1. Introduction

Monolithic aluminum components are widely employed in the aeronautical sector due to their good strength-to-weight ratio [

1]. The final quality of these parts is normally obtained or improved in the finishing operation and it is influenced by static and dynamic phenomena [

2].

On the one hand, from the static point of view, cutting forces and part clamping produce elastic deformation that can lead to deteriorating the final dimension and the surface of the workpiece [

3]. On the other hand, vibrations increase the roughness of the parts. These dynamic instabilities become frequent in the milling operation and are produced by the lack of dynamic stiffness in one or more components of the system [

4]. The most characteristic vibrations appeared in the milling operation are the self-excited vibrations or chatter [

5,

6]. However, even in the absence of chatter, it almost always exists forced vibrations derived from the periodic excitation of the intermittent cutting engagement of the milling cutter on the workpiece [

7].

Thus, in order to improve the part quality different approach has been studied. First, the tuning of the cutting parameters can lead to static and dynamic improvements. Thus, a process forces reduction leads to a decrease of the elastic deformation of the workpiece that it is reflected in the part accuracy. For instance, Perez et al. [

8] obtained a machining forces reduction and an improvement of the compressive residual stresses with the increase of the cutting speed. On the other hand, in terms of vibrations, different surveys have been developed for the improvement of the system dynamic stability and the obtained surface quality. Different stability models have been developed for the milling operations of compliant systems [

9,

10] and the effect of the cutting parameters on the process damping have been analyzed [

11]. However, these solutions are limited for the inherent stiffness of the system.

The key element for the increase of the system stiffness is the workpiece clamping. Thus, different part-fixture systems have been employed to guarantee a suitable part positioning and fixing [

12]. Due to the lack of dynamic stability of some of these solutions, different damping features have been implemented in the system in order to improve the machining process. Thus, different active features based on the use of eddy currents [

13,

14], pivot mechanism [

15,

16] and piezoelectric dampers [

17] have been studied. These solutions are cost efficient and their implementation is limited to certain applications.

The use of passive damping elements is increasing for milling operations as they are more cost efficient compared to the active developments. The passive damping systems are based in the implementation of different elements or fluids with outstanding damping properties to stabilize dynamically the system. Thus, by employing electrorheological [

18] or magnetorheological [

19] fluids, the vibration amplitude of the cutting processes varies and the part quality is improved. Moreover, in order to increase the narrow vibration band of these passive dampers, Yang et al. [

20] developed a tunable passive devices. However, the industrial implementation of these passive solutions are challenging as they interfere with the clamping of the workpiece and the machining process.

In the present study, the use of an elastomer layer employed as a passive damping element is proposed and characterized. Elastomers, particularly rubber materials, are ideal materials for vibrations isolation as they are low in cost with high internal friction [

21]. Moreover, the industrial implementation of these compounds for machining applications is feasible as they are employed as passive control of vibration [

22,

23,

24]. In fact, the damping properties of these elastomers have been analyzed for low frequency [

25] and high frequency applications [

26], including under certain machining operations. For instance, Kolloru et al. [

27] employed neoprene layers combined with torsion springs to reduce up to eight times the vibration in the milling process of circular thin-wall components. On the other hand, Liu et al. [

28] implemented a viscoelastic material in the toolholder to increase by 99% its damping ratio. Nevertheless, there is no study of the direct application of rubber materials as the clamping element of workpieces in milling operations.

In this case, in order to combine a fixture and a passive damping system the use of a nitrile butadiene rubber (NBR) layer is proposed. This sort of elastomers is one of the most employed seal component in the oil and gas industry [

29], and the proposed development benefitted from these outstanding sealing properties [

30,

31] to transform a flexible layer into a suitable vacuum table. Hence, these solutions enable milling in aggressive environments, with capacity to clamp different geometries. Moreover, as the passive damping element act as a fixture, its industrial implementation is feasible as the interference with the rest of the machining system is reduced.

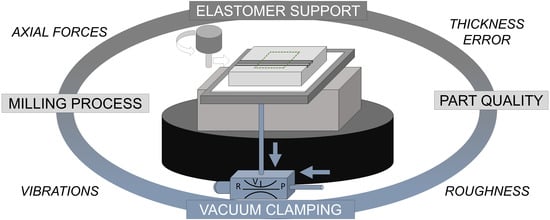

In order to characterize the behavior of these elastic polymers under the machining processes loads, compression tests and milling tests have been performed. Thus, these flexible solutions have been characterized in terms of chatter and forced vibrations performed by the milling tool.

Regardless the milling strategy, the most aggressive machining zone is the entrance of each pocketing where the tool machines with an axial pitch equal to its diameter. Thus, the analysis is focused in the grooving application with depth of cuts defined by finishing operations. The suitability survey is performed in terms of part quality. First, the machined depth is measured to quantify the groove thickness error. Then, the floor roughness is measured and analyzed. Finally, the dynamic behavior of each system is characterized, and a universal force model is developed for the grooving operation in finishing applications.

2. Materials and Methods

Two different NBR layers were selected for the analysis as these passive elements are defined by different vibration bands. The mechanical properties of both vulcanized rubber materials are shown on

Table 1. Besides the hardness and the density, the compounds ingredients are given, where the carbon black is a form of elemental carbon that is used to increase the resistance of rubber and also to improve the tensile strength [

32].

The mechanical behavior of rubber depends on the amplitude, feed rate and frequency of the applied load, combined with the temperature of the material [

33]. In the case of milling operations, the amplitude and feed rate of the applied forces are completely defined by the machining conditions.

Similarly, the load frequencies suffered by the part are generated by the milling tool rotation and by the workpiece fundamental modes. Finally, the temperature of the material is influenced by the heat generated on the cutting zone and the room temperature.

Based on the load application strategies employed on this survey, some simplifications were considered. For instance, the decrease in stiffness during the first few cyclic loads, the so-called Mullins effect [

34], was neglected. Therefore, different loads prior to each test were performed over each elastomer layer. The characteristics of these loads were defined in terms of the test to perform. Thus, for compression tests, a compression load was performed prior to each test. Likewise, prior to each milling test, a previous groove was performed to reduce the Mullins effect on the rubber and to level the upper side of each slot.

Finally, due to the reduced compression loads during the machining operation and the wide part area in contact with the elastomer layer, the expected strain amplitudes are minimal. Therefore, it is not considered a rubber heat up due to material damping derived from large harmonic loads [

33]. Hence, due to the part thickness located between the cutting zone and the rubber layer, the temperature of the rubber was considered as the room value.

Tests were performed in a standard 5-axis numeric control (NC) center. The selected geometry for the elastomer layers was a 300 × 300 mm

2. The mean value of the thickness for both cases was 14.2 mm with a tolerance of ±5%. In order to guarantee a uniform contact and clamping conditions between the part and the elastic material, a slot grid was machined in each rubber layer (

Figure 1a). Thus, the vacuum clamping force was distributed along the contact area by means of the channels. Then, the air was removed through a unique orifice and the part could be safely clamped during the machining operation, as shown in

Figure 1b.

Both, the compression of the rubber and the part profile before and after each milling tests were monitored with a GT1000 type linear variable differential transformer (LVDT) gauging transducer (RDP Group, Wolverhampton, UK). The forces were registered with Kistler 9257B measurement equipment (Kistler Ibérica S.L., Granollers, Spain). In each test, following another similar set-up [

35], the part and the elastic element were attached to the force sensor with a synthetic rubber adhesive. This double-sided filmic tape TESA 64620 (Tesa Tape S.A., Argentona, Spain) guaranteed a homogeneous clamping due to the compressive nature of the axial loads in compression and milling tests.