Review of Thermoplastic Drawing with Bulk Metallic Glasses

Abstract

:1. Introduction

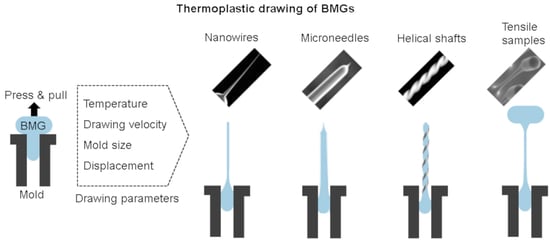

2. Thermoplastic Drawing versus Embossing

3. Fiber Drawing Kinetics

4. High-Aspect-Ratio Structures

5. Microneedles for Drug-Delivery

6. Nanoscale Tensile Specimens

7. Hybrid Drawing

8. Drawing of Oxidizing BMGs

9. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Greer, A.L. Metallic Glasses. Science 1995, 267, 1947–1953. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Johnson, W.L. Bulk Glass-Forming Metallic Alloys: Science and Technology. MRS Bull. 1999, 24, 42–56. [Google Scholar] [CrossRef]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mat. Sci. Eng. R. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Schroers, J. BULK Metallic Glasses. Phys. Today 2013, 66, 32–37. [Google Scholar] [CrossRef]

- Kelton, K.F. A new model for nucleation in bulk metallic glasses. Philos. Mag. Lett. 1998, 77, 337–344. [Google Scholar] [CrossRef]

- Miracle, D.B.; Egami, T.; Flores, K.; Kelton, K.F. Structural Aspects of Metallic Glasses. MRS Bull. 2007, 32, 629–634. [Google Scholar] [CrossRef]

- Busch, R.; Bakke, E.; Johnson, W.L. On the glass forming ability of bulk metallic glasses. Mater. Sci. Forum 1996, 235, 327–335. [Google Scholar] [CrossRef]

- Senkov, O.; Miracle, D. Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater. Res. Bull. 2001, 36, 2183–2198. [Google Scholar] [CrossRef]

- Mukherjee, S.; Schroers, J.; Zhou, Z.; Johnson, W.; Rhim, W.-K. Viscosity and specific volume of bulk metallic glass-forming alloys and their correlation with glass forming ability. Acta Mater. 2004, 52, 3689–3695. [Google Scholar] [CrossRef]

- Wang, W. Roles of minor additions in formation and properties of bulk metallic glasses. Prog. Mater. Sci. 2007, 52, 540–596. [Google Scholar] [CrossRef]

- Johnson, W. Thermodynamic and kinetic aspects of the crystal to glass transformation in metallic materials. Prog. Mater. Sci. 1986, 30, 81–134. [Google Scholar] [CrossRef]

- Tsai, P.; Flores, K. High-throughput discovery and characterization of multicomponent bulk metallic glass alloys. Acta Mater. 2016, 120, 426–434. [Google Scholar] [CrossRef] [Green Version]

- Ding, S.Y.; Liu, Y.H.; Li, Y.L.; Liu, Z.; Sohn, S.; Walker, F.J.; Schroers, J. Combinatorial development of bulk metallic glasses. Nat. Mater. 2014, 13, 494–500. [Google Scholar] [CrossRef] [PubMed]

- Hui, X.D.; Chen, G.L.; He, G.; Bian, Z.; Wang, X.M. Thermodynamic model for glass forming ability of ternary metallic glass systems. Trans. Nonferr. Metal. Soc. 2001, 11, 684–690. [Google Scholar]

- Inoue, A. Bulk Glassy Alloys: Historical Development and Current Research. Engineering 2015, 1, 185–191. [Google Scholar] [CrossRef] [Green Version]

- Ward, L.; O’Keeffe, S.C.; Stevick, J.; Jelbert, G.R.; Aykol, M.; Wolverton, C. A machine learning approach for engineering bulk metallic glass alloys. Acta Mater. 2018, 159, 102–111. [Google Scholar] [CrossRef]

- Li, M.-X.; Sun, Y.-T.; Wang, C.; Hu, L.-W.; Sohn, S.; Schroers, J.; Wang, W.-H.; Liu, Y.-H. Data-driven discovery of a universal indicator for metallic glass forming ability. Nat. Mater. 2021, 21, 165–172. [Google Scholar] [CrossRef]

- Masumoto, T.; Maddin, R. Mechanical Properties of Palladium-20 at.% Silicon Alloy Quenched from Liquid State. Acta Metall. 1971, 19, 725–741. [Google Scholar] [CrossRef]

- Gilbert, C.J.; Ritchie, R.O.; Johnson, W.L. Fracture toughness and fatigue-crack propagation in a Zr-Ti-Ni-Cu-Be bulk metallic glass. Appl. Phys. Lett. 1997, 71, 476–478. [Google Scholar] [CrossRef] [Green Version]

- Lewandowski, J.J.; Wangz, W.H.; Greer, A.L. Intrinsic plasticity or brittleness of metallic glasses. Philos. Mag. Lett. 2005, 85, 77–87. [Google Scholar] [CrossRef]

- Xi, X.K.; Zhao, D.Q.; Pan, M.X.; Wang, W.H.; Wu, Y.; Lewandowski, J.J. Fracture of Brittle Metallic Glasses: Brittleness or Plasticity. Phys. Rev. Lett. 2005, 94, 125510. [Google Scholar] [CrossRef] [Green Version]

- Mukai, T.; Kawamura, Y.; Inoue, A.; Nieh, T.G.; Higashi, K. Influence of strain rate on the tensile mechanical behavior in Pd40Ni40P20 bulk metallic glass. Impact Eng. Appl. 2001, 1–2, 577–582. [Google Scholar]

- Schuh, C.A.; Hufnagel, T.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Greer, A.L.; Cheng, Y.Q.; Ma, E. Shear bands in metallic glasses. Mat. Sci. Eng. R. 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Andersen, L.M.; Kolodziejska, J.; Roberts, S.; Borgonia, J.-P.; Johnson, W.L.; Vecchio, K.S.; Kennett, A. Optimizing Bulk Metallic Glasses for Robust, Highly Wear-Resistant Gears. Adv. Eng. Mater. 2016, 19, 1600541. [Google Scholar] [CrossRef]

- Boswell, P.G. The wear resistance of a liquid quenched metallic glass. J. Mater. Sci. 1979, 14, 1505–1507. [Google Scholar] [CrossRef]

- Lee, J.; He, M.; Yeo, C.-D.; Kumar, G.; Hu, Z.; Quitevis, E.L.; Thalangamaarachchige, V.D. Friction and wear of Pd-rich amorphous alloy (Pd43Cu27Ni10P20) under dry and ionic liquid (IL) lubricated conditions. Wear 2018, 408, 190–199. [Google Scholar] [CrossRef]

- Medina, M.A.; Acikgoz, O.; Rodriguez, A.; Meduri, C.S.; Kumar, G.; Baykara, M.Z. Comparative Tribological Properties of Pd-, Pt-, and Zr-Based Bulk Metallic Glasses. Lubricants 2020, 8, 85. [Google Scholar] [CrossRef]

- Gebert, A.; Wolff, U.; John, A.; Eckert, J. Corrosion behaviour of Mg65Y10Cu25 metallic glass. Scr. Mater. 2000, 43, 279–283. [Google Scholar] [CrossRef]

- Morrison, M.; Buchanan, R.; Liaw, P.; Green, B.; Wang, G.; Liu, C.; Horton, J. Corrosion–fatigue studies of the Zr-based Vitreloy 105 bulk metallic glass. Mater. Sci. Eng. A 2007, 467, 198–206. [Google Scholar] [CrossRef]

- Jagdale, S.; Hu, Q.; Ecker, M.; Kumar, G. Biocompatibility and thermoplastic formability of Pt-based metallic glasses. Mater. Lett. 2021, 295, 129870. [Google Scholar] [CrossRef]

- Qiu, C.; Chen, Q.; Liu, L.; Chan, K.; Zhou, J.; Chen, P.; Zhang, S. A novel Ni-free Zr-based bulk metallic glass with enhanced plasticity and good biocompatibility. Scr. Mater. 2006, 55, 605–608. [Google Scholar] [CrossRef]

- Schroers, J.; Kumar, G.; Hodges, T.M.; Chan, S.; Kyriakides, T.R. Bulk metallic glasses for biomedical applications. JOM 2009, 61, 21–29. [Google Scholar] [CrossRef]

- Huang, L.; Yokoyama, Y.; Wu, W.; Liaw, P.K.; Pang, S.; Inoue, A.; Zhang, T.; He, W. Ni-free Zr-Cu-Al-Nb-Pd bulk metallic glasses with different Zr/Cu ratios for biomedical applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100B, 1472–1482. [Google Scholar] [CrossRef] [PubMed]

- Meagher, P.; O’Cearbhaill, E.D.; Byrne, J.H.; Browne, D.J. Bulk Metallic Glasses for Implantable Medical Devices and Surgical Tools. Adv. Mater. 2016, 28, 5755–5762. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; He, W.; Pang, S.; Liaw, P.K.; Zhang, T. In vitro responses of bone-forming MC3T3-E1 pre-osteoblasts to biodegradable Mg-based bulk metallic glasses. Mater. Sci. Eng. C 2016, 68, 632–641. [Google Scholar] [CrossRef] [Green Version]

- Zberg, B.; Uggowitzer, P.J.; Löffler, J.F. MgZnCa glasses without clinically observable hydrogen evolution for biodegradable implants. Nat. Mater. 2009, 8, 887–891. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, X.; Li, H.; Wang, X.; Zhao, M.; Zhang, E.; Bai, Y.; Zheng, Y.; Qin, L. Biodegradable CaMgZn bulk metallic glass for potential skeletal application. Acta Biomater. 2011, 7, 3196–3208. [Google Scholar] [CrossRef]

- Katona, T.; Molnár, A. Amorphous Alloy Catalysis: VII. Activation and Surface Characterization of an Amorphous Cu-Ti Alloy Catalyst Precursor in the Dehydrogenation of 2-Propanol and Comparison with Cu-Zr1. J. Catal. 1995, 153, 333–343. [Google Scholar] [CrossRef]

- Deng, Z.; Zhang, X.; Chan, K.; Liu, L.; Li, T. Fe-based metallic glass catalyst with nanoporous surface for azo dye degradation. Chemosphere 2017, 174, 76–81. [Google Scholar] [CrossRef]

- Carmo, M.; Sekol, R.C.; Ding, S.; Kumar, G.; Schroers, J.; Taylor, A.D. Bulk Metallic Glass Nanowire Architecture for Electrochemical Applications. ACS Nano 2011, 5, 2979–2983. [Google Scholar] [CrossRef]

- Sekol, R.C.; Carmo, M.; Kumar, G.; Gittleson, F.; Doubek, G.; Sun, K.; Schroers, J.; Taylor, A.D. Pd-Ni-Cu-P metallic glass nanowires for methanol and ethanol oxidation in alkaline media. Int. J. Hydrog. Energy 2013, 38, 11248–11255. [Google Scholar] [CrossRef]

- Sekol, R.C.; Kumar, G.; Carmo, M.; Gittleson, F.; Hardesty-Dyck, N.; Mukherjee, S.; Schroers, J.; Taylor, A.D. Bulk Metallic Glass Micro Fuel Cell. Small 2012, 9, 2081–2085. [Google Scholar] [CrossRef]

- Das, S.; Garrison, S.; Mukherjee, S. Bi-Functional Mechanism in Degradation of Toxic Water Pollutants by Catalytic Amorphous Metals. Adv. Eng. Mater. 2015, 18, 214–218. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A.; Zhang, T. Ferromagnetic bulk amorphous alloys. Met. Mater. Trans. A 1998, 29, 1779–1793. [Google Scholar] [CrossRef]

- Tsai, A.; Kitazawa, Y.; Inoue, A.; Masumoto, T. Ferromagnetic Glasses with Stable Supercooled Liquid in Gd-Al-(Cu,Ni,Co) Alloys. High Temp. Mater. Process. 1998, 17, 203–207. [Google Scholar] [CrossRef]

- Sun, Z.; Kumar, G.; Löser, W.; Eckert, J.; Schultz, L. Effect of Y addition on the microstructure and magnetic properties of Nd60−xYxFe30Al10 mould-cast alloys. J. Alloy. Compd. 2004, 366, 248–253. [Google Scholar] [CrossRef]

- Xia, L.; Tang, M.B.; Pan, M.X.; Zhao, D.Q.; Wang, W.H.; Dong, Y.D. Primary crystallization and hard magnetic properties of Nd60Al10Fe20Co10metallic glasses. J. Phys. D Appl. Phys. 2003, 36, 2954–2957. [Google Scholar] [CrossRef]

- Inoue, A.; Wang, X.M.; Zhang, W. Developments and applications of bulk metallic glasses. Rev. Adv. Mater. Sci. 2008, 18, 1–9. [Google Scholar]

- Nishiyama, N.; Amiya, K.; Inoue, A. Novel applications of bulk metallic glass for industrial products. J. Non-Crystalline Solids 2007, 353, 3615–3621. [Google Scholar] [CrossRef]

- Schroers, J.; Pham, Q.; Desai, A. Thermoplastic Forming of Bulk Metallic Glass—A Technology for MEMS and Microstructure Fabrication. J. Microelectromechanical Syst. 2007, 16, 240–247. [Google Scholar] [CrossRef]

- Byrne, C.J.; Eldrup, M.; Ohnuma, M.; Eriksen, R.S. Free standing bulk metallic glass microcomponents: Tooling considerations. J. Mater. Process. Technol. 2010, 210, 1419–1428. [Google Scholar] [CrossRef]

- Wert, J.A.; Thomsen, C.; Jensen, R.D.; Arentoft, M. Forming of bulk metallic glass microcomponents. J. Mater. Process. Technol. 2009, 209, 1570–1579. [Google Scholar] [CrossRef]

- Fukushige, T.; Hata, S.; Shimokohbe, A. A MEMS conical spring actuator array. J. Microelectromech. Syst. 2005, 14, 243–253. [Google Scholar] [CrossRef]

- Kumar, G.; Desai, A.; Schroers, J. Bulk Metallic Glass: The Smaller the Better. Adv. Mater. 2010, 23, 461–476. [Google Scholar] [CrossRef]

- Schroers, J. The superplastic forming of bulk metallic glasses. JOM 2005, 57, 35–39. [Google Scholar] [CrossRef]

- Schroers, J. Processing of Bulk Metallic Glass. Adv. Mater. 2009, 22, 1566–1597. [Google Scholar] [CrossRef]

- Bakke, E.; Busch, R.; Johnson, W.L. The Viscosity of the Zr46.75ti8.25cu7.5ni10be27.5 Bulk Metallic-Glass Forming Alloy in the Supercooled Liquid. Appl. Phys. Lett. 1995, 67, 3260–3262. [Google Scholar] [CrossRef] [Green Version]

- Waniuk, T.; Busch, R.; Masuhr, A.; Johnson, W. Equilibrium viscosity of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass-forming liquid and viscous flow during relaxation, phase separation, and primary crystallization. Acta Mater. 1998, 46, 5229–5236. [Google Scholar] [CrossRef]

- Shao, Z.; Gopinadhan, M.; Kumar, G.; Mukherjee, S.; Liu, Y.; O’Hern, C.S.; Schroers, J.; Osuji, C.S. Size-dependent viscosity in the supercooled state of a bulk metallic glass. Appl. Phys. Lett. 2013, 22, 221901. [Google Scholar] [CrossRef] [Green Version]

- Pitt, B.; Kumar, G.; Schroers, J. Temperature dependence of the thermoplastic formability in bulk metallic glasses. J. Appl. Phys. 2011, 110, 43518. [Google Scholar] [CrossRef]

- Schroers, J. On the formability of bulk metallic glass in its supercooled liquid state. Acta Mater. 2008, 56, 471–478. [Google Scholar] [CrossRef]

- Jabed, A.; Meduri, C.S.; Kumar, G. Effect of time on the isothermal viscosity of metallic glass supercooled liquids. J. Alloy. Compd. 2020, 863, 158067. [Google Scholar] [CrossRef]

- Kawamura, Y.; Kato, H.; Inoue, A.; Masumoto, T. Full strength compacts by extrusion of glassy metal powder at the supercooled liquid state. Appl. Phys. Lett. 1995, 67, 2008–2010. [Google Scholar] [CrossRef]

- Saotome, Y.; Itoh, K.; Zhang, T.; Inoue, A. Superplastic nanoforming of Pd-based amorphous alloy. Scr. Mater. 2001, 44, 1541–1545. [Google Scholar] [CrossRef]

- Saotome, Y.; Imai, K.; Shioda, S.; Shimizu, S.; Zhang, T.; Inoue, A. The micro-nanoformability of Pt-based metallic glass and the nanoforming of three-dimensional structures. Intermetallics 2002, 10, 1241–1247. [Google Scholar] [CrossRef]

- Saotome, Y.; Fukuda, Y.; Yamaguchi, I.; Inoue, A. Superplastic nanoforming of optical components of Pt-based metallic glass. J. Alloy. Compd. 2007, 434-435, 97–101. [Google Scholar] [CrossRef]

- Martinez, R.; Kumar, G.; Schroers, J. Hot rolling of bulk metallic glass in its supercooled liquid region. Scr. Mater. 2008, 59, 187–190. [Google Scholar] [CrossRef]

- Chiu, H.M.; Kumar, G.; Blawzdziewicz, J.; Schroers, J. Thermoplastic extrusion of bulk metallic glass. Scr. Mater. 2009, 61, 28–31. [Google Scholar] [CrossRef]

- Kumar, G.; Tang, H.X.; Schroers, J. Nanomoulding with amorphous metals. Nature 2009, 457, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.; Staffier, P.A.; Blawzdziewicz, J.; Schwarz, U.D.; Schroers, J. Atomically smooth surfaces through thermoplastic forming of metallic glass. Appl. Phys. Lett. 2010, 97, 101907. [Google Scholar] [CrossRef] [Green Version]

- Schroers, J.; Hodges, T.M.; Kumar, G.; Raman, H.; Barnes, A.J.; Pham, Q.; Waniuk, T.A. Thermoplastic blow molding of metals. Mater. Today 2011, 14, 14–19. [Google Scholar] [CrossRef]

- Kumar, G.; Blawzdziewicz, J.; Schroers, J. Controllable nanoimprinting of metallic glasses: Effect of pressure and interfacial properties. Nanotechnology 2013, 24, 105301. [Google Scholar] [CrossRef]

- Chen, W.; Liu, Z.; Schroers, J. Joining of bulk metallic glasses in air. Acta Mater. 2014, 62, 49–57. [Google Scholar] [CrossRef]

- Hasan, M.; Schroers, J.; Kumar, G. Functionalization of Metallic Glasses through Hierarchical Patterning. Nano Lett. 2015, 15, 963–968. [Google Scholar] [CrossRef] [PubMed]

- Somekawa, H.; Inoue, A.; Higashi, K. Superplastic and diffusion bonding behavior on Zr-Al-Ni-Cu metallic glass in supercooled liquid region. Scripta Mater. 2004, 50, 1395–1399. [Google Scholar] [CrossRef]

- Chu, J.P.; Wijaya, H.; Wu, C.W.; Tsai, T.R.; Wei, C.S.; Nieh, T.G.; Wadsworth, J. Nanoimprint of gratings on a bulk metallic glass. Appl. Phys. Lett. 2007, 90, 034101. [Google Scholar] [CrossRef]

- Zhang, N.; Chu, J.S.; Byrne, C.J.; Browne, D.; Gilchrist, M. Replication of micro/nano-scale features by micro injection molding with a bulk metallic glass mold insert. J. Micromech. Microeng. 2012, 22, 065019. [Google Scholar] [CrossRef] [Green Version]

- Kuo, P.-H.; Wang, S.-H.; Liaw, P.K.; Fan, G.-J.; Tsang, H.-T.; Qiao, D.; Jiang, F. Bulk-metallic glasses joining in a supercooled-liquid region. Mater. Chem. Phys. 2010, 120, 532–536. [Google Scholar] [CrossRef]

- Hasan, M.; Kahler, N.; Kumar, G. Shape-Controlled Metal–Metal and Metal–Polymer Janus Structures by Thermoplastic Embossing. ACS Appl. Mater. Interfaces 2016, 8, 11084–11090. [Google Scholar] [CrossRef]

- Sarac, B.; Kumar, G.; Hodges, T.; Ding, S.; Desai, A.; Schroers, J. Three-Dimensional Shell Fabrication Using Blow Molding of Bulk Metallic Glass. J. Microelectromech. Syst. 2010, 20, 28–36. [Google Scholar] [CrossRef]

- Kinser, E.R.; Padmanabhan, J.; Yu, R.; Corona, S.L.; Li, J.; Vaddiraju, S.; Legassey, A.; Loye, A.; Balestrini, J.; Solly, D.A.; et al. Nanopatterned Bulk Metallic Glass Biosensors. ACS Sens. 2017, 2, 1779–1787. [Google Scholar] [CrossRef] [PubMed]

- Uzun, C.; Meduri, C.; Kahler, N.; de Peralta, L.G.; McCollum, J.M.; Pantoya, M.; Kumar, G.; Bernussi, A.A. Photoinduced heat conversion enhancement of metallic glass nanowire arrays. J. Appl. Phys. 2019, 125, 015102. [Google Scholar] [CrossRef]

- Uzun, C.; Kahler, N.; de Peralta, L.G.; Kumar, G.; Bernussi, A.A. Photo-induced-heat localization on nanostructured metallic glasses. J. Appl. Phys. 2017, 122, 094306. [Google Scholar] [CrossRef]

- Tarigan, H.J.; Kahler, N.; Ramos, N.S.; Kumar, G.; Bernussi, A.A. Low reflectance of nano-patterned Pt-Cu-Ni-P bulk metallic glass. Appl. Phys. Lett. 2015, 107, 021903. [Google Scholar] [CrossRef]

- Hasan, M.; Warzywoda, J.; Kumar, G. Decoupling the effects of surface texture and chemistry on the wetting of metallic glasses. Appl. Surf. Sci. 2018, 447, 355–362. [Google Scholar] [CrossRef] [Green Version]

- Arora, H.S.; Xu, Q.; Xia, Z.; Ho, Y.-H.; Dahotre, N.B.; Schroers, J.; Mukherjee, S. Wettability of nanotextured metallic glass surfaces. Scr. Mater. 2013, 69, 732–735. [Google Scholar] [CrossRef]

- Gao, M.; Wang, D.P.; Huang, Y.F.; Meng, S.; Wang, W.H. Tunable hydrophobicity on fractal and micro-nanoscale hierarchical fracture surface of metallic glasses. Mater. Des. 2016, 95, 612–617. [Google Scholar] [CrossRef] [Green Version]

- Xia, T.; Li, N.; Wu, Y.; Liu, L. Patterned superhydrophobic surface based on Pd-based metallic glass. Appl. Phys. Lett. 2012, 101, 081601. [Google Scholar] [CrossRef]

- Kawamura, Y.; Nakamura, T.; Inoue, A.; Masumoto, T. High-strain-rate superplasticity due to Newtonian viscous flow in La55Al25Ni20 metallic glass. Mater. Trans. JIM 1999, 40, 794–803. [Google Scholar] [CrossRef] [Green Version]

- Kawamura, Y.; Nakamura, T.; Inoue, A. Superplasticity in Pd40Ni40P20 metallic glass. Mater. Sci. For. 1999, 304, 349–354. [Google Scholar] [CrossRef]

- Wang, G.; Shen, J.; Sun, J.F.; Lu, Z.P.; Stachurski, Z.H.; Zhou, B.D. Tensile fracture charactareistics and deformation behavior of a Zr-based bulk metallic glass at high temperatutes. Intermetallics 2005, 13, 642–648. [Google Scholar] [CrossRef]

- Nieh, T.; Mukai, T.; Liu, C.; Wadsworth, J. Superplastic behavior of a Zr–10Al–5Ti-–17.9Cu–14.6Ni metallic glass in the supercooled liquid region. Scr. Mater. 1999, 40, 1021–1027. [Google Scholar] [CrossRef]

- Kim, W.; Ma, D.; Jeong, H. Superplastic flow in a Zr65Al10Ni10Cu15 metallic glass crystallized during deformation in a supercooled liquid region. Scr. Mater. 2003, 49, 1067–1073. [Google Scholar] [CrossRef]

- Vormelker, A.; Vatamanu, O.; Kecskes, L.; Lewandowski, J. Effects of Test Temperature and Loading Conditions on the Tensile Properties of a Zr-Based Bulk Metallic Glass. Met. Mater. Trans. A 2007, 39, 1922–1934. [Google Scholar] [CrossRef]

- Soinila, E.; Bossuyt, S.; Hanninen, H. Steady-state tensile viscous flow forming of bulk metallic glass. J. Alloy. Compd. 2012, 536, S109–S112. [Google Scholar] [CrossRef]

- Inoue, A. High Strength Bulk Amorphous Alloys with Low Critical Cooling Rates (Overview). Mater. Trans. JIM 1995, 36, 866–875. [Google Scholar] [CrossRef] [Green Version]

- Nieh, T.; Wadsworth, J. Homogeneous deformation of bulk metallic glasses. Scr. Mater. 2006, 54, 387–392. [Google Scholar] [CrossRef]

- Yi, J.; Xia, X.X.; Zhao, D.Q.; Pan, M.X.; Bai, H.Y.; Wang, W.H. Micro-and Nanoscale Metallic Glassy Fibers. Adv. Eng. Mater. 2010, 12, 1117–1122. [Google Scholar] [CrossRef]

- Wang, Y.B.; Lee, C.C.; Yi, J.; An, X.H.; Pan, M.X.; Xie, K.Y.; Liao, X.Z.; Cairney, J.M.; Ringer, S.P.; Wang, W.H. Ultrahigh-strength submicron-sized metallic glass wires. Scr. Mater. 2014, 84, 27–30. [Google Scholar] [CrossRef]

- Yi, J.; Wang, W.H.; Lewandowski, J. Sample size and preparation effects on the tensile ductility of Pd-based metallic glass nanowires. Acta Mater. 2015, 87, 1–7. [Google Scholar] [CrossRef]

- Mota, R.M.O.; Lund, E.T.; Sohn, S.; Browne, D.J.; Hofmann, D.C.; Curtarolo, S.; van de Walle, A.; Schroers, J. Enhancing ductility in bulk metallic glasses by straining during cooling. Commun. Mater. 2021, 2, 23. [Google Scholar] [CrossRef]

- Wang, W.H. Metallic glassy fibers. Sci. China-Phys. Mech. Astron. 2013, 56, 2293–2301. [Google Scholar] [CrossRef]

- Yi, J. Fabrication and Properties of Micro- and Nanoscale Metallic Glassy Wires: A Review. Adv. Eng. Mater. 2017, 20, 1700875. [Google Scholar] [CrossRef]

- Hasan, M.; Kumar, G. High-throughput drawing and testing of metallic glass nanostructures. Nanoscale 2017, 9, 3261–3268. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.; Kumar, G. High strain rate thermoplastic demolding of metallic glasses. Scr. Mater. 2016, 123, 140–143. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.; Meduri, C.S.; Blawzdziewicz, J.; Kumar, G. Nanoshaping of glass forming metallic liquids by stretching: Evading lithography. Nanotechnology 2018, 30, 075302. [Google Scholar] [CrossRef]

- Gill, H.S.; Denson, D.D.; Burris, B.A.; Prausnitz, M.R. Effect of Microneedle Design on Pain in Human Volunteers. Clin. J. Pain 2008, 24, 585–594. [Google Scholar] [CrossRef] [Green Version]

- Prausnitz, M.R.; Mikszta, J.A.; Cormier, M.; Andrianov, A.K. Microneedle-Based Vaccines. In Vaccines for Pandemic Influenza; Compans, R.W., Orenstein, W.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 369–393. [Google Scholar]

- Hu, Z.; Meduri, C.S.; Ingrole, R.S.J.; Gill, H.S.; Kumar, G. Solid and hollow metallic glass microneedles for transdermal drug-delivery. Appl. Phys. Lett. 2020, 116, 203703. [Google Scholar] [CrossRef]

- Meduri, C.S.; Hu, Z.; Blawzdziewicz, J.; Kumar, G. Buckling of metallic glass supercooled liquid layer during embossing. Appl. Phys. Lett. 2019, 114, 113102. [Google Scholar] [CrossRef]

- Guo, H.; Yan, P.; Wang, Y.B.; Tan, J.; Zhang, Z.F.; Sui, M.L.; Ma, E. Tensile ductility and necking of metallic glass. Nat. Mater. 2007, 6, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Volkert, C.A.; Donohue, A.; Spaepen, F. Effect of sample size on deformation in amorphous metals. J. Appl. Phys. 2008, 103, 083539. [Google Scholar] [CrossRef]

- Jang, D.; Greer, J.R. Transition from a strong-yet-brittle to a stronger-and-ductile state by size reduction of metallic glasses. Nat. Mater. 2010, 9, 215–219. [Google Scholar] [CrossRef] [PubMed]

- Schuster, B.; Wei, Q.; Hufnagel, T.; Ramesh, K. Size-independent strength and deformation mode in compression of a Pd-based metallic glass. Acta Mater. 2008, 56, 5091–5100. [Google Scholar] [CrossRef]

- Kuzmin, O.; Pei, Y.; Chen, C.; De Hosson, J. Intrinsic and extrinsic size effects in the deformation of metallic glass nanopillars. Acta Mater. 2012, 60, 889–898. [Google Scholar] [CrossRef]

- Dubach, A.; Raghavan, R.; Löffler, J.; Michler, J.; Ramamurty, U. Micropillar compression studies on a bulk metallic glass in different structural states. Scr. Mater. 2009, 60, 567–570. [Google Scholar] [CrossRef]

- Tönnies, D.; Maaß, R.; Volkert, C.A. Room Temperature Homogeneous Ductility of Micrometer-Sized Metallic Glass. Adv. Mater. 2014, 26, 5715–5721. [Google Scholar] [CrossRef]

- Magagnosc, D.J.; Chen, W.; Kumar, G.; Schroers, J.; Gianola, D.S. Thermomechanical Behavior of Molded Metallic Glass Nanowires. Sci. Rep. 2016, 6, 19530. [Google Scholar] [CrossRef] [Green Version]

- Magagnosc, D.; Kumar, G.; Schroers, J.; Felfer, P.; Cairney, J.; Gianola, D. Effect of ion irradiation on tensile ductility, strength and fictive temperature in metallic glass nanowires. Acta Mater. 2014, 74, 165–182. [Google Scholar] [CrossRef]

- Magagnosc, D.; Ehrbar, R.; Kumar, G.S.; He, M.R.; Schroers, J.; Gianola, D.S. Tunable Tensile Ductility in Metallic Glasses. Sci. Rep. 2013, 3, 1096. [Google Scholar] [CrossRef] [Green Version]

- Bharathula, A.; Flores, K.M. Variability in the yield strength of a metallic glass at micron and submicron length scales. Acta Mater. 2011, 59, 7199–7205. [Google Scholar] [CrossRef]

- Meduri, C.S.; Blawzdziewicz, J.; Kumar, G. Size-temperature equivalence in tensile deformation of metallic glass. Mater. Sci. Eng. A 2020, 805, 140595. [Google Scholar] [CrossRef]

- Liu, Z.; Schroers, J. General nanomoulding with bulk metallic glasses. Nanotechnology 2015, 26, 145301. [Google Scholar] [CrossRef] [PubMed]

- Dickey, M.D. Stretchable and Soft Electronics using Liquid Metals. Adv. Mater. 2017, 29, 1606425. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jagdale, S.; Jabed, A.; Theeda, S.; Meduri, C.S.; Hu, Z.; Hasan, M.; Kumar, G. Review of Thermoplastic Drawing with Bulk Metallic Glasses. Metals 2022, 12, 518. https://doi.org/10.3390/met12030518

Jagdale S, Jabed A, Theeda S, Meduri CS, Hu Z, Hasan M, Kumar G. Review of Thermoplastic Drawing with Bulk Metallic Glasses. Metals. 2022; 12(3):518. https://doi.org/10.3390/met12030518

Chicago/Turabian StyleJagdale, Shweta, Akib Jabed, Sumanth Theeda, Chandra Sekhar Meduri, Zhonglue Hu, Molla Hasan, and Golden Kumar. 2022. "Review of Thermoplastic Drawing with Bulk Metallic Glasses" Metals 12, no. 3: 518. https://doi.org/10.3390/met12030518