit with the design working parameters that were expected.

- -

- The investigations performed on the running furnace confirmed that the working temperature on the failure site exceeded design temperature and that working loads even doubled design load at some positions of the stroke.

- -

- The actual working parameters perfectly fit the observations in the fractured component, both regarding microstructural and fractographical evolutions.

- -

- Actions against the root cause, leveling the contact of the rollers with the beam, adjusting the thermal barriers, and reducing the stress in the failure site were successfully implemented and the service times of the rollers working in these conditions doubled the failure times of the original broken rollers without showing any crack traces in liquid penetrant inspections.

Author Contributions

Funding

Conflicts of Interest

References

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Neugebauer, R.; Schieck, F.; Polster, S.; Mosel, A.; Rautenstrauch, A.; Schönherr, J.; Pierschel, N. Press hardening—An innovative and challenging technology. Arch. Civil. Mech. Eng. 2012, 12, 113–118. [Google Scholar] [CrossRef]

- Mori, K.; Bariani, P.F.; Behrens, B.-A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. Manuf. Technol. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Mori, K.; Maki, S.; Tanaka, Y. Warm and hot stamping of ultra high tensile strength steel sheets using resistance heating. CIRP Ann. Manuf. Technol. 2005, 54, 209–212. [Google Scholar] [CrossRef]

- Kolleck, R.; Veit, R.; Merklein, M.; Lechler, J.; Geiger, M. Investigation on induction heating for hot stamping of boron alloyed steels. CIRP Ann. Manuf. Technol. 2009, 58, 275–278. [Google Scholar] [CrossRef]

- Pedraza, J.P.; Landa-Mejía, R.; García-Rincón, O.; García, C.I. The effect of rapid heating and fast cooling on the transformation behavior and mechanical properties of an advanced high strength steel (AHSS). Metals 2019, 9, 545. [Google Scholar] [CrossRef]

- Rasera, J.N.; Daun, K.J.; Shi, C.J.; Souza, M.D. Direct contact heating for hot forming die quenching. Appl. Therm. Eng. 2016, 98, 1165–1173. [Google Scholar] [CrossRef]

- Oh, J.; Han, U.; Park, J.; Lee, H. Numerical investigation on energy performance of hot stamping furnace. Appl. Thermal. Eng. 2019, 147, 694–706. [Google Scholar] [CrossRef]

- Saez, A.; Angulo, D.; Berasategui, J. Advanced technology for hot stamping. Heat Process. 2018, 3, 77–80. [Google Scholar]

- Pantazopoulos, G.A. A short review on fracture mechanisms of mechanical components operated under industrial process conditions: Fractographic analysis and selected prevention strategies. Metals 2019, 9, 148. [Google Scholar] [CrossRef]

- Álvarez, J.A.; Lacalle, R.; Arroyo, B.; Cicero, S.; Gutiérrez-Solana, F. Failure analysis of high strength galvanized bolts used in steel towers. Metals 2019, 6, 163. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, H.; Zhang, J.; Dai, W.; Huang, Y. Brittle fracture behaviors of large die holders used in hot die forging. Metals 2017, 7, 198. [Google Scholar] [CrossRef]

- Al-Meshari, A.; Al-Rabie, M.; Al-Dajane, M. Failure analysis of furnace tube. J. Fail. Anal. Preven. 2013, 13, 282–291. [Google Scholar] [CrossRef]

- Babakr, A.M.; Al-Ahmrai, A.; Al-Jumayiah, K.; Habiby, F. Failure investigation of a furnace tube support. J. Fail. Anal. Preven. 2009, 9, 16–22. [Google Scholar] [CrossRef]

- Acevedo, F.; Sáenz, L. Study of embrittlement in austenitic stainless steel AISI 304H with 15 years in service exposed to high temperature. Dyna 2018, 93, 428–434. [Google Scholar] [CrossRef]

- Yang, Y.P.; Mohr, W.C. Finite element creep-fatigue analysis of a welded furnace roll for identifying failure root cause. J. Mat. Eng. Perform. 2015, 24, 4388–4399. [Google Scholar] [CrossRef]

- Davies, J.R. ASM Specialty Handbook––Heat-Resistant Materials; ASM Materials, Materials Park: Russell, OH, USA, 1997. [Google Scholar]

- ASTM A479/A479M–18 Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E8/E8M–16 Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2013.

- Pozo, D.; López de Lacalle, L.D.; López, J.M.; Hernández, A. Prediction of press/die deformation for an accurate manufacturing of drawing dies. Int. J. Adv. Manuf. Technol. 2008, 37, 649–656. [Google Scholar] [CrossRef]

- Gere, J.M. Mechanics of Materials; Brooks Cole: Hampshire, UK, 2003. [Google Scholar]

- Peterson, R.E. Stress Concentration Factors; John Wiley and Sons: New York, NY, USA, 1974. [Google Scholar]

- Shigley, J.E.; Mischke, C.R.; Brown, T.H., Jr. Standard Handbook of Machine Design; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Milella, P.P. Fatigue and Corrosion in Metals; Springer Verlag: Milano, Italia, 2013. [Google Scholar]

- Nikitin, I.; Scholtes, B.; Maier, H.J.; Altenberg, I. High temperature fatigue behavior and residual stress stability of laser-shock peened and deep roller austenitic steel AISI 304. Scr. Mater. 2004, 50, 1345–1350. [Google Scholar] [CrossRef]

- Borja, F.; Beatriz, G.; Artola, G.; López de Lacalle, N.; Angulo, C. A Quick Cycle Time Sensitivity Analysis of Boron Steel Hot Stamping. Metals 2019, 9, 235. [Google Scholar] [CrossRef]

| Reference | C | Mn | Si | S | P | Cr | Ni |

|---|---|---|---|---|---|---|---|

| AISI 304 Specification [18] | 0.08 | <2 | <1 | <0.03 | <0.045 | 18–20 | 8–10.5 |

| Broken Roll 1 (BR1) | 0.05 | 1.04 | 0.62 | <0.02 | <0.02 | 19.58 | 9.14 |

| Broken Roll 2 (BR2) | 0.06 | 1.05 | 0.58 | <0.02 | <0.02 | 19.61 | 9.15 |

| Reference | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation E (%) | Reduction in Area RA (%) |

|---|---|---|---|---|

| Purchasing specification from design | >210 | >560 | >58 | - |

| Tensile specimen from BR1 | 248 ± 5 | 602 ± 5 | 61.0 ± 1.5 | 75.0 ± 1.5 |

| Tensile specimen from BR2 | 250 ± 5 | 610 ± 5 | 60.0 ± 1.5 | 74.0 ± 1.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Ciordia, B.; Fernández, B.; Artola, G.; Muro, M.; Sanz, Á.; López de Lacalle, L.N. Failure-Analysis Based Redesign of Furnace Conveyor System Components: A Case Study. Metals 2019, 9, 816. https://doi.org/10.3390/met9080816

González-Ciordia B, Fernández B, Artola G, Muro M, Sanz Á, López de Lacalle LN. Failure-Analysis Based Redesign of Furnace Conveyor System Components: A Case Study. Metals. 2019; 9(8):816. https://doi.org/10.3390/met9080816

Chicago/Turabian StyleGonzález-Ciordia, Beatriz, Borja Fernández, Garikoitz Artola, Maider Muro, Ángel Sanz, and Luis Norberto López de Lacalle. 2019. "Failure-Analysis Based Redesign of Furnace Conveyor System Components: A Case Study" Metals 9, no. 8: 816. https://doi.org/10.3390/met9080816