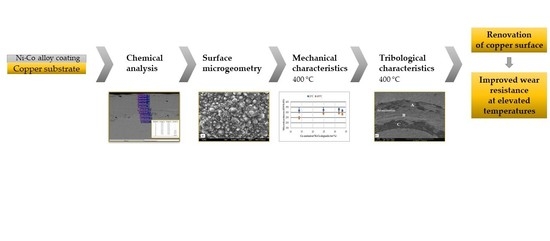

Renovation of Crystallizer Surface Using Electrodeposited Alloy Coating to Increase High-Temperature Abrasion Resistance

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Chemical Analysis of Ni-Co Coatings

3.2. Surface and Surface Microgeometry

3.3. Mechanical Characteristics

3.4. Tribological Characteristics

3.5. Profile Analysis

4. Conclusions

- Knowledge of the dependence between the components content in the electrolyte, which are part of the binary system of formed coating, and the content of these components in the crystallized coating is the basis for effective galvanic process control.

- Coating hardness depends on chemical composition, microstructure, coating strength, etc. By increasing the amount of Co by 13.83 wt. % up to 31.80 wt. %, the microhardness raises from 318 HV0.05 to 329 HV0.05 at 23 °C and from 248 HV0.05 to 297 HV0.05 at 400 °C. However, a further increase in Co content results in a drop in the microhardness to 316 HV0.05 at 23 °C and 282 HV0.05 at 400 °C. When heated to 400 °C, the microhardness values decreased by 9.5 to 22% (depending on Co content in the coating) compared to the values which were measured at 23 °C.

- The COF values at room temperature ranged from 0.373 to 0.451 for the Ni-Co coating with increasing Co content. The change in COF for the Ni-Co coating at 400 °C was in the range of values from 0.680 to 0.750 depending on the Co amount in the coating. Cobalt redistribution in the tribo track affected tribo behavior. The places with higher wt. % Co had better friction properties than the places with lower wt. % Co.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahidashti, Z.; Aliofkhazraei, M.; Lotfi, N. Review of Nickel-Based Electrodeposited Tribo-Coatings. Trans. Indian Inst. Met. 2018, 71, 257–295. [Google Scholar] [CrossRef]

- Merz, R.; Brodyanski, A.; Kopnarski, M. On the Role of Oxidation in Tribological Contacts under Environmental Conditions. In Proceedings of the European Symposium on Friction, Wear, and Wear Protection, Karlsruhe, Germany, 6–8 May 2014; Dienwiebel, M., Ed.; Hindawi: London, UK, 2015. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Shipway, P.H.; Sun, W. The Role of Temperature and Frequency on Fretting Wear of a Like-on-Like Stainless Steel Contact. Tribol. Lett. 2017, 65, 77. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8, 221–300. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Guo, X.; Zhang, J. Abrasive Resistant Coatings—A Review. Lubricants 2014, 2, 66–89. [Google Scholar] [CrossRef] [Green Version]

- Kharmachi, I.; Dhouibi, L.; Berçot, P.; Rezrazi, M. Co-deposition of Ni-Co alloys on carbon steel and corrosion resistance. J. Mater. Environ. Sci. 2015, 6, 1807–1812. [Google Scholar]

- Mbugua, N.S.; Kang, M.; Zhang, Y.; Ndiithi, N.J.; Bertrand, G.V.; Yao, L. Electrochemical Deposition of Ni, NiCo Alloy and NiCo–Ceramic Composite Coatings—A Critical Review. Materials 2020, 13, 3475. [Google Scholar] [CrossRef]

- Srivastava, M.; Ezhil Selvi, V.; William Grips, V.K.; Rajam, K.S. Corrosion resistance and microstructure of electrodeposited nickel–cobalt alloy coatings. Surf. Coat. Technol. 2006, 201, 3051–3060. [Google Scholar] [CrossRef]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. On Coating Techniques for Surface Protection: A Review. J. Manuf. Mater. Process. 2019, 3, 28. [Google Scholar] [CrossRef] [Green Version]

- Dzedzina, R. Influence of Galvanic Deposition Parameters on the Properties of Ni-Based Coatings. Ph.D. Thesis, Technical University of Košice, Košice, Slovakia, 2013. [Google Scholar]

- Yu, J.; Wang, Y.; Zhao, X.; Li, Q.; Qiao, Q.; Zhao, J.; Zhai, S. Wear resistance of Ni-based Alloy Coatings. Adv. Mater. Sci. Eng. 2019, 2019, 2548285. [Google Scholar] [CrossRef] [Green Version]

- Al Radadi, R.M.; Ibrahim, M.A.M. Nickel-cobalt alloy coatings prepared by electrodeposition Part II: Morphology, structure, microhardness, and electrochemical studies. Korean J. Chem. Eng. 2021, 38, 152–162. [Google Scholar] [CrossRef]

- Mohanty, U.S.; Tripathy, B.C.; Singh, P.; Keshavarz, A.; Iglauer, S. Roles of organic and inorganic additives on the surface quality, morphology, and polarization behavior during nickel electrodeposition from various baths: A review. J. Appl. Electrochem. 2019, 49, 847–870. [Google Scholar] [CrossRef]

- Kamel, M.M.; Hamid, Z.A.; Rashwan, S.M.; Ibrahim, I.S.; El-Sheikh, S.M.; Mohamed, M.M. Electrodeposition of Ni–Co/nano Al2O3 composite coating on low carbon steel and its characterization. Int. J. Electrochem. Sci. 2020, 15, 6343–6358. [Google Scholar] [CrossRef]

- Karimzadeh, A.; Aliofkhazraei, M.; Walsh, F.C. A review of electrodeposited Ni-Co alloy and composite coatings: Microstructure, properties and applications. Surf. Coat. Technol. 2019, 372, 463–498. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, C.; Chang, T.M.; Luo, X.; Yamane, D.; Sone, M. Electrodeposition of Ni-Co Alloys and Their Mechanical Properties by Micro-Vickers Hardness Test. Electrochem 2021, 2, 1. [Google Scholar] [CrossRef]

- Hagarová, M. Electrodeposition of nickel and its alloys. In Electrodeposition of Nickel and Its Alloys, 1st ed.; Brezinová, J., Ševčíková, J., Eds.; Technical University of Košice: Košice, Slovakia, 2019; Volume 1, pp. 55–104. ISBN 978-80-553-3261-1. [Google Scholar]

- Hagarová, M.; Jakubéczyová, D.; Hvizdoš, P.; Fečková, Z.; Vojtko, M.; Dúl, G. The influence of current density on tribological behaviour Ni- Co coatings. Key Eng. Mater. 2015, 635, 127–130. [Google Scholar] [CrossRef]

- Yelton, W.G.; Harper, J.C. Electroplated Coatings for Friction, Lubrication, and Wear Technology. In Friction, Lubrication, and Wear Technology, 2nd ed.; Totten, E.G., Ed.; ASM International: Novelty, OH, USA, 2017; Volume 18, pp. 623–633. [Google Scholar] [CrossRef]

- Marita, Y.; Ridwan; Nanda, S. Nurdin Preparation of Ni-Co Alloy by Electrodeposition. Appl. Mech. Mater. 2014, 525, 58–61. [Google Scholar] [CrossRef]

- Hansal, W.E.G.; Tury, B.; Halmdienst, M.; Varsányi, M.L.; Kautek, W. Pulse reverse plating of Ni–Co alloys: Deposition kinetics of Watts, sulfamate and chloride electrolytes. Electrochim. Acta 2006, 52, 1145–1151. [Google Scholar] [CrossRef]

- Bakhit, B.; Akbari, A. Nanocrystalline Ni–Co alloy coatings: Electrodeposition using horizontal electrodes and corrosion resistance. J. Coat. Technol. Res. 2012, 10, 285–295. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Y.; Xuea, Q.; Liu, H.; Xu, T. Microstructure and tribological properties of electrodeposited Ni–Co alloy deposits. Appl. Surf. Sci. 2015, 242, 326–332. [Google Scholar] [CrossRef]

- Hagarová, M.; Dzedzina, R.; Gavendová, P. Properties of Ni-Co alloy coating prepared from sulphate bath. Mater. Sci. Forum 2014, 782, 598–603. [Google Scholar] [CrossRef]

- Hagarová, M.; Jakubeczyová, D.; Cervová, J. Microstructure and Properties of Electroplated Ni-Co Alloy Coatings. Int. J. Electrochem. Sci. 2015, 10, 9968–9974. [Google Scholar]

- A kind of Continuous Casting Roll-Type Crystallizer. Available online: https://patents.google.com/patent/CN105543551B/en (accessed on 17 September 2021).

- Equilibrium diagrams. In Smithells Metals References Book, 8th ed.; Gale, W.F.; Totemeier, T.C. (Eds.) Elsevier Inc.: Oxford, UK, 2004; p. 1-11-1-1-553. ISBN 978-0-7506-7509-3. [Google Scholar]

- Liu, X.; Xu, Y.; Qu, Y.; Sun, L. Structure, Morphology and Wear Resistance of Electrodeposited Ni–Co Alloy Deposits. Integr. Ferroelectr. 2014, 152, 144–151. [Google Scholar] [CrossRef]

- Stylus Profilometer. Available online: http://images.frompo.com/854e40028326d5fa6be79bb32ae9fb80 (accessed on 23 July 2021).

| Sample Number | Electrolyte Parameters | Coating Process Parameters | |||

|---|---|---|---|---|---|

| Composition | pH | Temperature (°C) | Current Density (A dm−2) ** | Deposit Time (min) | |

| 1 | 640 g L−1 NiSO4. 6H2O, 10–20 g L−1 NiCl2, 8–40 g L−1 CoSO4. 7H2O, 20–30 g L−1 H3BO3 * | 4 | 55 | 1 | 15–25 |

| 2 | 2 | ||||

| 3 | 4 | ||||

| 4 | 6 | ||||

| Parameter | Value |

|---|---|

| Pin-on-ball | Al2O3 ø 6 mm |

| Path length | 500 m |

| Load | 5 N |

| Path radius | 2 mm |

| Temperature | 400 °C |

| Sliding speed | 5·10−2 m s−1 |

| Sample Number | Parameter | Copper Substrate | Ni-Co Coatings | ||||

|---|---|---|---|---|---|---|---|

| Deposit Current Density (A·dm−2) | Ra (µm) | Rz (µm) | Pc (1/cm) | Ra (µm) | Rz (µm) | Pc (1/cm) | |

| 1 | 1 | 5.4 | 29.5 | 54 | 4.7 | 24.5 | 50 |

| 2 | 2 | 2.8 | 18.1 | 133 | 2.3 | 14.5 | 110 |

| 3 | 4 | 2.7 | 16.8 | 146 | 2.1 | 11.4 | 173 |

| 4 | 6 | 2.8 | 18.7 | 88 | 2.8 | 18.0 | 72 |

| Place/Element | Sample | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 (1 A dm−2) | 2 (2 A dm−2) | 3 (4 A dm−2) | 4 (6 A dm−2) | |||||||||||||

| O | Co | Ni | Cu | O | Co | Ni | Cu | O | Co | Ni | Cu | O | Co | Ni | Cu | |

| A | 19.2 | 27.4 | 51.3 | 3.4 | 16.9 | 9.8 | 39.1 | 34.2 | 17.1 | 8.3 | 37.4 | 38.0 | 15.4 | 8.1 | 31.1 | 45.4 |

| B | 20.2 | 11.3 | 23.0 | 45.1 | 17.6 | 3.6 | 17.5 | 61.3 | 23.3 | 3.4 | 18.1 | 55.3 | 18.3 | 4.4 | 15.2 | 62.1 |

| C | 18.4 | 24.4 | 46.3 | 11.2 | 49.7 | 4.8 | 20.3 | 25.1 | 23.3 | 9.0 | 46.2 | 20.2 | 19.2 | 10.4 | 37.1 | 21.0 |

| Data | 400 °C | 23 °C | ||||||

|---|---|---|---|---|---|---|---|---|

| Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 1 | Sample 2 | Sample 3 | Sample 4 | |

| Width (mm) | 1.2 | 1.1 | 1.2 | 0.8 | 0.6 | 0.4 | 0.7 | 0.4 |

| Depth (µm) | 61.1 | 60.2 | 71.4 | 32.1 | 6.4 | 10.1 | 11.6 | 5.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brezinová, J.; Hagarová, M.; Jakubéczyová, D.; Baranová, G.; Prentkovskis, O. Renovation of Crystallizer Surface Using Electrodeposited Alloy Coating to Increase High-Temperature Abrasion Resistance. Metals 2021, 11, 1629. https://doi.org/10.3390/met11101629

Brezinová J, Hagarová M, Jakubéczyová D, Baranová G, Prentkovskis O. Renovation of Crystallizer Surface Using Electrodeposited Alloy Coating to Increase High-Temperature Abrasion Resistance. Metals. 2021; 11(10):1629. https://doi.org/10.3390/met11101629

Chicago/Turabian StyleBrezinová, Janette, Mária Hagarová, Dagmar Jakubéczyová, Gabriela Baranová, and Olegas Prentkovskis. 2021. "Renovation of Crystallizer Surface Using Electrodeposited Alloy Coating to Increase High-Temperature Abrasion Resistance" Metals 11, no. 10: 1629. https://doi.org/10.3390/met11101629